Efficient steel pipe machining device

A technology for processing equipment and steel pipes, applied in positioning equipment, metal processing equipment, metal processing machinery parts, etc., can solve the problems of large overall size of processing equipment, high spindle center, and heavy steel pipe weight, reducing labor intensity of workers and improving The effect of work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

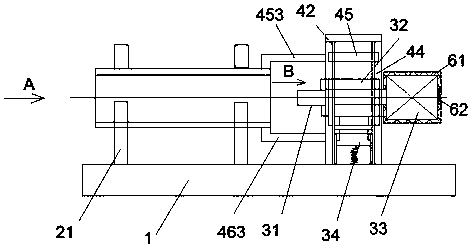

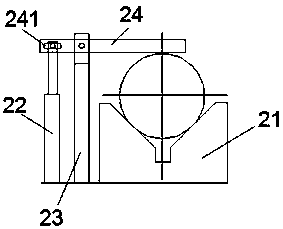

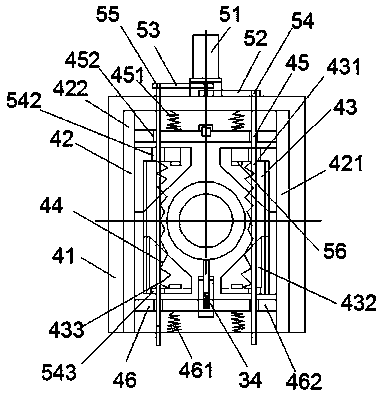

[0029] Such as Figure 1-Figure 8 As shown, a high-efficiency steel pipe processing device of the present invention includes a frame 1, a steel pipe clamping unit, a spindle unit and a spindle adjustment unit, the steel pipe clamping unit is fixed on the upper surface of the frame 1, and the spindle The unit is installed in the middle of the main shaft adjustment unit, and the main shaft adjustment unit is installed on the upper surface of the frame on the right side of the steel pipe clamping unit and can slide in the left and right directions. The main shaft unit includes a support sleeve 32, a main shaft 31, a motor 33 and a support seat assembly 34, the support seat assembly 34 is fixed on the upper surface of the frame 1, the support sleeve 32 is placed on the top surface of the support seat assembly 34, and the main shaft 31 is supported and installed on the Inside the supporting sleeve 32, the motor 33 is fixed on the right end of the supporting sleeve 32 and the shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com