Air compressor

一种空气压缩机、气孔的技术,应用在压力容器、机械设备、机器/发动机等方向,能够解决无法提升空气压缩机空气压缩效能、妨碍速率、影响等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

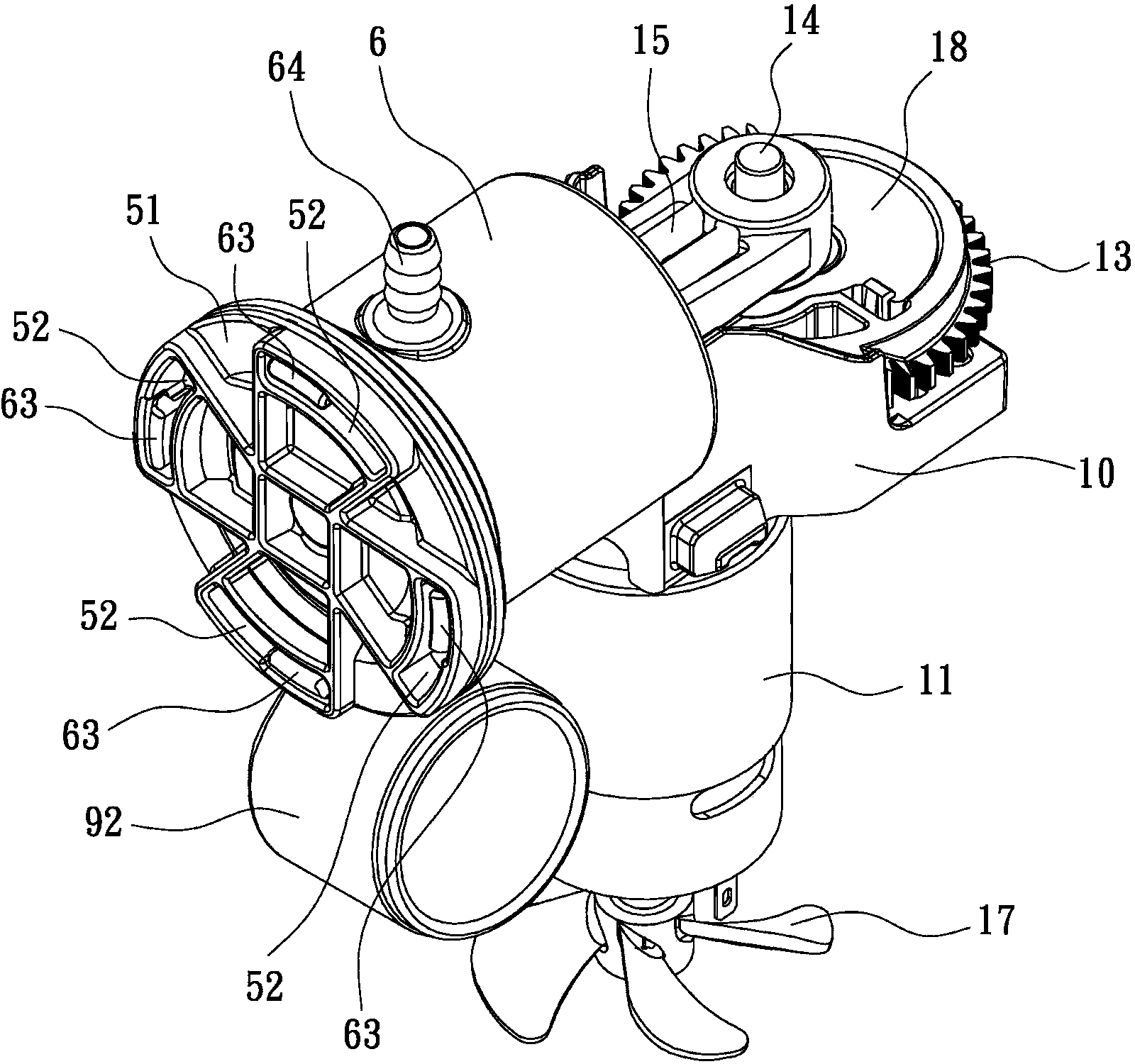

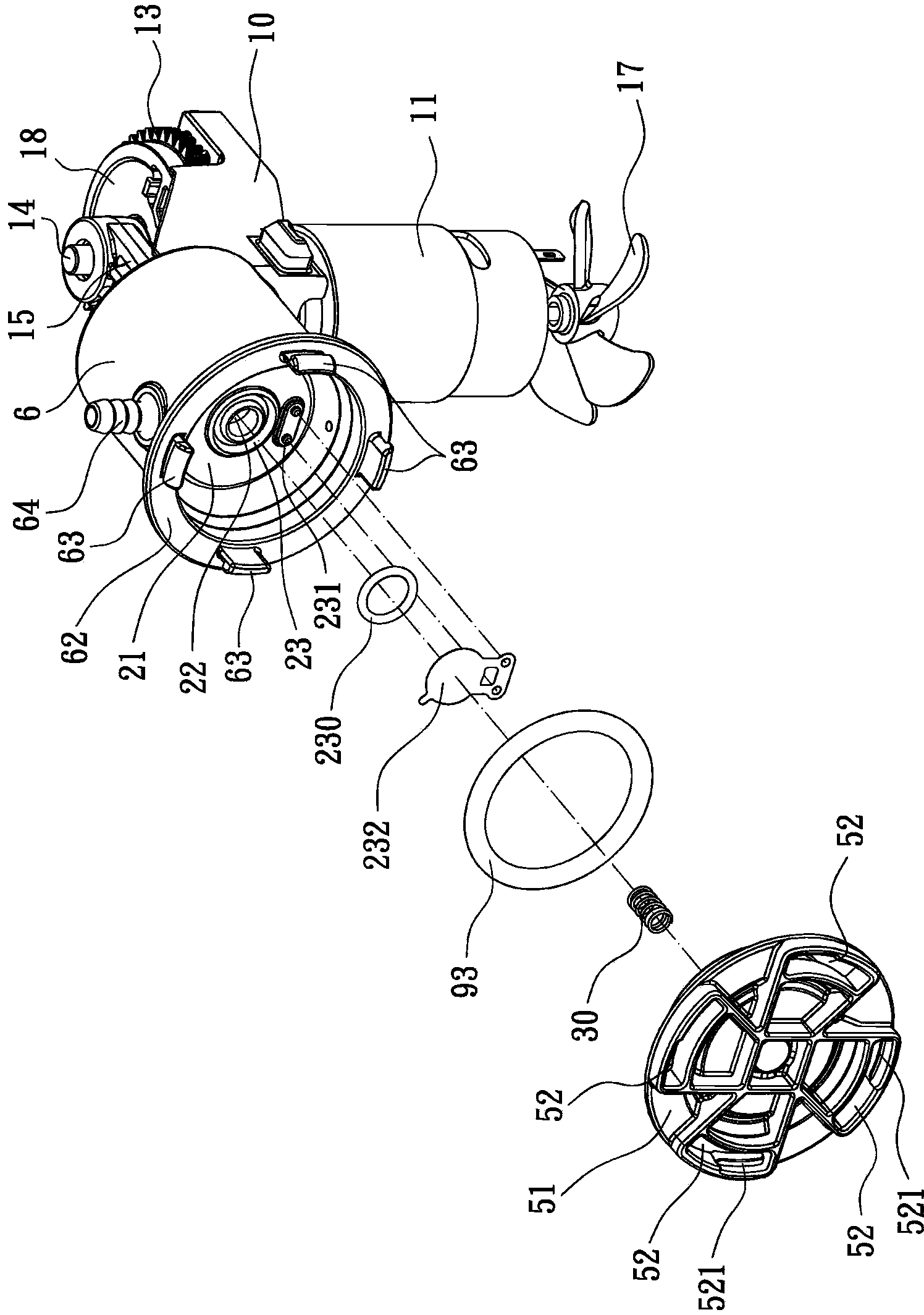

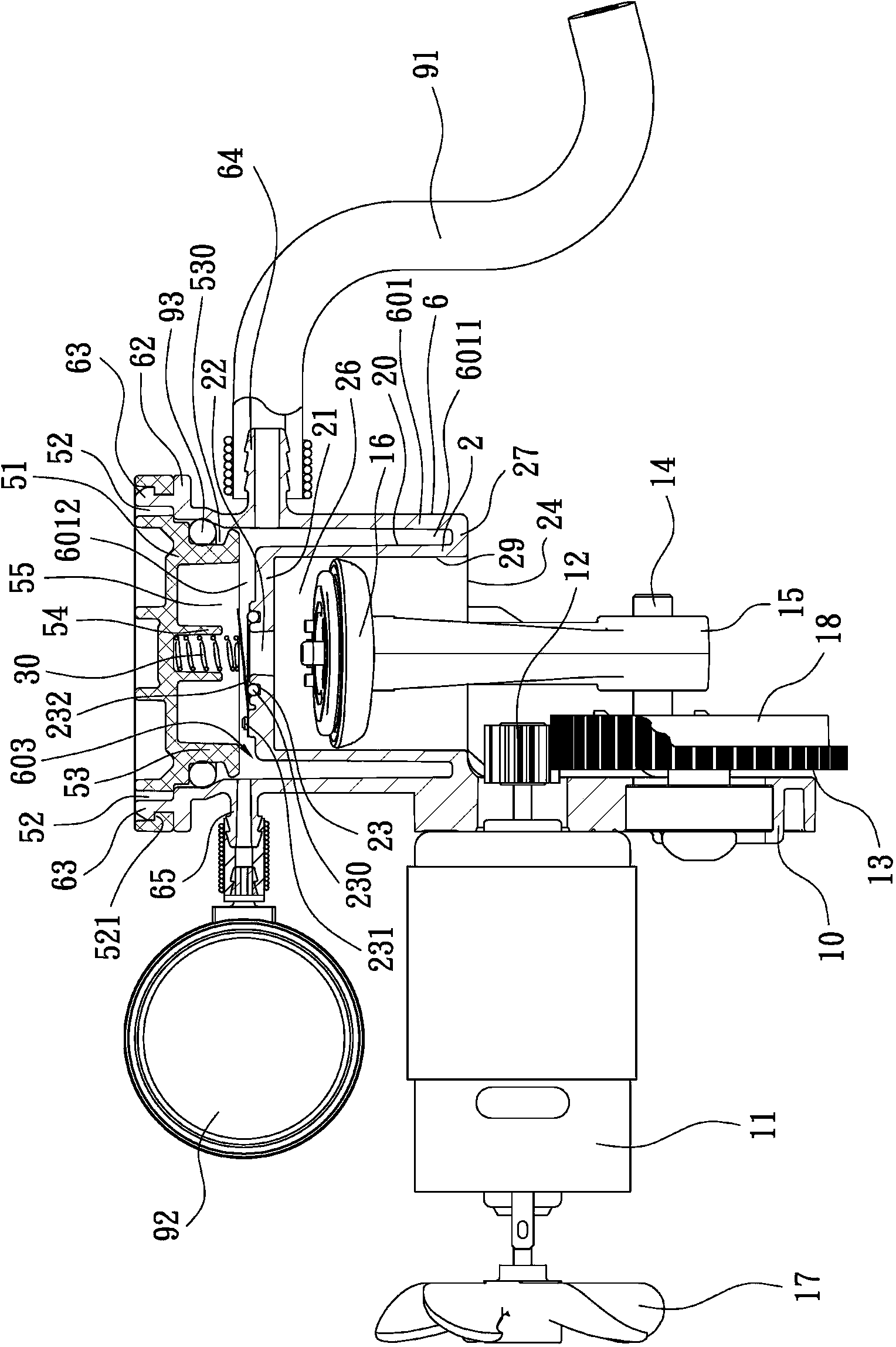

[0049] Please see first image 3 The present invention provides an air compressor, which can design the cylinder 2 that provides the operation of the piston body 15 and the main frame body 10 that provides the fixing of the motor 11 into an integrally formed structural state, and the main frame body 10 can fix the air compressor. The power mechanism includes a motor 11, a pinion gear 12 for transmission, a large gear 13, a weight rotating disk 18 with a crank pin 14, and a cooling fan blade 17 for heat dissipation. The motor 11 drives the power mechanism of the air compressor so that the piston head 16 of the piston body 15 can perform reciprocating compression in the compression chamber 26 of the cylinder 2 .

[0050] please cooperate Figure 1 to Figure 4 The cylinder 2 of the air compressor has a top wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com