Feed guide device and method of freeze dryer

A technology of a guiding device and a freeze-drying machine, which is applied in the directions of packaging, packaging protection, transportation and packaging, etc., can solve the problems affecting the number of vials on a single shelf of a freeze-drying machine, irregular arrangement, and squeezing and bursting bottles, etc. Achieve the effect of avoiding product contamination risks and equipment damage, improving overall speed and speeding up push speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

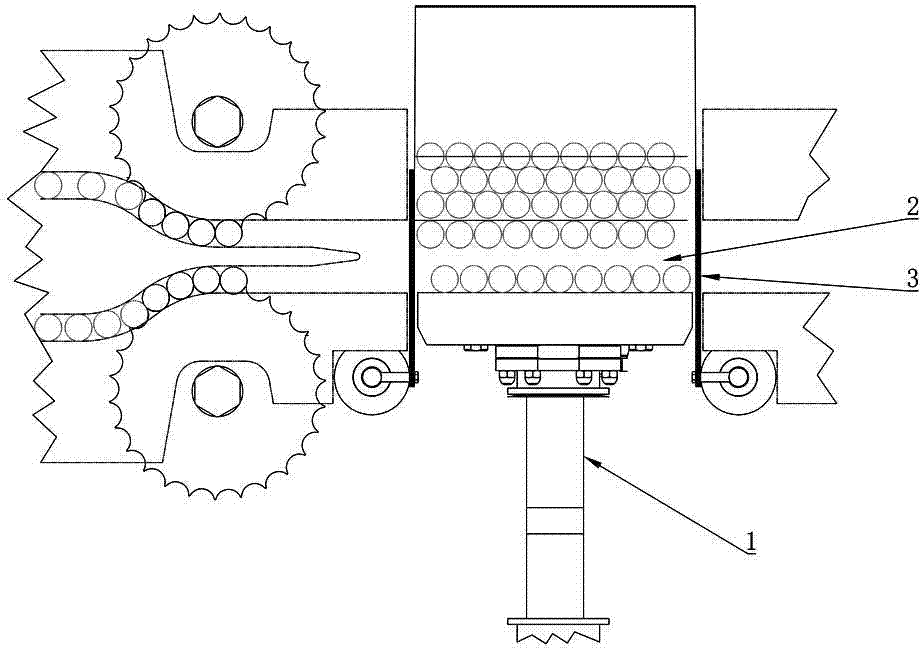

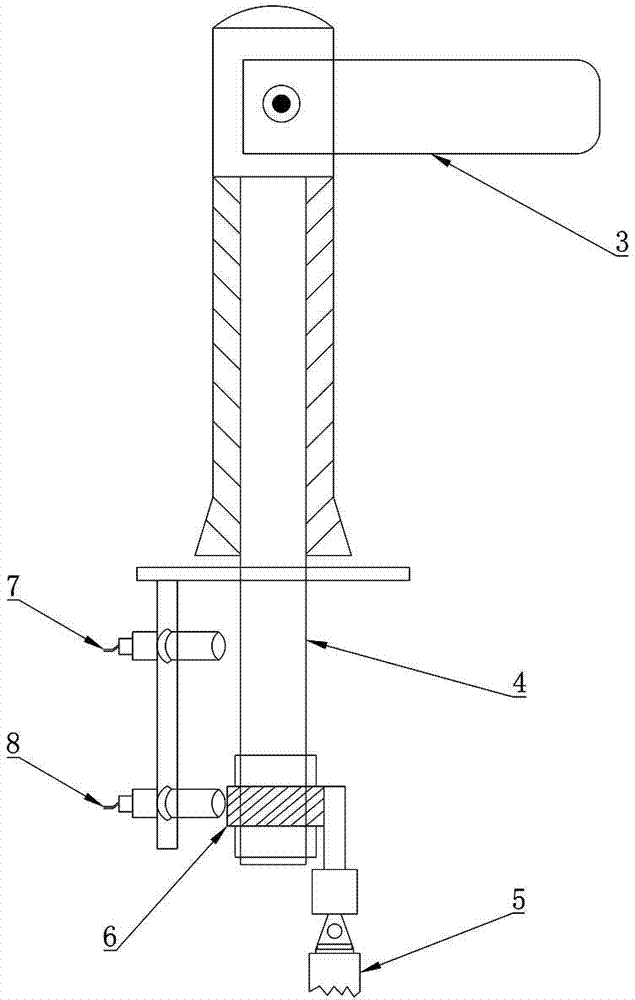

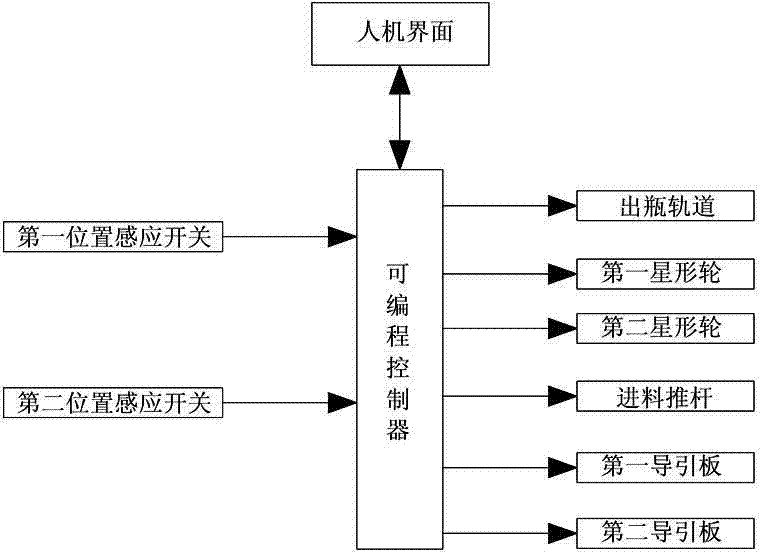

[0030] Such as figure 1 As shown, the feed guide device of the freeze dryer in this embodiment includes a guide plate 3 and a driving member. The guide plate 3 is arranged on both sides of the feed push rod 1 of the freeze dryer and is located at the outlet of the freeze dryer. Above the bottle track 2, the guide plate 3 is connected to the driver by a connecting rod 4, and the connecting rod 4 drives the guide plate 3 to lift up and down under the drive of the driver. When the feeding push rod 1 is advancing, since the two sides of the guide plate 3 are fixed, it acts as a limiter, which effectively guarantees the effect of the misalignment of the odd and even rows, and at the same time prevents the vials on the bottle outlet track from being damaged due to friction and other reasons. Sliding occurs during the advancing process, which can pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com