Embossing device for printing with exact positioning

An embossing and accurate technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of paper waste, embossing position offset, etc., and achieve the effect of ensuring embossing effect, not easy to deflection, and good positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

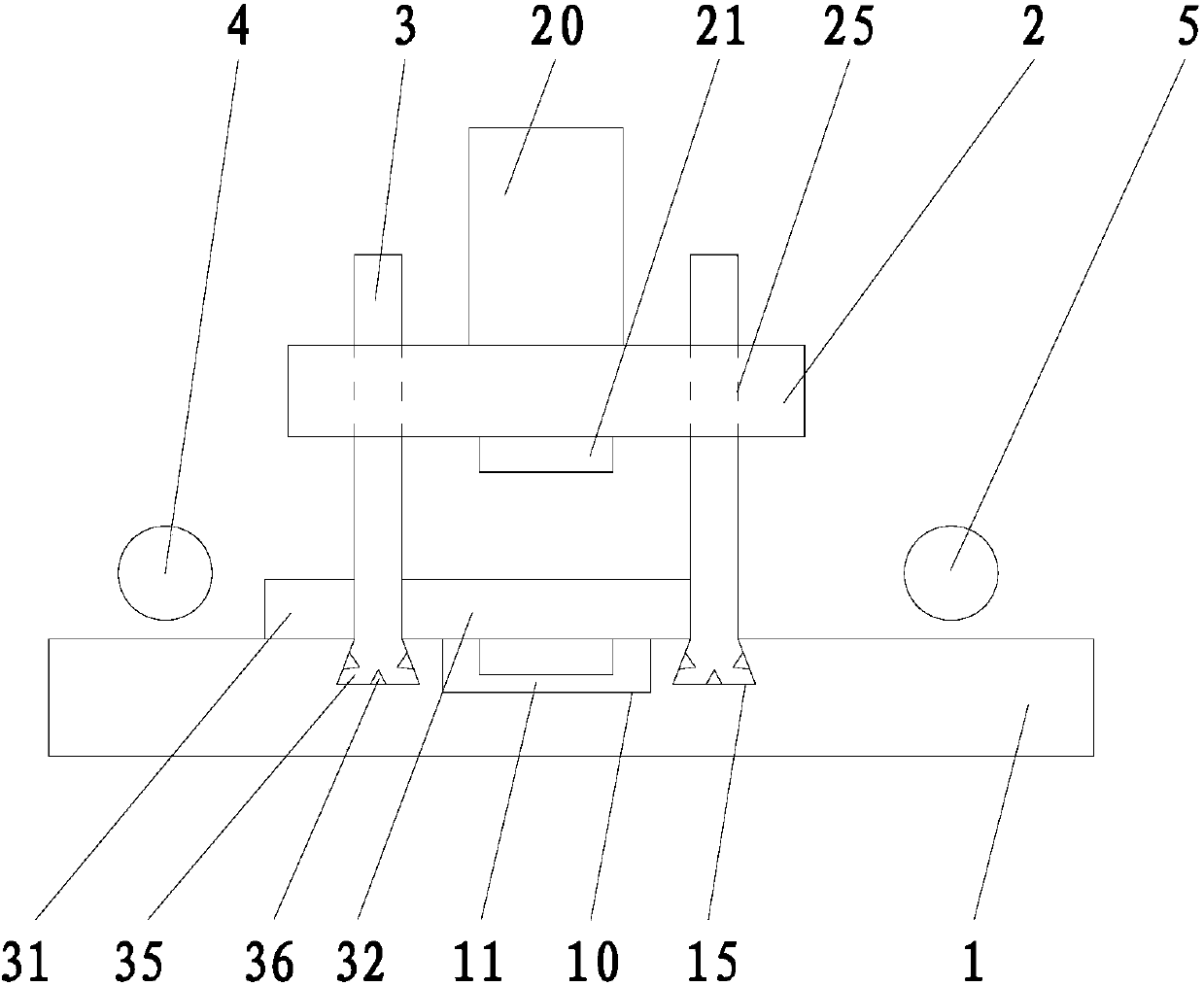

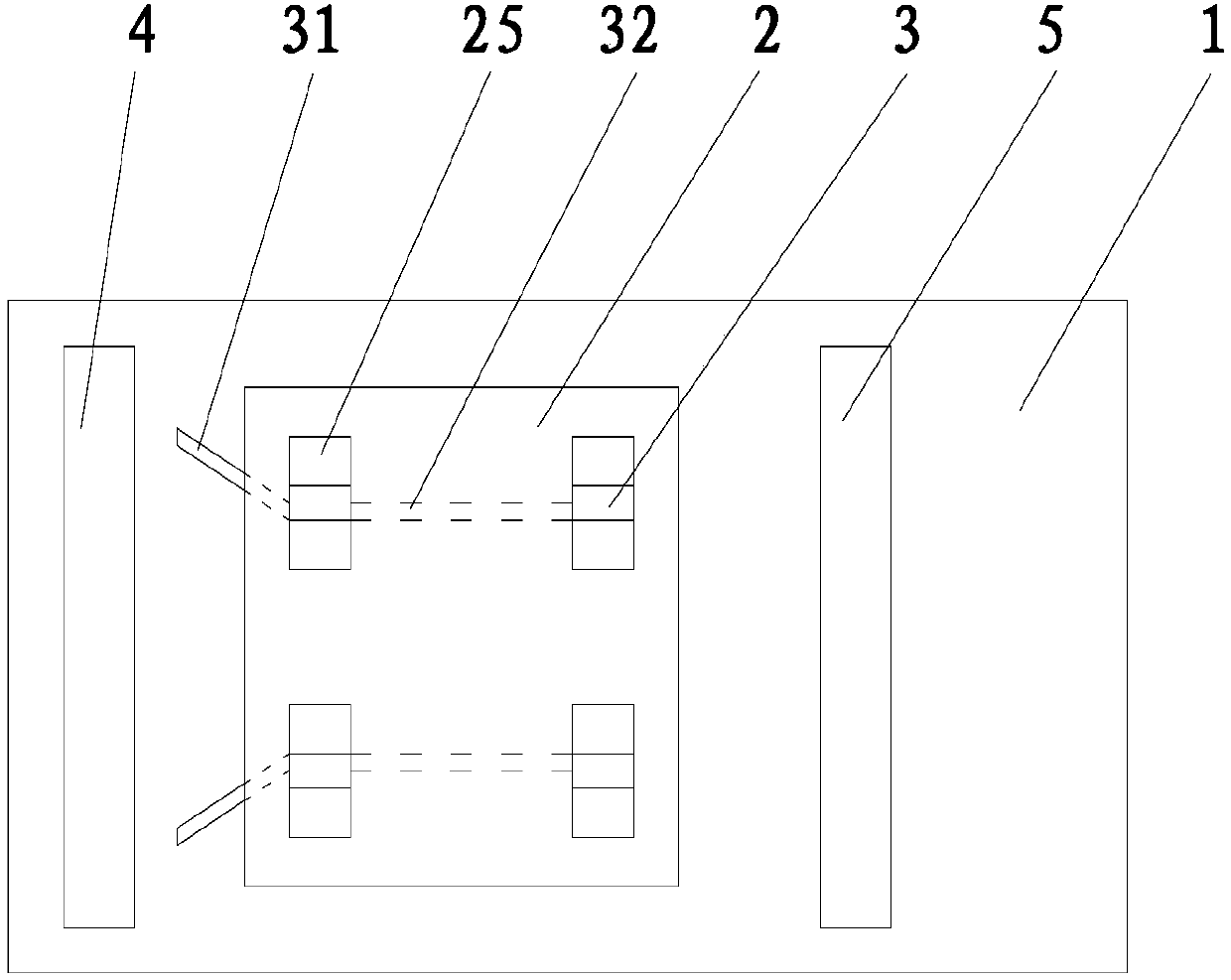

[0015] refer to figure 1 with figure 2 , an embossing device for printing with accurate positioning in the present invention, comprising a conveying table 1, a first conveying roller 4, a second conveying roller 5, a pressing plate 2, a pressing device 20, an embossing die 21, a concave die 11, an adjustment Rod 3, a first conveying roller 4, a pressing plate 2, and a second conveying roller 5 are sequentially arranged on the top of the conveying platform 1 along the conveying direction of the paper. The pressing device 20 is connected to each other, and a concave die 11 matched with the embossing die 21 is installed on the conveying table 1 directly below the pressing plate 2, and a strip-shaped through groove 25 is respectively provided on the four corners of the pressing plate 2, through which The length direction of the groove 25 is perpendicular to the conveying direction of the paper, the section of the adjusting rod 3 is rectangular, the adjusting rod 3 passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com