Fin embossing mechanism capable of adapting to embossing of blanks with different thicknesses

A technology that adapts to different embossing and is applied in decorative arts, embossed ornaments, etc. It can solve the problems of inconvenience, damage, and inconvenient replacement of the staff, and achieve the effect of increasing output speed, increasing friction, and ensuring embossing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

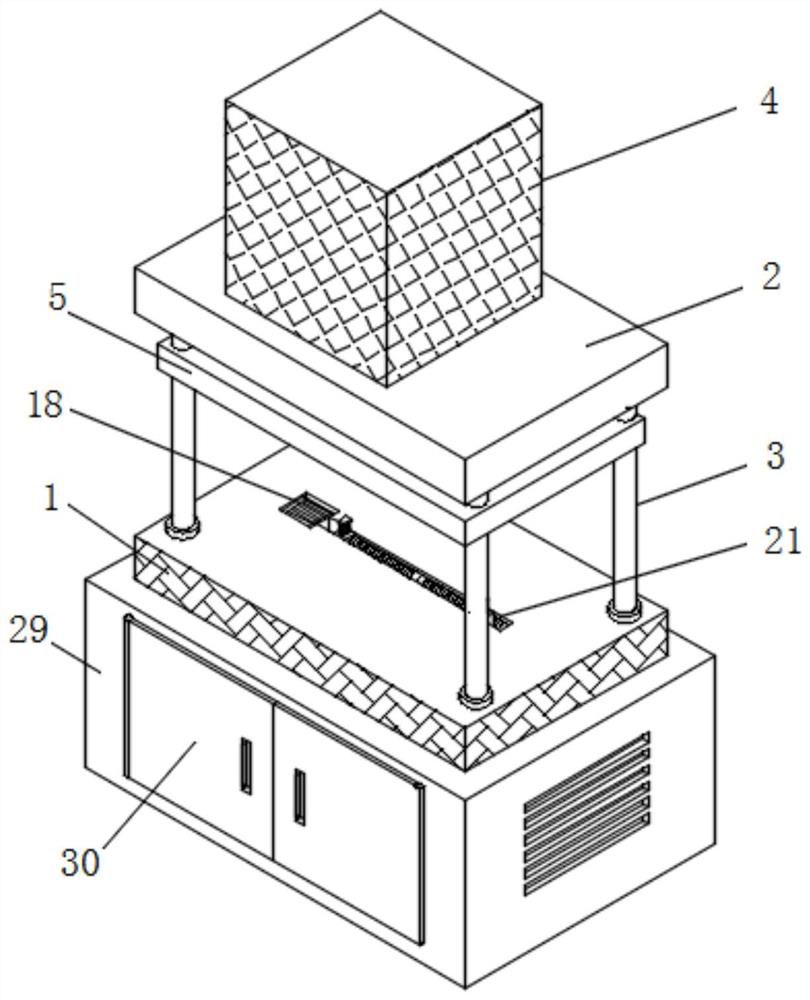

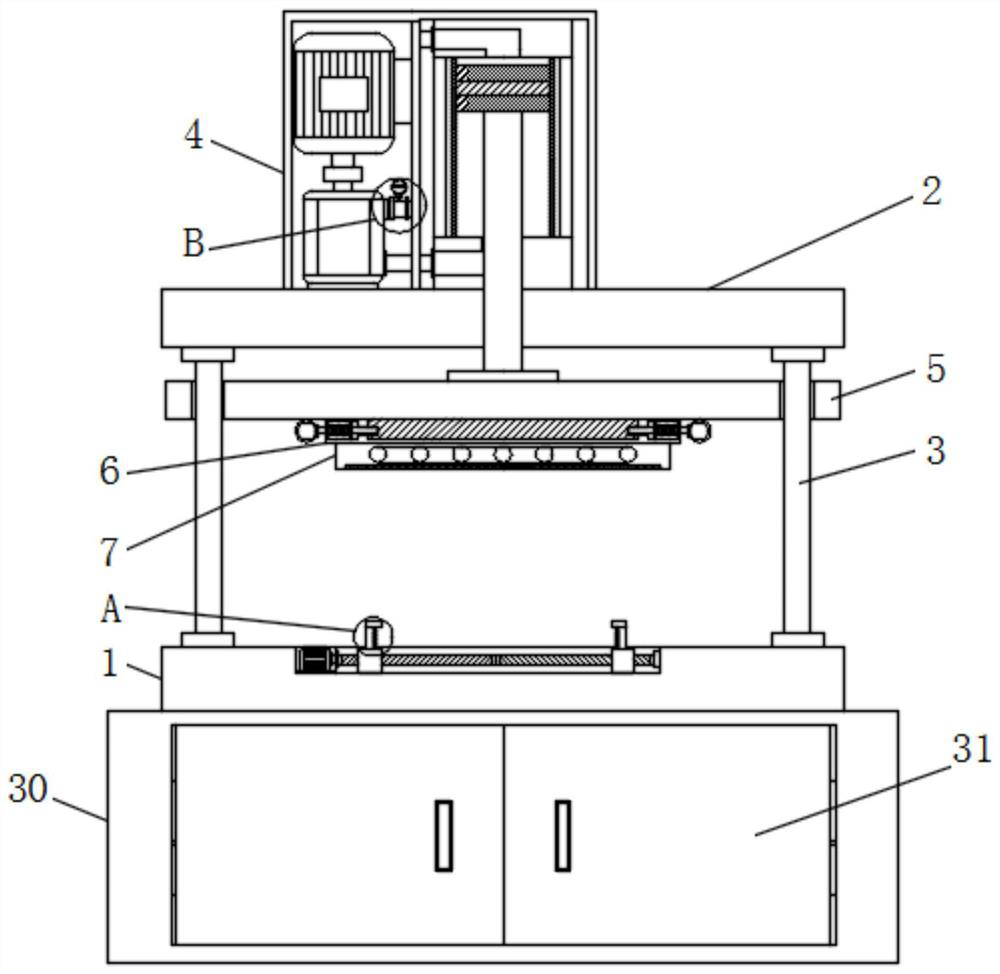

[0037] see figure 1 , figure 2 , Figure 6 , Figure 7 ,and Figure 8 , a fin embossing mechanism that can adapt to the embossing of blanks of different thicknesses, including a base 1, a working box 4 and a pressing plate 5, guide columns 3 are installed on the top four corners of the base 1, and a support seat is installed on the top of the guide column 3 2. A working box 4 is installed on the top surface of the support base 2;

[0038] Specifically, the embossing mechanism is provided with an installation space through the base 1, and the working box 4 on the top is carried through the support base 2, and the four sets of guide columns 3 provided between the base 1 and the support base 2 can control the movable pressing plate. 5. Carry out guiding support function.

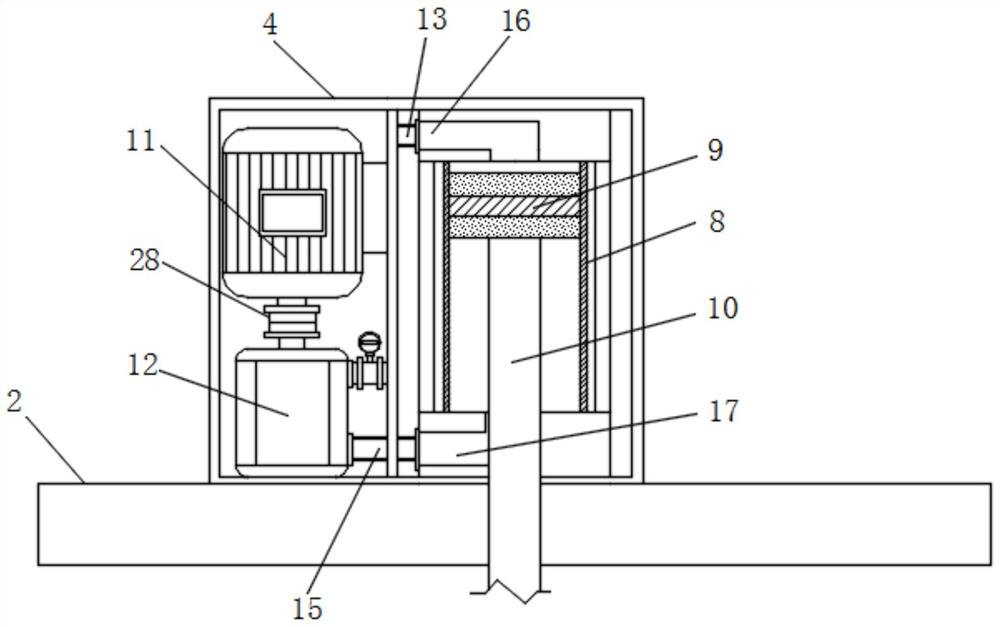

[0039] Such as image 3 As shown, a finned embossing mechanism that can adapt to the embossing of blanks of different thicknesses, the inner wall of the working box 4 is installed with a partition, the i...

Embodiment 2

[0044] Such as Figure 4 As shown, a finned embossing mechanism that can adapt to the embossing of blanks of different thicknesses, a chute 21 is provided through the top surface of the base 1, a drive motor 18 is installed inside the chute 21, and the output end of the drive motor 18 is installed There is a first screw 19, one end of the first screw 19 is connected with a second screw 20, the surfaces of the first screw 19 and the second screw 20 are sleeved with a sliding block 22, and the sliding block 22 is located in the chute 21, the top surfaces of two groups of sliding blocks 22 are equipped with clamping blocks 23, the top surfaces of two groups of clamping blocks 23 are equipped with limit blocks 24, and the surfaces of two groups of clamping blocks 23 that are close to each other are equipped with anti-skid pad 25, and the anti-skid pad 25 is located below the limit block 24.

[0045] Specifically, in the process of using the embossing mechanism, the output end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com