Upper cap forming method and device for negative angle collector of heavy rocket engine

A rocket engine and collector technology, which is applied to engine components, forming tools, mechanical equipment, etc., can solve the problems of difficult forming, high deformation resistance of room temperature forming, and the inability to use integral forming on the upper cover of negative angle collectors of heavy rocket engines. To achieve the effect of improving the forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0041] The present invention will be described in detail below in conjunction with the drawings and specific embodiments.

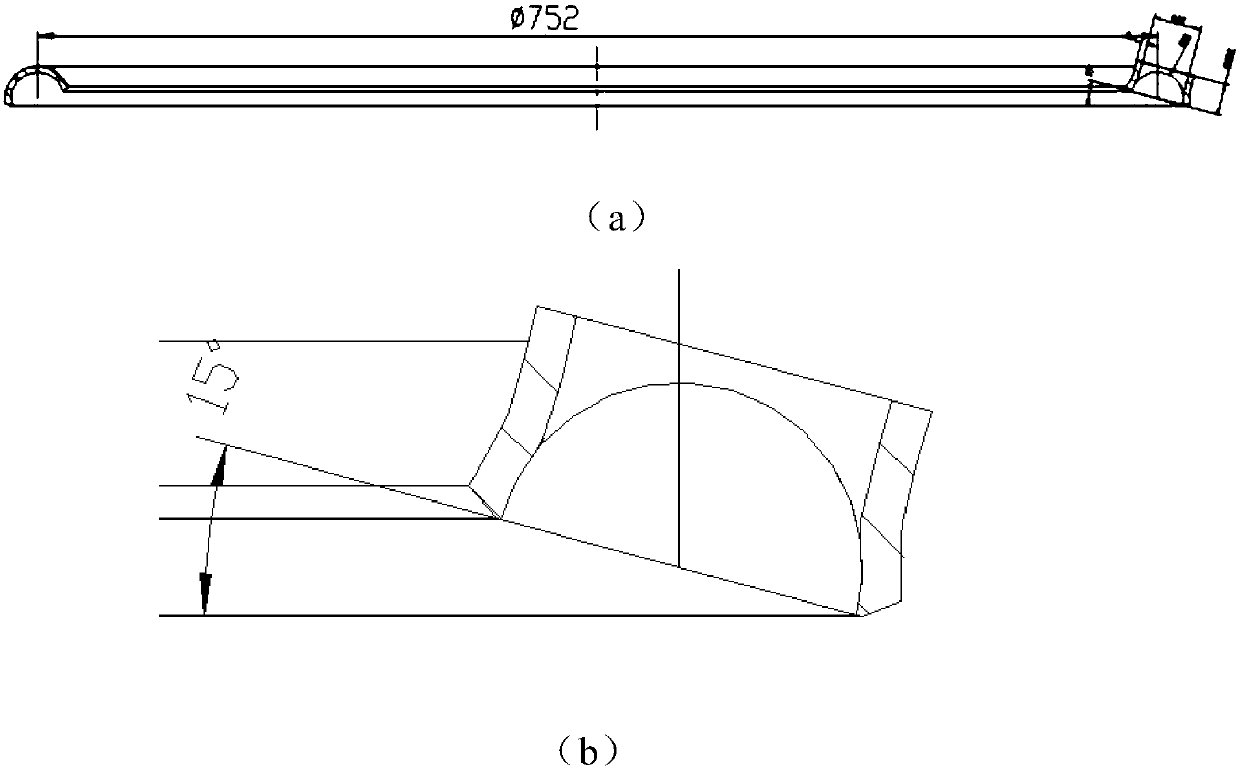

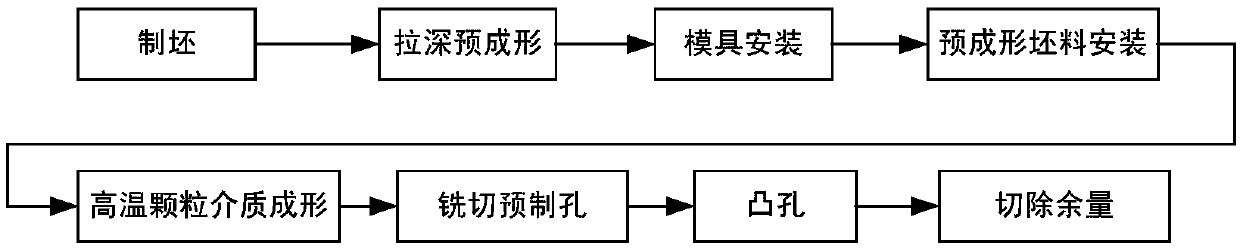

[0042] Such as figure 1 (a), figure 1 (b) shows the structure diagram of the upper cover of the negative angle collector of the heavy rocket engine. The upper cover of the negative angle collector of the heavy rocket engine is a disc structure with a semicircular edge cross-sectional shape. The angle between the port plane of the upper cover of the device is 15°, and there is a flanging hole on the edge;

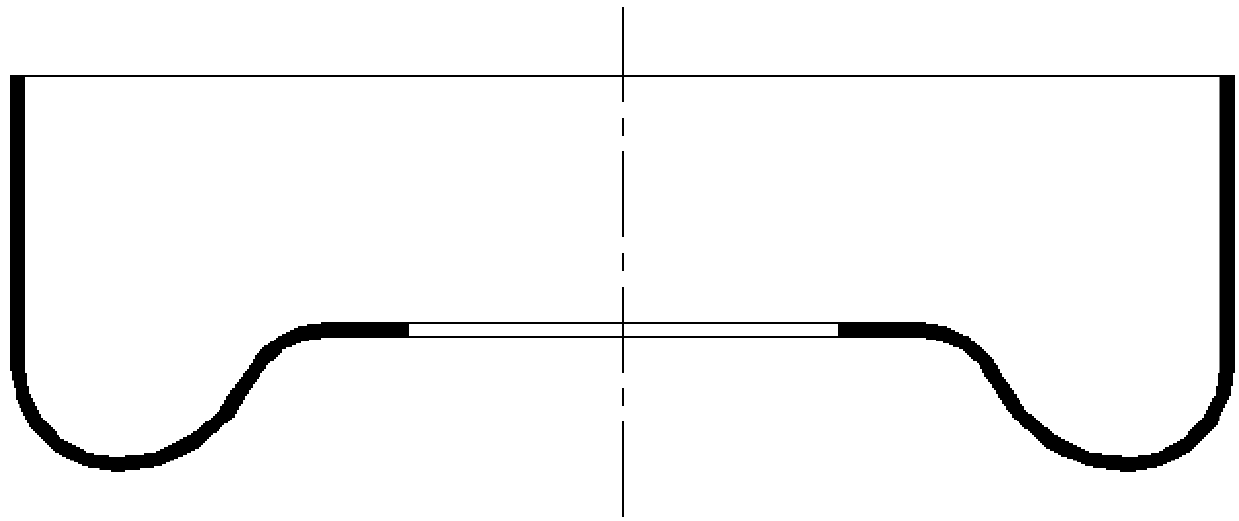

[0043] A forming device for the upper cover of the negative angle collector of a heavy rocket engine, such as Figure 4 (a), Figure 4 As shown in (b), it includes: lower mold 1, upper mold 4, indenter 5, core mold 6; upper mold 4 and lower mold 1 are opened with a surface that matches the theoretical shape of the upper cover of the collector; preformed blank 2 Placed on the lower mold 1, the core mold 6 is connected to the lower mold 1 by bolts 7; the lower...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap