Patents

Literature

68results about How to "Push speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

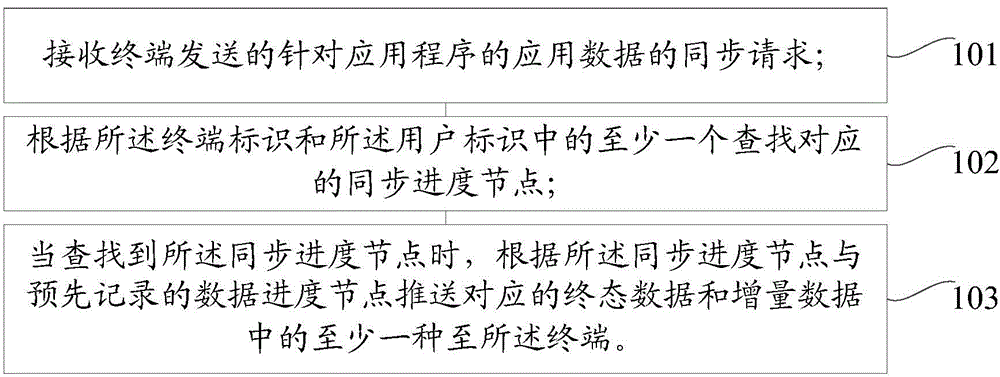

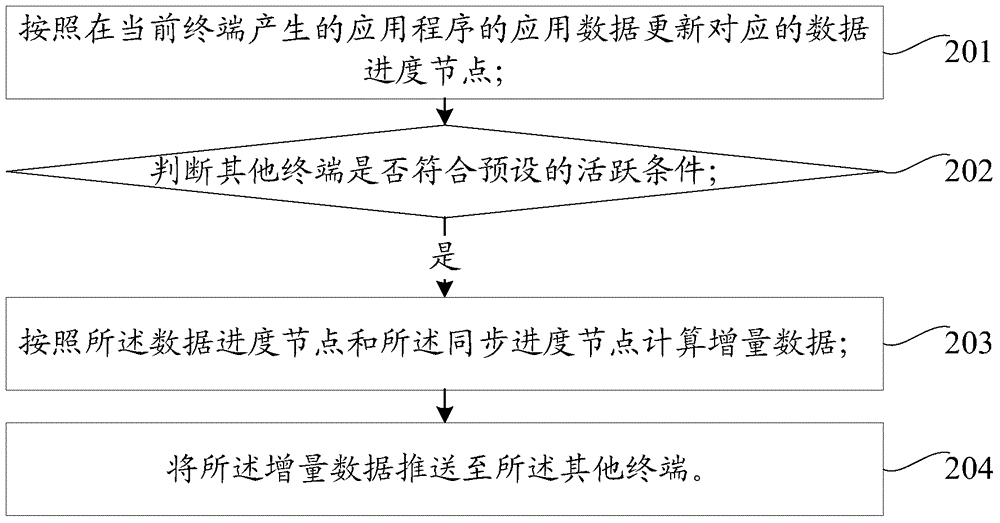

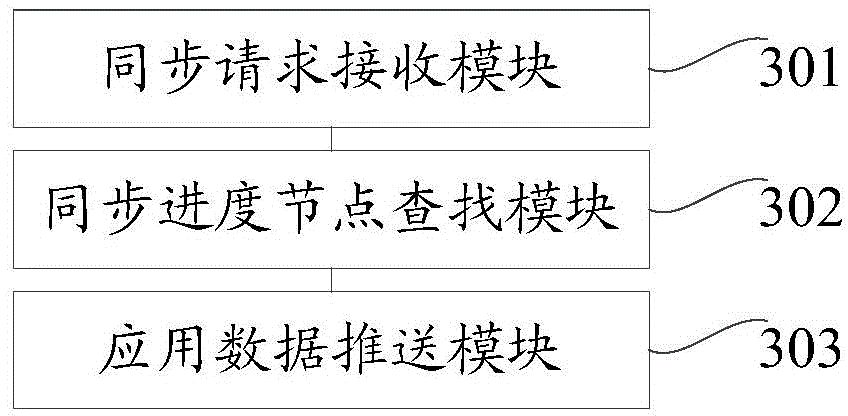

Method and device for application data synchronization

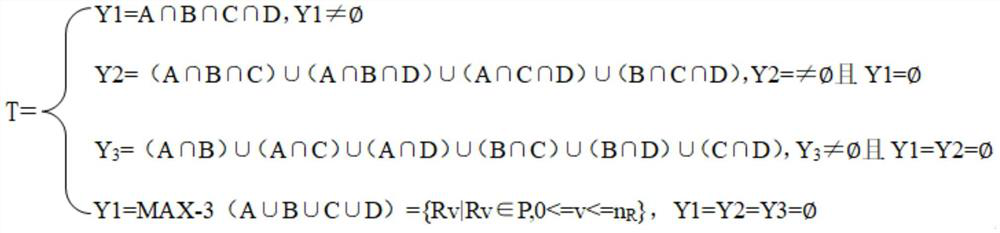

The invention provides a method and a device for application data synchronization. The method comprises steps that a synchronization request which is for an application data of an application program and is sent by a terminal is received; the synchronization request comprises at least one of a terminal identification and a user identification, and the application data comprises one type of the final state data and the increment data; the corresponding synchronization progress node is searched according to the at least one of the terminal identification and the user identification; when the synchronization progress node is searched, the at least one type of the final state data and the increment data is pushed to the terminal according to the synchronization progress node and a pre-recorded data progress node. Through the method, the application data can be flexibly pushed according to actual synchronization difference, push flexibility of the application data is improved, so all the application data is not acquired at each time, network flow consumption is reduced, the push speed is accelerated, and synchronization efficiency is improved.

Owner:ADVANCED NEW TECH CO LTD

Blockchain-based information pushing method

The invention discloses a blockchain-based information pushing method. To be specific, the method comprises: step one, determining a use keyword and a subscription keyword, carrying out Monte Carlo tree prediction based on the use keyword and the subscription keyword to obtain first Monte Carlo tree prediction information and second Monte Carlo tree prediction information, correcting the first Monte Carlo tree prediction information by using the second Monte Carlo tree prediction information and generating a Monte Carlo tree of predictive information, and using a trunk of the Monte Carlo treeas an alternative blockchain of a distributed node; step two, compressing push information into a data block and establishing a mapping relationship between the compression data and the alternative blockchain; and step three, selecting compression data associated with the alternative blockchain among the compression data and sending the compression data corresponding to the main blockchain to theuser. According to the invention, the blockchain technology is applied to the information push field to avoid leakage of privacy information of the user; and the main blockchain is determined from multiple alternative blockchains, so that the generation speed of the blockchain is increased.

Owner:尹煦

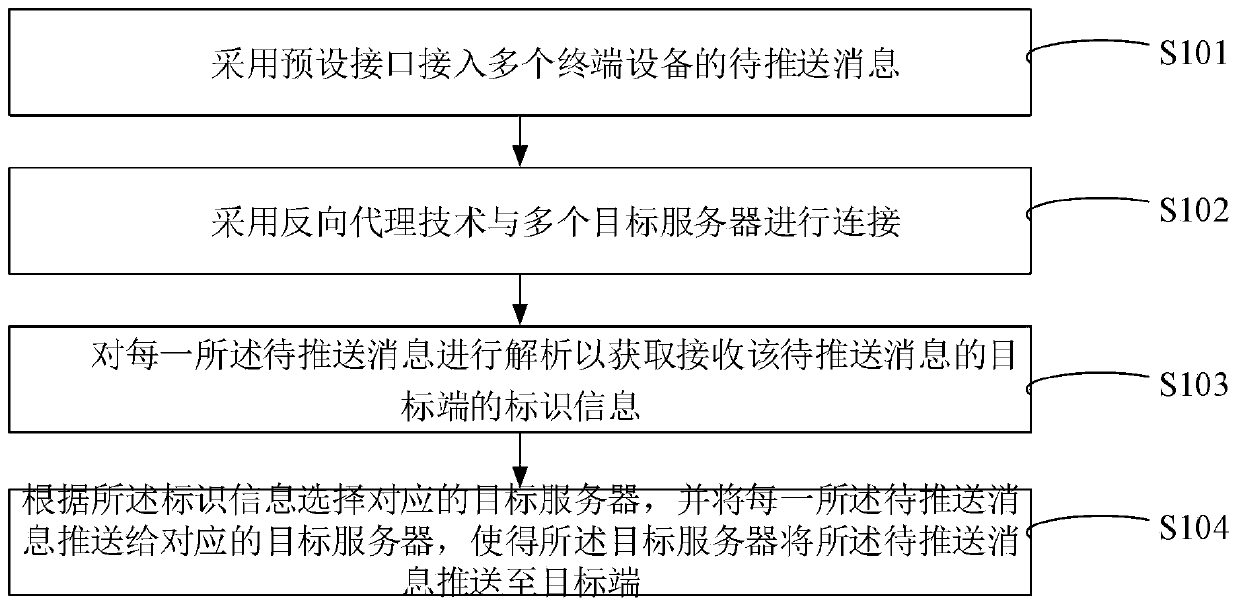

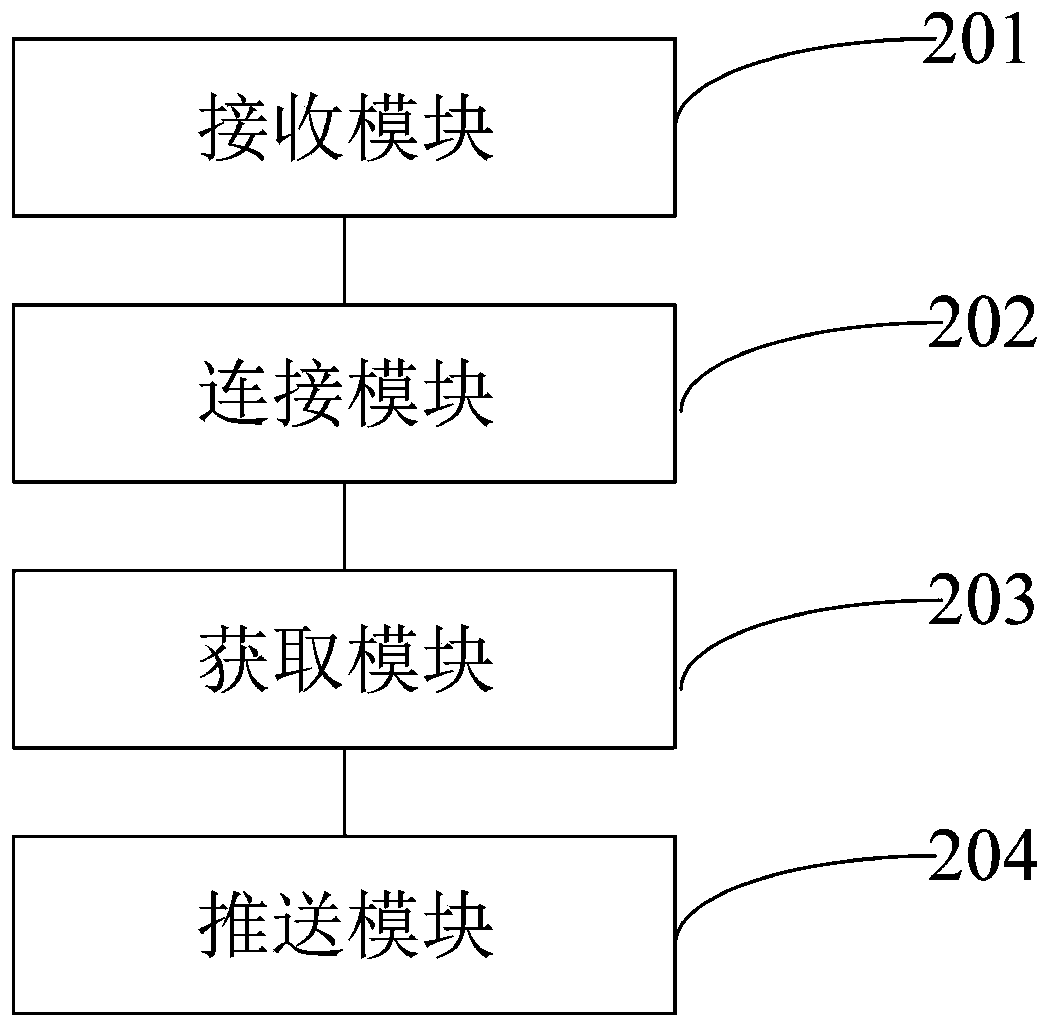

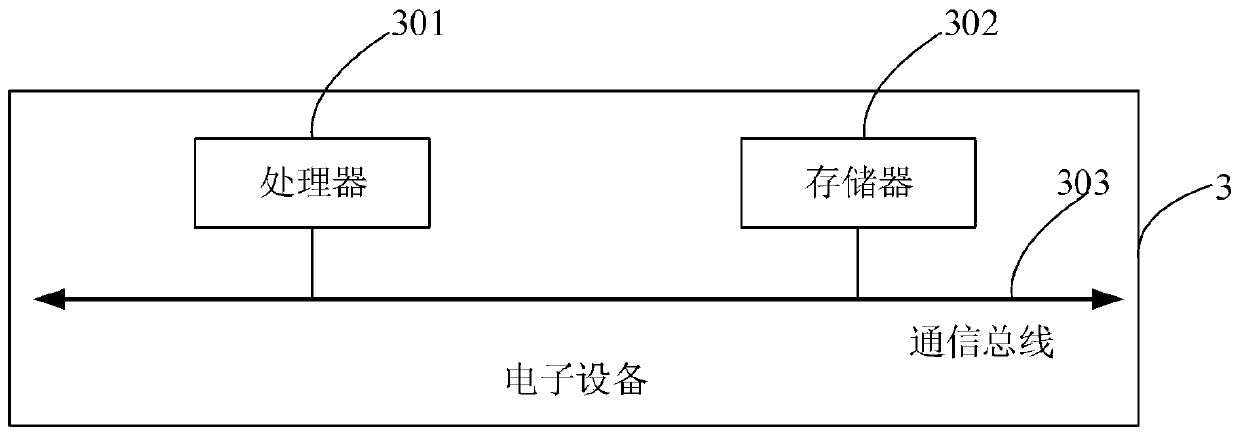

Message pushing method and device, electronic equipment and storage medium

ActiveCN111555963AImprove throughput performanceImprove message push speedData switching networksEmbedded systemReverse proxy

The embodiment of the invention provides a message pushing method and device, electronic equipment and a storage medium. The message pushing method is applied to a reverse proxy server, and comprisesthe following steps: accessing to-be-pushed messages of a plurality of terminal devices by adopting a preset interface; connecting with a plurality of target servers by adopting a reverse proxy technology; analyzing each to-be-pushed message to obtain identification information of a target end receiving the to-be-pushed message; and selecting a corresponding target server according to the identification information, and pushing each to-be-pushed message to the corresponding target server, so that the target server pushes the to-be-pushed message to a target end. According to the method, pushing of a large number of messages can be realized, the throughput performance of the messages can be improved, and the message pushing speed is improved.

Owner:北京思特奇信息技术股份有限公司

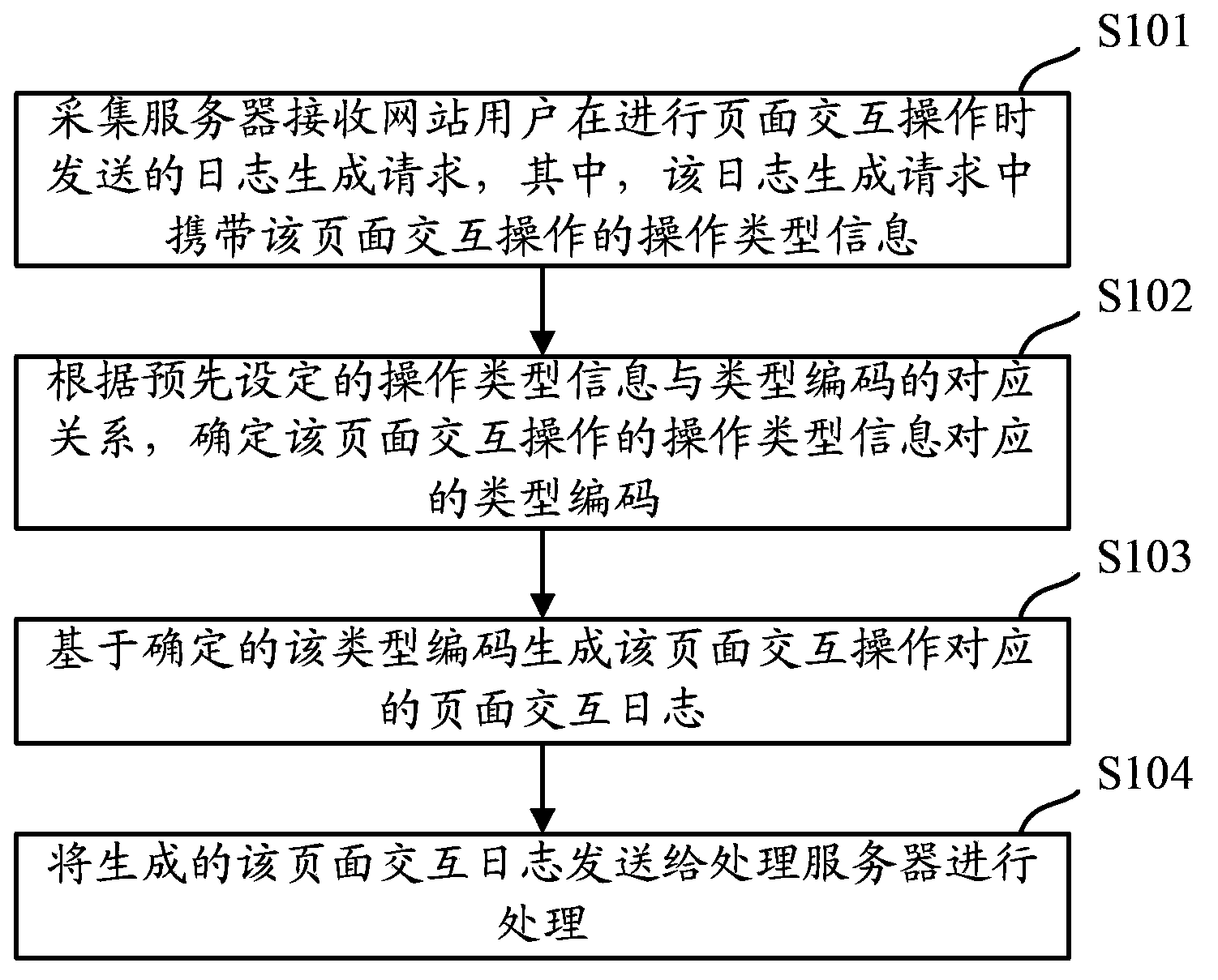

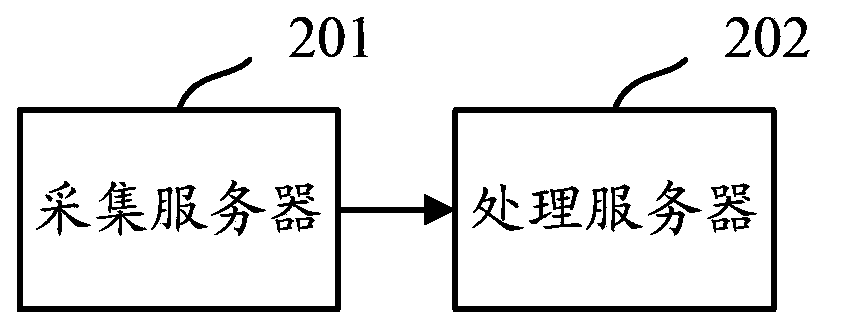

Data processing method, system and device

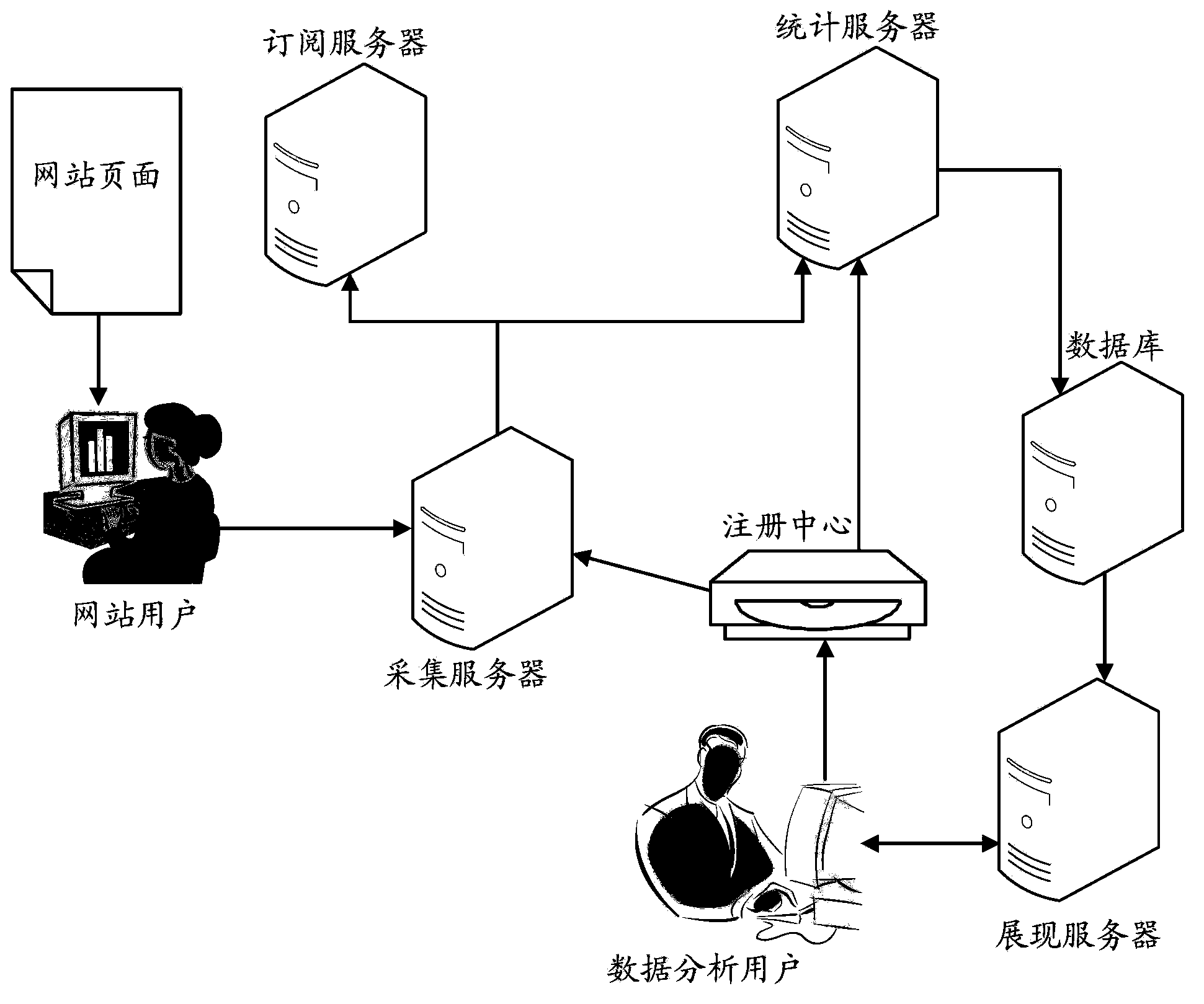

ActiveCN103729380AImprove optimization effectEasy loadingWebsite content managementSpecial data processing applicationsData processingWeb page

The embodiment of the invention provides a data processing method, system and device. The data processing method is used for solving the problems that in the prior art, the web page optimization effect is poor, and loading speed and pushing speed of web pages are low. According to the method, an acquisition server receives log generation requests sent by website users, determines type codes corresponding to operating type information according to the operating type information of page interaction operation carried in the log generation requests, generates page interaction logs based on the determined type codes, and sends the generated page interaction logs to a processing server for processing. Through the method, the acquisition server can collect the page interaction operation on the web pages by the website users and generate the corresponding page interaction logs, so the generated page interaction logs can provide accurate reference frames for subsequent web page optimization, and accordingly the web page optimization effect is improved and the loading speed and the pushing speed of the optimized web pages are improved.

Owner:TAOBAO CHINA SOFTWARE

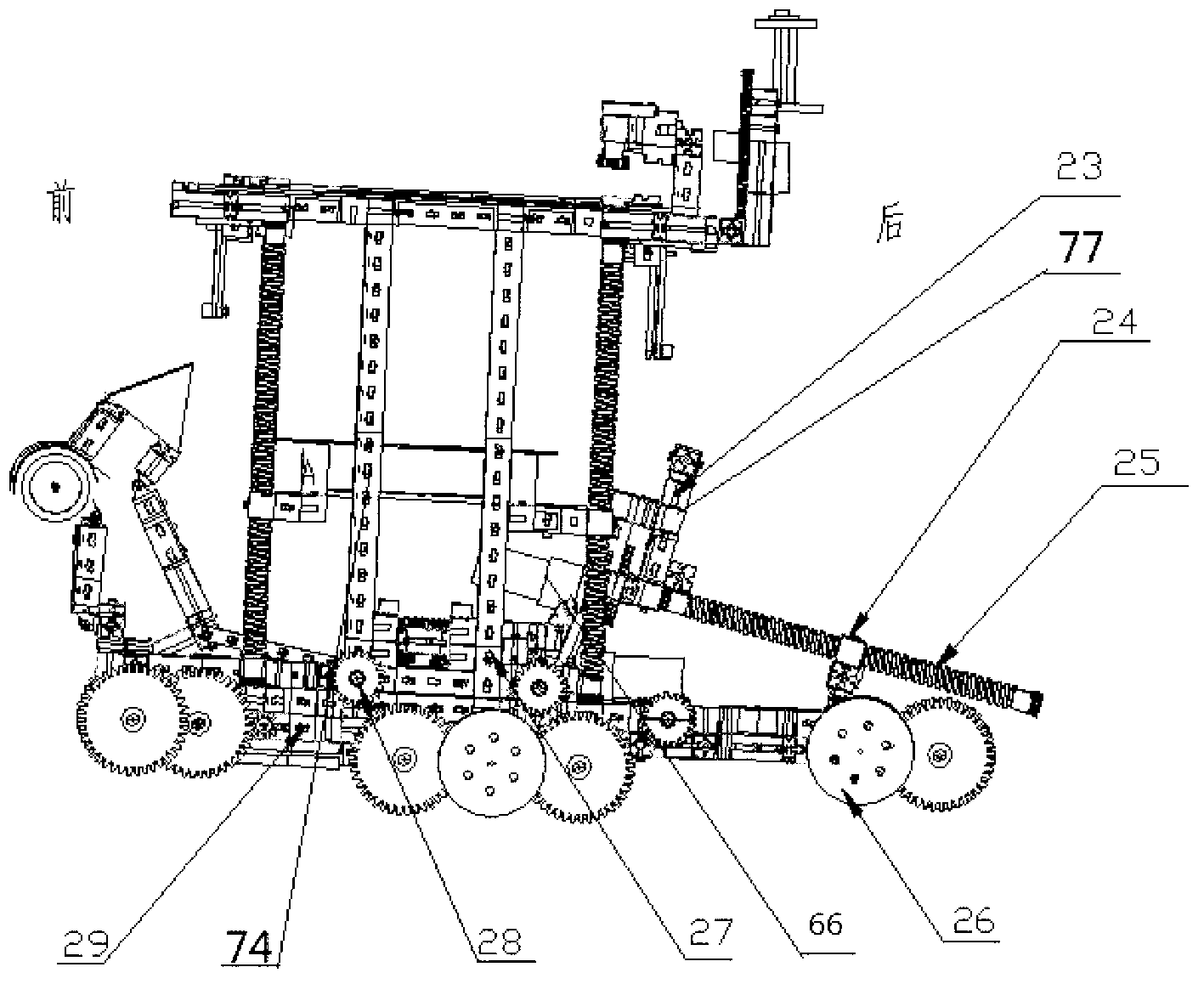

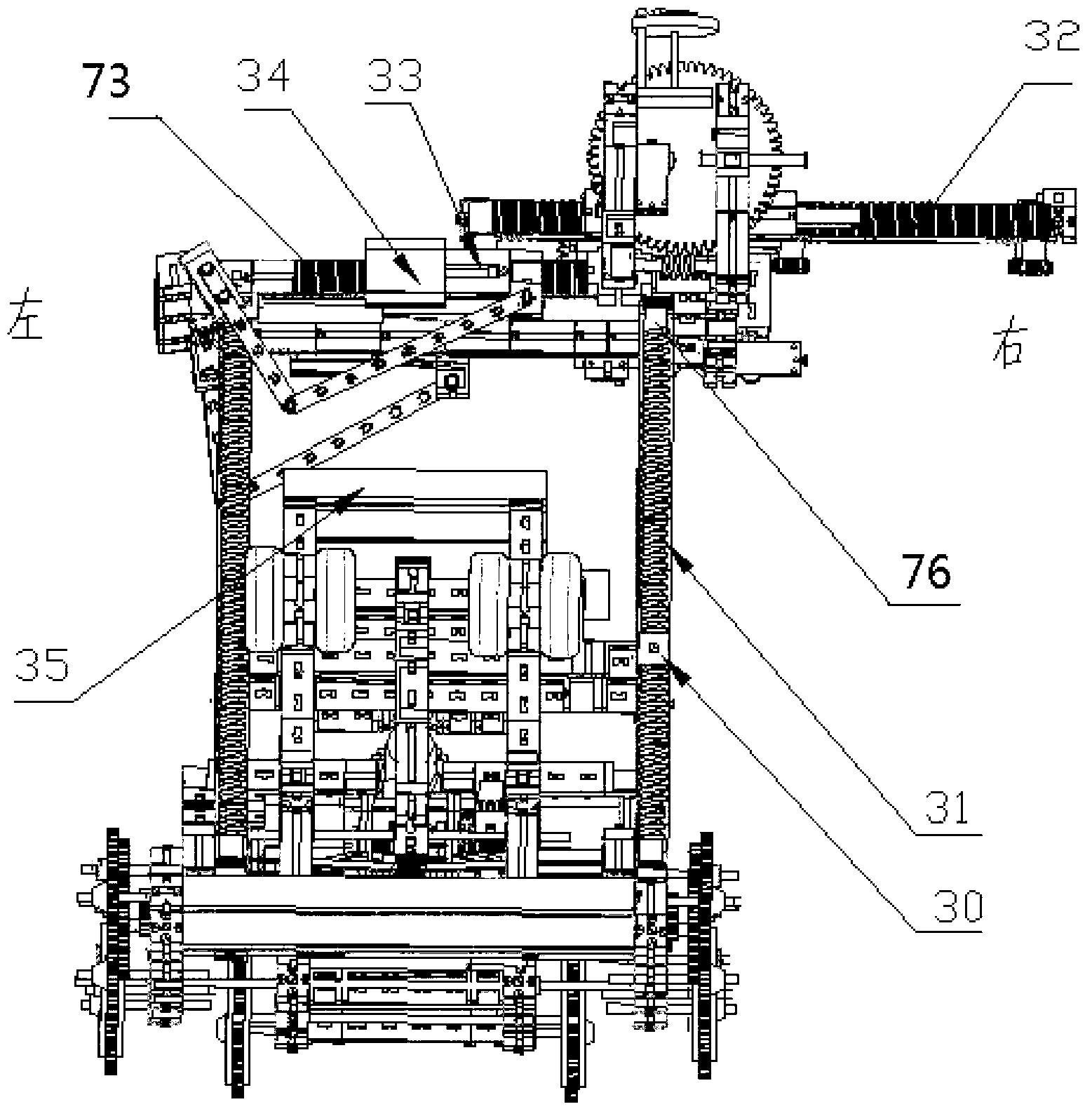

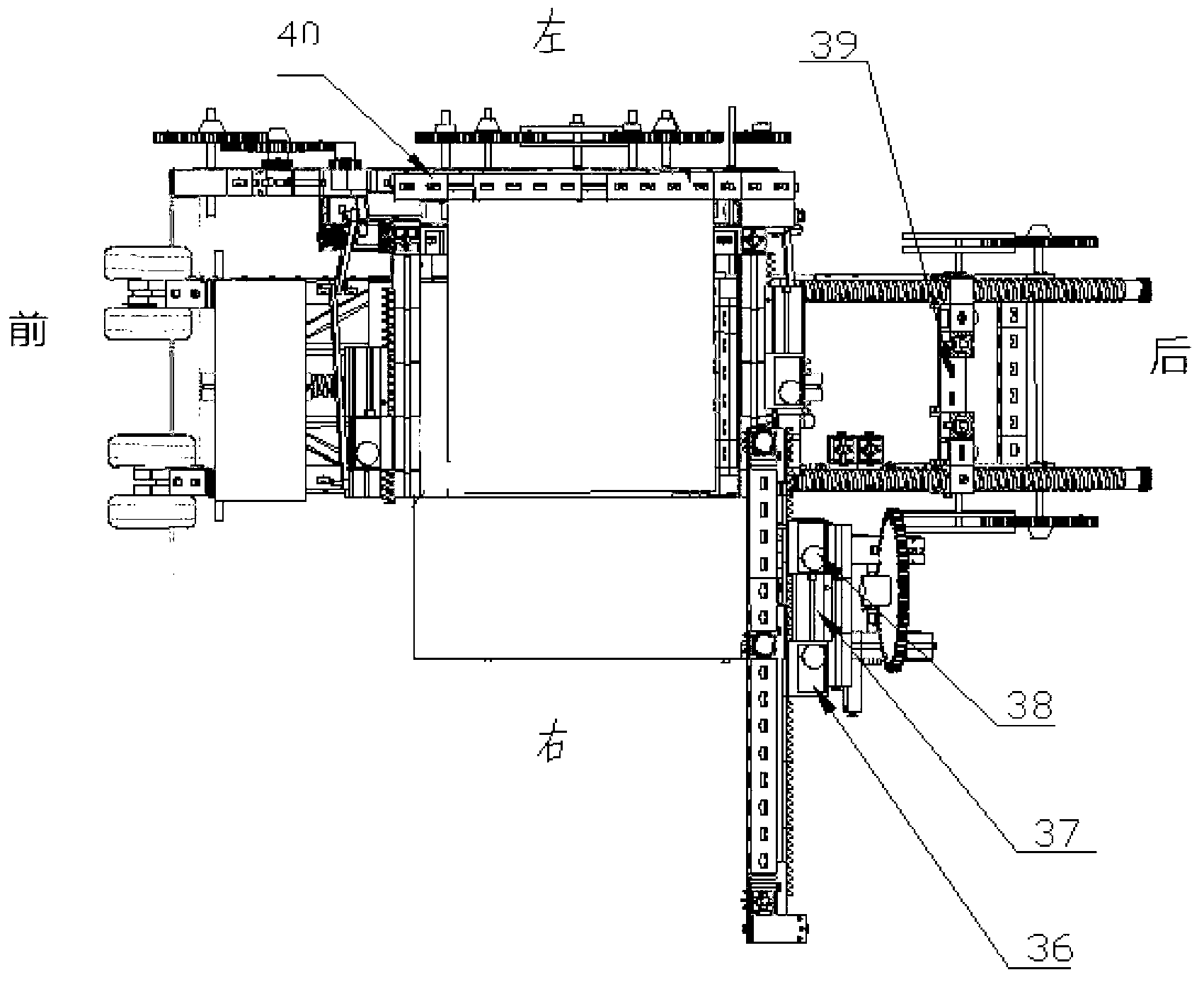

Multifunctional household service robot

InactiveCN102794758AAchieve diversificationRealize three-dimensional finishingProgramme-controlled manipulatorEndless track vehiclesRemote controlButt joint

The invention provides a multifunctional household service robot which uses a crawler-type running system. The multifunctional household service robot comprises a maintenance system and a clear-up system; the maintenance system comprises a maintenance table and a butt-joint lamp group; the maintenance table mainly consists of a maintenance table lifting mechanism, a maintenance table push arm transmission mechanism, a maintenance table push arm cleaning mechanism, a charging joint, a positioning detection light sensation triode, a shooting indication lamp and the like; main mechanisms of the clear-up system are distributed in a chassis rack, and comprise a push arm, an ejector door and a lifting table from top to down in sequence; the push arm consists of two moving pairs; the ejecting door comprises an ejecting door right face and an ejecting door left face, which are connected through a connecting rod of a crank sliding block, and are driven by transmission mechanisms which are symmetrically arranged at the top of the chassis rack; and the lifting table consists of a platform and four screw rod nut mechanisms for supporting the platform. According to the multifunctional household service robot provided by the invention, the basic moving technology of the household service robot, such as simple indoor positioning and path planning can be realized, so that the multifunctional household service robot has actual use values when mission is carried out indoors; the full-automatic services can be basically realized; and the inconvenience brought by remote control can be avoided.

Owner:XI AN JIAOTONG UNIV

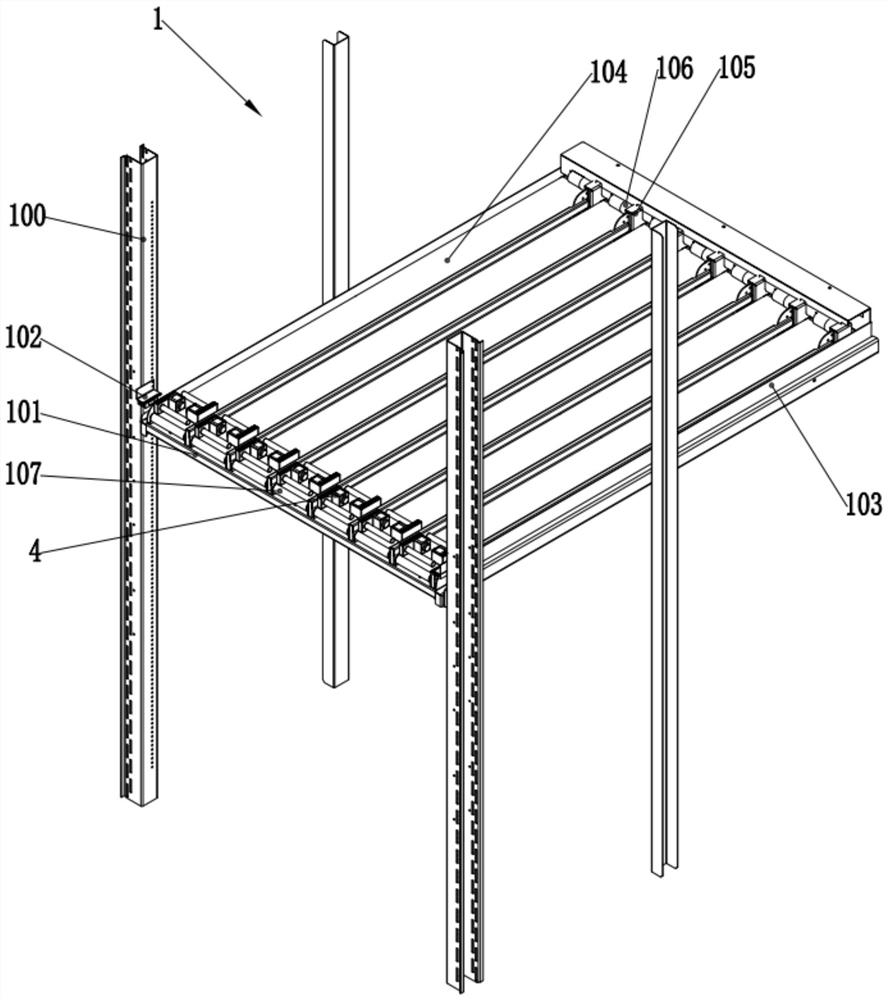

Full-automatic material arraying mechanism

The invention relates to the field of pesticide packaging machinery, in particular to a full-automatic material arraying mechanism. The full-automatic material arraying mechanism comprises a frame, a conveying belt and a stop plate, wherein the conveying belt is mounted on the frame, and the stop plate is arranged at the end of the conveying belt. A clamping device arranged above the conveying belt is mounted on the frame, a photoelectric device for detecting materials is arranged at the rear of the clamping device, a push device is mounted on one side of the conveying belt and arranged on the right side of the clamping device, a material platform corresponding to the push device is mounted on the other side of the conveying belt, and a push buffer device is arranged on the material platform. The full-automatic material arraying mechanism can effectively clamp bottles containing the materials to prevent toppling and skewing of the bottles by the aid of the clamping device, can more conveniently and quickly push the materials by the aid of the push device so as to be high in push speed and accurate in push and can effectively prevent toppling and skewing of the bottles by the aid of the push buffer device during the material push process. Besides, the full-automatic material arraying mechanism is convenient to mount and simple in use.

Owner:JIANGSU JINWANG PACKING SCI TECH CO LTD

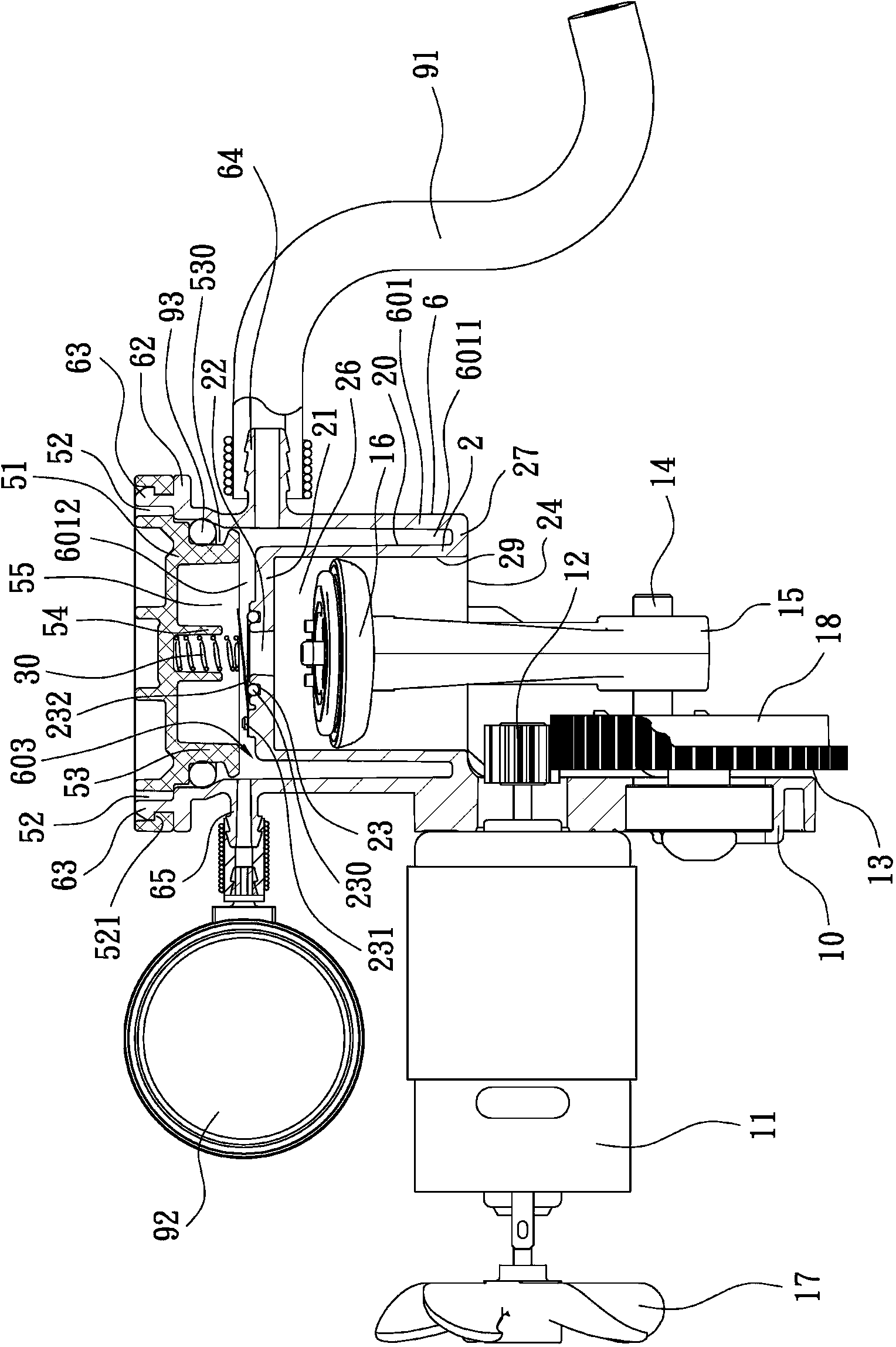

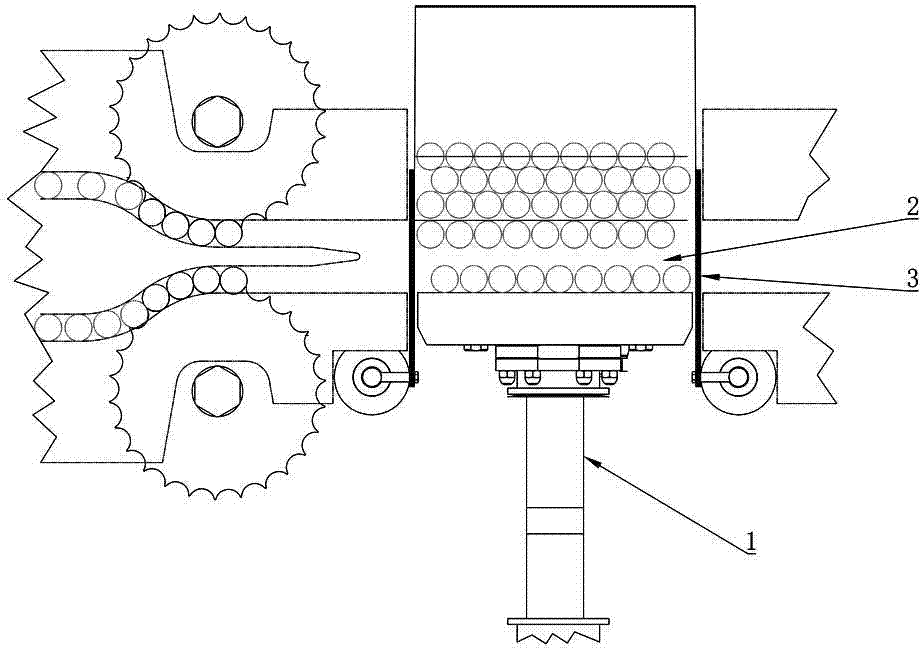

Air compressor

ActiveCN102465860APush speed is fastImprove compression performancePositive displacement pump componentsPositive-displacement liquid enginesAir compressionReciprocating motion

The invention discloses an air compressor. The resistance of a piston body of the compressor reciprocating in a cylinder chamber can be reduced, so that the air compression effectiveness of the air compressor can be further improved. An air storage seat of which the diameter of an internal hollow part is at least equal to or greater than the diameter of an inner cavity of a cylinder is closely adjacent to the cylinder and is directly arranged extendedly from the cylinder, so the pressure of the piston body in reciprocating movement is reduced, the propelling movement is accelerated, and the air compression effectiveness is greatly improved. The upper end of the air storage seat is provided with a plurality of circularly arranged riveting columns in parallel, and a pair of top covers provided with circularly arranged circular riveting holes is firmly fixed on the air storage seat mechanically by a stamping machine.

Owner:周文三

Air compressor

ActiveCN102865208AImprove performanceReduce resistancePositive displacement pump componentsPiston pumpsAir compressionReciprocating motion

The invention discloses an air compressor, especially to an air compressor which can reduce resistance of reciprocating motion of a compressor in a cylinder chamber so as to increase air compressing efficiency. The air compressor is in connection with a cover body with a section diameter greater than that of a cylinder at the periphery of a drum cylinder chamber. The top height of the cover body is greater than the top wall of the cylinder. An expanded chamber is formed between the cylinder chamber outer circumferential wall and the cover body so as to reduce resistance of reciprocating motion of a compressor in the cylinder chamber and increase pushing speed so as to greatly increase air compression efficiency.

Owner:周文三

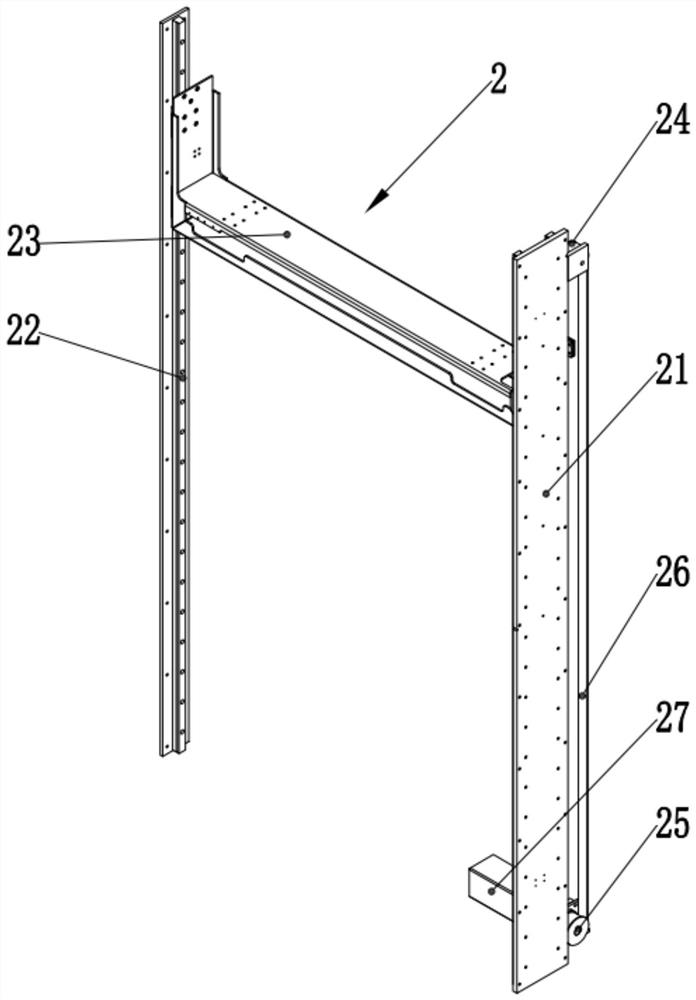

Automatic-locating continuous pushing device for large box beams

InactiveCN104164837ARealize automatic positioningReduce time spentBridge erection/assemblyContinuous/uninterruptedEngineering

The invention discloses an automatic-locating continuous pushing device for large box beams. According to the technical scheme, a plurality of sets of wedge-shaped counter force bases are symmetrically and fixedly installed on the inner side and the outer side of a double-track sliding way respectively in the pushing direction at equal intervals and with the same section, locating clamping grooves are symmetrically and fixedly formed in the lower portions of a pushing support base and meshed with the wedge-shaped counter force bases respectively, jacks are installed inside the pushing support base in a sleeved mode, the front ends of ejection rods of the jacks are fixedly connected with the rear ends of buffering ejection rods through flange plates respectively, and the front ends of the buffering ejection rods are fixedly connected with the box beams respectively. The device overcomes the shortcomings of an existing device used for pushing construction, the positions of the counter force bases do not need to be replaced continuously or the ejection rods do not need to be added or reduced continuously, continuous pushing operation can be carried out, the pushing speed is increased greatly, automatic locating of a pushing system is achieved, the occupation time of hoisting equipment is shortened, the construction cost is saved, and the potential safety hazards on the site are reduced.

Owner:CHINA RAILWAY 21TH BUREAU GROUP

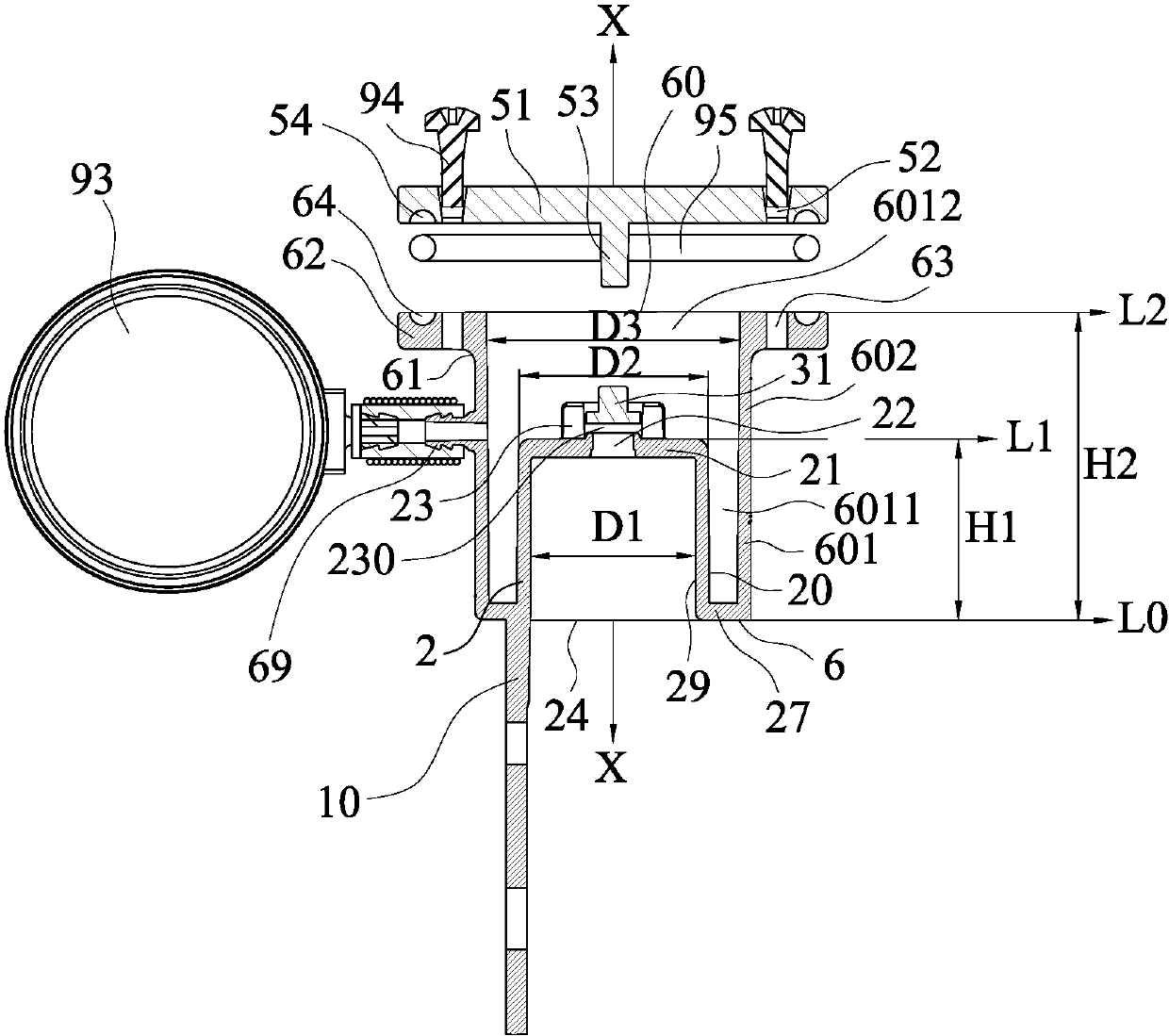

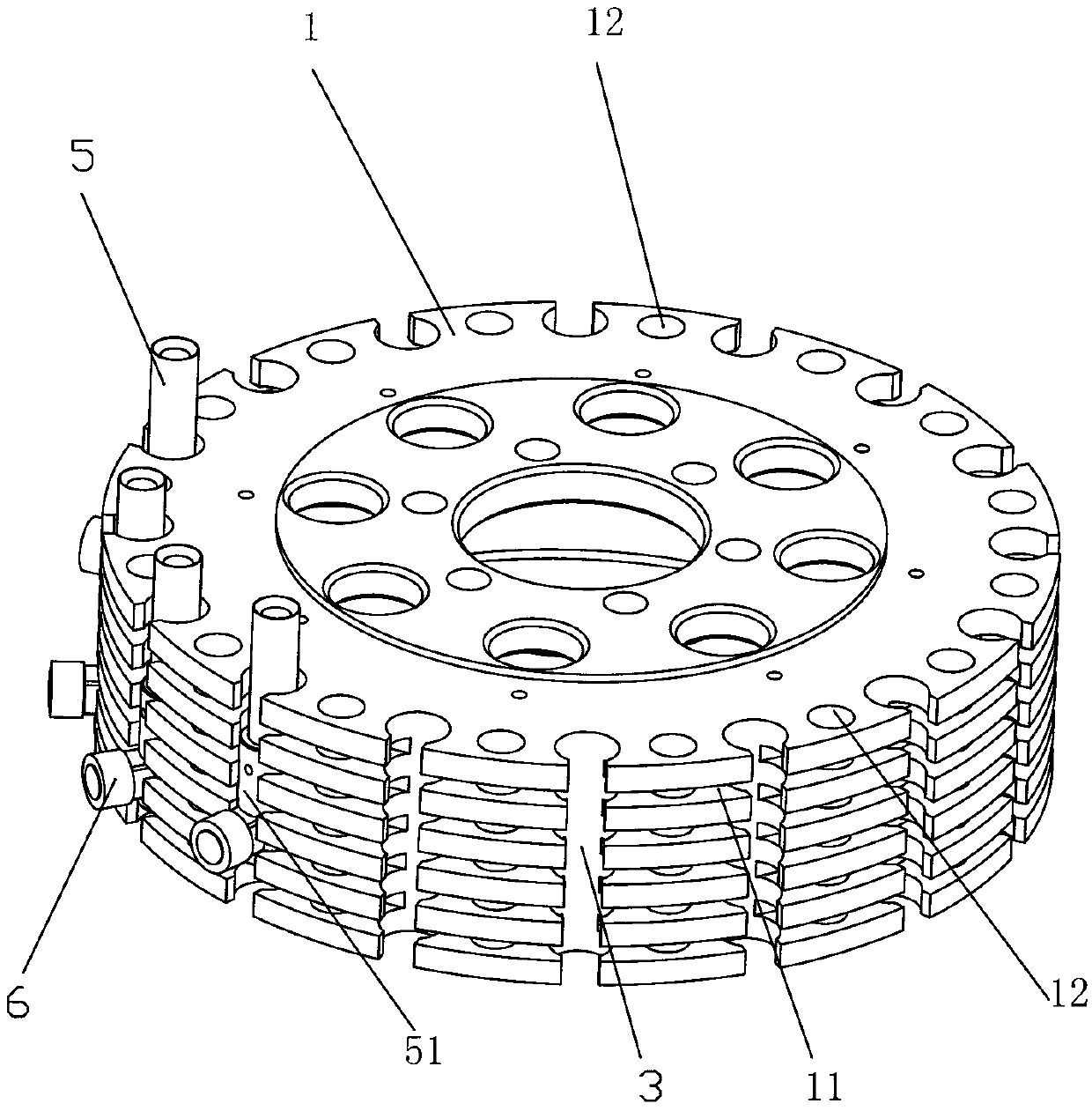

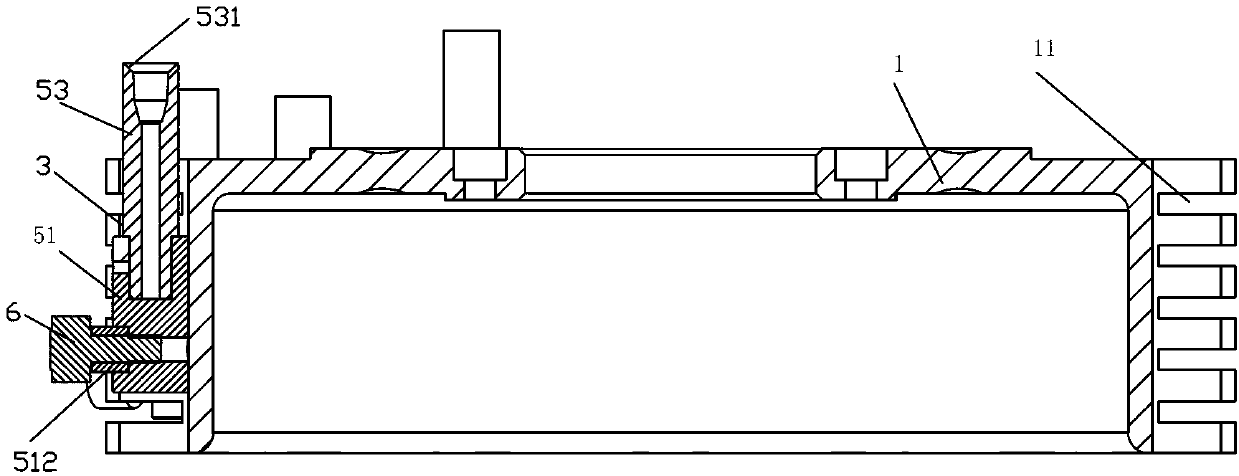

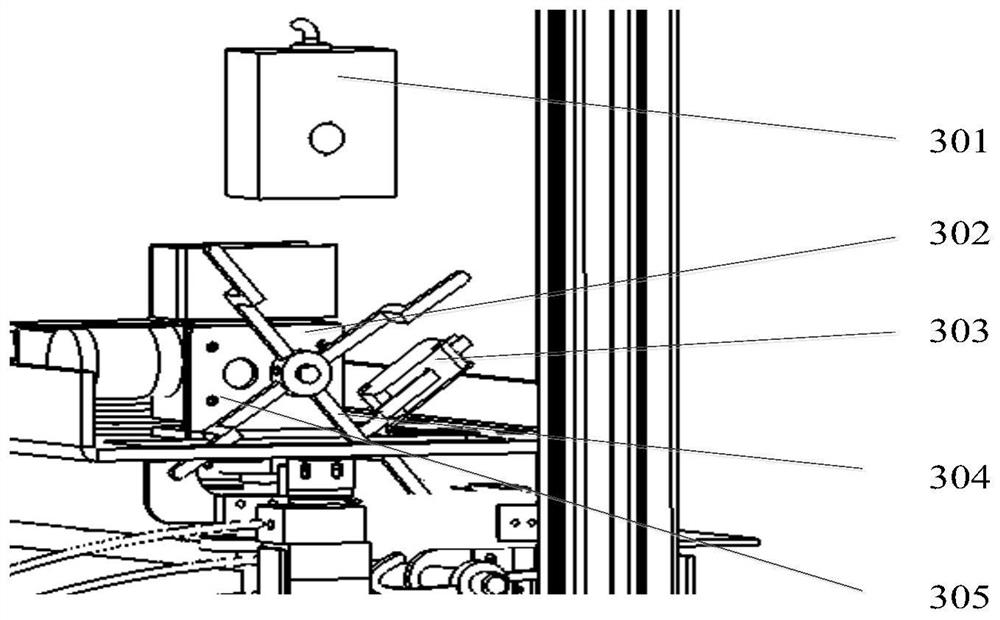

Turntable mechanism of aerosol valve assembling machine

InactiveCN102990324APushing speed is fastRealize mechanical automationMetal working apparatusEngineeringAutomation

The invention discloses a turntable mechanism of an aerosol valve assembling machine. The turntable mechanism comprises a turntable, wherein a roller rail is arranged on the outer side of the turntable; a lower roller rail comprises a lower section and a higher section; a plurality of ejection chutes are also formed in the turntable, and an ejector rod component capable of moving up and down in each ejection chute is arranged in each ejection chute; and a roller which is blocked in the roller rail is arranged on one side of the lower end of each ejector rod component. By the turntable mechanism, the mechanical automation of the ejection action is completely realized, the ejection speed is high, the efficiency is high, the mechanical automation of the assembly of components of an aerosol valve is realized, the assembling speed is high, the efficiency is high, and the cost is reduced.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

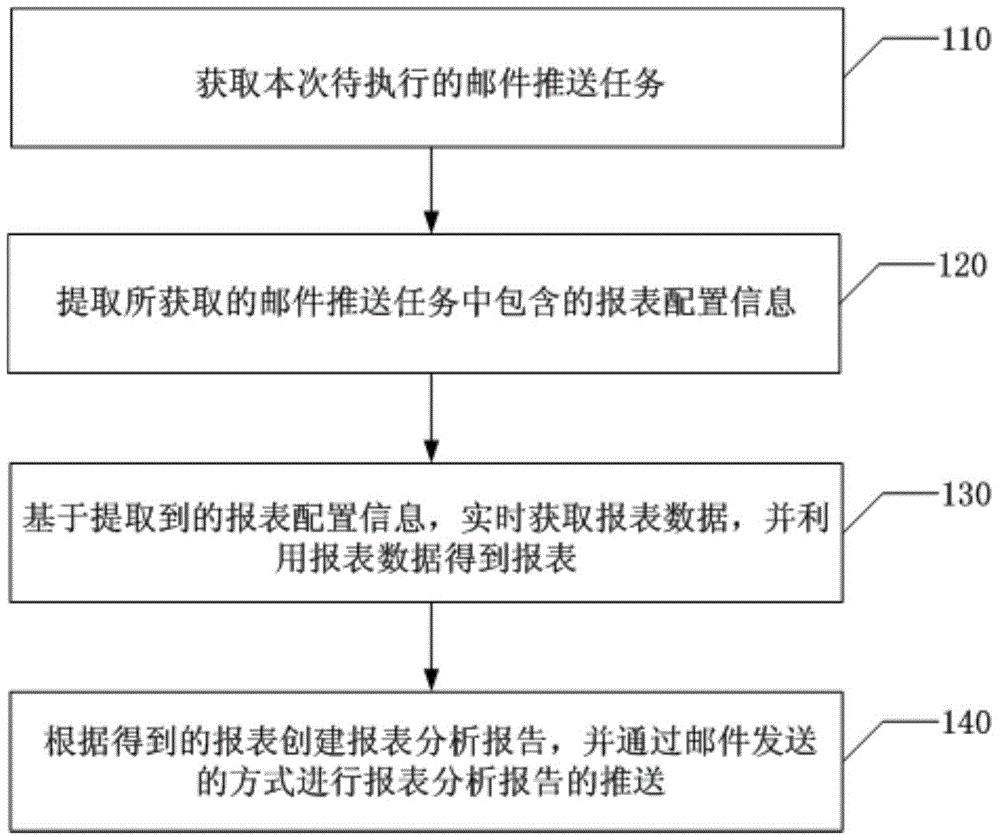

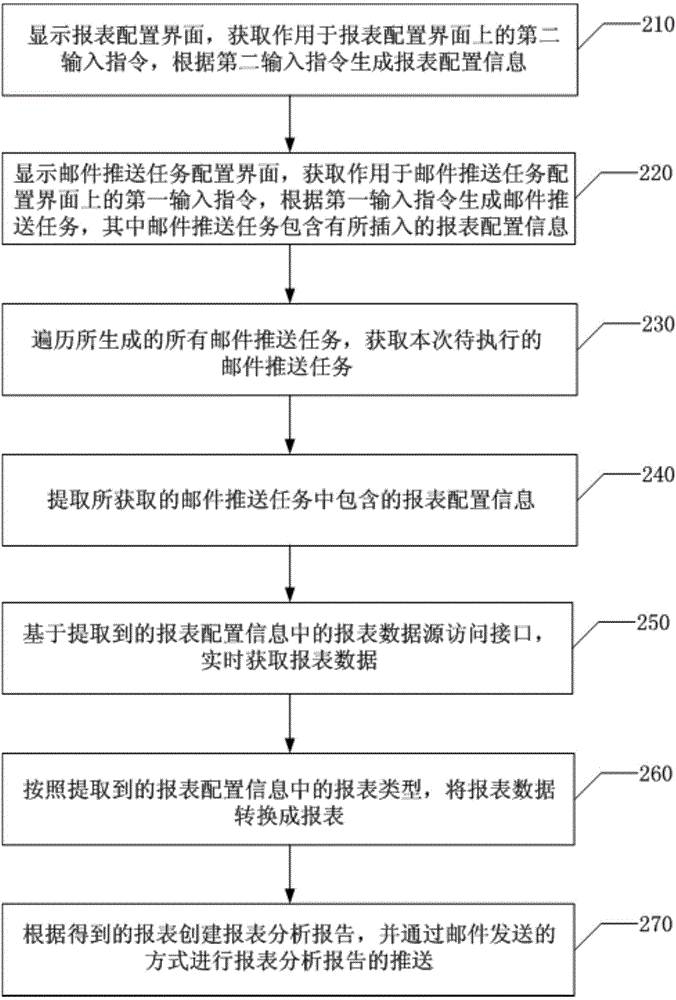

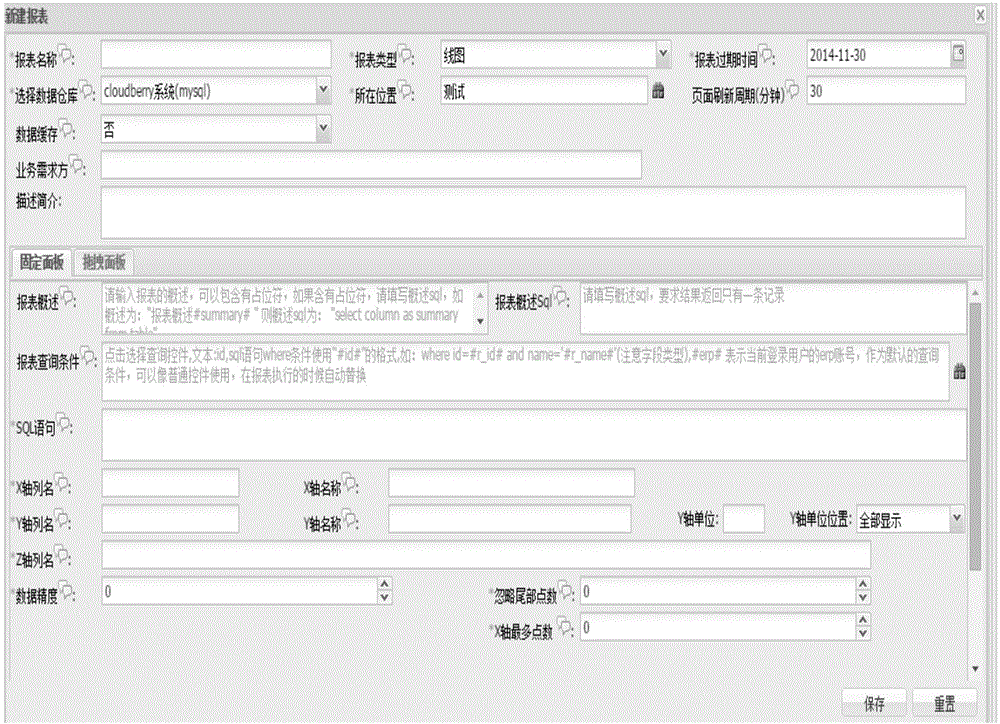

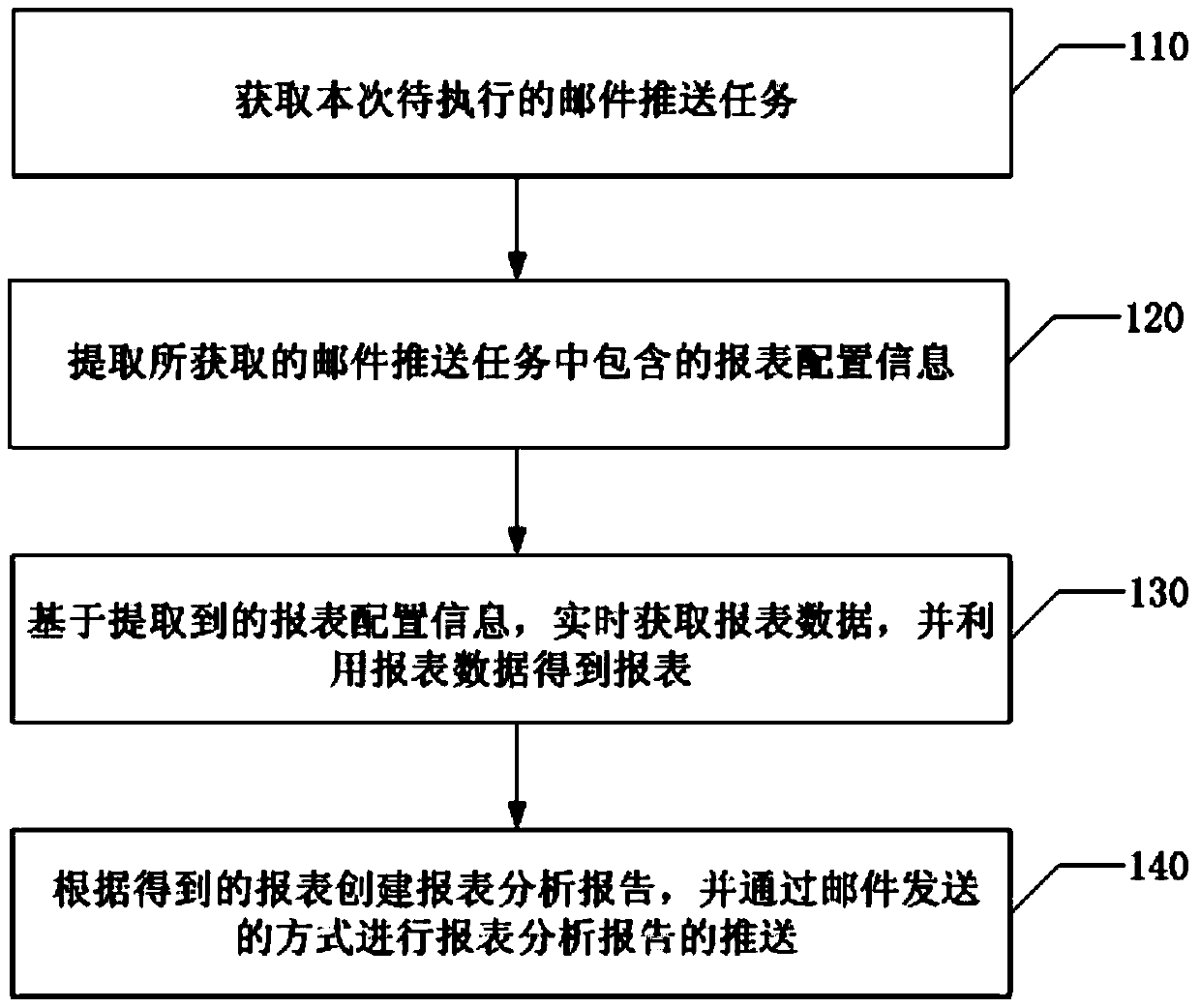

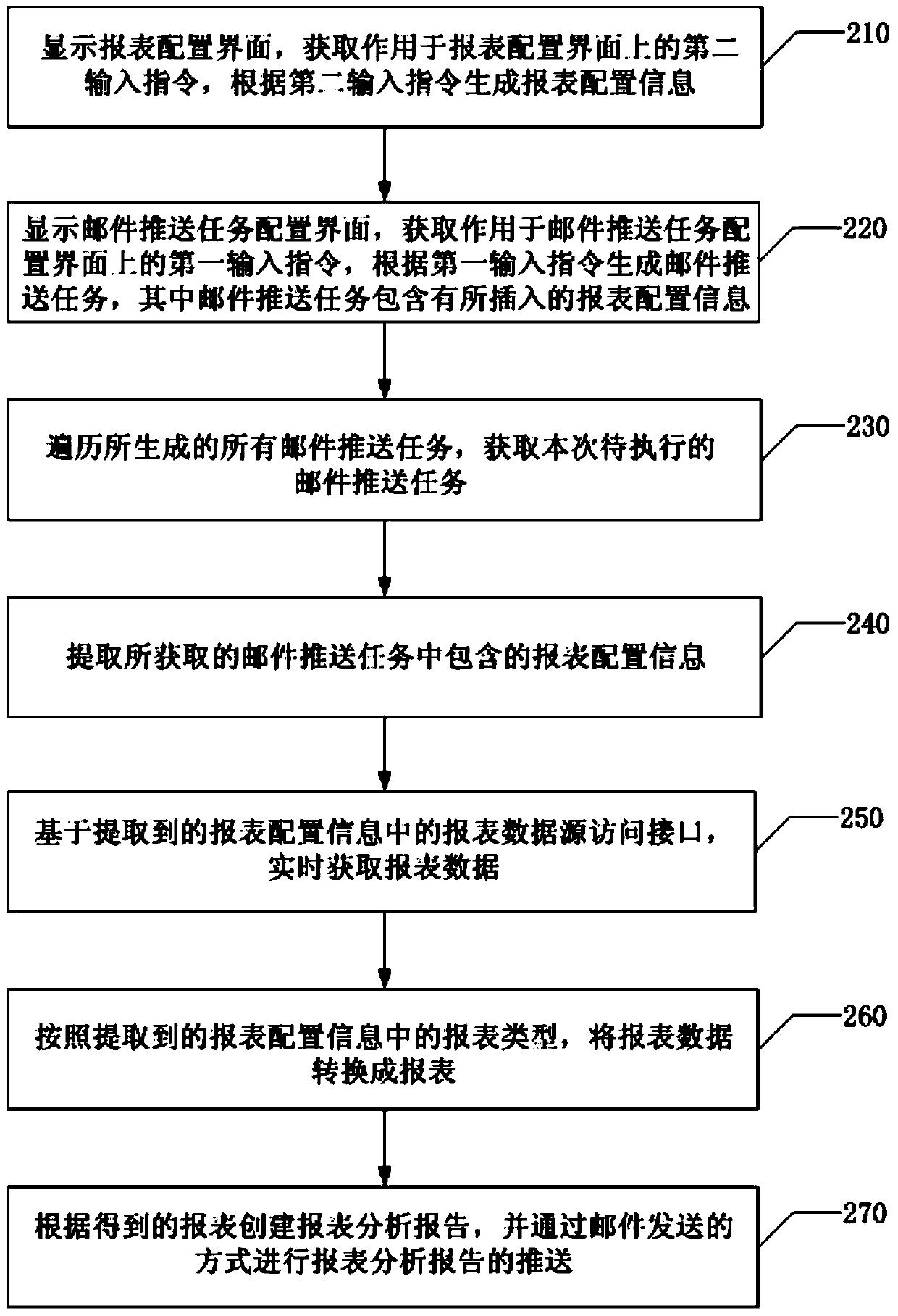

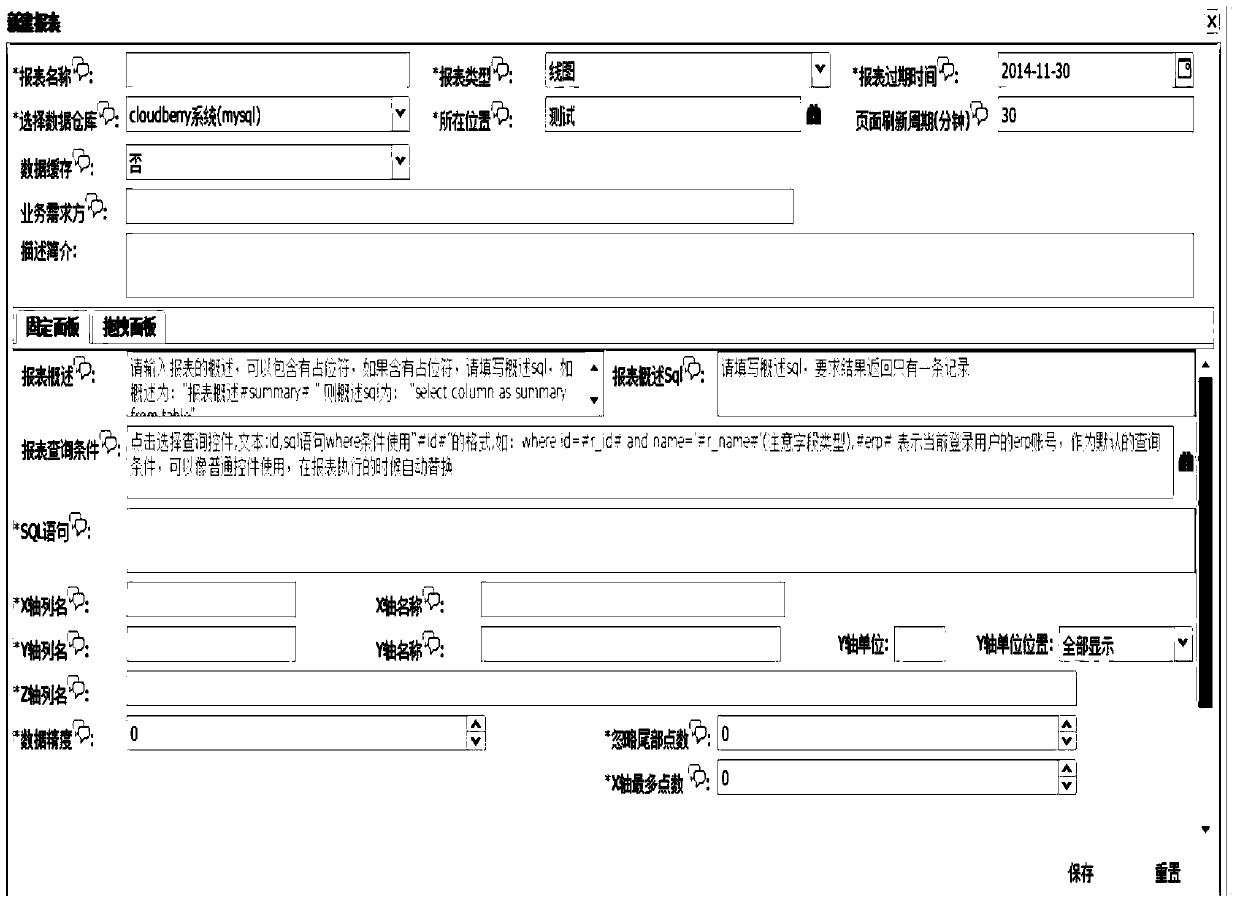

Statement analysis report pushing method and device

ActiveCN104616134ARealize intelligent pushIncrease flexibilityOffice automationReusabilityData mining

An embodiment of the invention discloses a statement analysis report pushing method and a statement analysis report pushing device. The method comprises the following steps: obtaining the e-mail pushing task to be executed at this time; extracting the report configuration information included in the extracted e-mail pushing task; obtaining the real time report data based on the extracted report configuration information and using the report data to obtain the report; and building the report analyzing report according to the report and pushing the report analyzing report according to the e-mail transmitting mode. According to the technical scheme, the report analyzing report can be intelligently pushed, the pushing speed is faster, the degree of accuracy is high and the flexibility and reusability of the report analyzing report can be improved.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

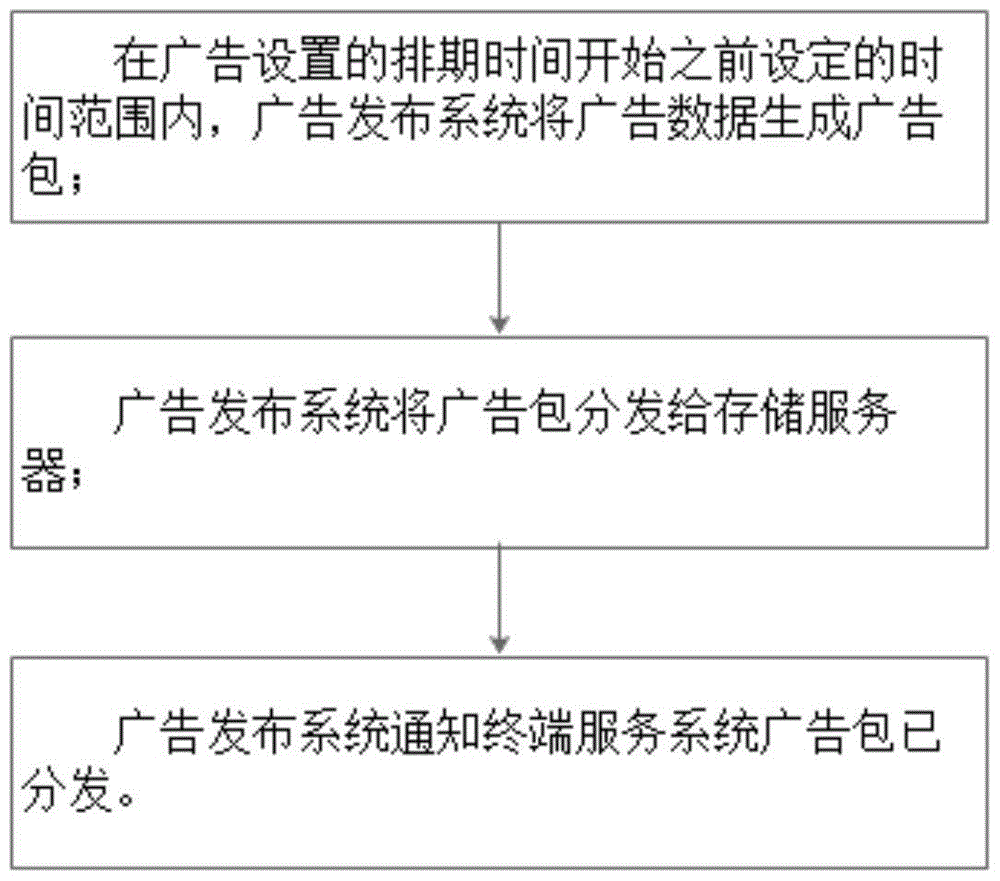

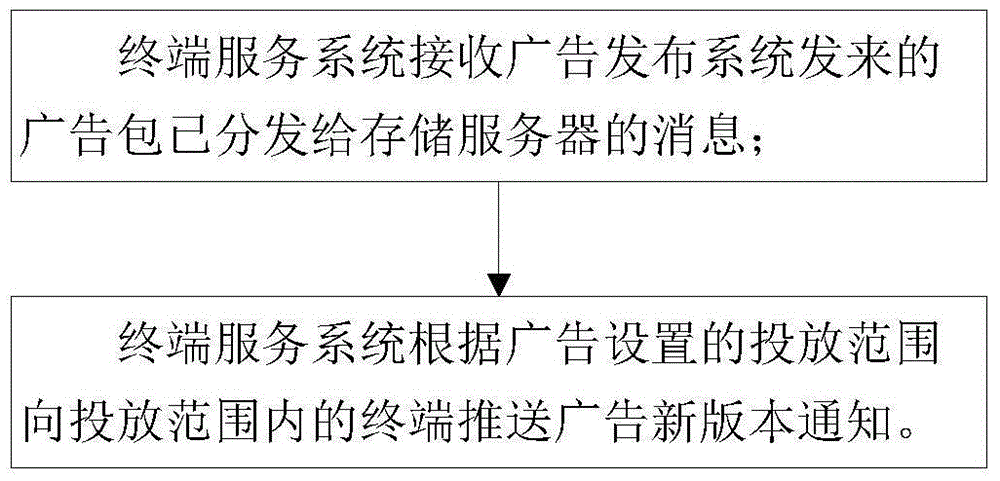

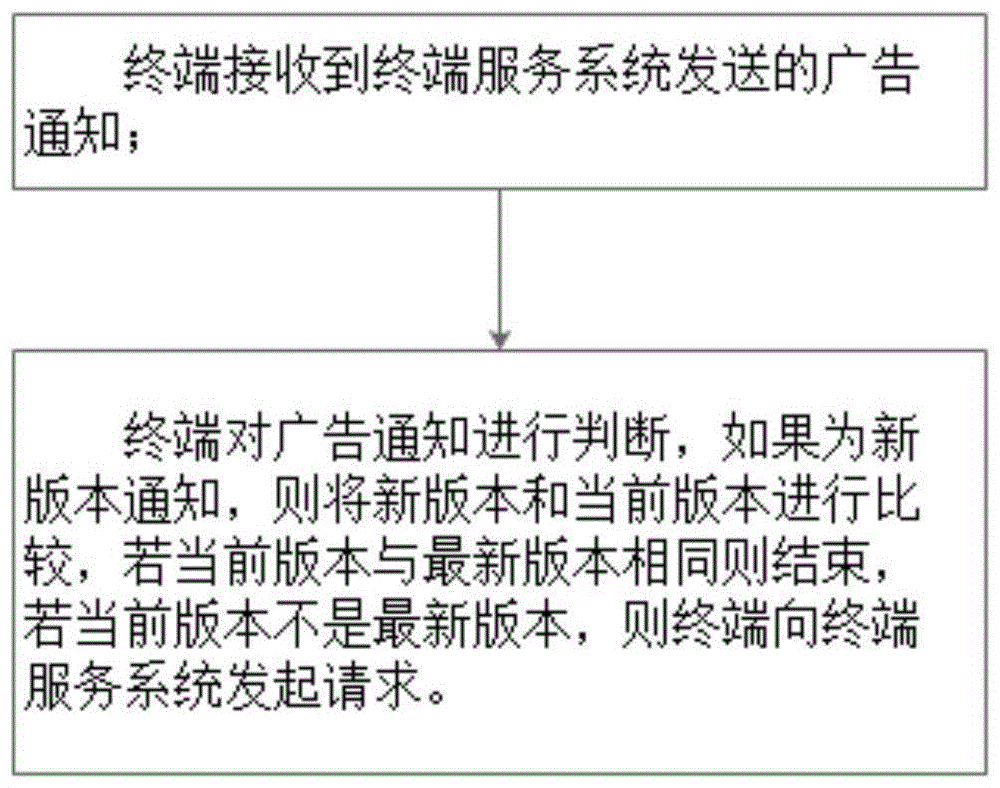

Advertisement release system, terminal service system, terminal and method for generating push release

InactiveCN105701679AAvoid repeated operationsReduce the burden onSpecial data processing applicationsMarketingTime rangeTransfer procedure

The invention discloses an advertisement release system, a terminal service system, a terminal and a method for generating a push release. A advertisement generating method includes the following steps: Step (11): in a set time range before scheduling time set for an advertisement begins, an advertisement release system generates an advertisement packet with advertisement data; Step (12): the advertisement release system distributes the advertisement packet to a storage server; and Step (13): the advertisement release system notifies a terminal service system that the advertisement packet is distributed. The advertisement generating method has the advantages of saving bandwidth of an advertisement transmission process, reducing pressure of the advertisement release system and the terminal service system, facilitating management, and being safe and reliable.

Owner:SHANDONG TAIXIN ELECTRONICS CO LTD

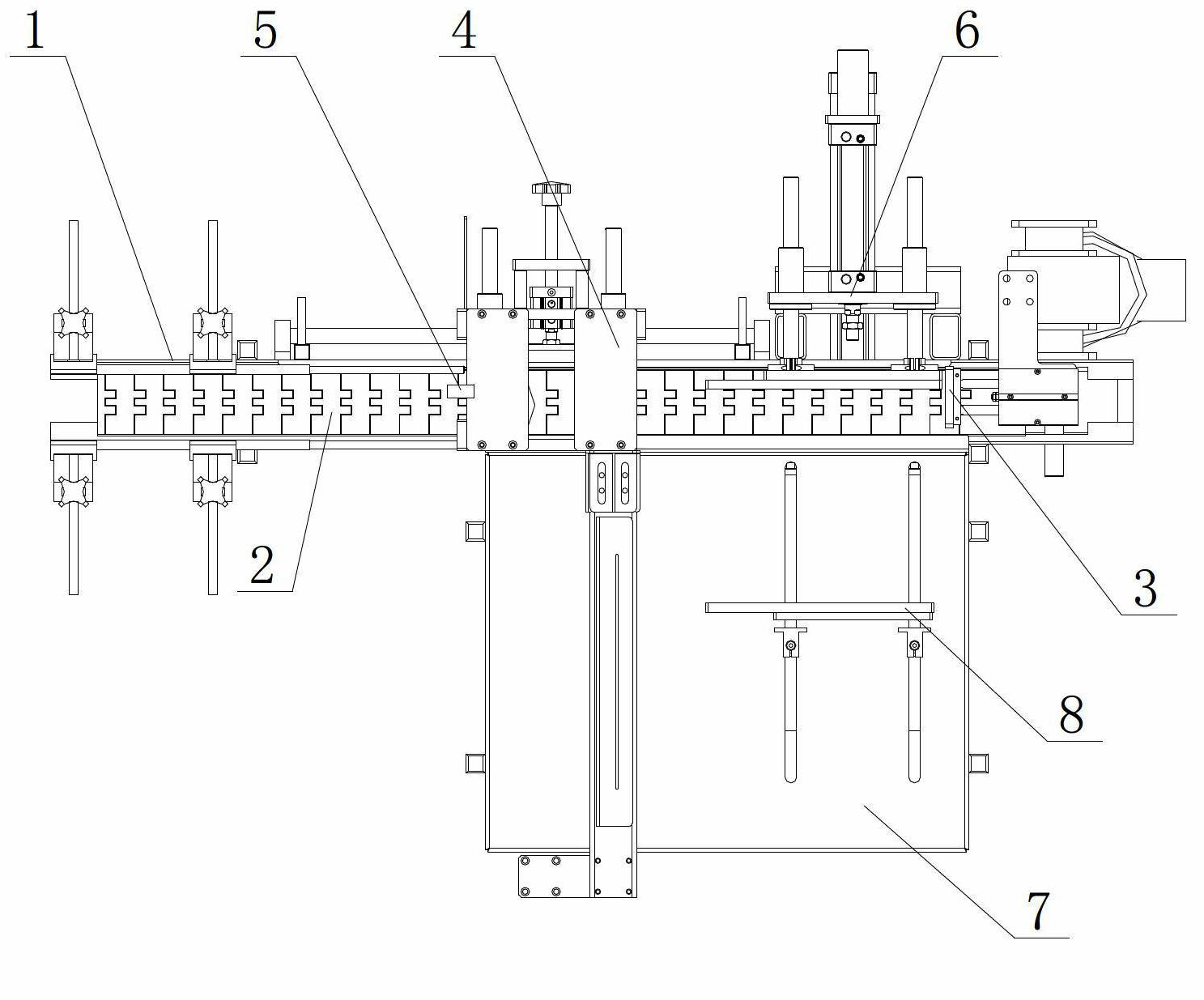

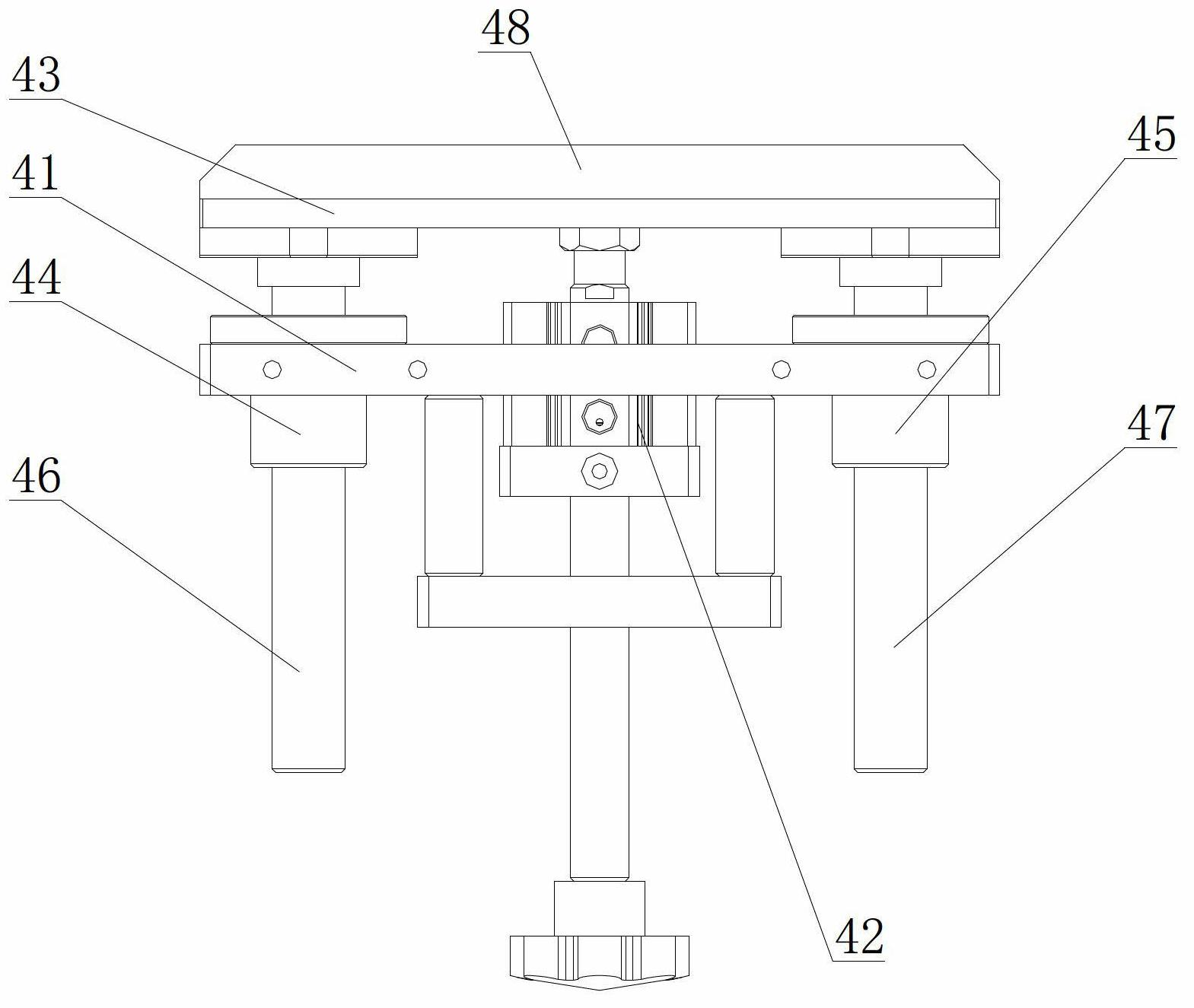

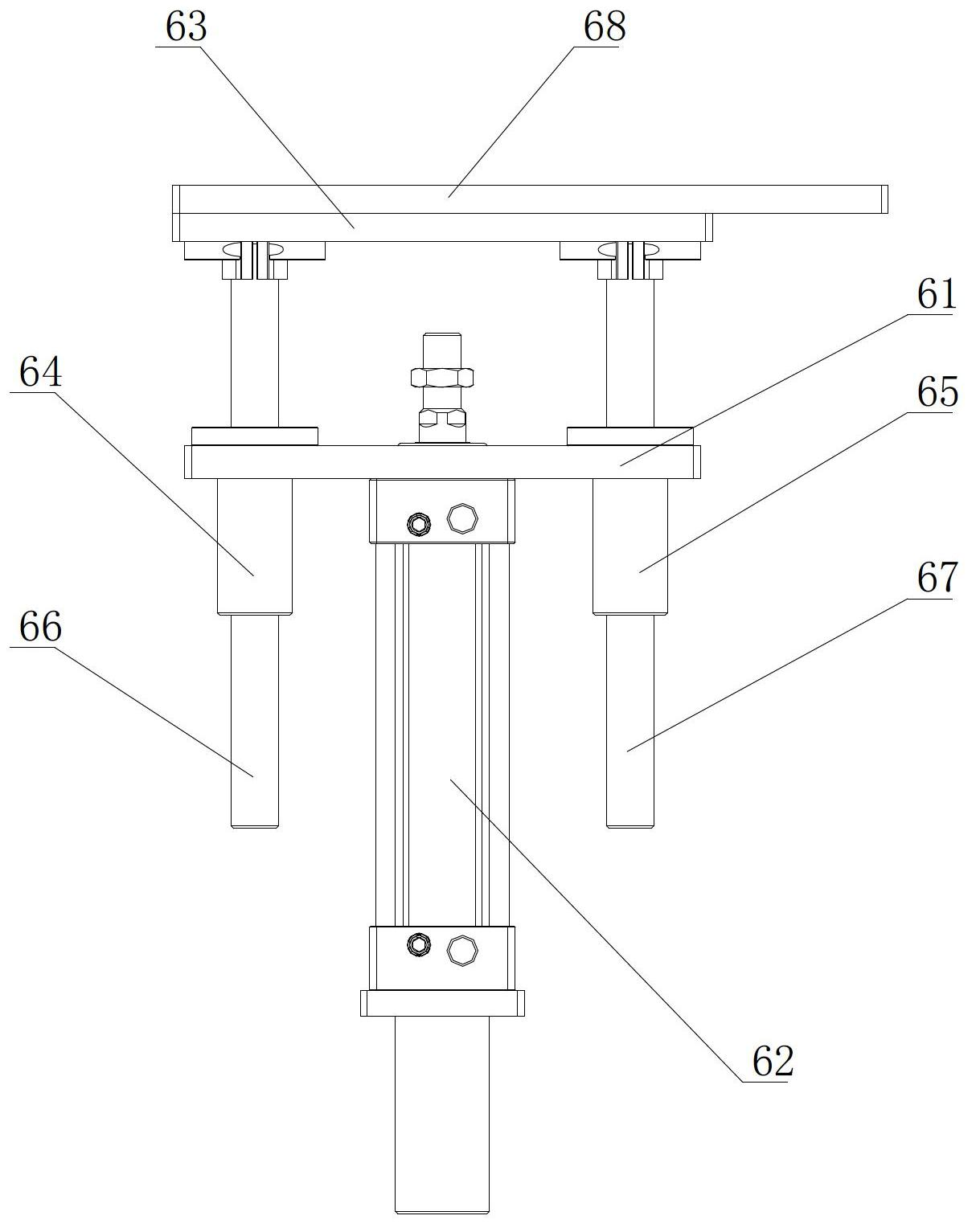

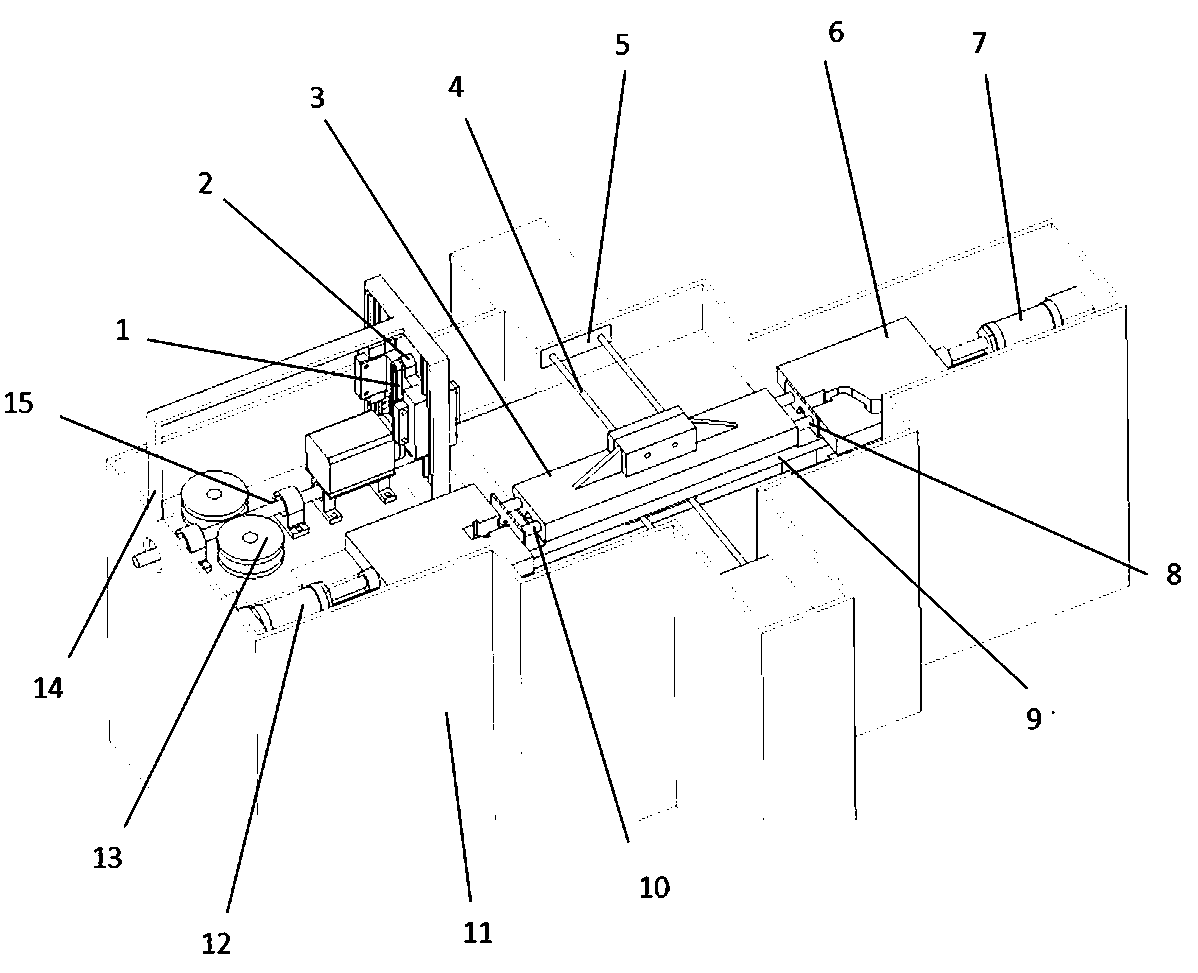

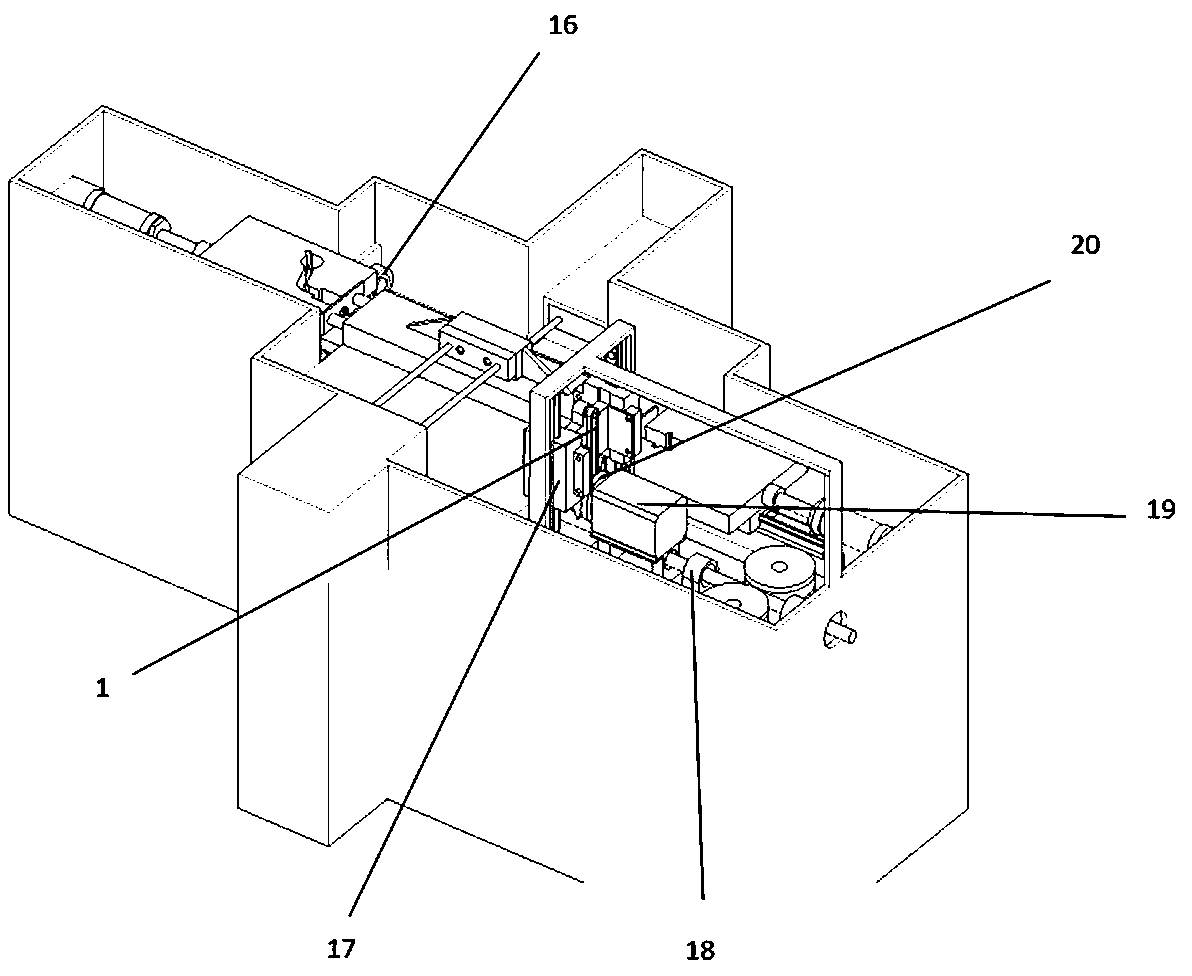

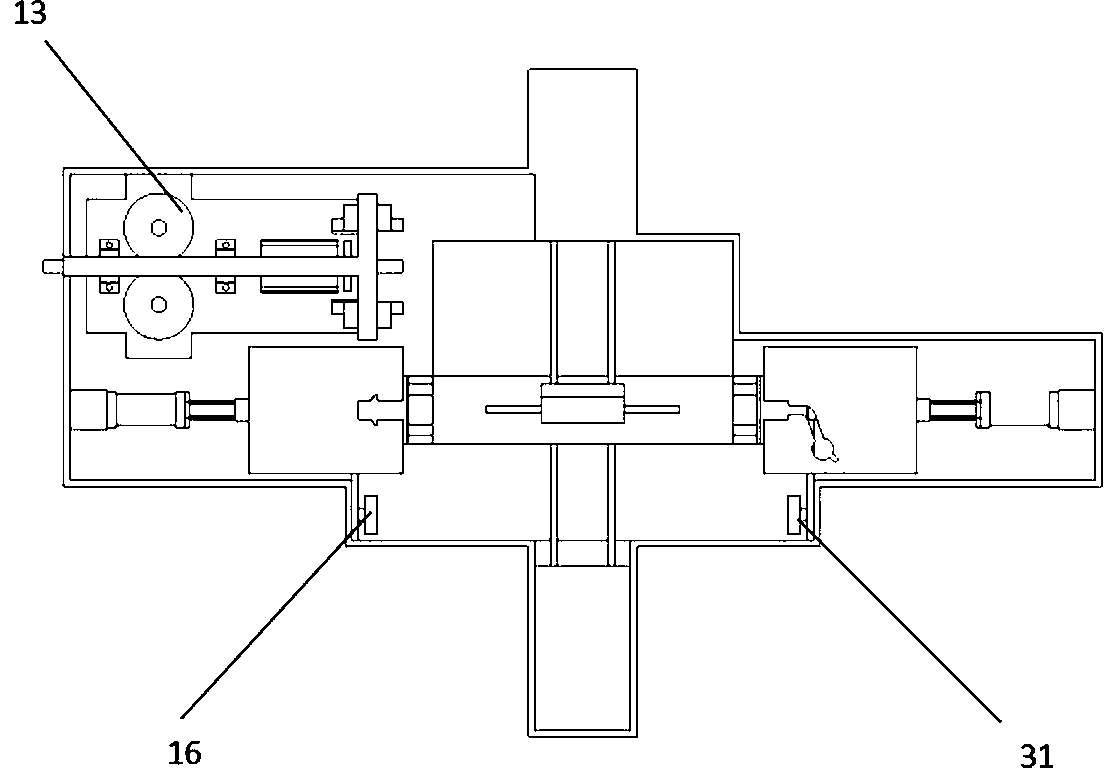

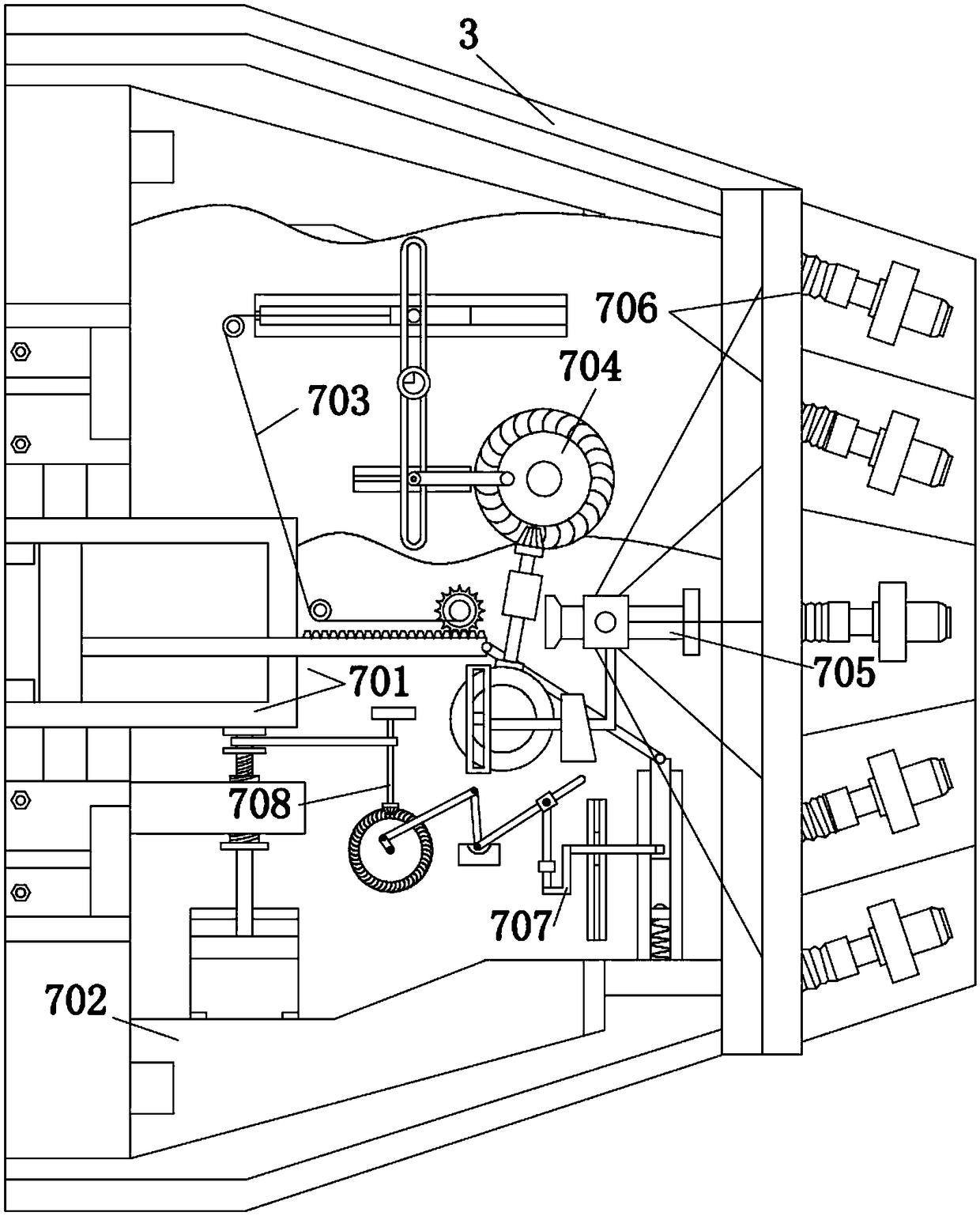

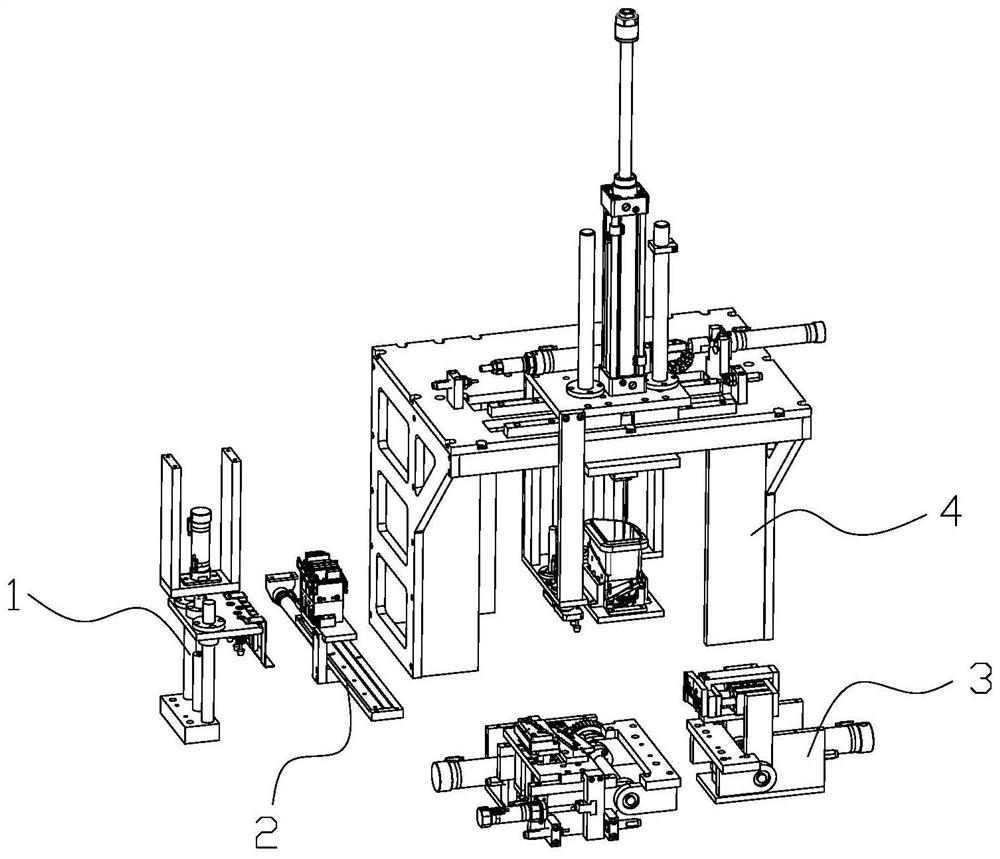

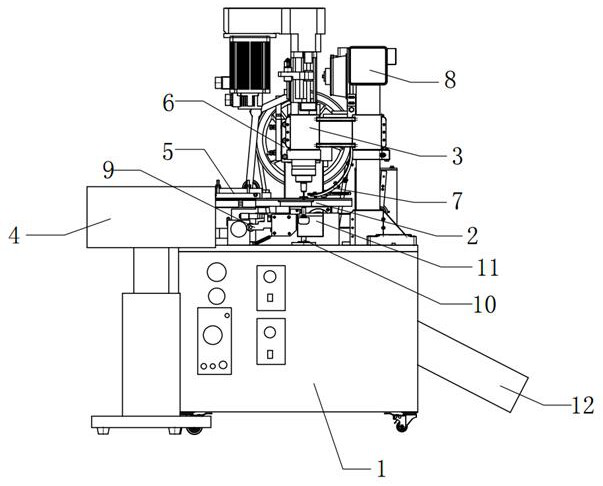

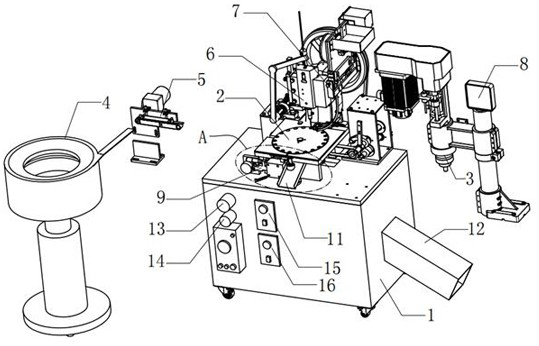

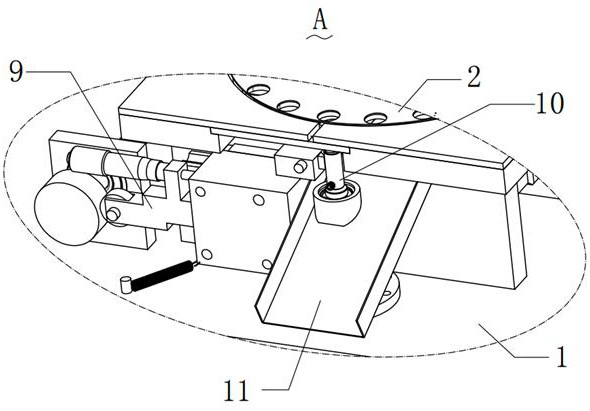

Brake hose assembly machining center

PendingCN110422157AAchieve reductionRealize fully automatic processing and productionMetal working apparatusPiping arrangementsEngineeringMachining

The invention provides a brake hose assembly machining center. The brake hose assembly machining center integrates conveying, cutting, positioning, assembling, sealing and collecting of a brake hose,and solves the problems of low machining efficiency and high machining cost of the brake hose assembly in the prior art. The brake hose assembly machining center comprises a rubber-shaped pipe conveying device, a rubber-shaped pipe cutting device, a rubber-shaped pipe positioning and automatic pushing device, a joint installing device and a double-side hydraulic sealing device, wherein the rubber-shaped pipe conveying device is used for conveying a rubber-shaped pipe forwards in the linear direction; the rubber-shaped pipe cutting device is positioned at the down stream of the rubber-shaped pipe conveying device and is used for cutting the rubber-shaped pipe conveyed by the rubber-shaped pipe conveying device; the rubber-shaped pipe positioning and automatic pushing device is positioned atthe down stream of the rubber-shaped pipe cutting device and is used for pushing the rubber-shaped pipe cut by the rubber-shaped pipe cutting device to an installation position; the joint installingdevice is positioned on the two sides of the rubber-shaped pipe positioning and automatic pushing device and is used for installing joints at the two ends of the rubber-shaped pipe; and the double-side hydraulic sealing device is positioned below the joint installing device and is used for sealing the installed joints.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

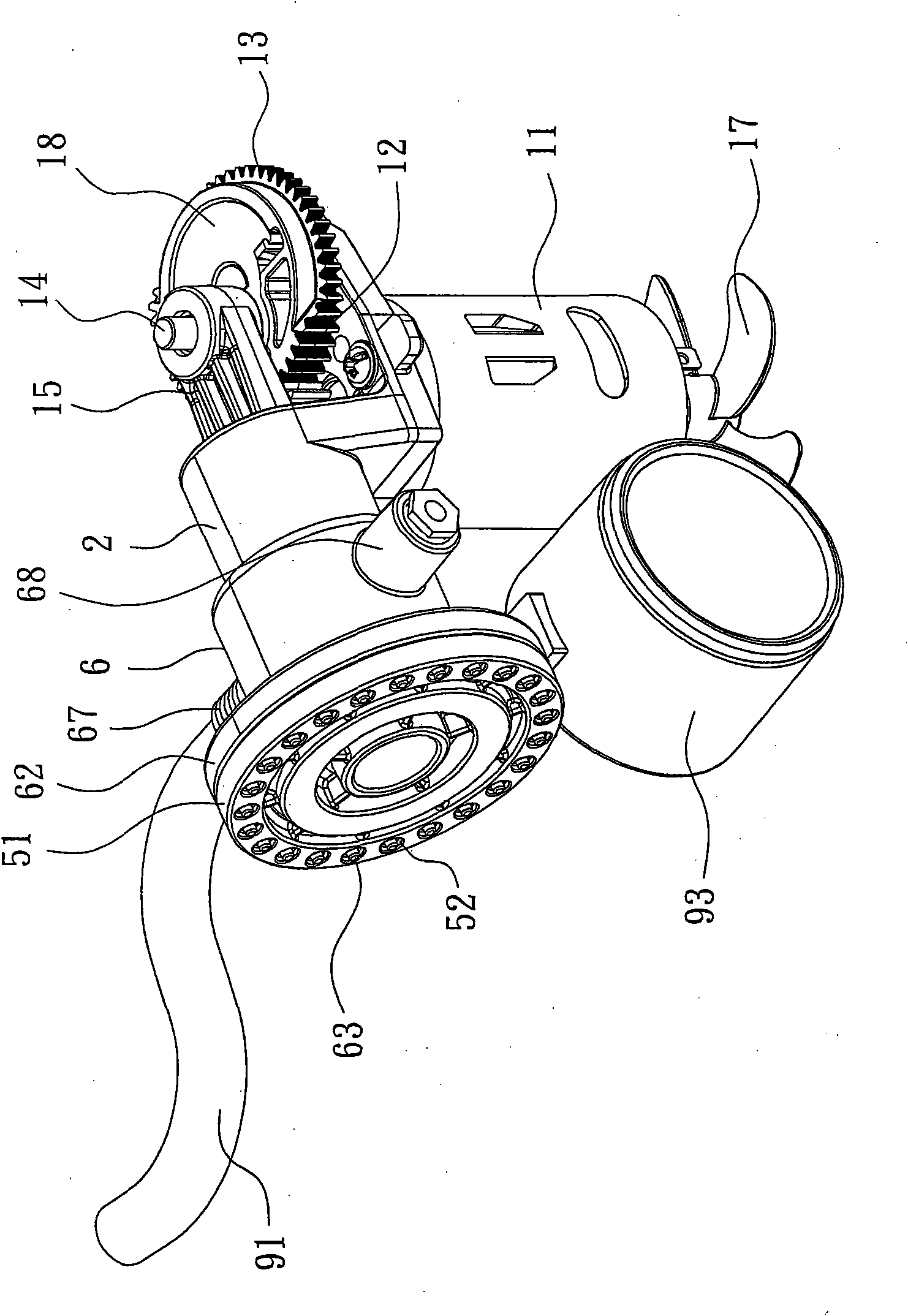

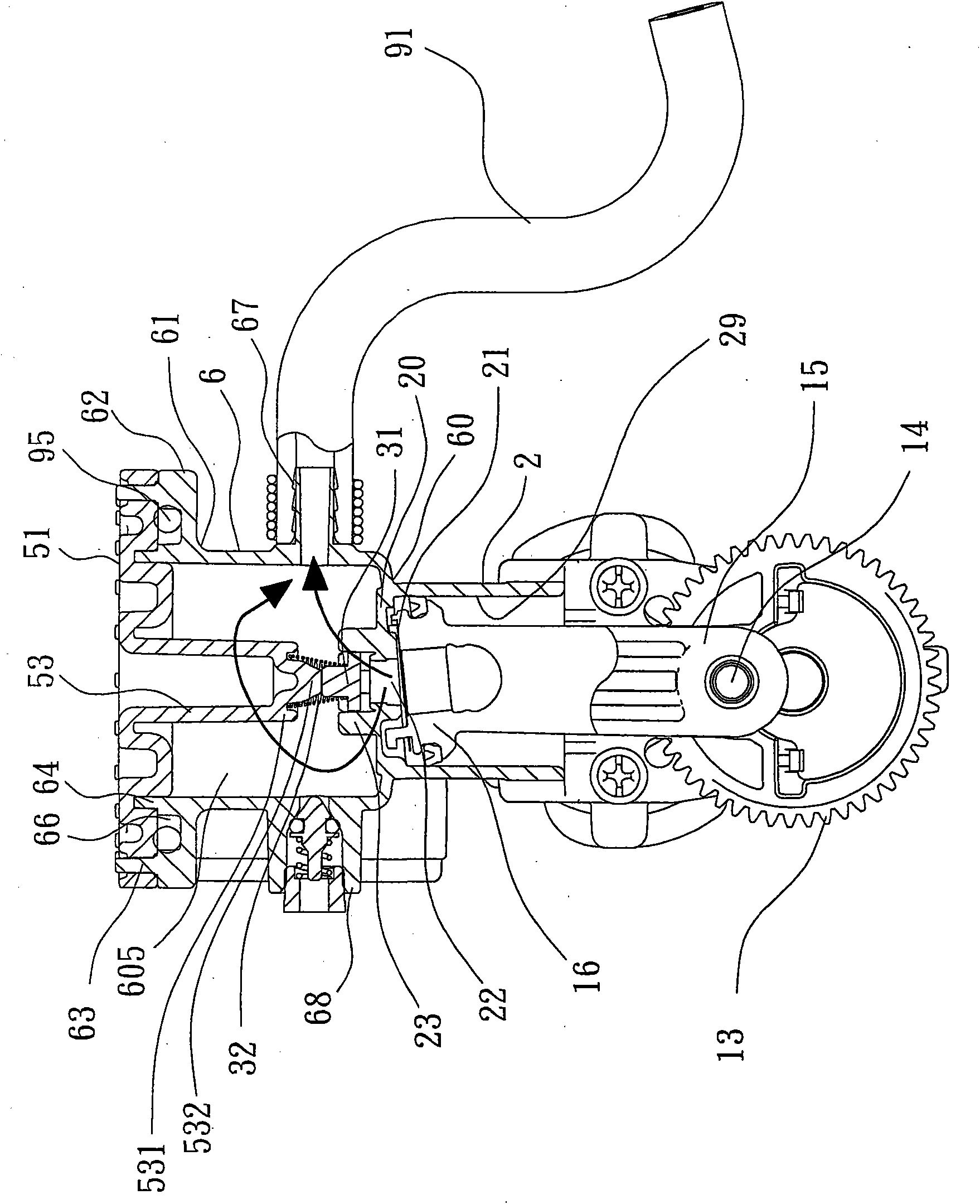

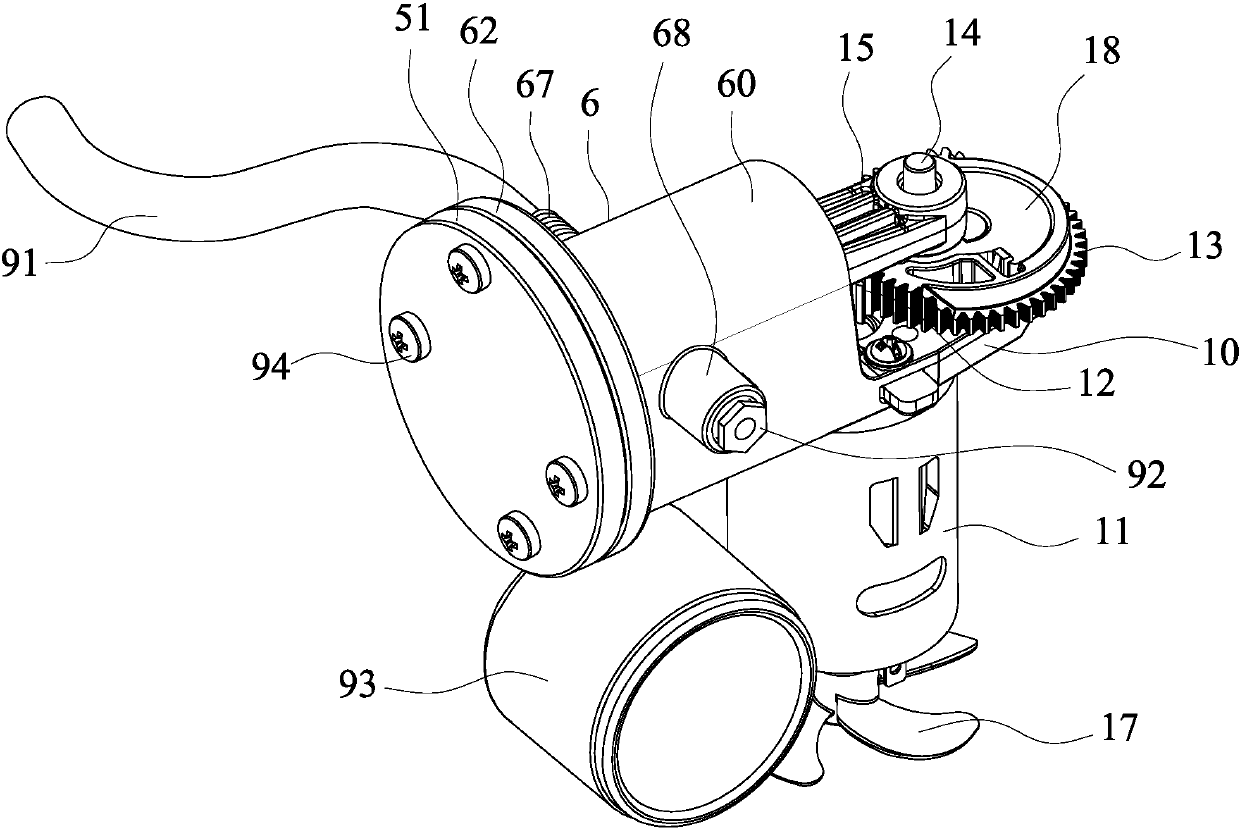

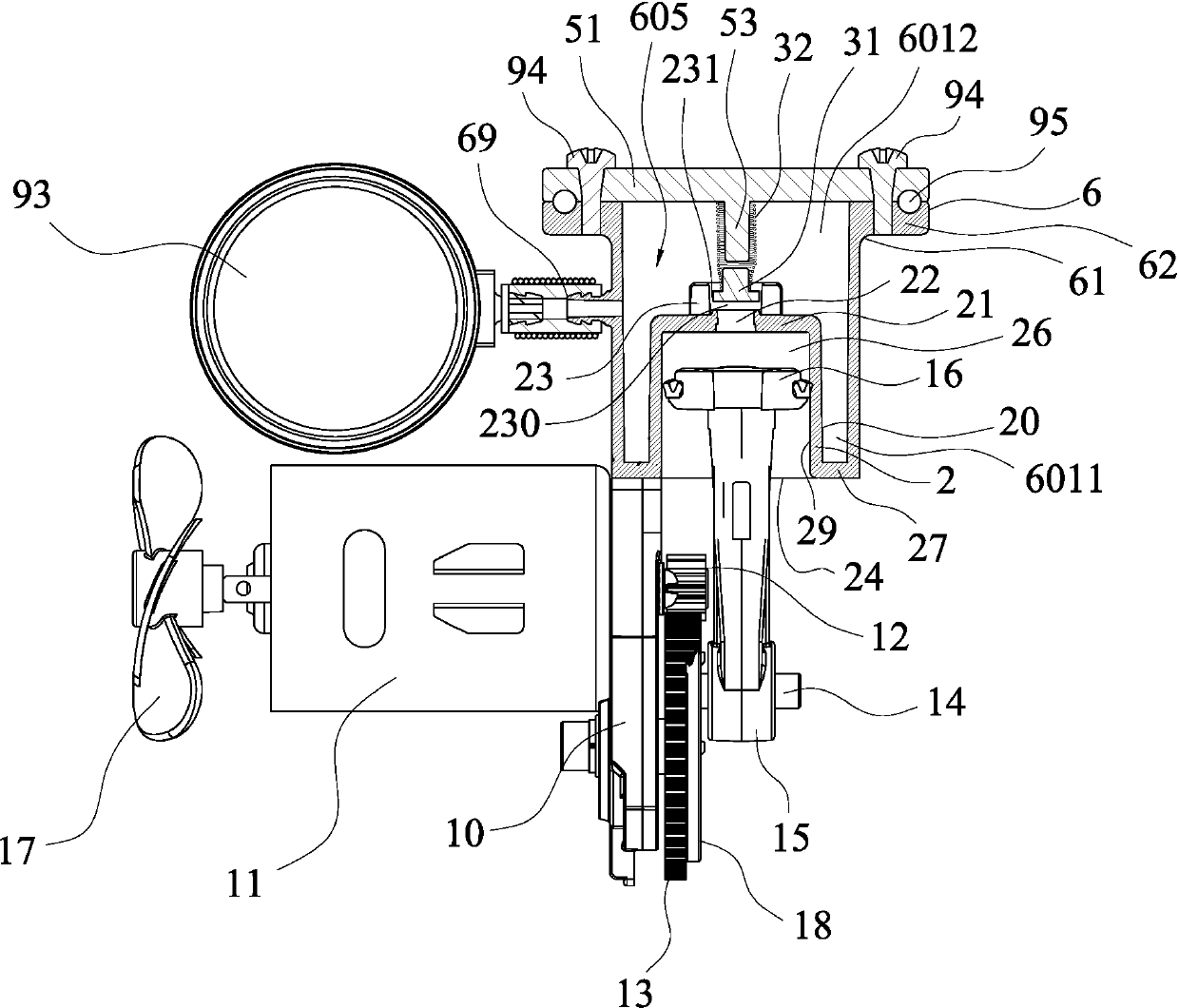

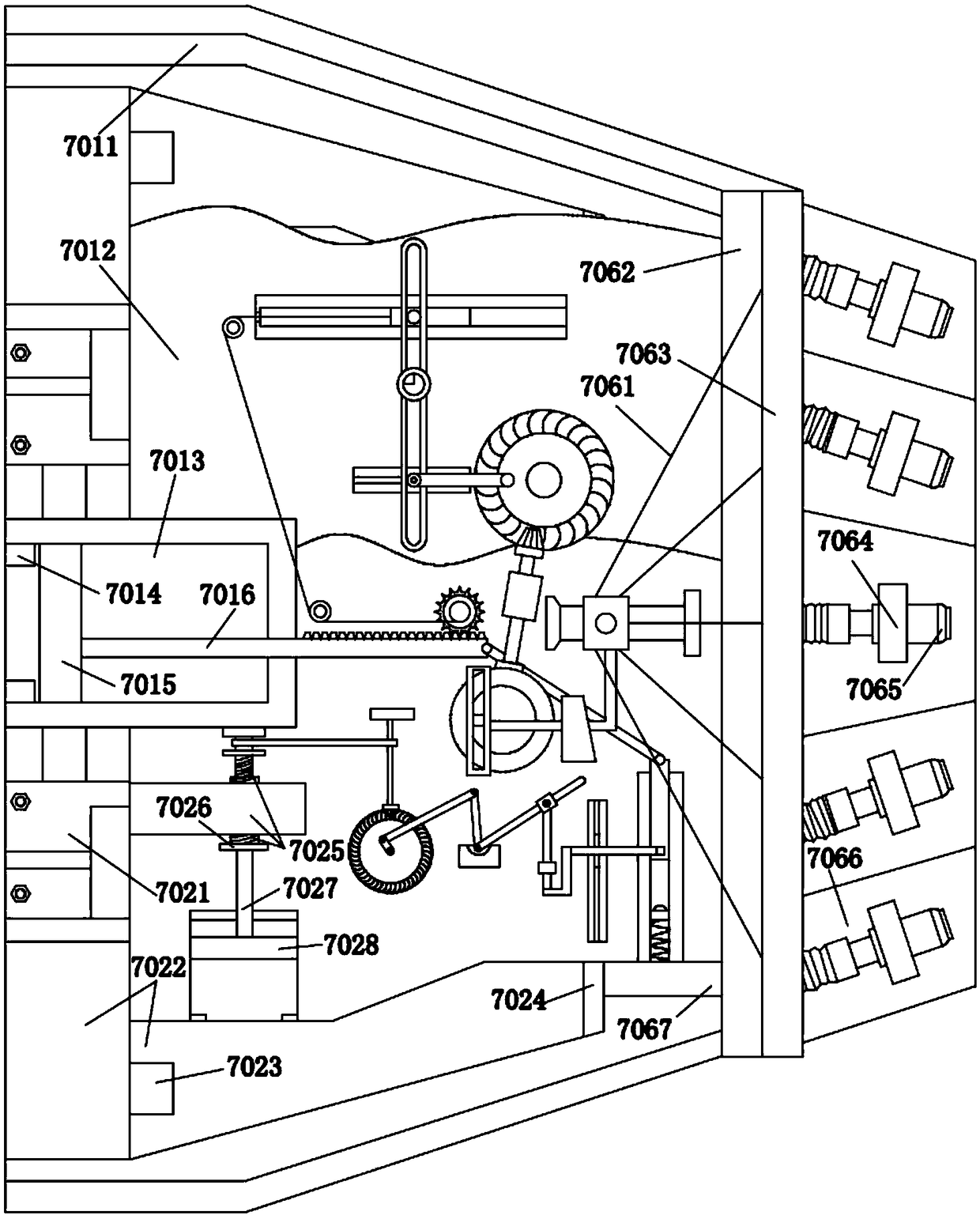

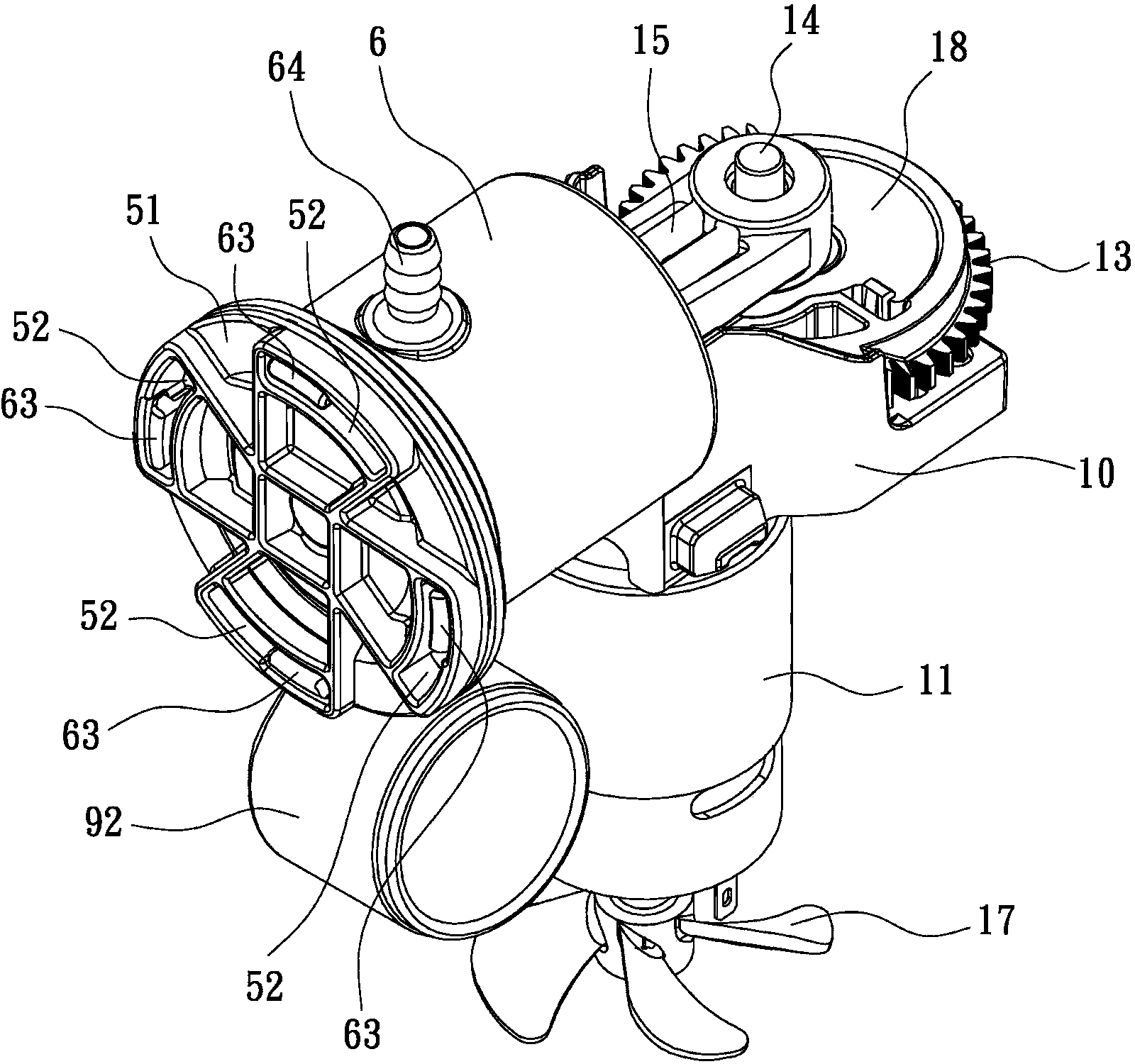

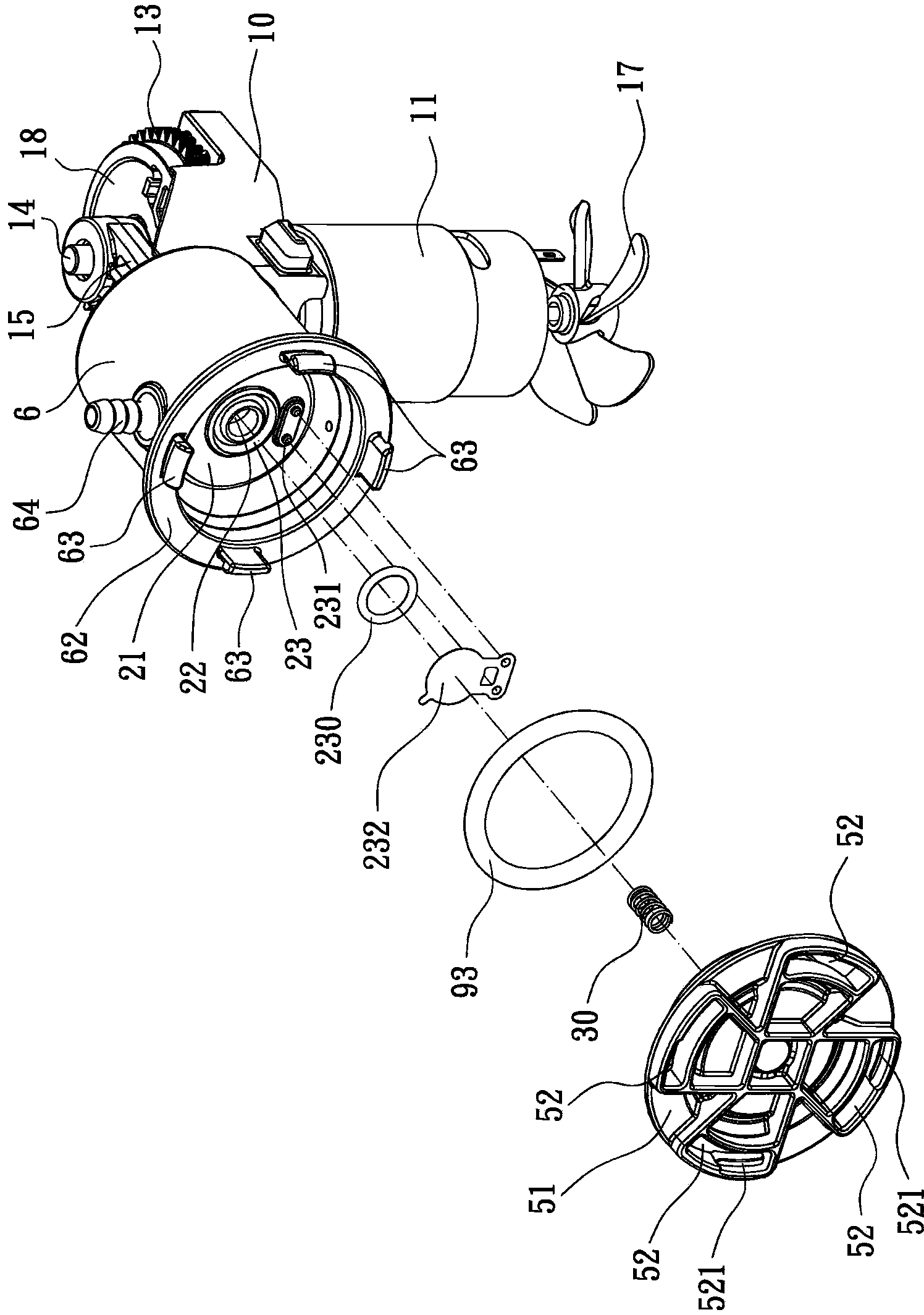

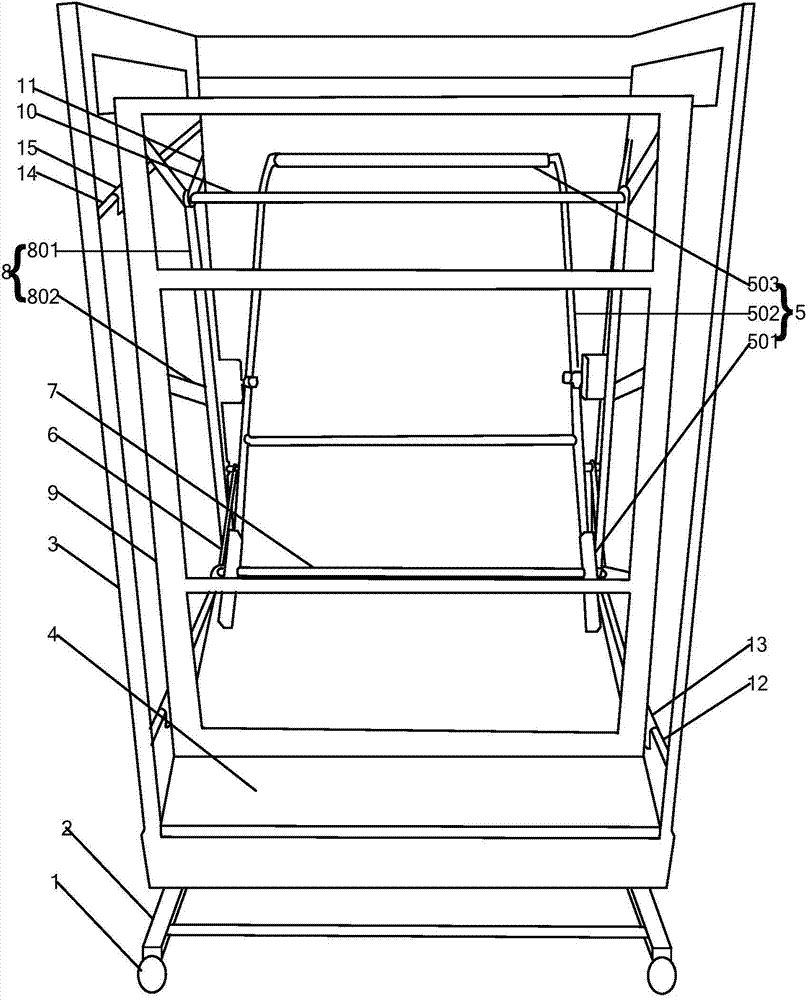

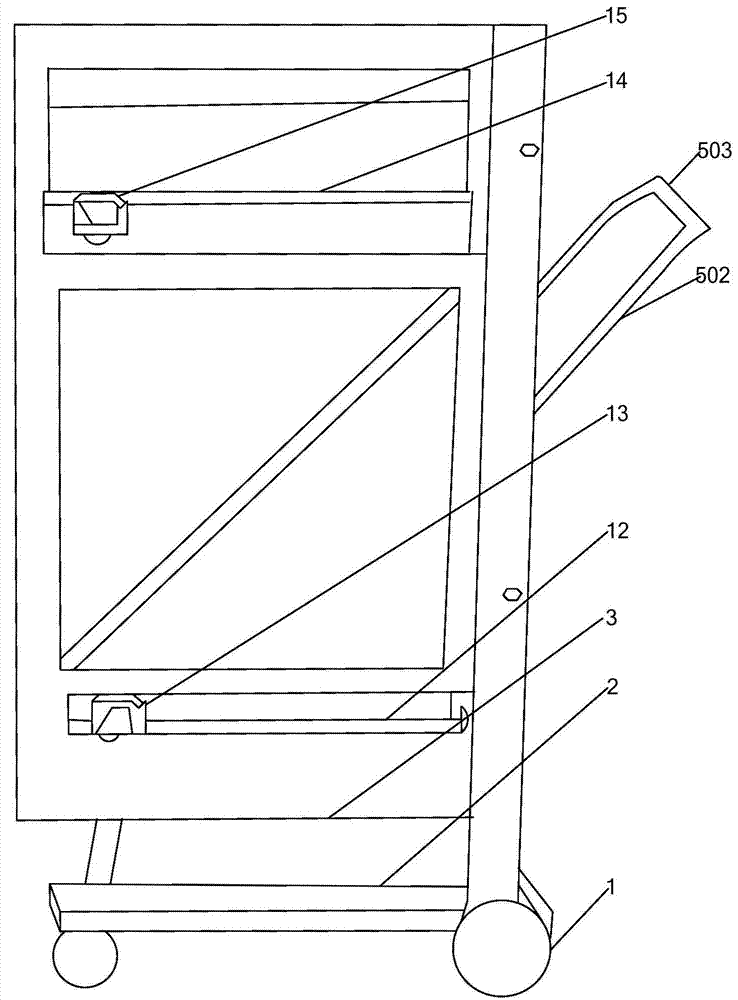

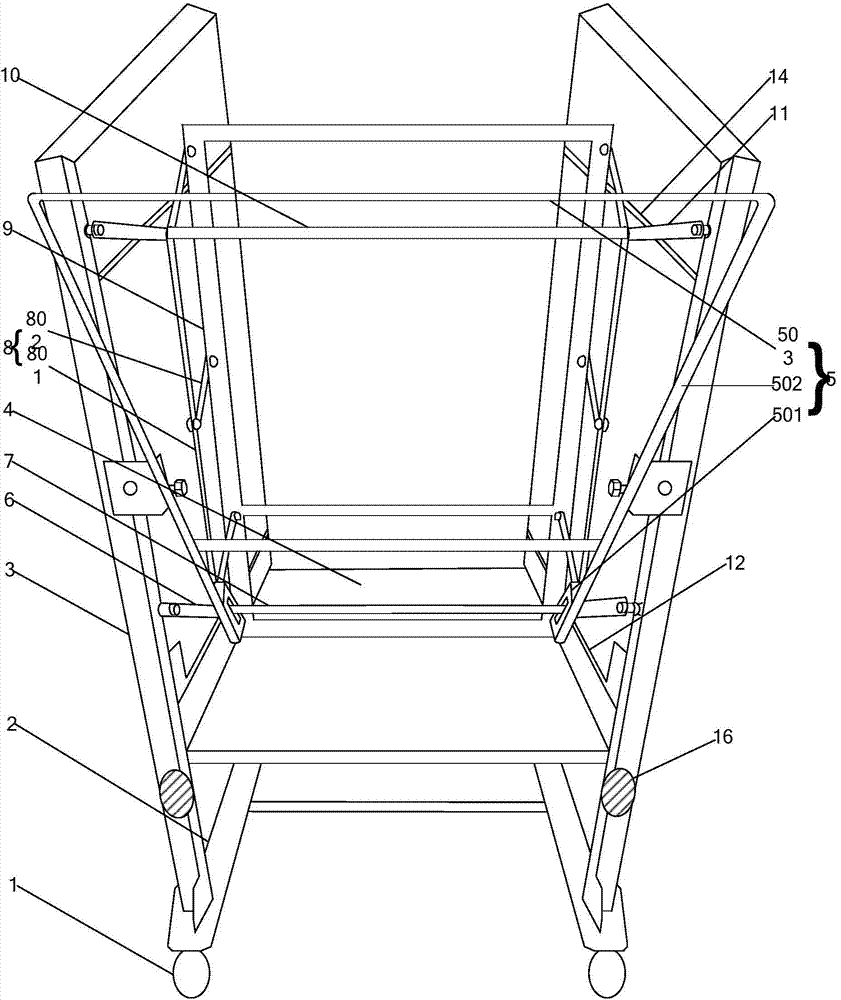

Angle-adjustable humidifier

InactiveCN109028424AThe humidification effect meetsCompatible with indoor conditionsMechanical apparatusLighting and heating apparatusCircular discDrive shaft

The invention discloses an angle-adjustable humidifier. A distance measuring sensor, an angle-adjustable device and a water tank are arranged to check the distance between the top of the water tank and an indoor ceiling, the height range to be covered by the humidifier is judged, and the humidifying angle of an atomizing nozzle 7064 is adjusted by the angle-adjustable device to achieve the effectof adapting to the covering height range, so that the humidifying effect is more in line with the indoor condition. According to the angle-adjustable humidifier, through the arrangement of an aromatherapy liquid storage device and an aromatherapy liquid delivery device, when the aromatherapy function needs to be used, an aromatherapy liquid pressurizing pump is opened, and the matching of a lifting mounting rod, a lifting connecting rod, a lifting column, a transmission rod group, a threaded transmission disc, a transmission shaft and a transmission belt drives the pushing of a threaded three-piece sleeve, so that the pushing speed of the aromatherapy liquid is increased, the aromatherapy liquid can be further mixed with water, and the ejection of the aromatherapy liquid is more uniform.

Owner:芜湖兆润商贸有限公司

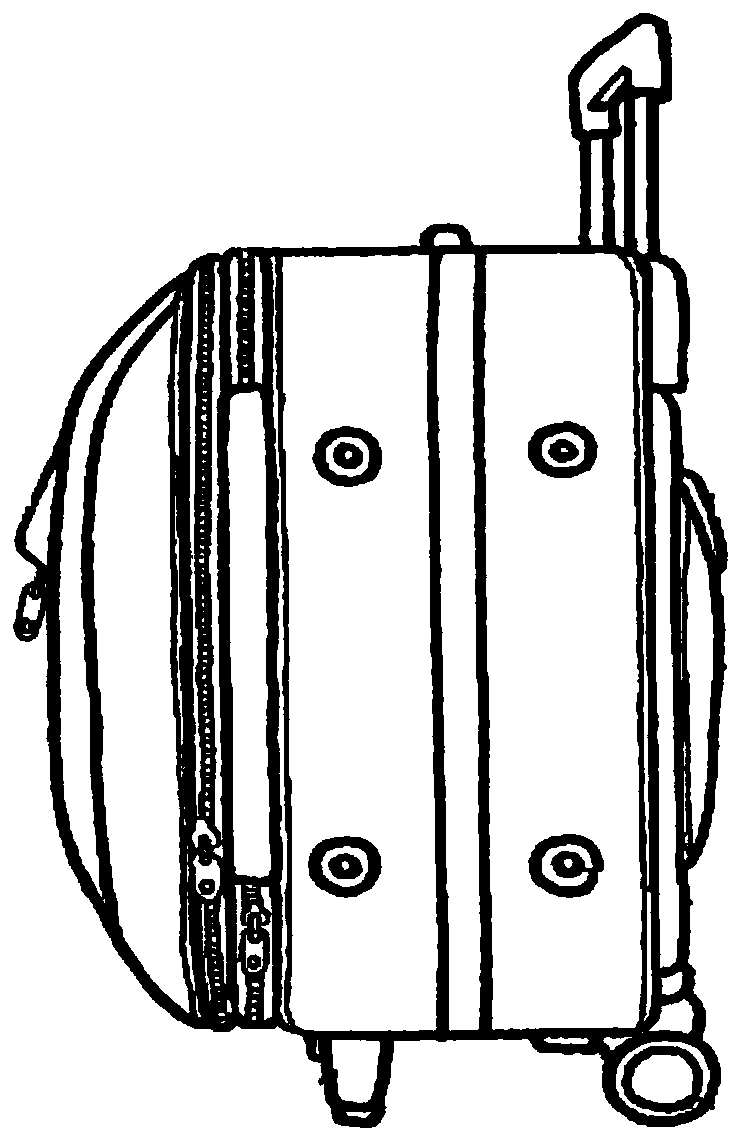

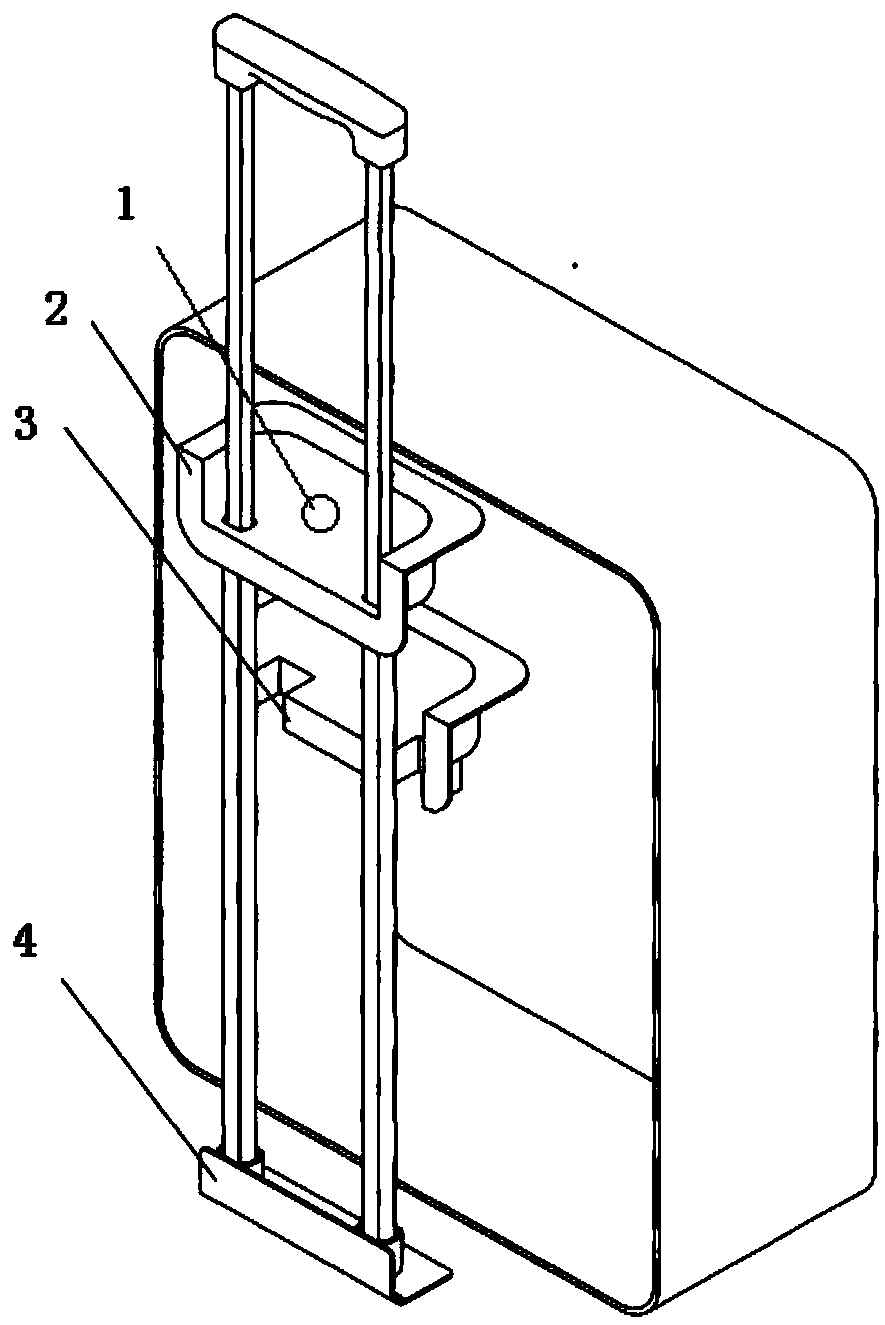

Current Carpet Type Identification System

ActiveCN109118449APush speed is fastImprove push efficiencyImage enhancementImage analysisLower limitGray level

The present invention relates to a current carpet type identification system, comprising: a start button arranged at the top of a box and located near the handle of the box, for receiving the pressingoperation of a user to determine whether the box enters a power-assisted control mode at present or not; the start button is arranged at the top of the box and located near the handle of the box. A large data storage end is used for storing a carpet gray level threshold range in advance, wherein that carpet gray level threshold range consist of a carpet gray level upper threshold value and a carpet gray level lower threshold value, and the values of the carpet gray level upper threshold value and the carpet gray level low threshold value are both 0. 255; a carpet photographing apparatus arranged at the top end of the box for photographing an instant image of the carpet near the box to obtain a corresponding instant carpet image; A dynamic range detecting device is arranged at the top of the box, and is used for receiving the instant carpet image and detecting the current dynamic range of the instant carpet image to obtain the current dynamic range. Through the invention, the performance of the pushing box can be effectively improved.

Owner:许剑清

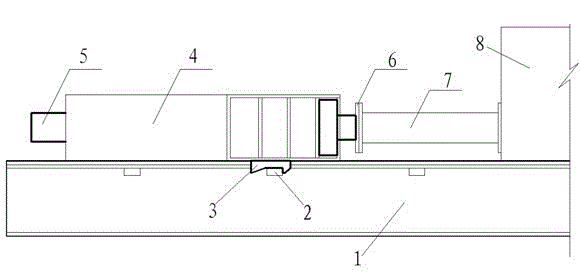

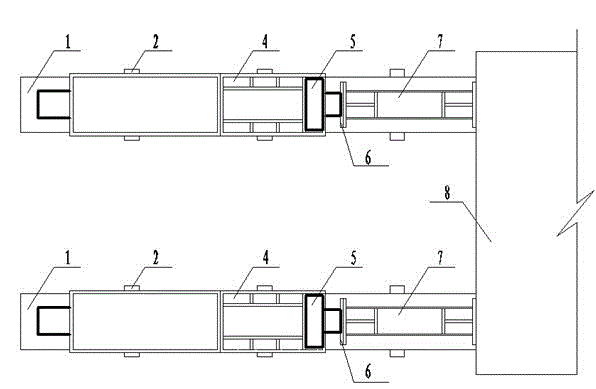

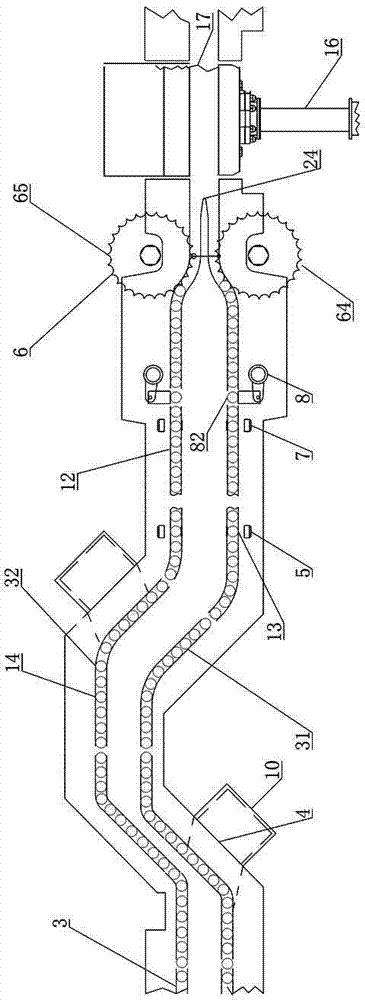

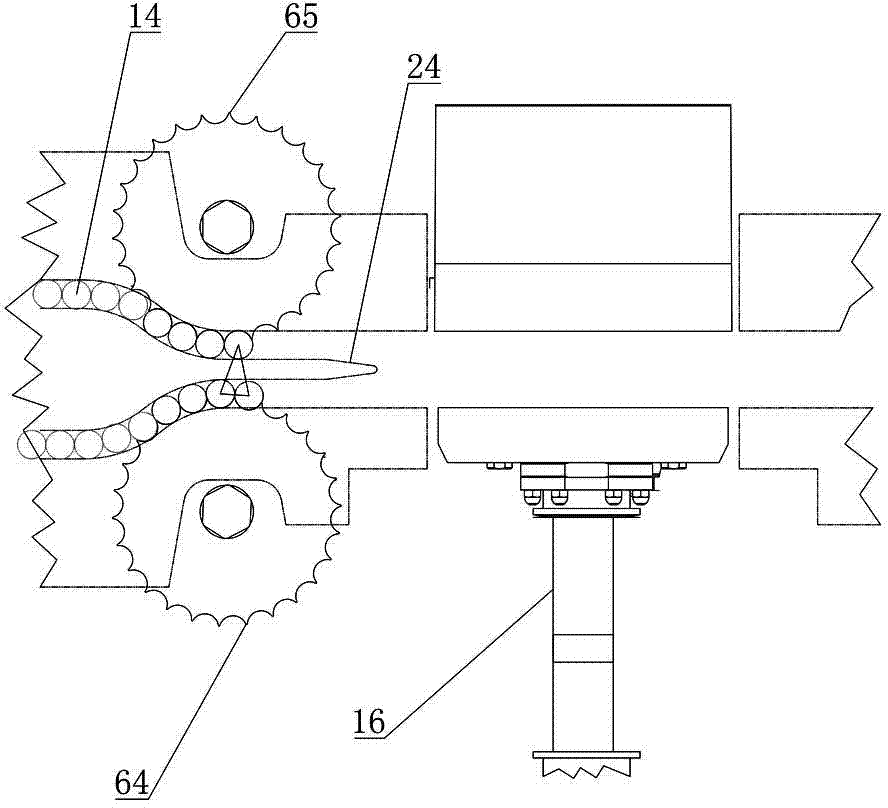

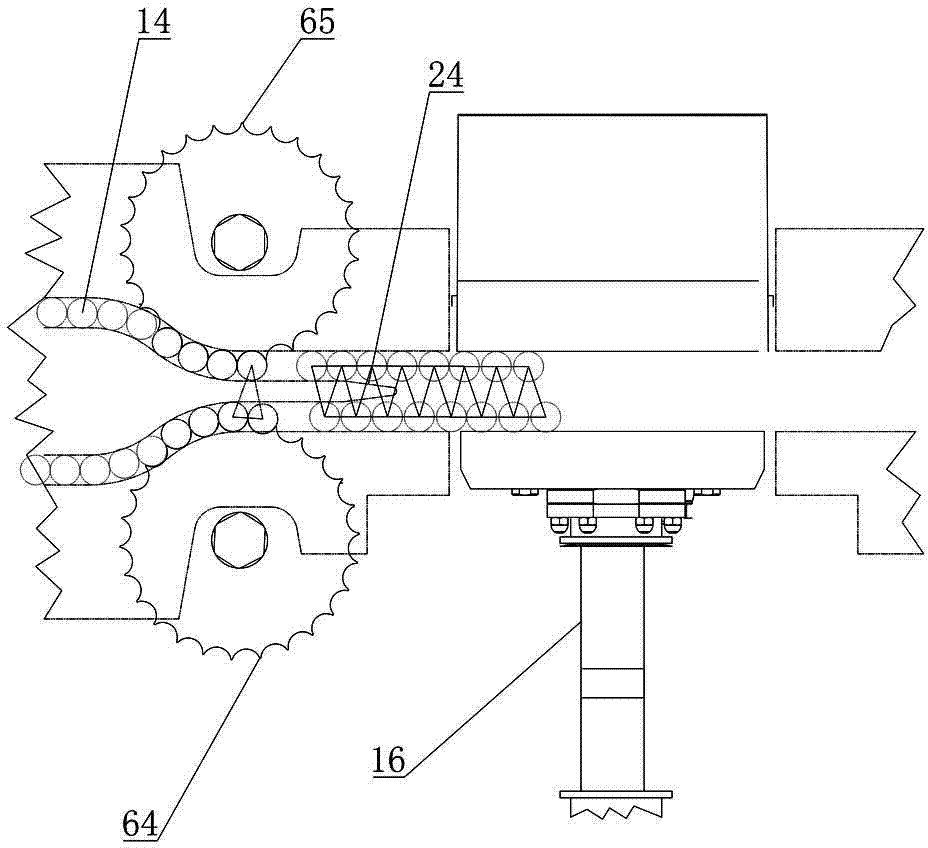

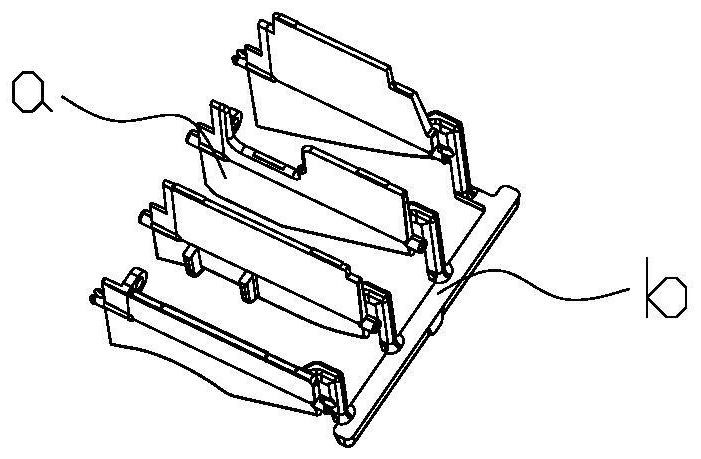

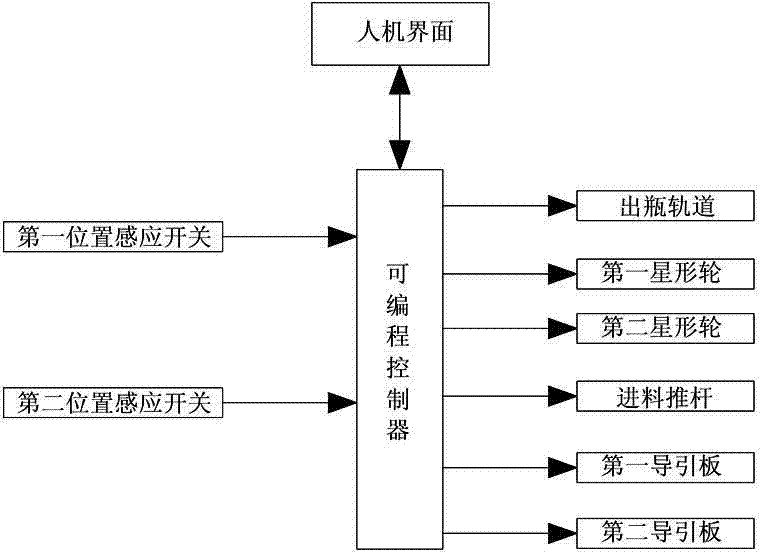

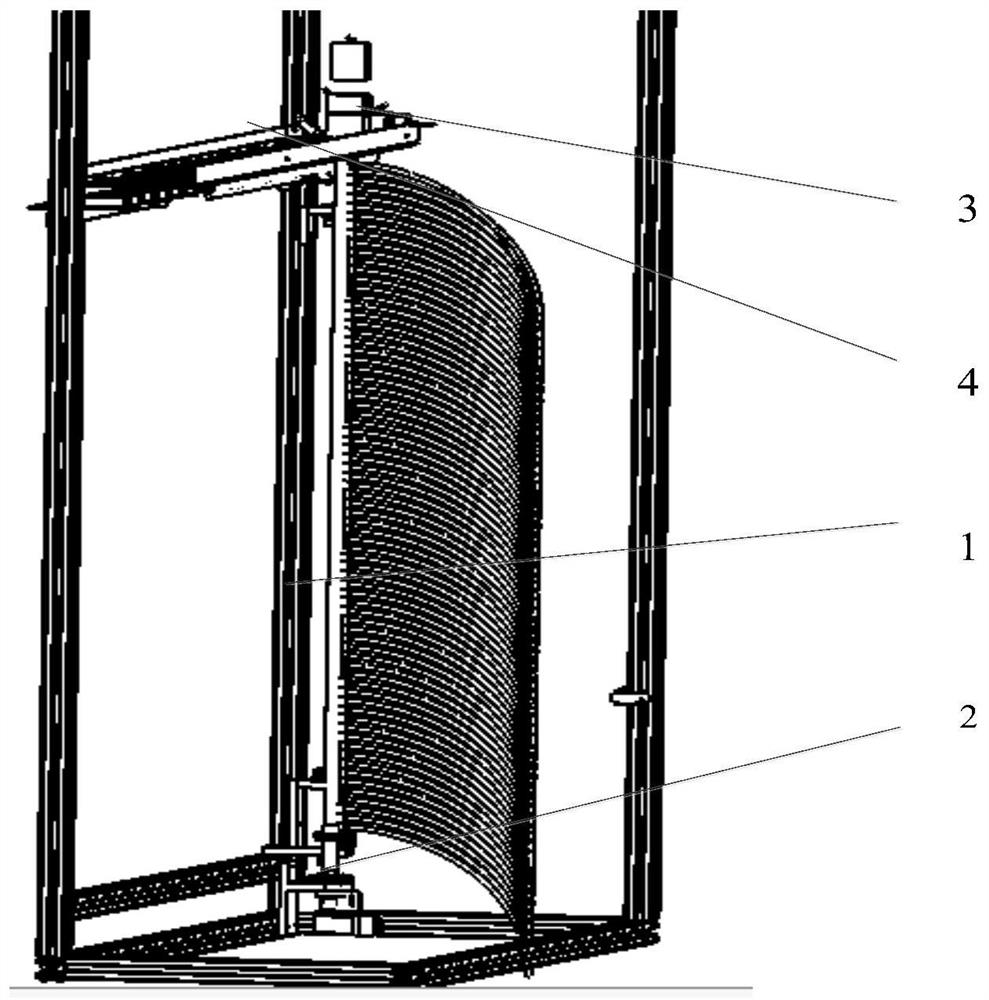

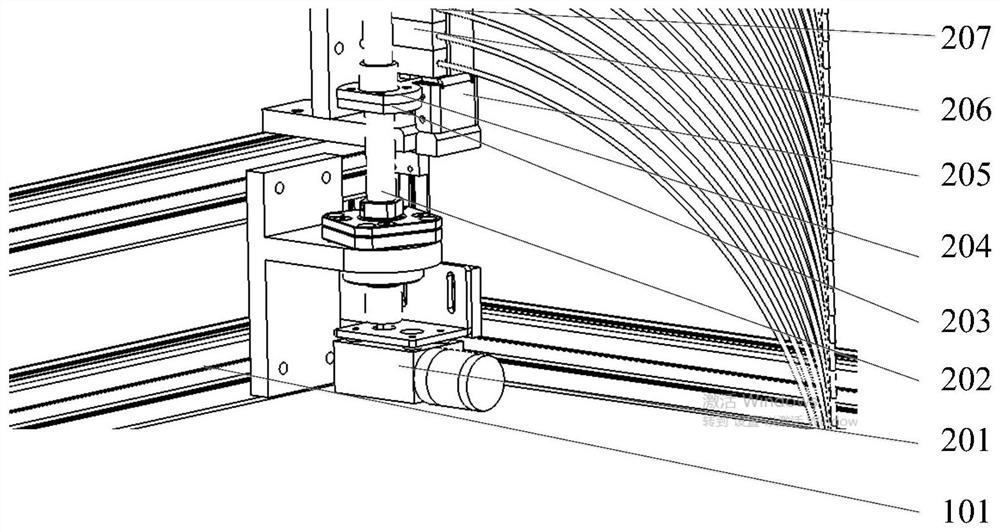

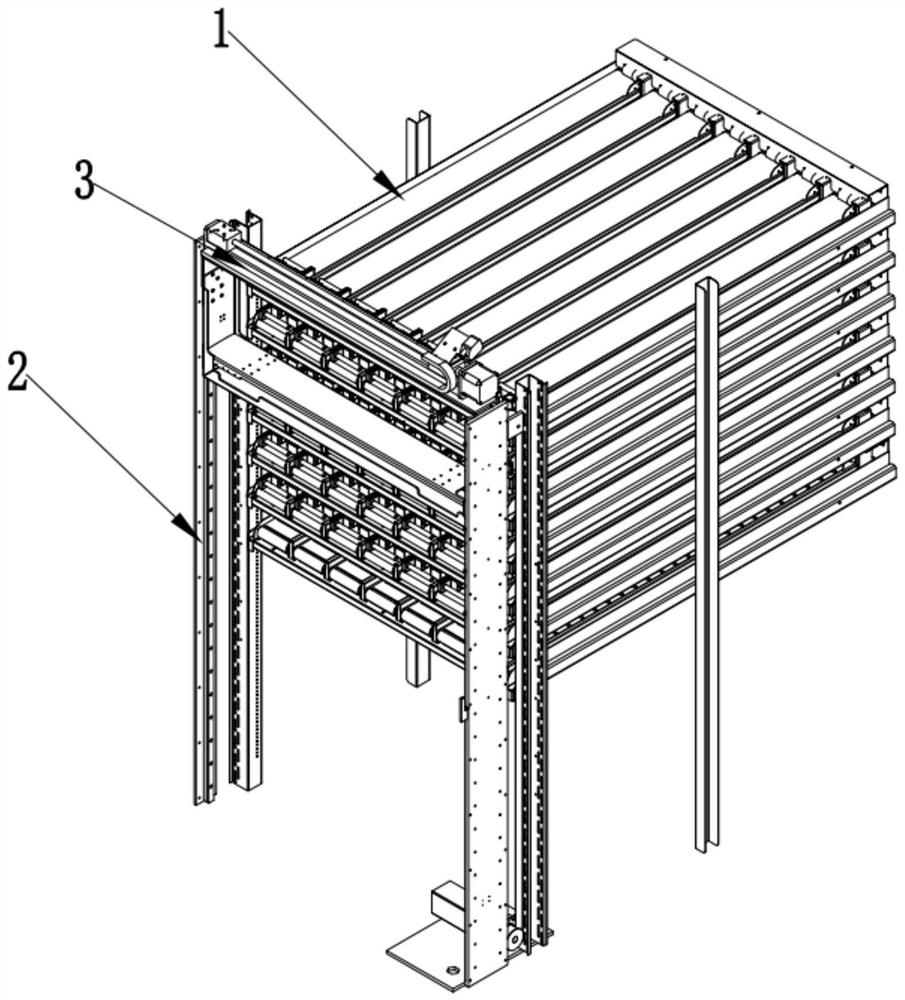

Double-row feed system and method of freeze dryer

The invention discloses a double-row feed system of a freeze dryer. The system comprises a conveying belt, and a push rod rail in butt joint with the conveying belt, wherein the conveying belt comprises a first conveying belt and a second conveying belt operated in parallel; a first star wheel is arranged in the butt joint place of the first conveying belt and the push rod rail; a second star wheel is arranged in the butt joint place of the second conveying belt and the push rod rail; the first star wheel is opposite to the second star wheel; and small bottles on the first conveying belt and the second conveying belt are conveyed onto the push rod rail one by one under the rotation of the first star wheel and the second star wheel. The invention further discloses a double-row feed method of the freeze dryer; and double rows of small bottles are pushed into a plate layer or a buffer area after being arranged through the rotating number of the double star wheels and the rotating offset of push rods. The feed system and method greatly accelerate the feed speed, and has a measure of multilayer elimination of falling bottles.

Owner:TRUKING TECH LTD

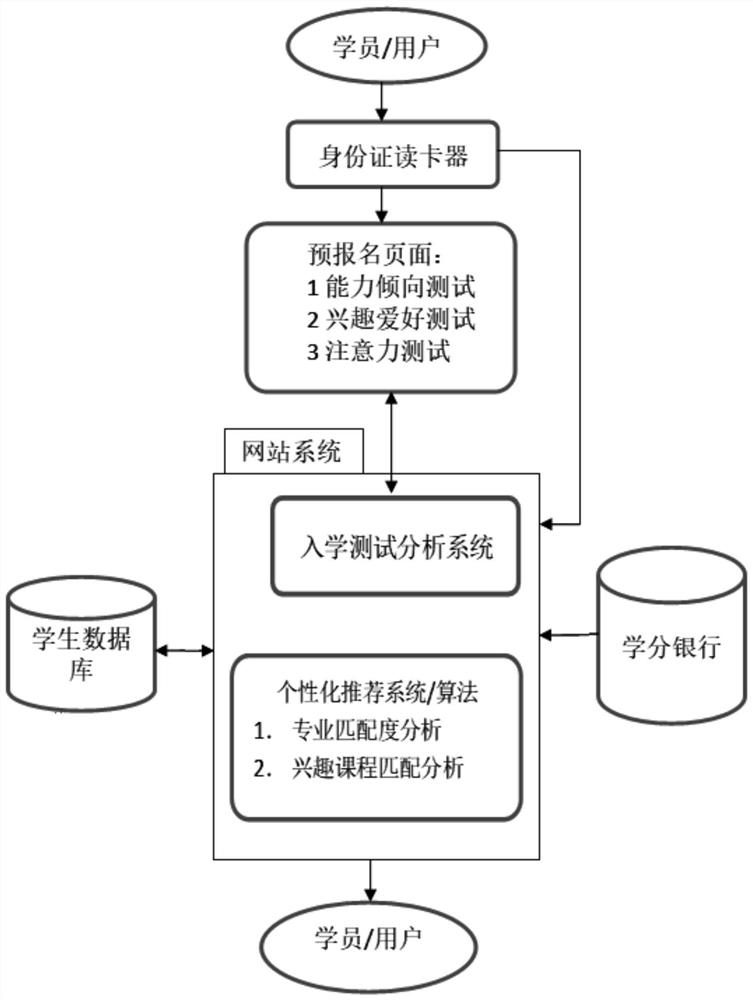

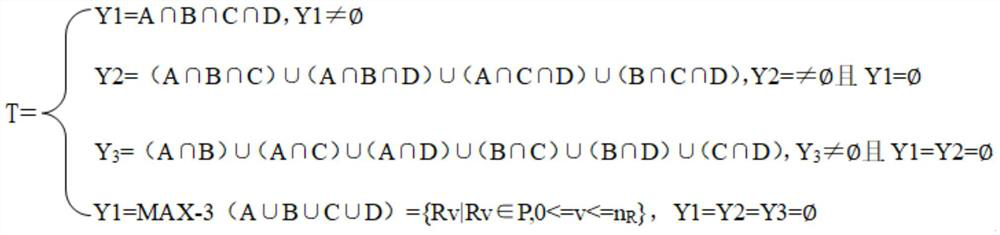

Lifelong learning resource intelligent pushing method based on credit banking and big data analysis

ActiveCN112685470AAvoid wastingMake it easy for people to do their bestData processing applicationsDigital data information retrievalLearning resourceEngineering

Owner:阳江开放大学

Wheel conversion method based on big data analysis for box bottom

InactiveCN109034243APush speed is fastImprove effectivenessCharacter and pattern recognitionSharpeningBig data

The invention relates to a case bottom wheel conversion method based on big data analysis. The method includes converting a bottom wheel of a cabinet using a bottom wheel conversion system based on big data analysis. The bottom wheel conversion system based on big data analysis includes a wheel switching device for replacing a current wheel of a tie rod cabinet from an overcoming resistance wheelto an anti-skid wheel upon receiving an anti-skid switching command. The wheel switching device is also used for replacing the current wheel of the pull rod case by an anti-skid wheel when receiving the overcoming resistance switching command; an accommodating space arranged at the bottom of the pull rod box for accommodating the resistance wheel or the anti-skid wheel; a contour sharpening devicefor performing the following contour sharpening actions based on the big data analysis; a DSP process chip is used for issuing an overcoming resistance switching command when the fatigue level exceeds the limit, and for issuing an anti-skid switching command when the fatigue level doe not exceed the limit.

Owner:张亮

Air compressor

ActiveCN103807148AImprove performanceLarge capacityPositive displacement pump componentsPressure vesselsAir compressionReciprocating motion

Owner:UNIK WORLD IND CO LTD

Push mechanism

Owner:长沙金属狂潮农用机械科技有限公司 +1

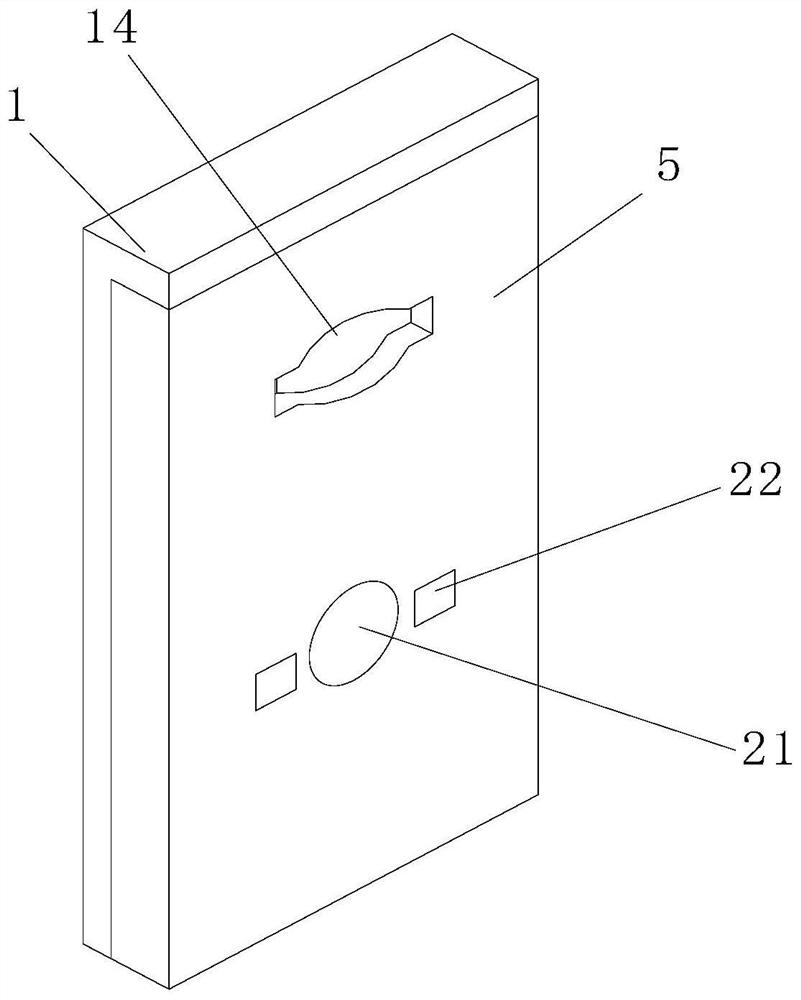

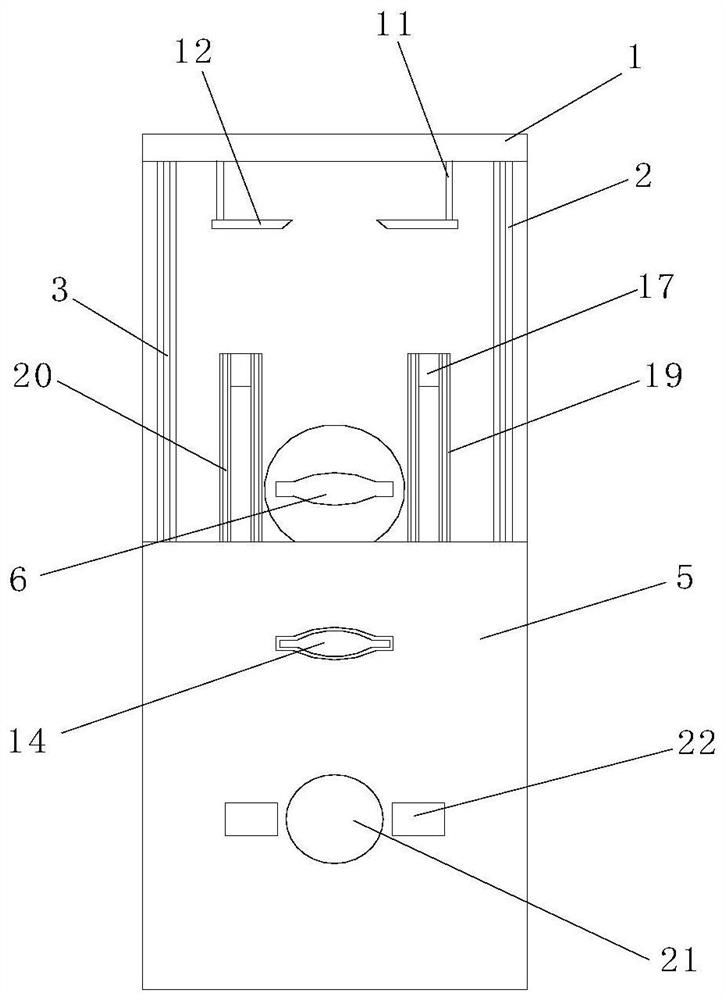

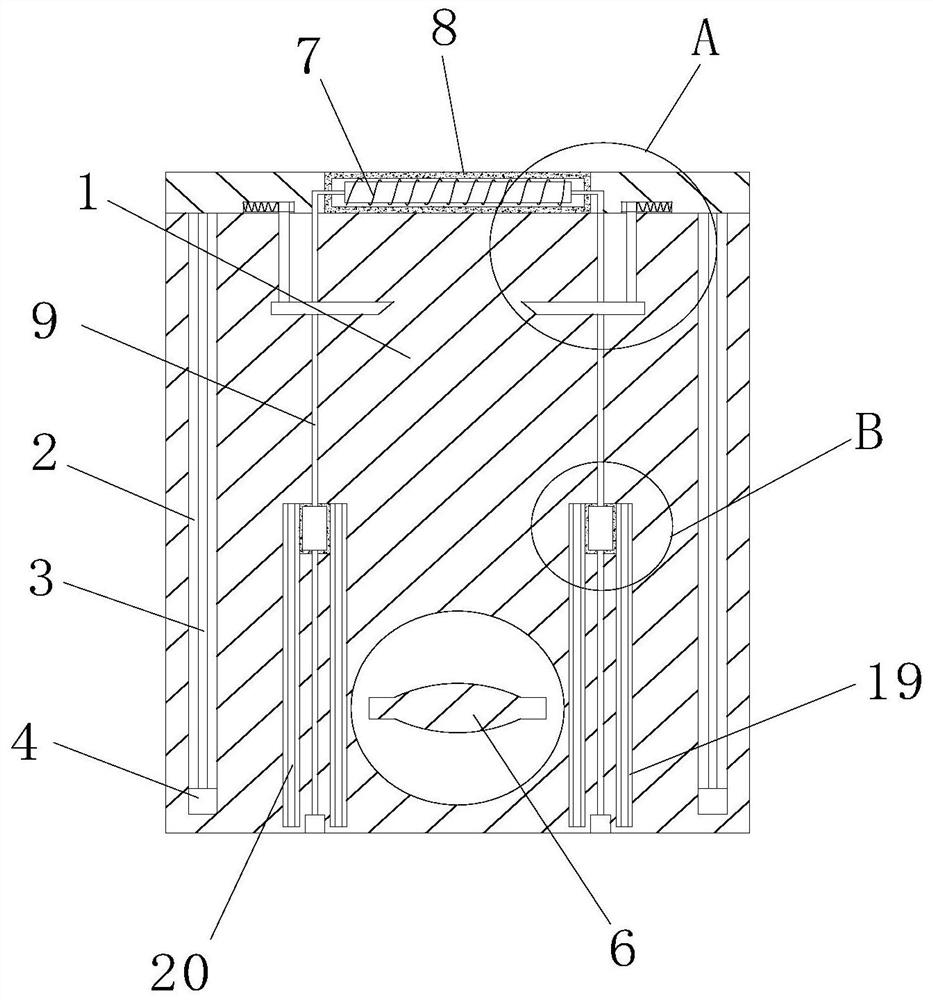

Key hole protection device for intelligent lock

InactiveCN111636771APlay a protective effectAvoid unfoldingBuilding locksStructural engineeringMechanical engineering

The invention relates to the technical field of intelligent locks, and discloses a key hole protection device for an intelligent lock. The key hole protection device comprises a key hole face board and a cover plate, wherein sliding grooves A are formed in the two sides of the front face of the key hole face board correspondingly, sliding rods A are fixedly connected to the top faces of the sliding grooves A, lantern rings are connected with the outer walls of the sliding rods A in a sleeving mode, and the two sides of the back side face of the cover plate are fixedly connected with the two lantern rings correspondingly. Through the arrangement of the cover plate, a key hole is automatically closed when the intelligent lock is used, so that the key hole is and protected; the cover plate isfixed through limiting blocks, so that the problem that the cover plate is unfolded due to mistaken touch is avoided; the key hole is automatically unfolded after a circuit board of the intelligent lock is powered off, so that the effect of reminding a user that the intelligent lock is powered off is achieved; and during a fire disaster, when the circuit board of the intelligent lock is powered off due to the fire disaster, the problem that time is wasted when the user searches for the position of the key hole and opens the cover plate can be solved, so that the door opening speed of the useris increased, and the speed of the user escaping from the dangerous environment is accelerated under the condition of every minute counts.

Owner:杭州艾洋洋信息科技有限公司

Automobile air conditioner air outlet and production equipment and method thereof

InactiveCN111791505AImprove cut qualityAvoid warpingDomestic articlesAutomobile air conditioningWorkbench

The invention relates to the field of automobile air conditioner air outlet production, in particular to automobile air conditioner air outlet production equipment. The automobile air conditioner airoutlet production equipment comprises a workbench, as well as a rear blade cutting device, a jig conveying device, a rear blade side edge mounting device and a pressing device which are fixed to the workbench, wherein the cutting device is connected with the pressing device; the cutting device is connected with one end of the jig conveying device; and the other end of the jig conveying device is respectively connected with the rear blade side edge mounting device and the pressing device. By arranging the blade cutting device, the thickness of a cutting trace is uniform, and the cutting qualityof a blade mold base is improved; parts such as a connecting rod can be rapidly fed by arranging a turnover driving mechanism; and by arranging a double-side-edge mounting mechanism, the number of push-mounting devices is reduced, and the push-mounting speed of the push-mounting devices is increased.

Owner:魏玉燕

Feed guide device and method of freeze dryer

InactiveCN104743159AAvoid the risk of product contamination and equipment damagePush speed is fastPackaging automatic controlDouble rowEngineering

The invention discloses a feed guide device of a freeze dryer. The device comprises guide plates and a driving piece, wherein the guide plates are arranged at the two sides of a feed push rod of the freeze dryer, and are positioned above a bottle outlet rail of the freeze dryer; the guide plates are connected with the driving piece through a connecting rod; and the connecting rod is driven by the driving piece to drive the guide plates to ascend and descend. The invention further discloses a feed guide method of the freeze dryer; the method comprises the following steps: in feeding, the guide plate far from an inlet of the bottle outlet rail descends, and the guide plate near the inlet of the bottle outlet rail ascends; arranged bottles are counted and positioned to finish once arrangement of double rows of small bottles; the guide plate near the inlet of the bottle outlet rail descends, and the small bottles are pushed to a pushing area; and the guide plate near the inlet of the bottle outlet rail ascends to finish the feeding. The guide device and method both have the advantages of simple structure, increase of feeding speed and prevention of extruding explosion of the small bottles.

Owner:TRUKING TECH LTD

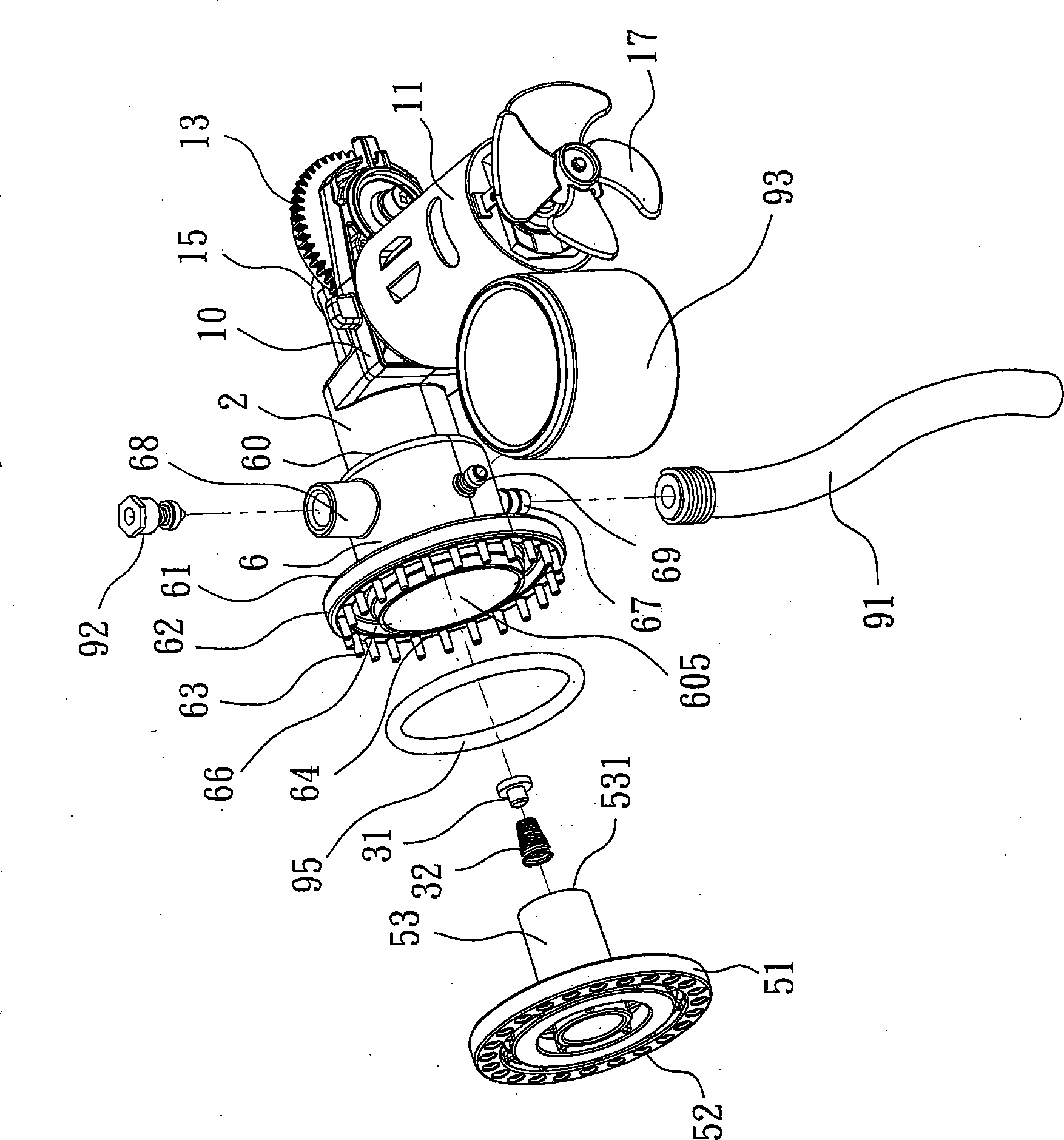

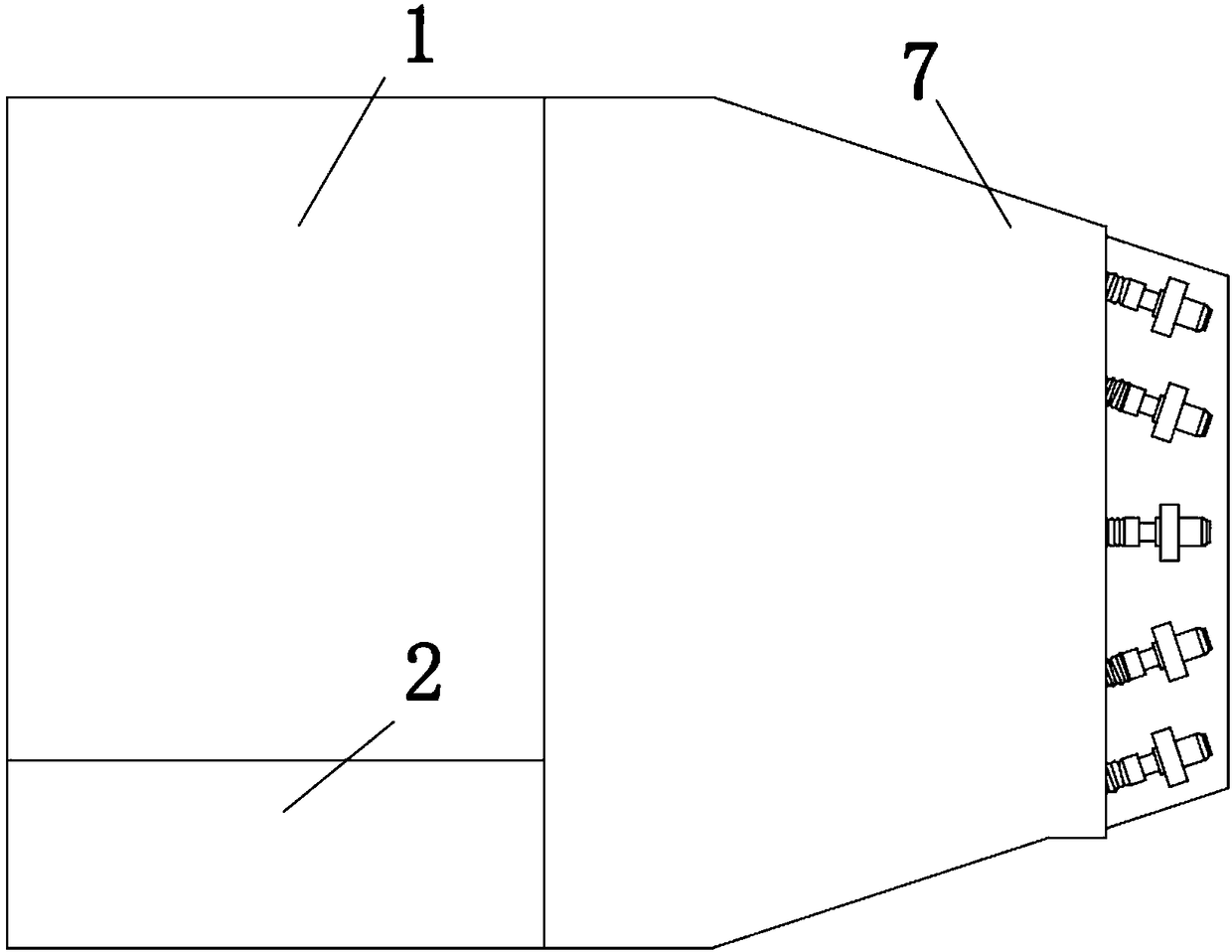

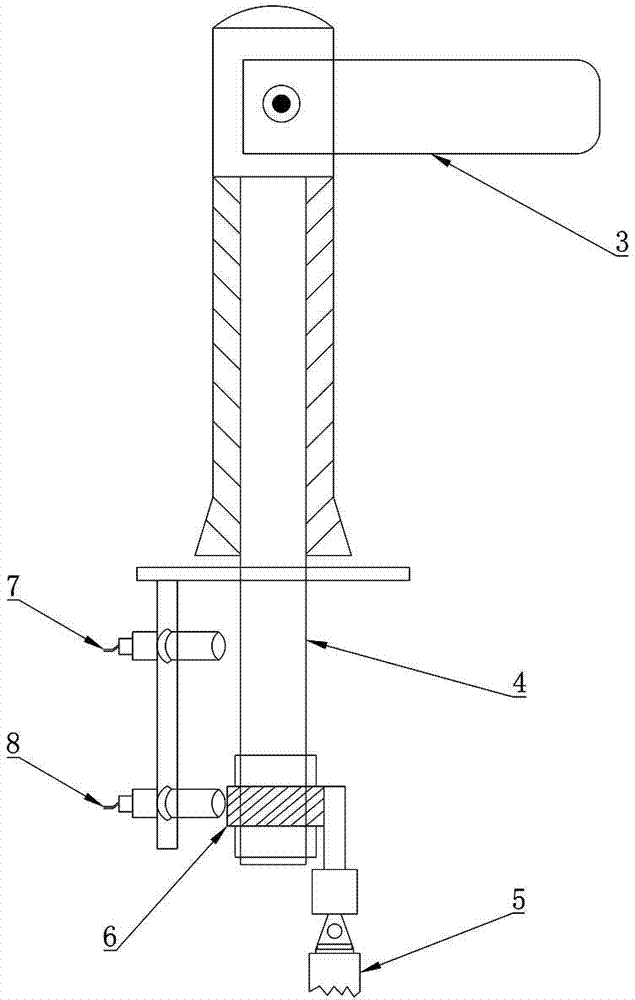

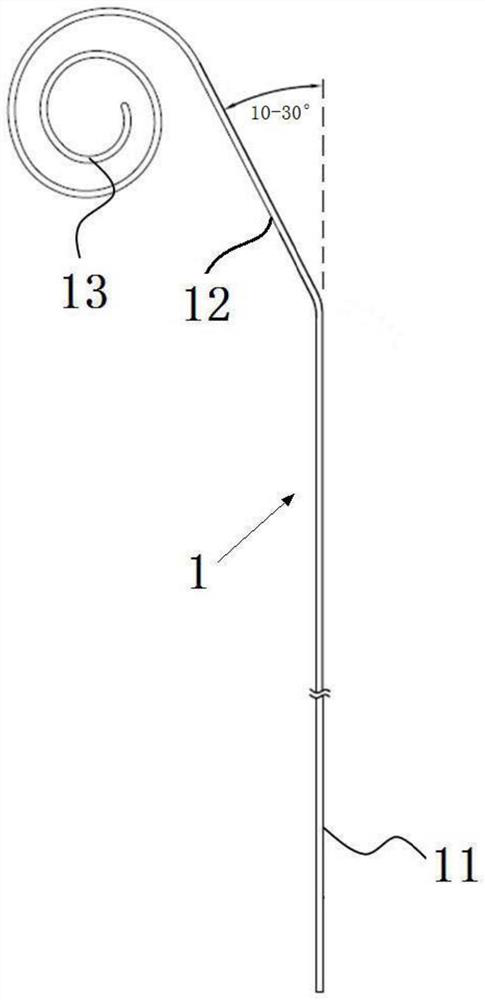

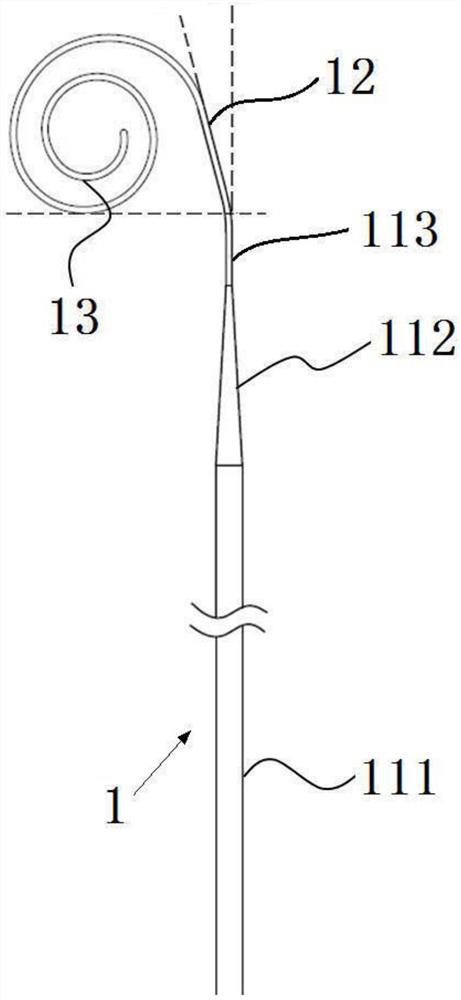

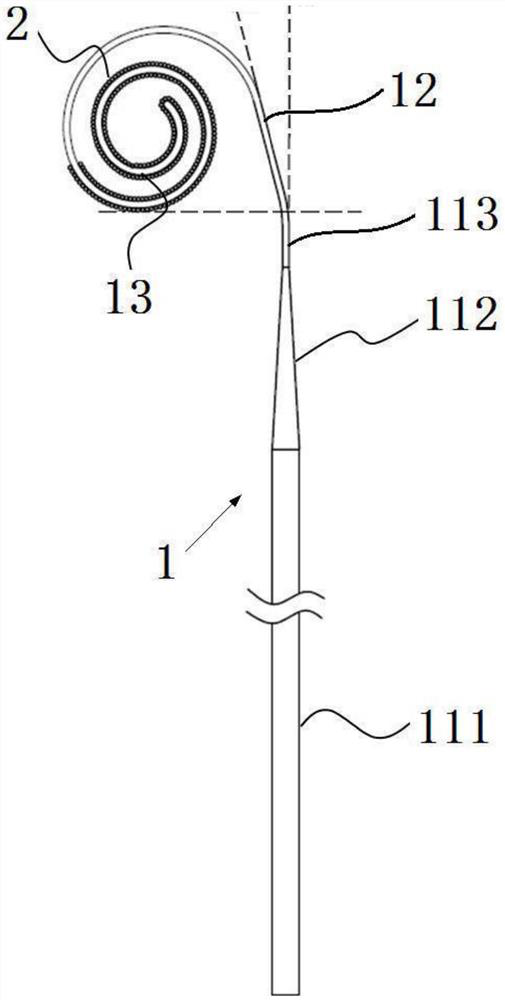

Percutaneous aortic valve implantation guide wire

The percutaneous aortic valve implantation guide wire comprises a guide wire body (1), the guide wire body (1) comprises a first section (11), a second section (12) and a spiral section (13) which are connected, the first section (11) is located at the near end, the spiral section (13) is located at the far end, and the two ends of the second section (12) are connected with the first section (11) and the spiral section (13) respectively; a first included angle is formed between the first section (11) and the second section (12); the spiral section (13) is formed by curling a guide wire into a spiral ring, and the spiral ring of the spiral section (13) is located in the same plane. According to the percutaneous aortic valve implantation guide wire, the guide wire pushing efficiency and speed are improved through the bending between the first section and the second section, the myocardial perforation risk is reduced through the spiral section, the anchoring effect is improved, the structural design is reasonable, operation is easy, mastering is easy, and the percutaneous aortic valve implantation success rate can be increased.

Owner:APT MEDICAL HUNAN INC +1

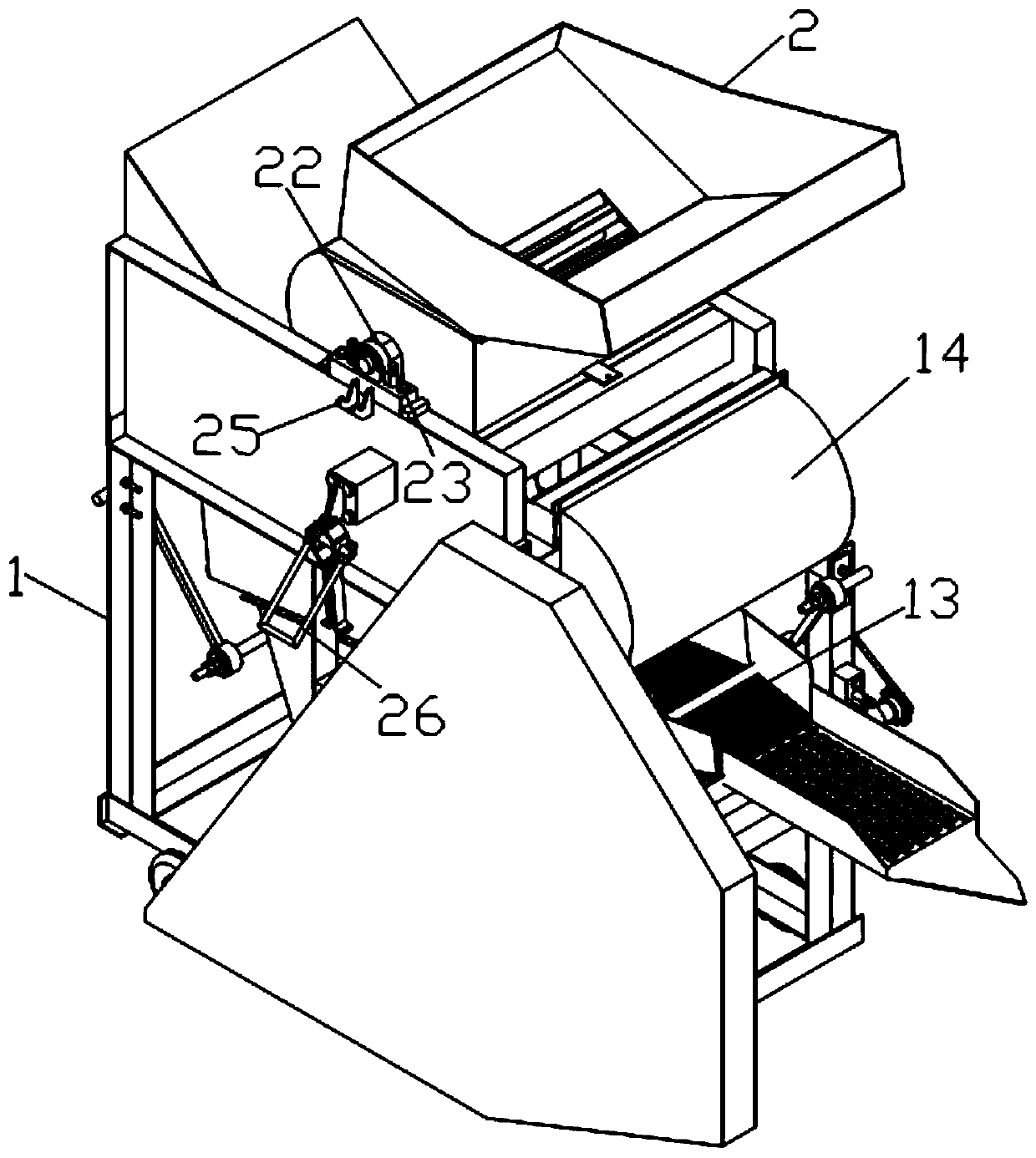

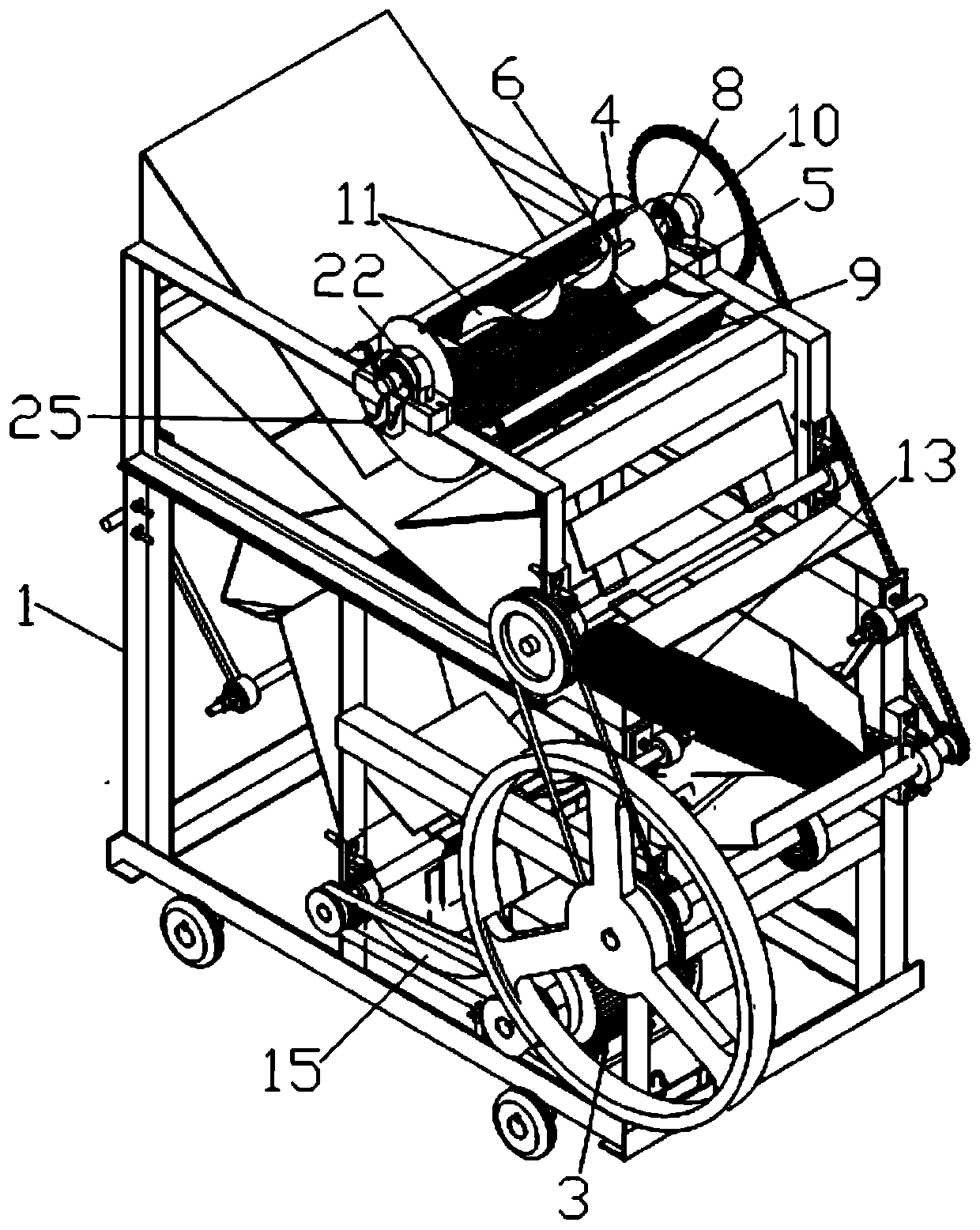

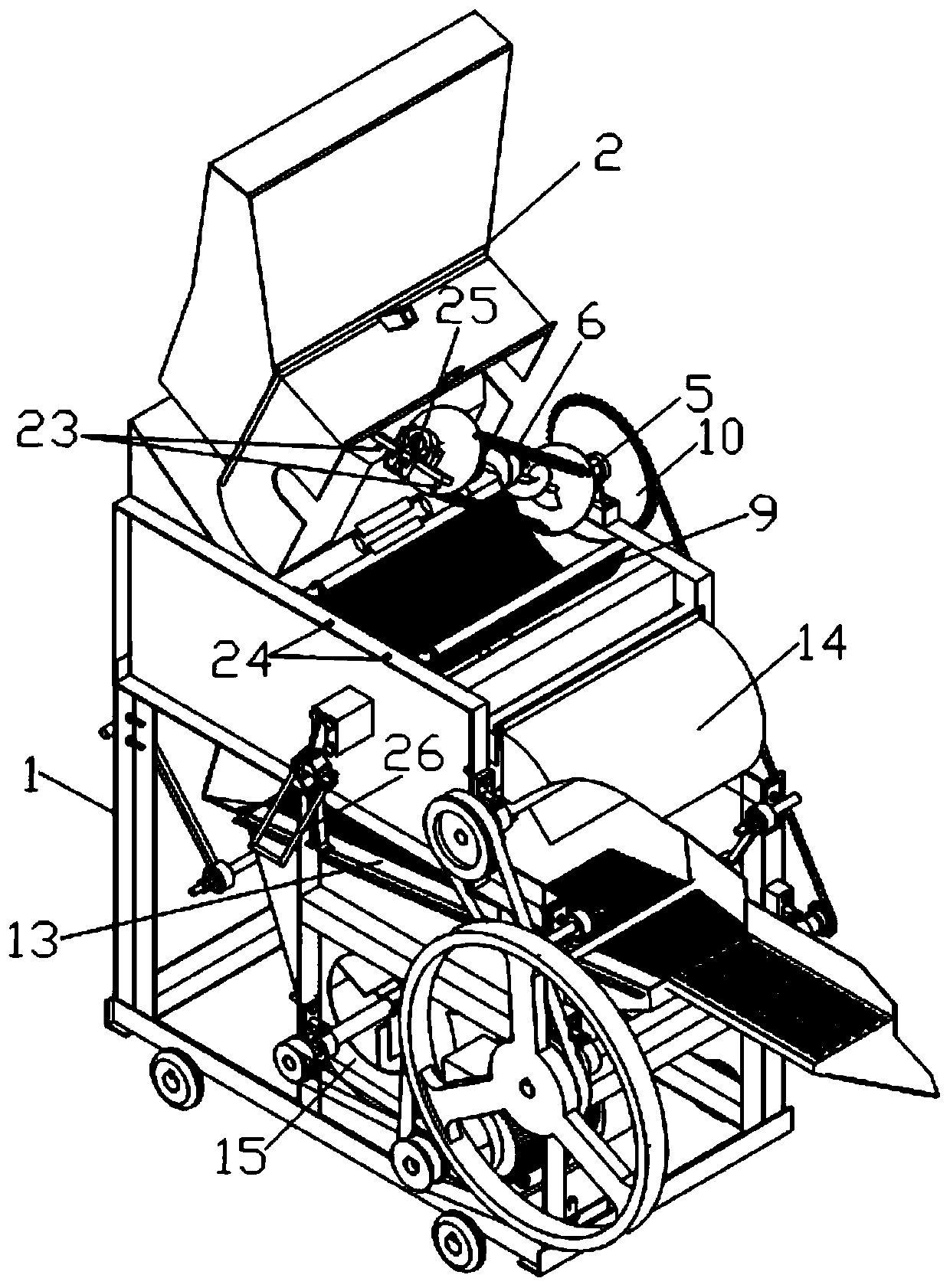

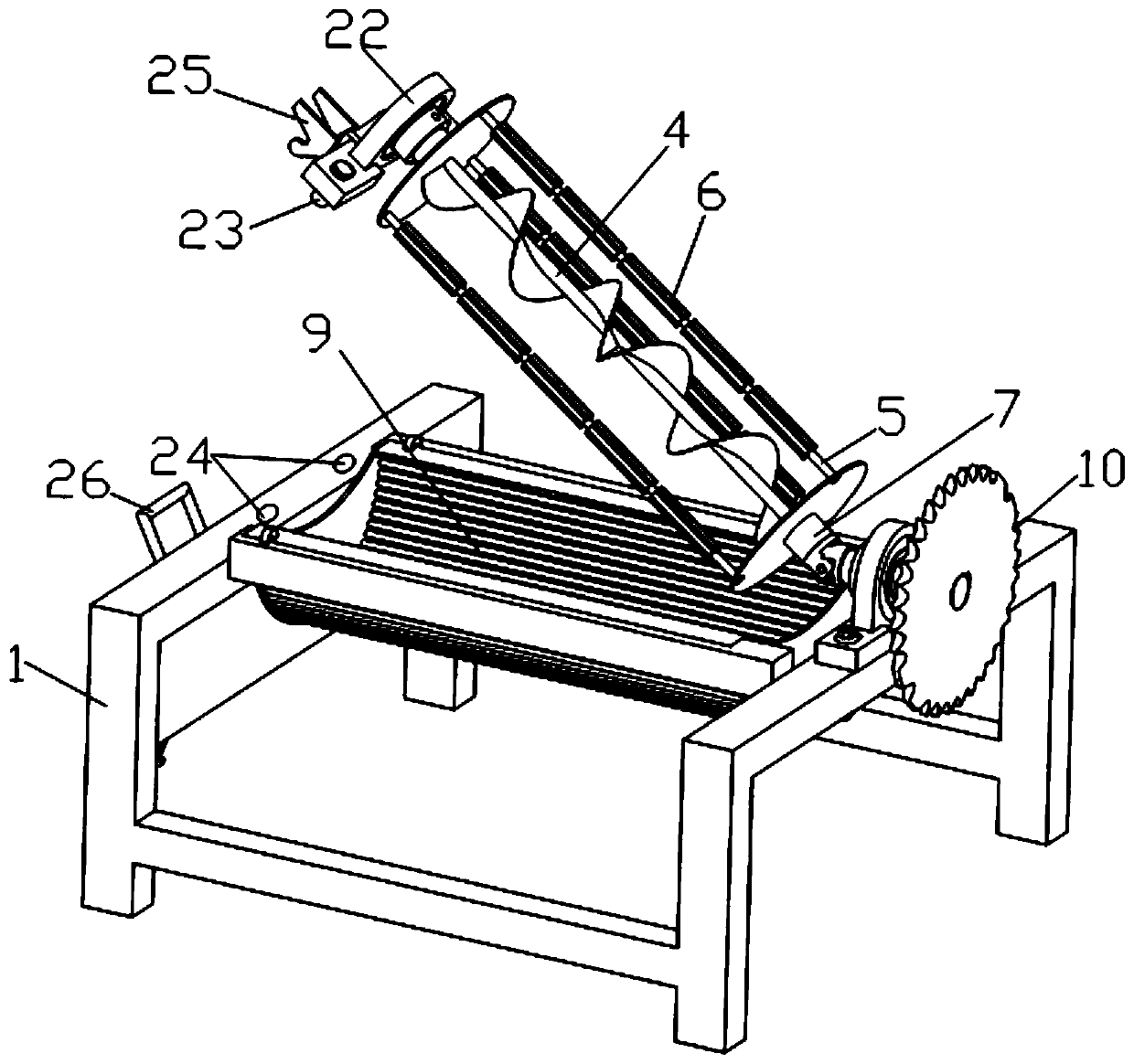

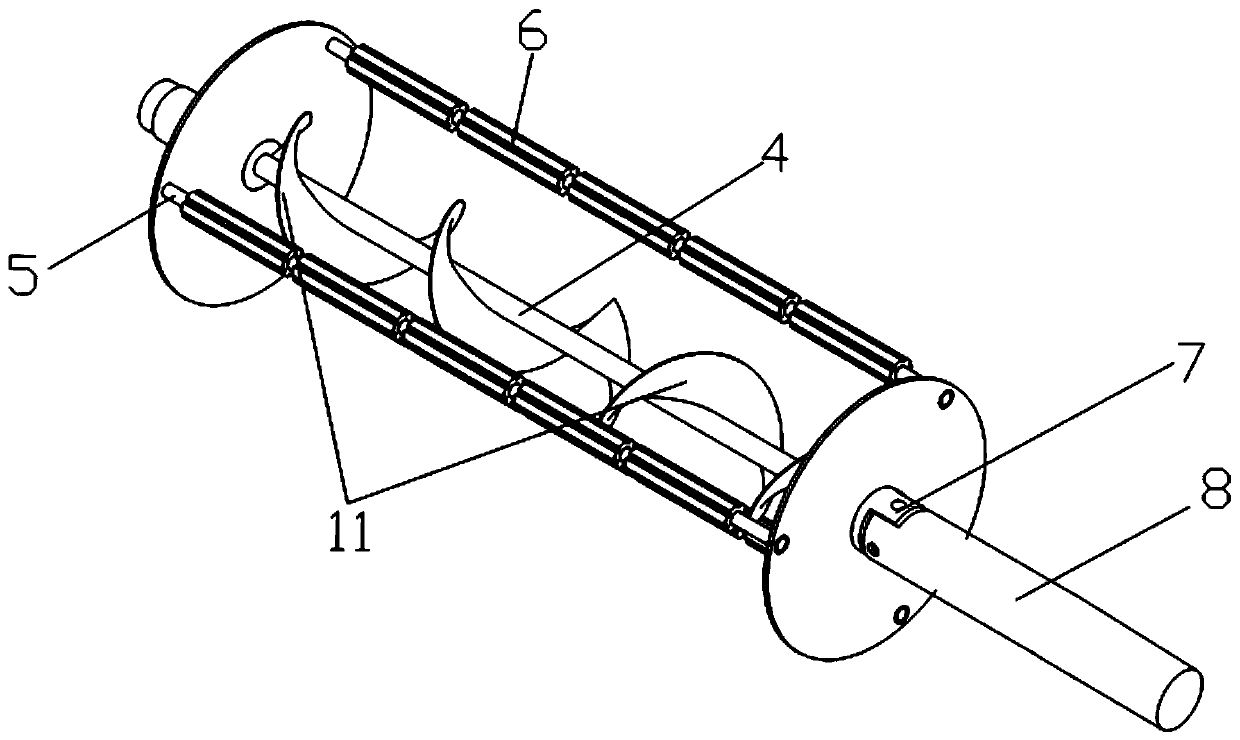

Peanut seed sheller

PendingCN111183799AIncrease the burden of differentiationRich varietySievingGas current separationAgricultural engineeringEngineering

The invention discloses a peanut seed sheller, and belongs to the technical field of peanut seed shellers. The peanut seed sheller comprises a rack, a feed hopper which is arranged on the rack, a peanut shelling device, a kernel / shell winnowing and separation device, a driving motor and a transmission device; the outer wall of the feed hopper is hinged with the rack; the peanut shelling device isarranged below the feed hopper through the rack and comprises a shelling structure, a replication structure and a peanut shell / kernel uniform distribution structure; the shelling structure comprises aroller and an arc-shaped screen body; the roller comprises a roller shaft and a plurality of rubbing columns; each rubbing column comprises a column core and a nylon sleeve; the inner holes of the nylon sleeves are connected with the column cores in a sliding matching manner; a plurality of grooves are radially formed in the column surfaces of the nylon sleeves; the grooves are uniformly arrangedalong the circumferences of the column surfaces of the nylon sleeves; and the replication structure comprises a cross joint type universal coupling and a short shaft which is connected with the crossjoint type universal coupling end to end. The peanut seed sheller has the advantages of being convenient to clean the sundries of arc-shaped screens, causing less damages to the peanut seed kernels and the skins of the peanut seed kernels in the shelling process, and being high in efficiency of obtaining high-quality peanut seeds.

Owner:HEBEI AGRICULTURAL UNIV. +1

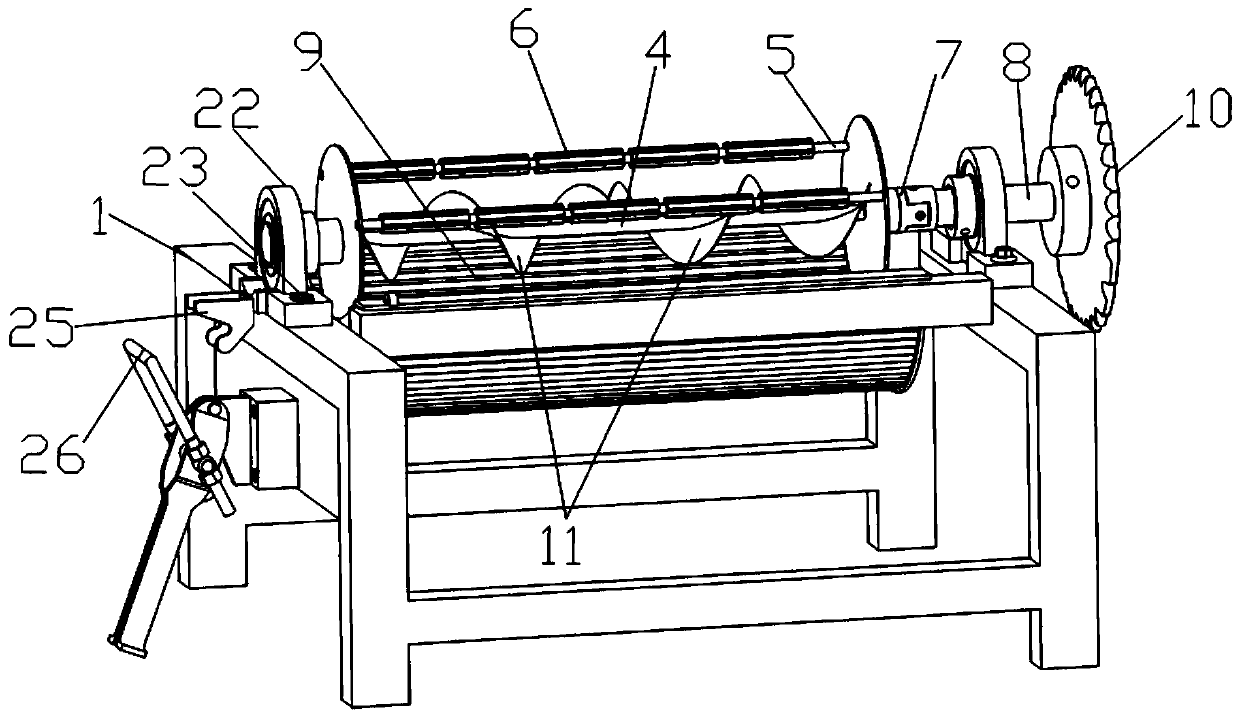

Peanut shelling device for peanut seed shelling machine

PendingCN111183798AIncrease the burden of differentiationRich varietyGas current separationSeed and root treatmentSpiral bladeAgricultural engineering

The invention discloses a peanut shelling device for a peanut seed shelling machine, and belongs to the technical field of peanut shelling machines. The peanut shelling device includes a shelling structure, a turning structure and an uniform distribution structure of peanut pods. The shelling structure includes a roller and an arc-shaped sieve body. The roller includes a roller shaft and a plurality of rubbing columns, each rubbing column includes a column core and a nylon sleeve. The inner hole of the nylon sleeve is slidably connected with the column core, and a plurality of grooves are provided radially on the cylindrical surface of the nylon sleeve, and each groove is evenly distributed along the circumferential direction of the cylindrical surface of the nylon sleeve. The turning structure includes a cross shaft universal coupling and a short shaft connected from end to end. The uniform distribution structure of peanut pods includes two spiral blades symmetrically arranged on theroller shaft. The rotation direction of the two spiral blades causes the peanut pods to be pushed from the middle to both ends, and the pitch of the two spiral blades gradually increases from the inner end to the outer end. The device has the advantages of being convenient for cleaning the debris of the arc-sieve, thereby causing less damage to the peanut seed kernel and the peanut seed red coat during the shelling process and obtaining high-quality peanut seeds with high efficiency.

Owner:HEBEI AGRICULTURAL UNIV. +1

A wire seal distribution device and distribution method

ActiveCN111573315BCompact structureSmall sizeConveyorsControl devices for conveyorsDistribution methodControl engineering

Owner:佛山市明睿达科技有限公司

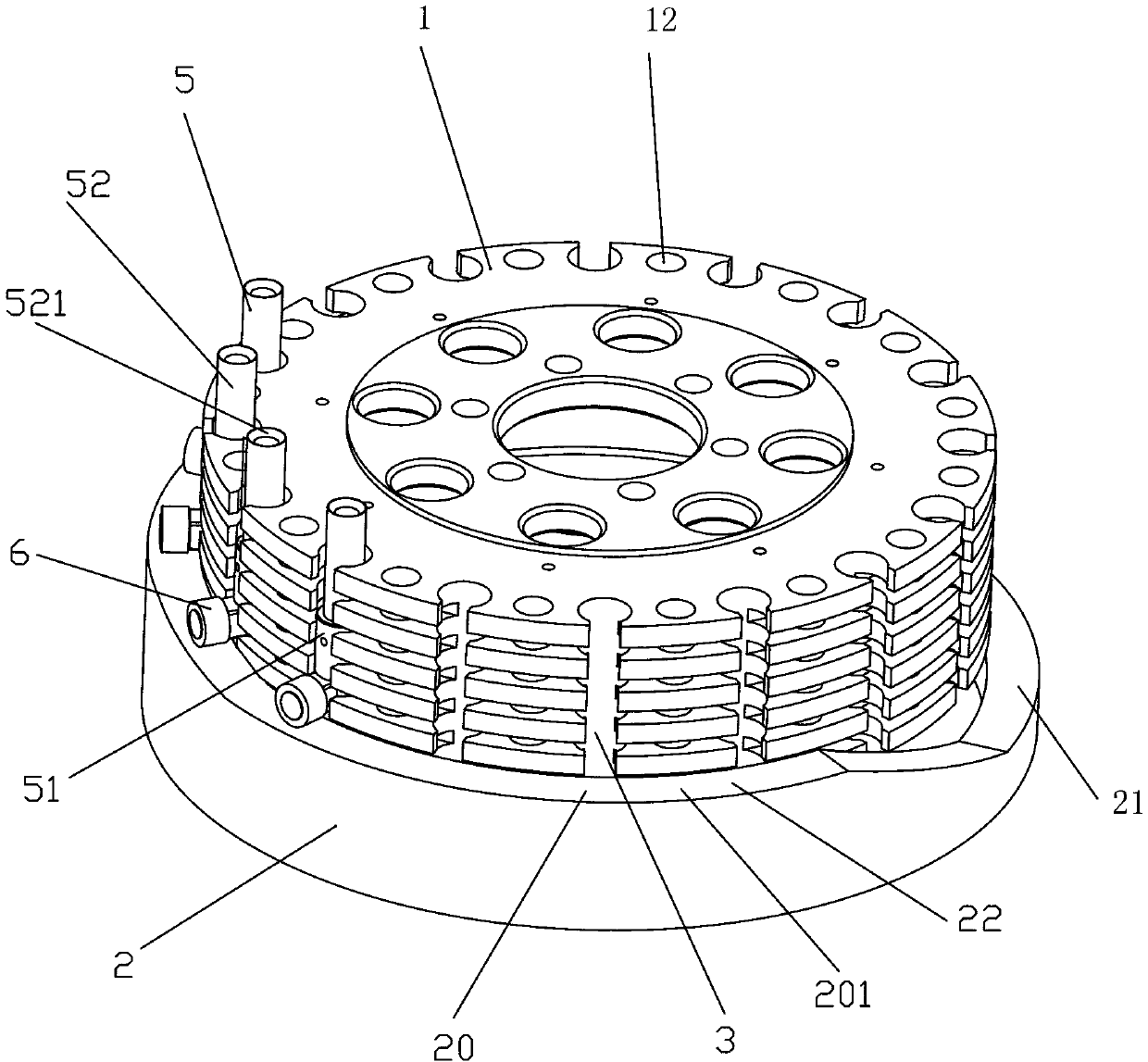

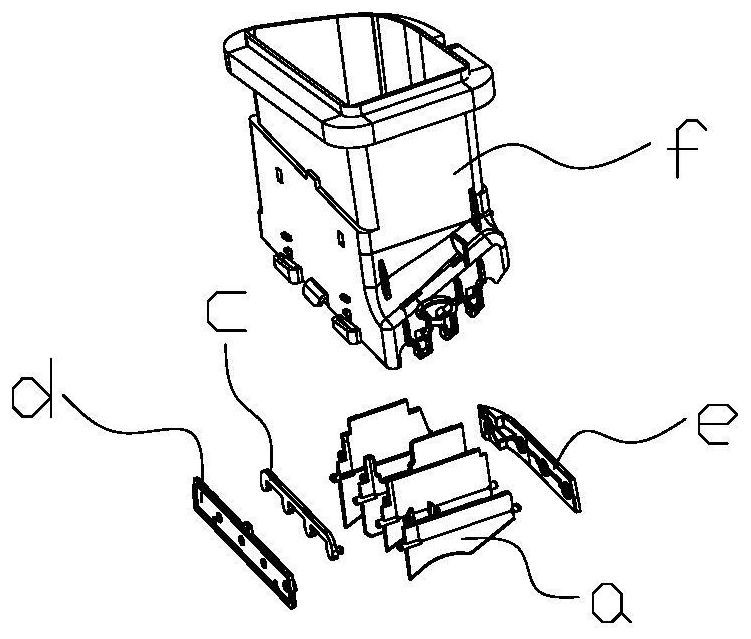

Zinc alloy button edge turning and foot fitting all-in-one machine

PendingCN113523823AImprove processing efficiencyReduce process stepsOther manufacturing equipments/toolsEngineeringZinc alloys

The invention provides a zinc alloy button edge turning and foot fitting all-in-one machine. The zinc alloy button edge turning and foot fitting all-in-one machine comprises a machine box, a button feeding rotary table device mounted at the top of the machine box, an edge turning power head assembly mounted at the top of the machine box, a vibration disc arranged on one side of the machine box, a belt feeding accelerator installed on the top of the machine box and a button foot fitting device; a discharging track of the vibration disc is connected with a feeding port of the belt feeding accelerator, and a discharging port of the belt feeding accelerator is connected with a feeding port of the button feeding rotary table device; and the button foot fitting device is mounted at the top of the machine box. The zinc alloy button edge turning and foot fitting all-in-one machine has the advantages of being high in machining efficiency and low in labor input.

Owner:李保锋

A report analysis report push method and device

ActiveCN104616134BRealize intelligent pushIncrease flexibilityOffice automationReusabilityData mining

An embodiment of the invention discloses a statement analysis report pushing method and a statement analysis report pushing device. The method comprises the following steps: obtaining the e-mail pushing task to be executed at this time; extracting the report configuration information included in the extracted e-mail pushing task; obtaining the real time report data based on the extracted report configuration information and using the report data to obtain the report; and building the report analyzing report according to the report and pushing the report analyzing report according to the e-mail transmitting mode. According to the technical scheme, the report analyzing report can be intelligently pushed, the pushing speed is faster, the degree of accuracy is high and the flexibility and reusability of the report analyzing report can be improved.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Seal character recognition device and using method thereof

ActiveCN112918973ACompact structureOverall compact sizeStorage devicesCharacter recognitionMotion recognition

The invention relates to a seal character recognition device. The seal character recognition device comprises a goods channel module, a lifting module and a recognition module, wherein the goods channel module comprises a plurality of sets of goods channel shelves, a driving assembly and a stock sensor, each set of goods channel shelf is divided into a plurality of goods channels through goods channel metal plates, the goods channels are provided with goods channel belts, and the goods channel belts are connected with the driving assembly; each set of goods channel shelf is provided with a pair of stock sensors, and the stock sensors are arranged on supporting stand columns on the two sides and are located in front of the recognition ends of the goods channels; the recognition module is installed on the lifting module, and the lifting module is used for driving the recognition module to carry out lifting motion; and the recognition area of the recognition module and the sensing area of the stock sensor cover the recognition end of the goods channel, and the range of the recognition area is larger than the range of the sensing area. According to the seal character recognition device, lifting treatment is used in the lifting frame module, the structural stability is good, and the recognition effect of the recognition module cannot be hindered; and meanwhile, different goods treatment methods can be carried out on whether the character recognition result is successful or not, and the overall treatment accuracy of the system is higher.

Owner:佛山市明睿达科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com