Brake hose assembly machining center

A technology for machining centers and brake hoses, applied in metal processing, pipeline layout, etc., can solve the problems of low processing efficiency and high processing costs of brake hose assemblies, achieve a high degree of integrated automation, and reduce machine production. Cost, the effect of fast delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

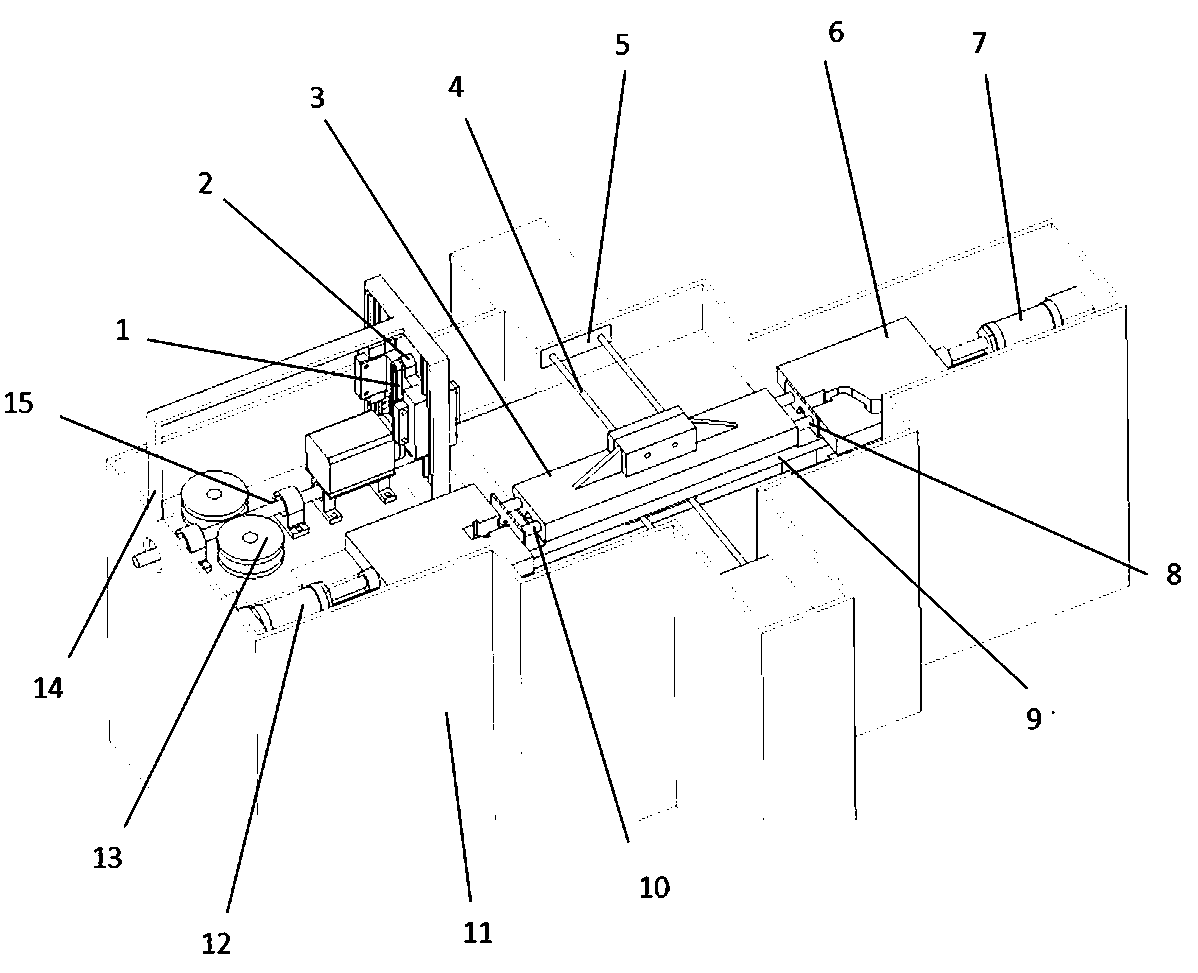

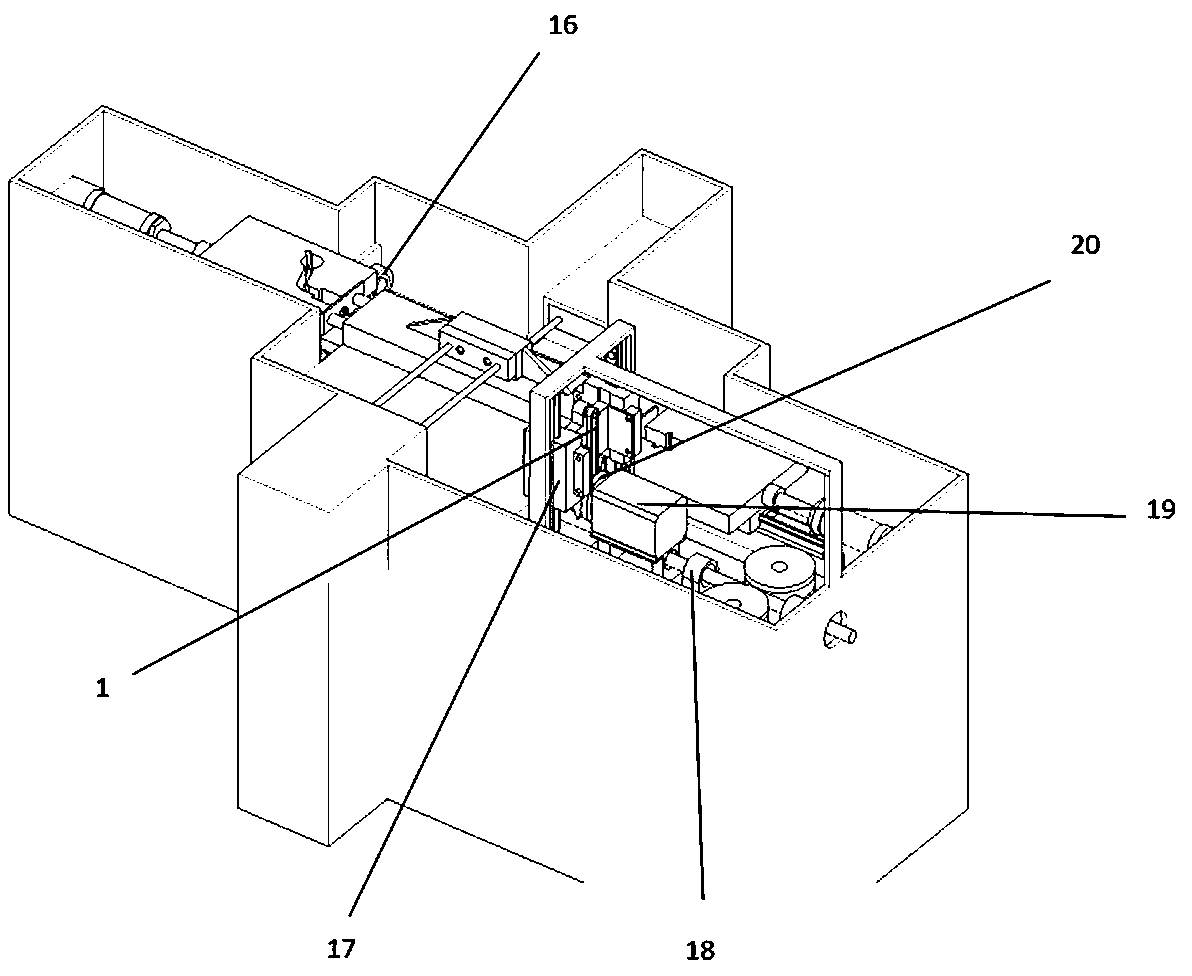

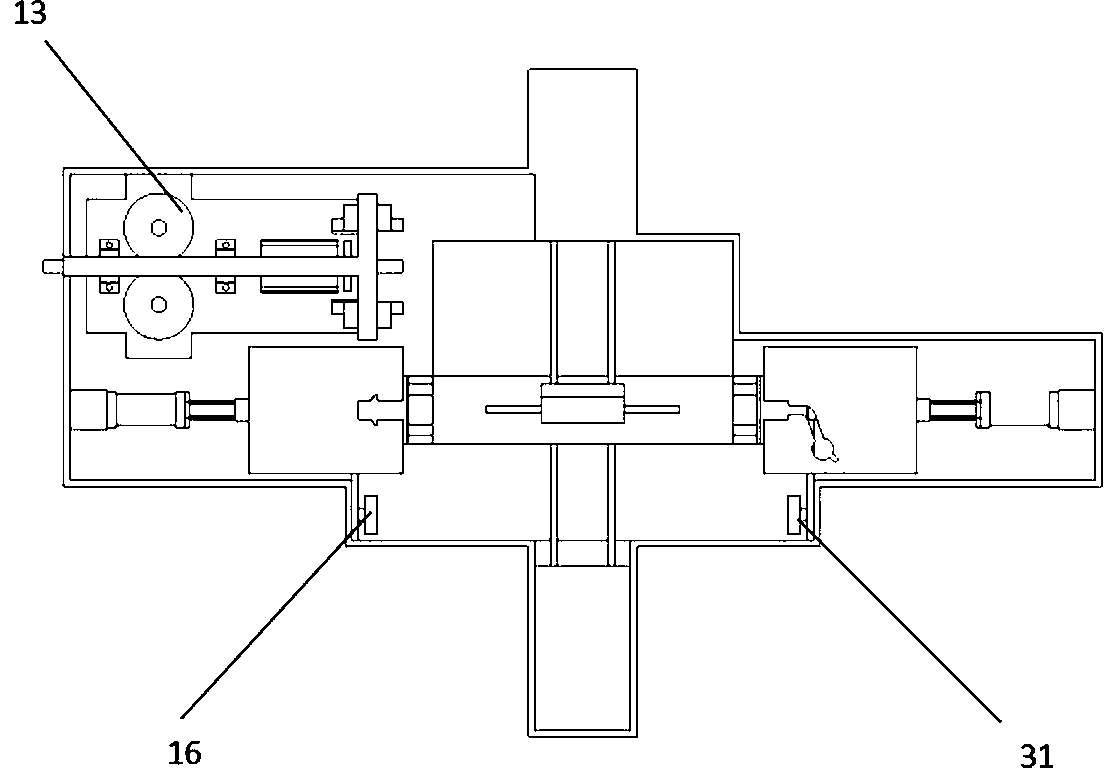

[0049] Such as figure 1 , figure 2 As shown, it is an embodiment of the brake hose assembly machining center of the present invention, which mainly includes several parts: rubber tube conveying device, rubber tube cutting device, rubber tube positioning and automatic pushing device, joint installation device And the double-sided hydraulic sealing device, the above-mentioned several devices are installed in a chassis baffle 11, and cooperate with each other to complete the production and assembly of the brake hose. Among them, the jelly tube conveying device is mainly used to straighten the coiled colloidal tubes and transport them forward along a straight line to the colloidal tube cutting device at the downstream position; the colloidal tube cutting device is used for The conveyed rubber tube is cut, and the rubber tube is cut into equal lengths; the rubber tube positioning and automatic pushing device is located downstream of the rubber tube cutting device, and is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com