Self-aligning clutch release bearing

A separation bearing, self-alignment technology, applied in the direction of clutches, mechanically driven clutches, bearings, etc., can solve the problems of loose parts, noise bearing ring wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

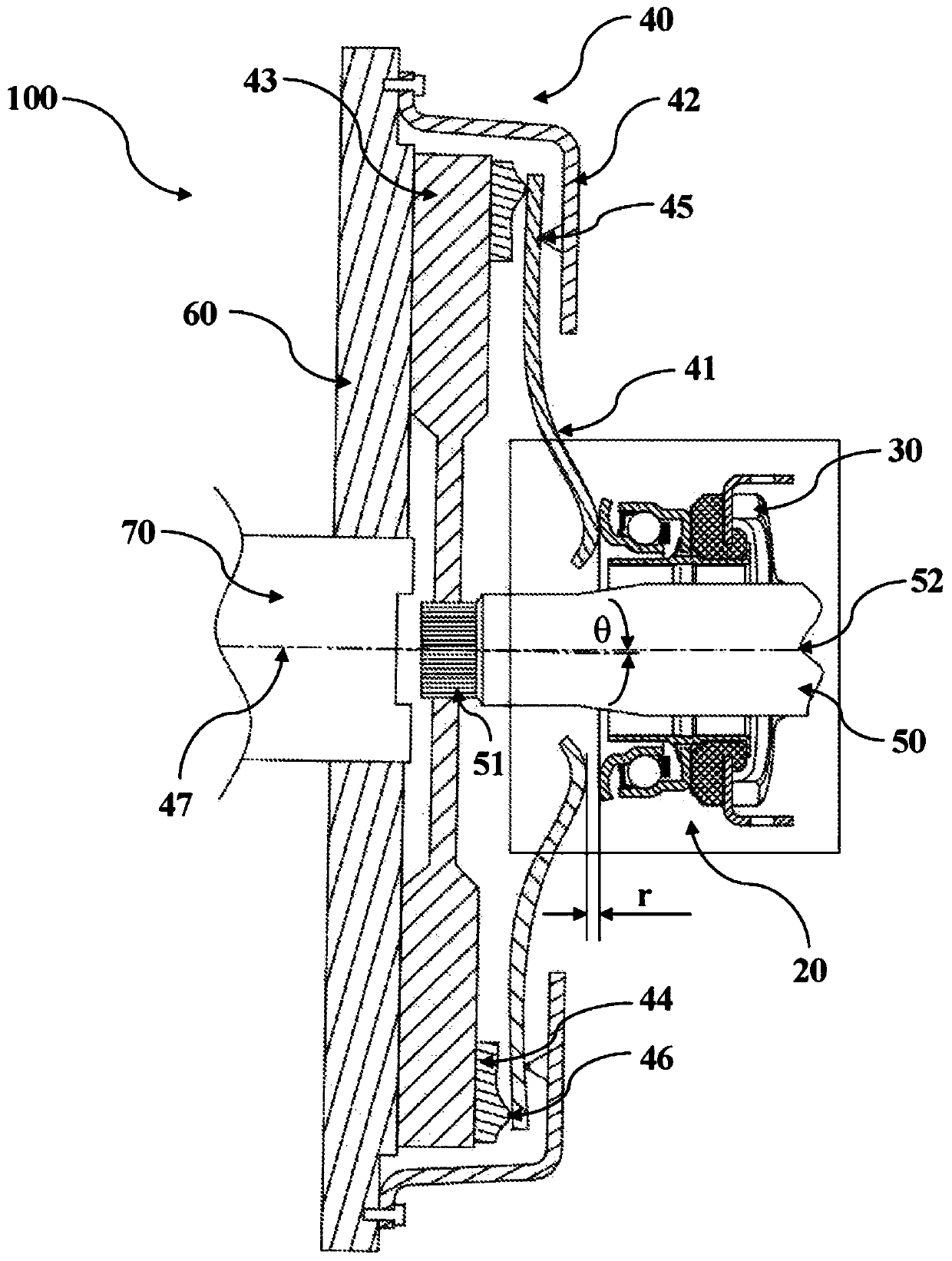

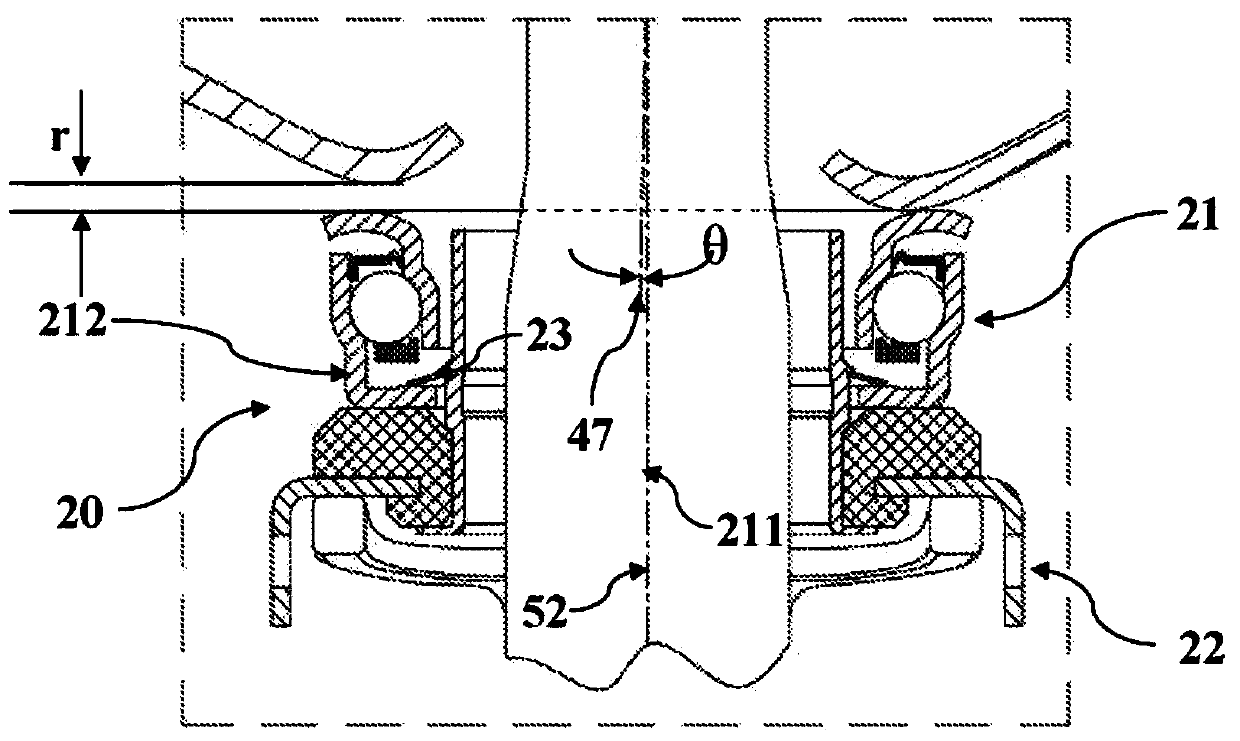

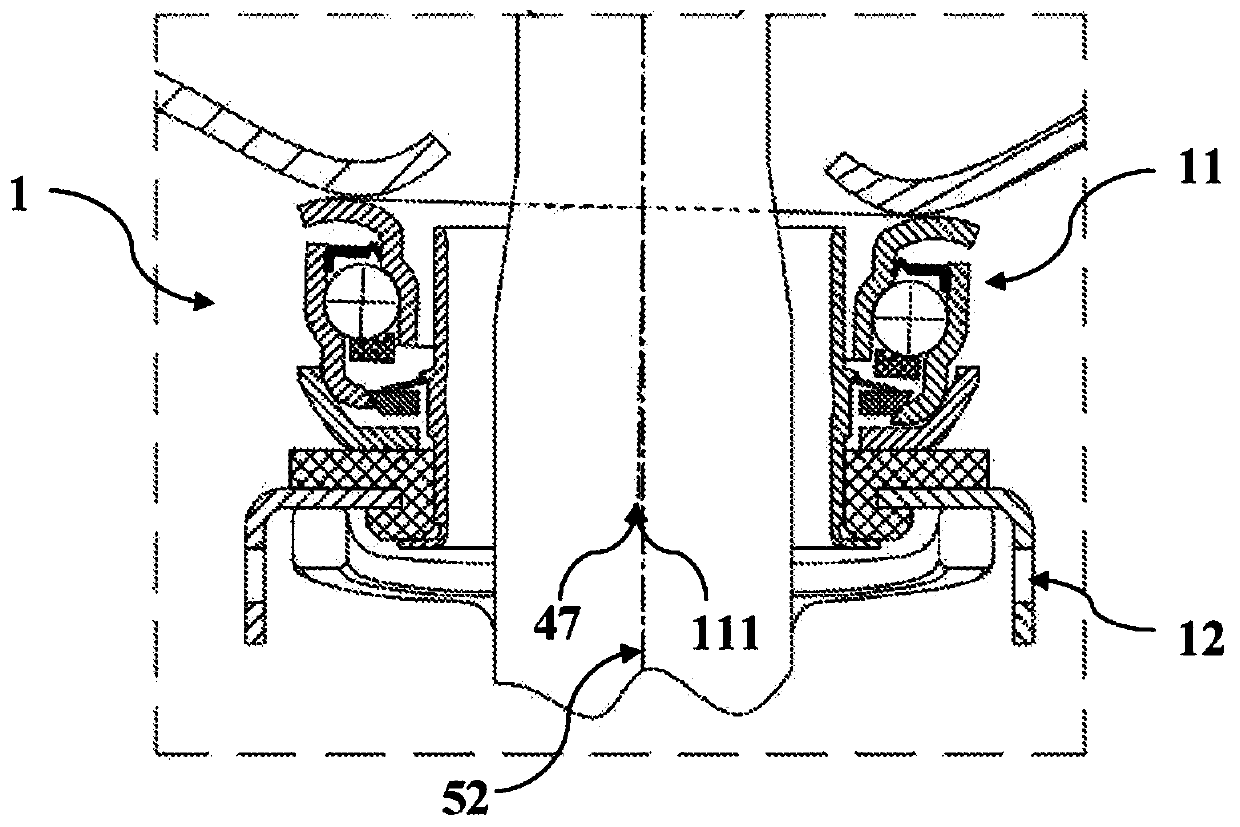

[0134] The second embodiment of the present invention provides the self-aligning clutch release bearing 1A of the present invention as an improvement over the conventional bearing 11A.

[0135] Such as Figure 5 As shown in, the improvement includes a cover 16. The bearing 11A is press-fitted in the cover 16. The cover 16 includes an outer spherical surface 161 and an inner spherical surface 162. The spherical surface 161 has a radius R1 that is the same as the radius of the spherical cup 13. In addition, the spherical surface 162 has the same radius R2 as the radius of the spherical ring 14. The cover 16 is preloaded between the spherical cup 13 and the spherical ring 14 by a spring 15. The center point of the spherical surface is at the same position on point 10. In this embodiment, the cover 16 and the bearing 11A can be tilted around the point 10 and compensate for the yaw r and misalignment θ. Therefore, the present invention allows the conventional clutch bearing to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com