Turntable mechanism of aerosol valve assembling machine

A turntable mechanism and installation machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing labor costs and production costs, slow assembly speed, time-consuming and labor-intensive, etc. The effect of fast speed and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

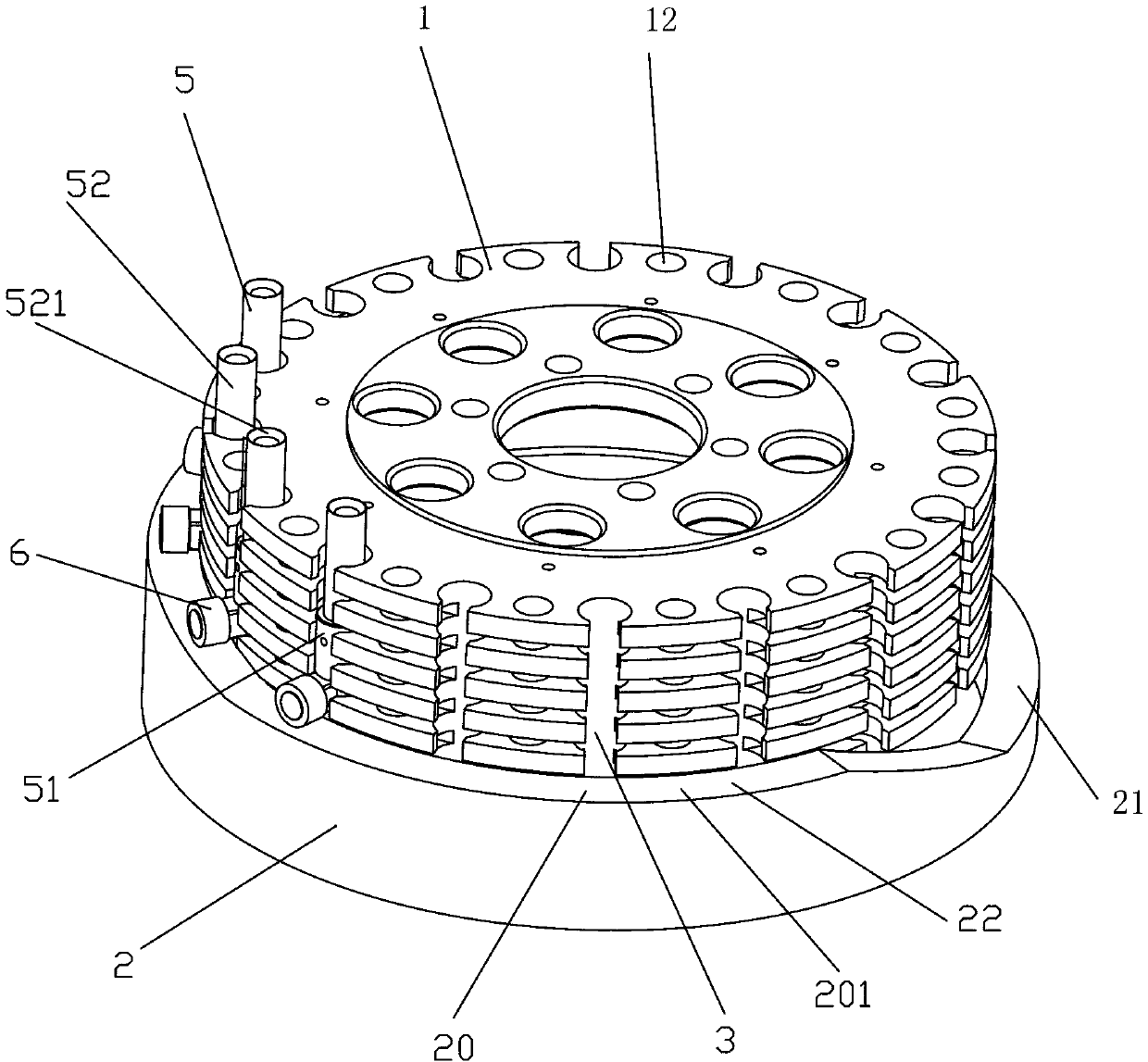

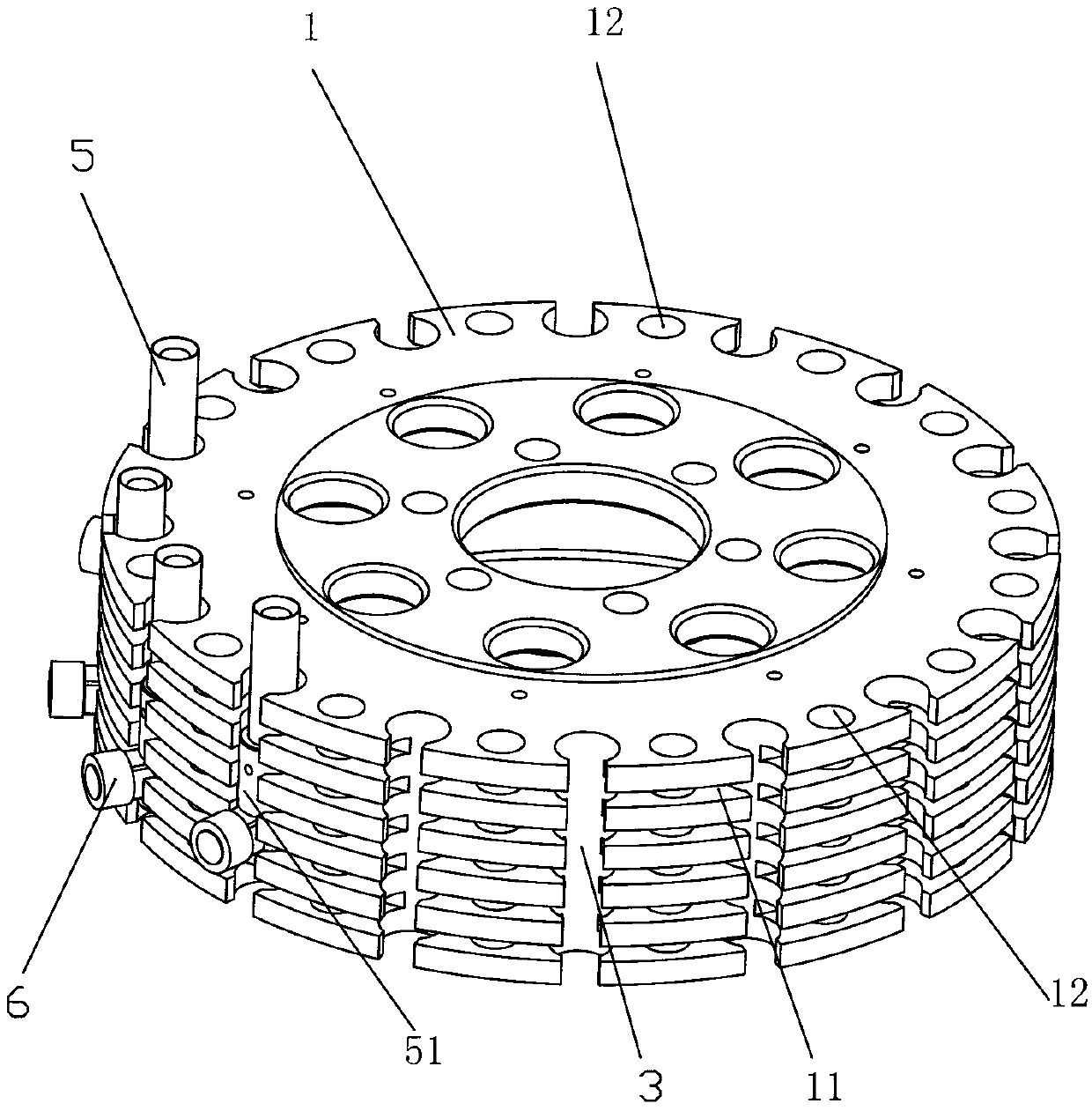

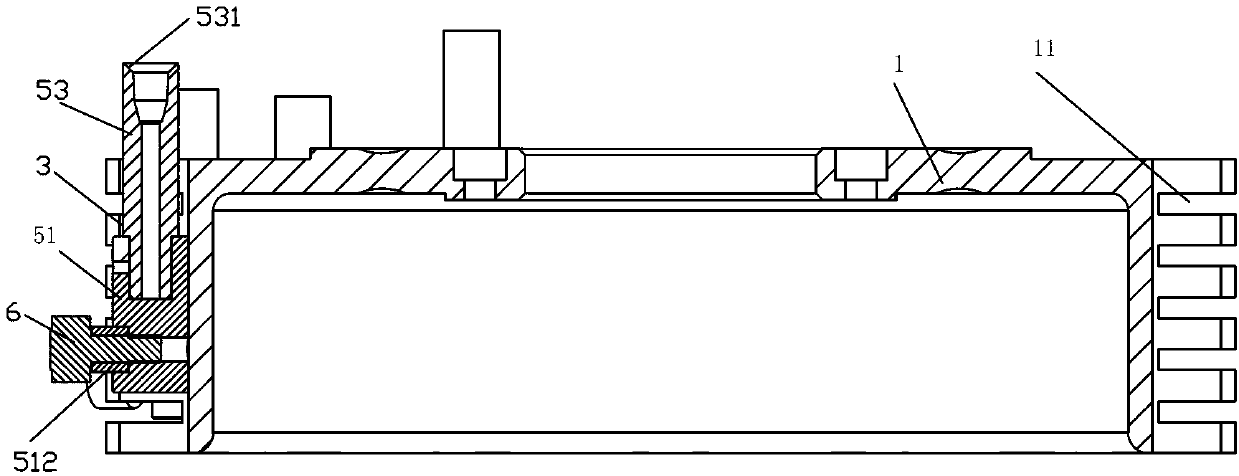

[0017] The turntable mechanism of the aerosol valve installation machine includes a turntable 1, the outer side of the turntable 1 is provided with a roller track 2, the lower roller track 2 includes a low section 21 and a high section 22, and the turntable 1 is also provided with a plurality of ejection chutes 3 , The ejector chute 3 is provided with a push rod assembly 5 that can move up and down in the ejector chute 3 , and one side of the lower end of the ejector rod assembly 5 is provided with a roller 6 that snaps into the roller track 2 .

[0018] The push rod assembly 5 includes a sliding tube 51 , and the sliding tube 51 is provided with an insertion hole 52 , and a top sleeve 53 is inserted into the insertion hole 52 . The middle of the top cover 53 is hollowed out, and a concave platform 531 is provided on the top cover 53 .

[0019] The lower end of the sliding tube 51 is provided with a square groove 511, and an orientation block 512 is fixed in the square groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com