A clutch master cylinder structure with power assist

A master cylinder and booster block technology, applied in the field of auto parts, can solve the problems of increased clutch separation force, too large clutch pedal force, inability to increase booster springs, etc., and achieve the effect of reducing pedal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

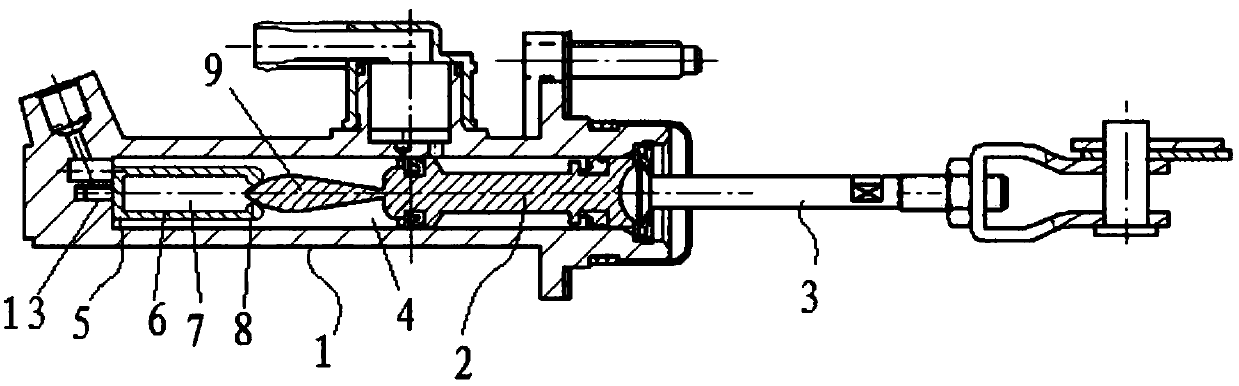

[0019] The embodiments described below with reference to the accompanying drawings are exemplary and are only used to explain the present invention, but not to be construed as a limitation of the present invention.

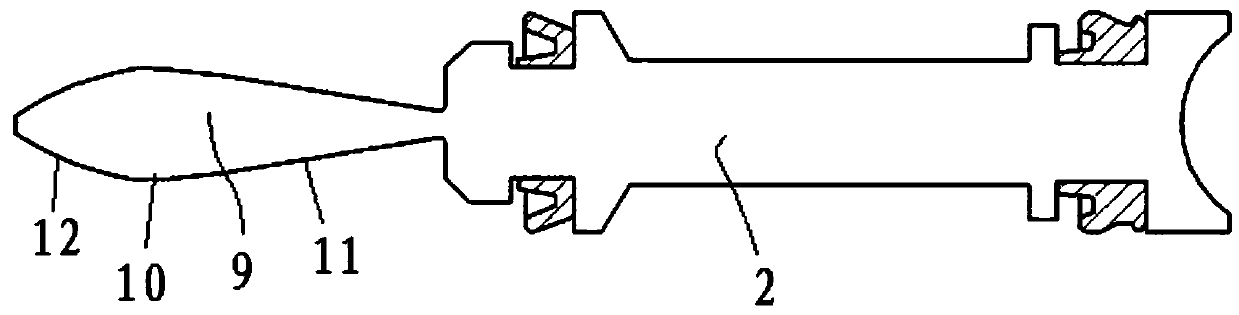

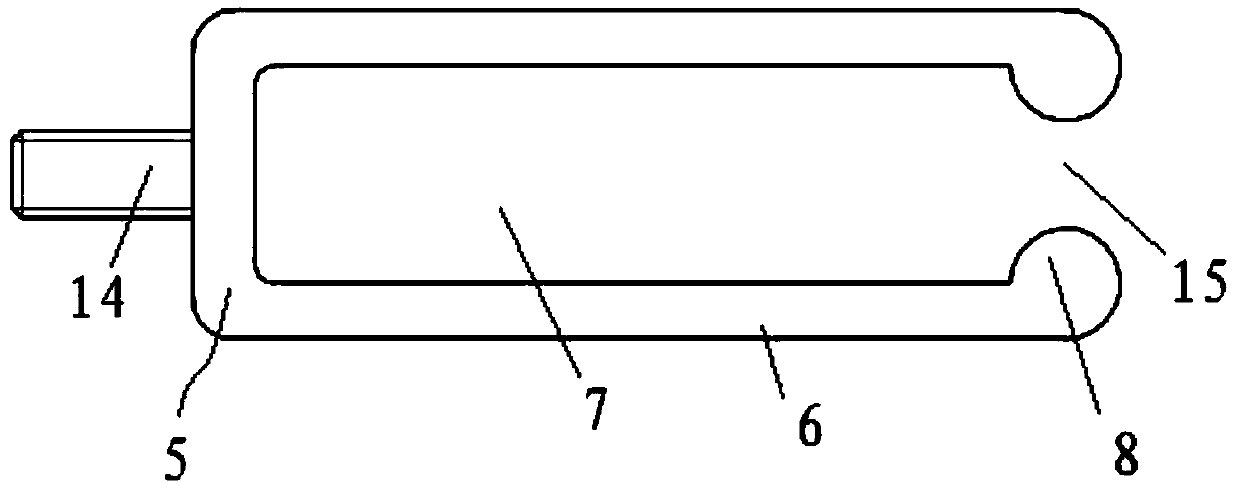

[0020] like Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a power-assisted clutch master cylinder structure, including: a master cylinder block assembly 1, which has a working chamber 4; a master cylinder piston assembly 2, which is accommodated in the working chamber 4 ; Push rod assembly 3, one end extends into the working chamber 4 and is connected to the master cylinder piston assembly 2; Spring fork 5, fixed in the working chamber 4, the spring fork 5 has an accommodating space 7 , an opening 15 is formed at the opposite end of the accommodating space 7 and the master cylinder piston assembly 2; the master cylinder piston assembly 2 is provided with a booster block 9, and the free end of the booster block 9 faces the spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com