A pedal force simulation and braking force control system for electric vehicle brake-by-wire system

An electric vehicle, brake-by-wire technology, applied in electric braking system, electric vehicle, hydraulic brake transmission, etc., can solve the problem of low braking energy recovery rate, poor driver braking feeling, hydraulic braking force and electric motor Braking force coordination and other problems, to achieve the effect of good braking stability, uniform change, and reduced pedal stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

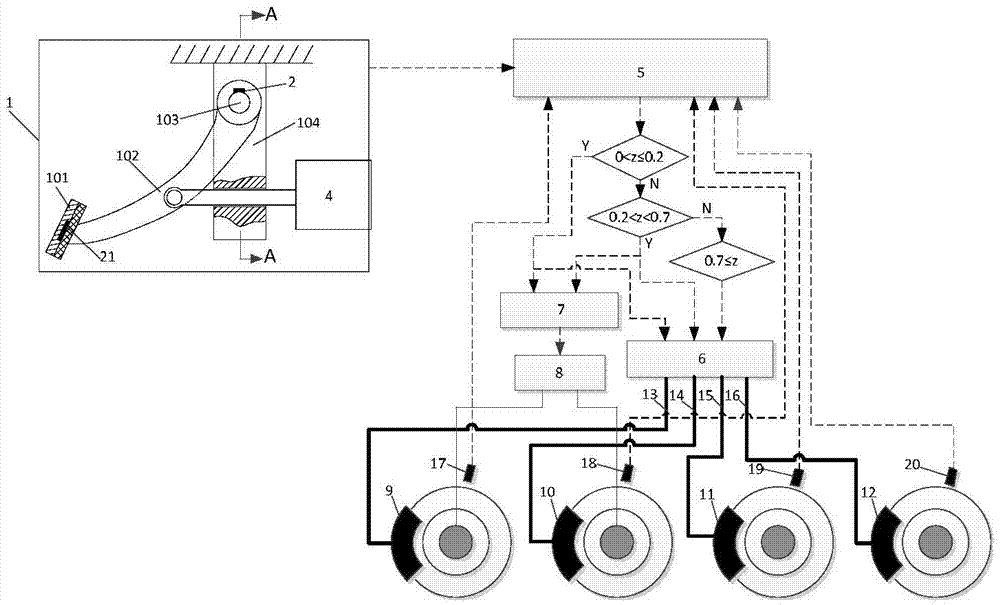

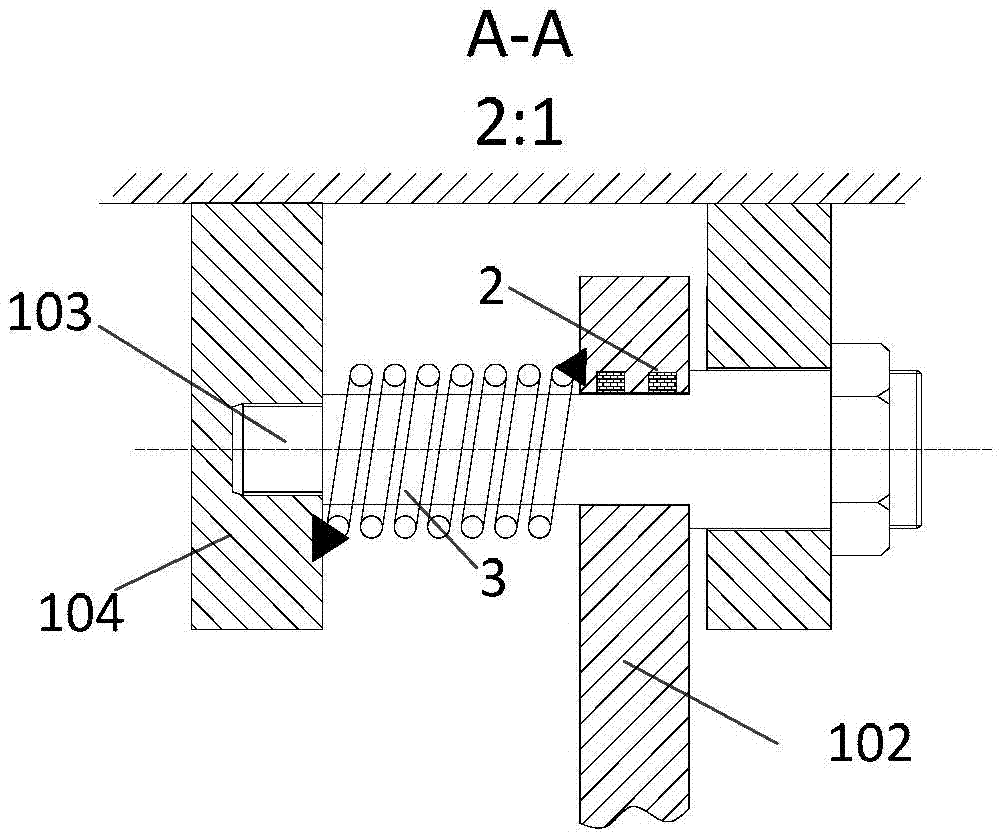

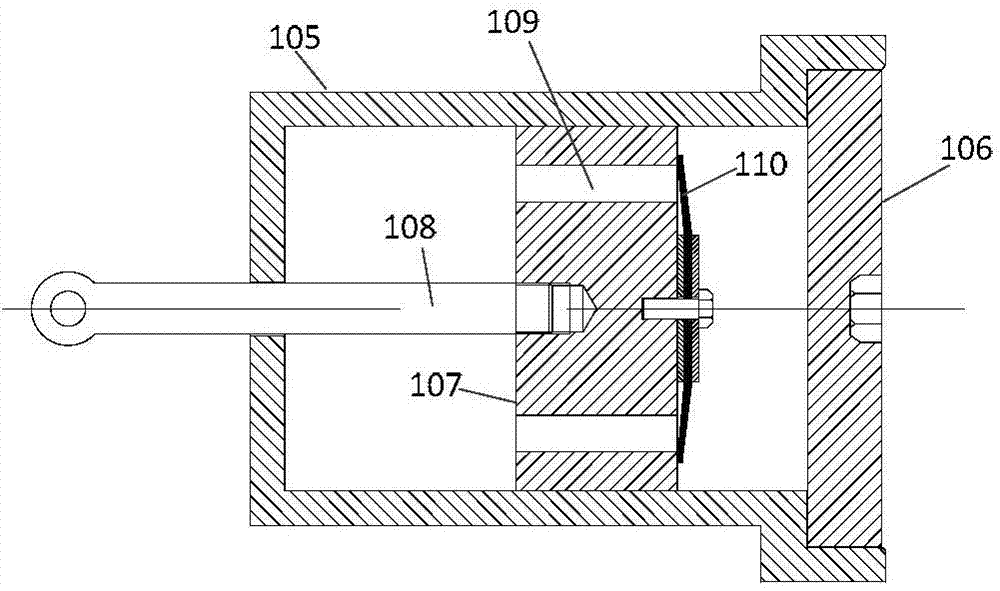

[0022] Such as Figure 1a , Figure 1b Shown is a schematic diagram of the overall structure of the present invention. The electric vehicle brake-by-wire system includes a brake control mechanism 1, a pedal angular displacement sensor 2, a torsion spring 3, a pedal feeling simulator 4, an electro-hydraulic composite brake control unit 5, a hydraulic control unit 6, a motor control unit 7, and an electric motor 8 , left front brake 9, right front brake 10, left rear brake 11, right rear brake 12, hydraulic brake pipelines 13, 14, 15, 16, four wheel speed sensors 17, 18, 19, respectively arranged on each wheel 20 and pedal force sensor 21.

[0023] Such as Figure 1a , Figure 1b shown. The brake operating mechanism of the electric vehicle brake-by-wire system includes a brake pedal 101 , a pedal operating arm 102 , a pedal shaft 103 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com