Double-row feed system and method of freeze dryer

A technology of feeding system and feeding method, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of blocked vial transmission, damage to automatic feeding and discharging equipment, star wheel and vial extrusion, etc., to reduce product contamination and equipment damage, reducing the probability of bottle pouring failure, and improving the overall speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

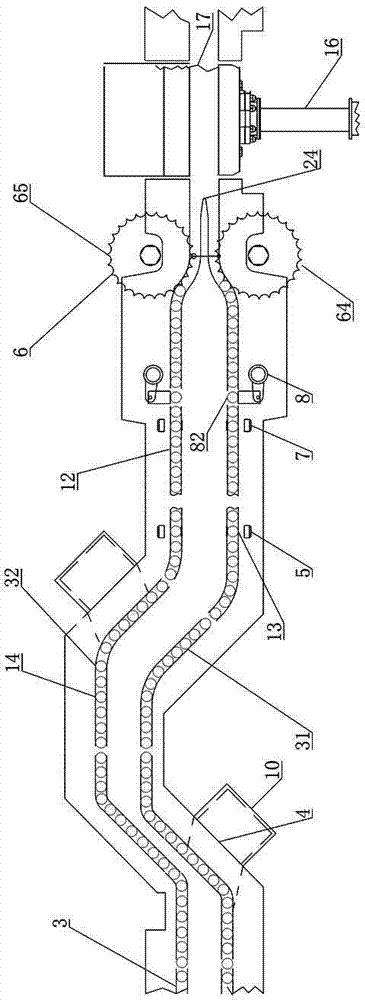

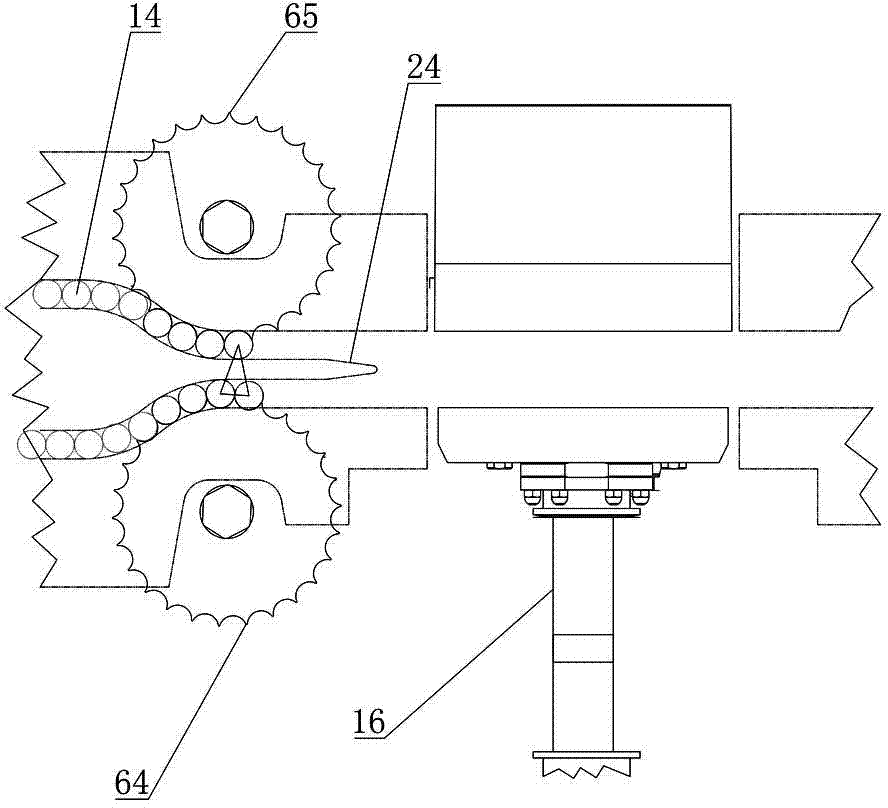

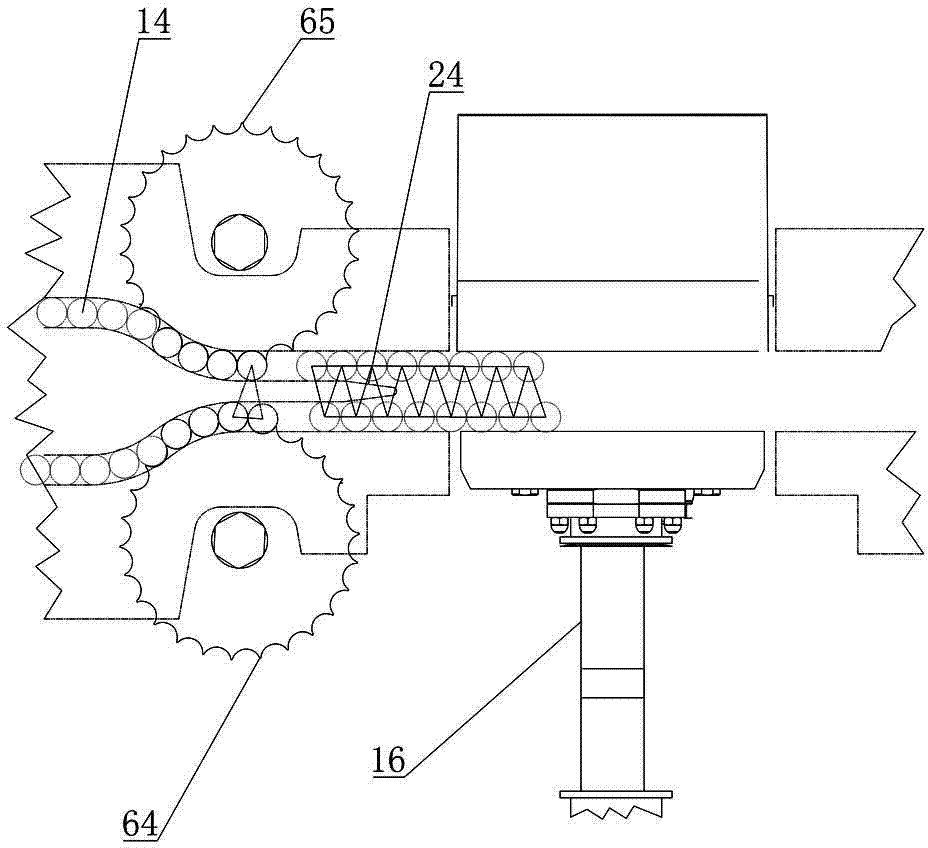

[0041] Such as Figure 1 to Figure 10 As shown, the feeding system of the lyophilizer in this embodiment includes a conveyor belt 3 and a push rod track 17 docked with the conveyor belt 3, and the conveyor belt 3 includes two parallel-running first conveyor belts 31 and a second conveyor belt 32. A first star wheel 64 is provided at the joint of the first conveyor belt 31 and the push rod track 17, a second star wheel 65 is provided at the joint of the second conveyor belt 32 and the push rod track 17, and the first star wheel 64 Set opposite to the second star wheel 65 , the vials 14 on the first conveyor belt 31 and the second conveyor belt 32 are transferred to the push rod track 17 one by one under the rotation of the first star wheel 64 and the second star wheel 65 . The feeding system of the present invention adopts the mode of double-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com