Polyurethane pouring machine with liquid-guiding self-sealing function

A pouring machine and self-sealing technology, which is applied in the field of polyurethane pouring machines, can solve problems such as burns on the outer wall of the pipeline, splashes around, pollution, etc., and achieve the effects of avoiding pollution, reducing pollution, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

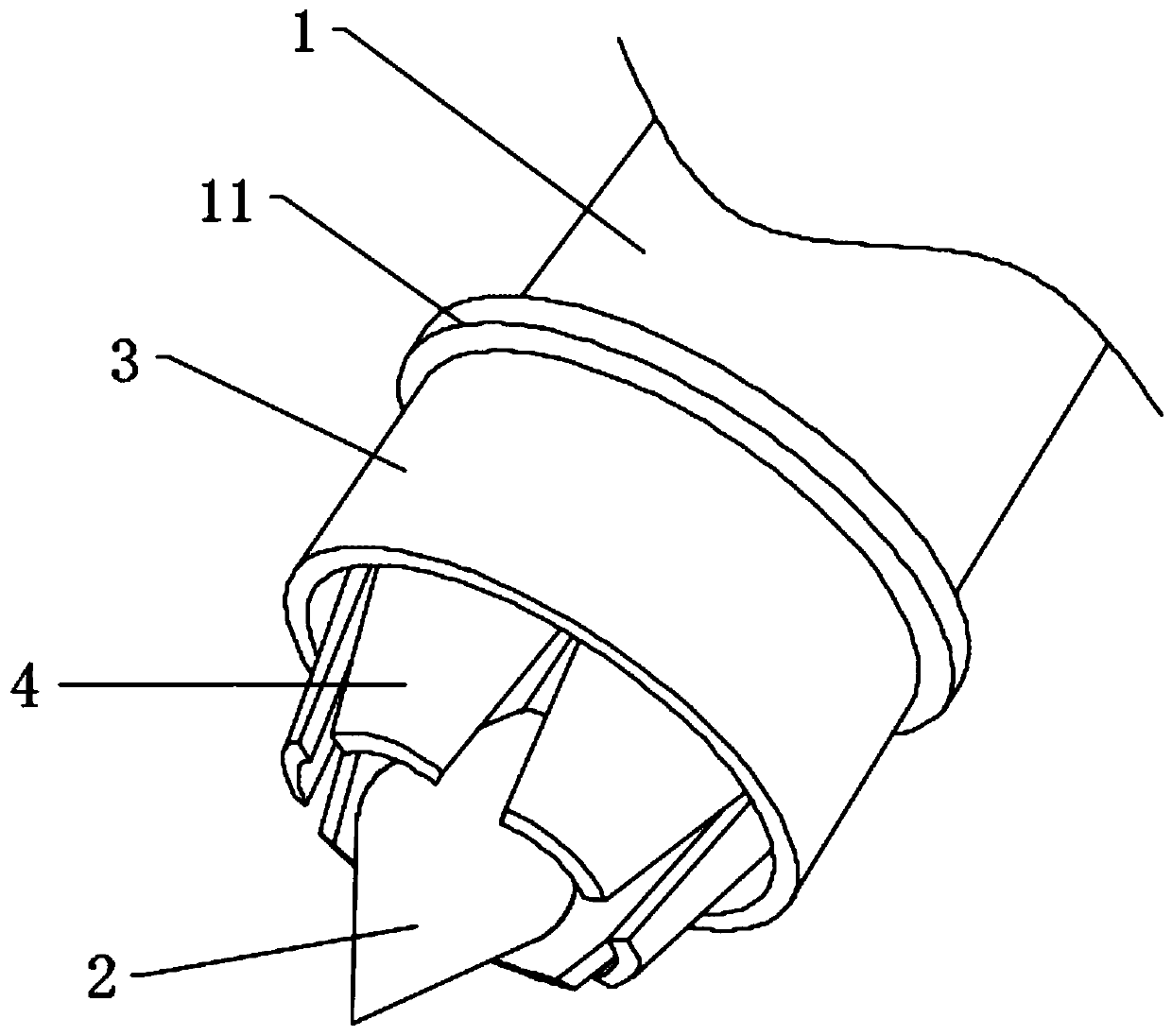

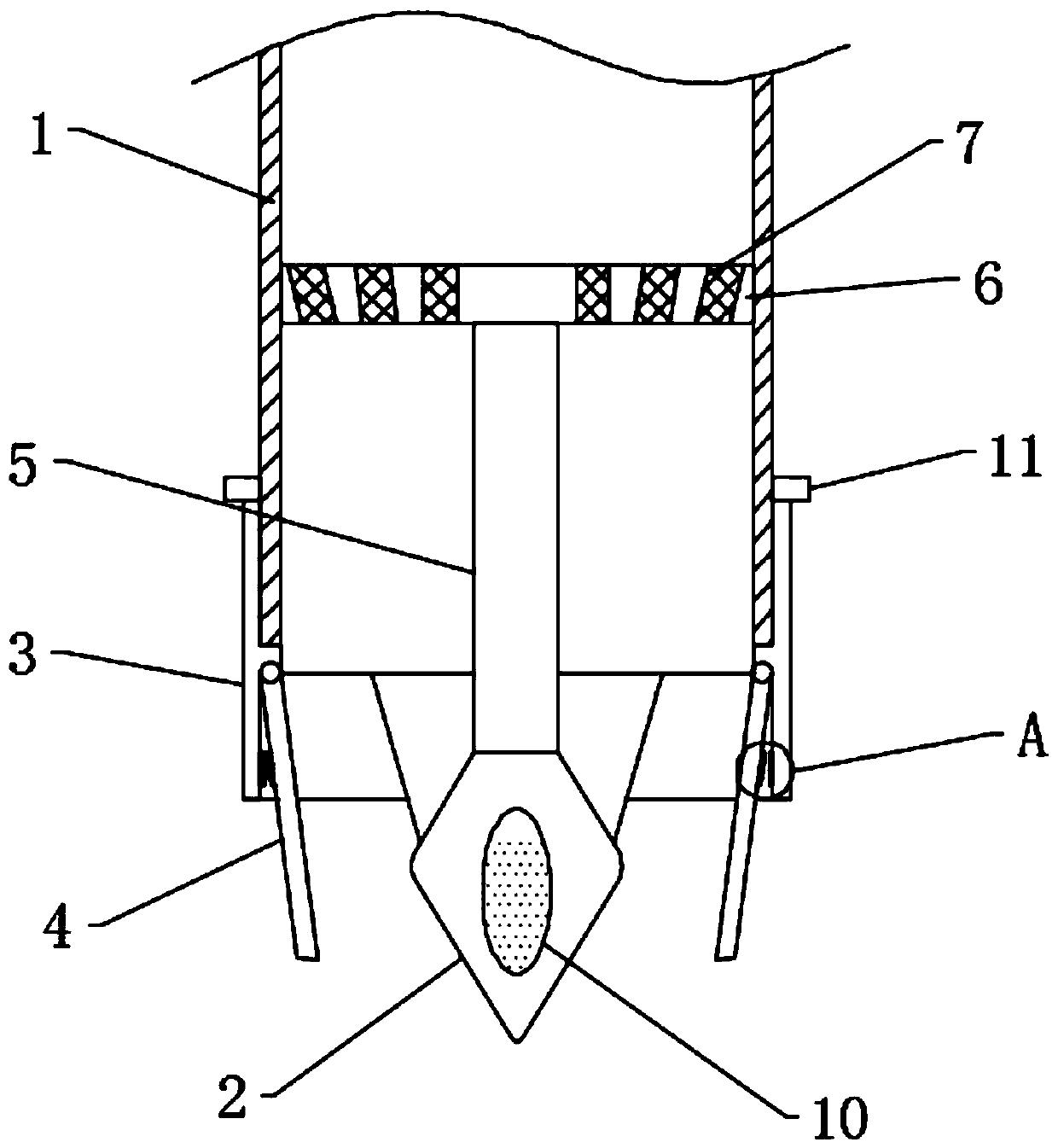

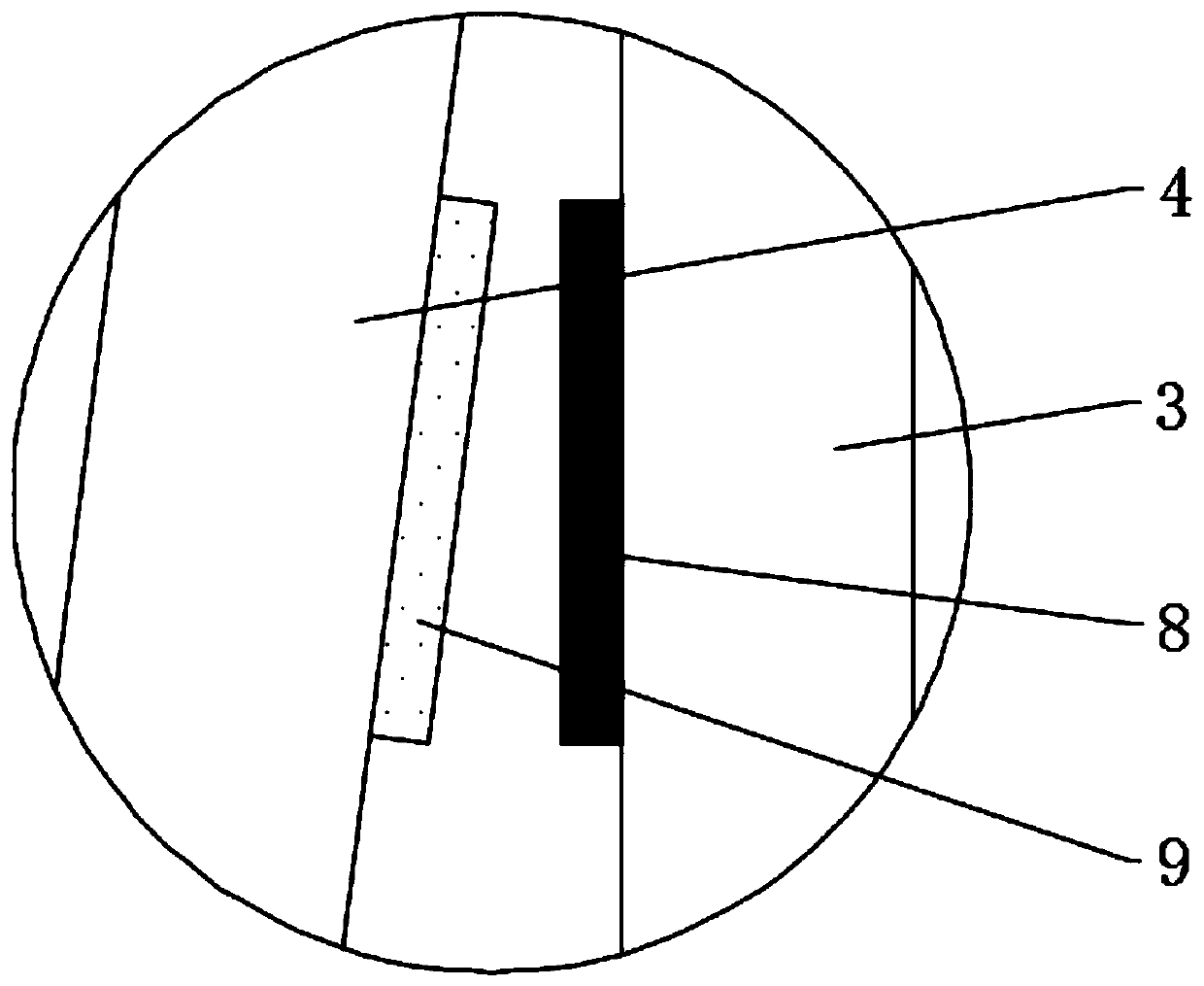

[0040] see Figure 1-3 , a polyurethane pouring machine with a self-sealing function that can induce liquid, including a pouring pipe 1 installed on the pouring machine, the inner side of the pouring pipe 1 is provided with a guide head 2, and the guide head 2 is located on a side of the pouring pipe 1 away from the pouring machine On the side, the inner end of the pouring pipe 1 is fixedly connected with a positioning plate 6, and a plurality of evenly distributed distribution holes 7 are dug on the positioning plate 6, and a connecting column 5 is fixedly connected between the positioning plate 6 and the guide head 2, and the pouring pipe 1 The outer end is connected with a protective ring 3, and the end of the protective ring 3 close to the guide head 2 is rotatably connected with a movable plate group 4, the movable plate group 4 is located outside the guide head 2, and a plurality of first magnets 8 are connected to the inner wall of the protective ring 3 One end of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com