Percutaneous aortic valve implantation guide wire

A technology of aortic valve and guide wire, which is applied in the field of medical devices, can solve the problems of uneven distribution of guide wire, aortic distortion, aortic dissection, etc., achieve good bioprofiling, improve the success rate, and reduce the risk of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

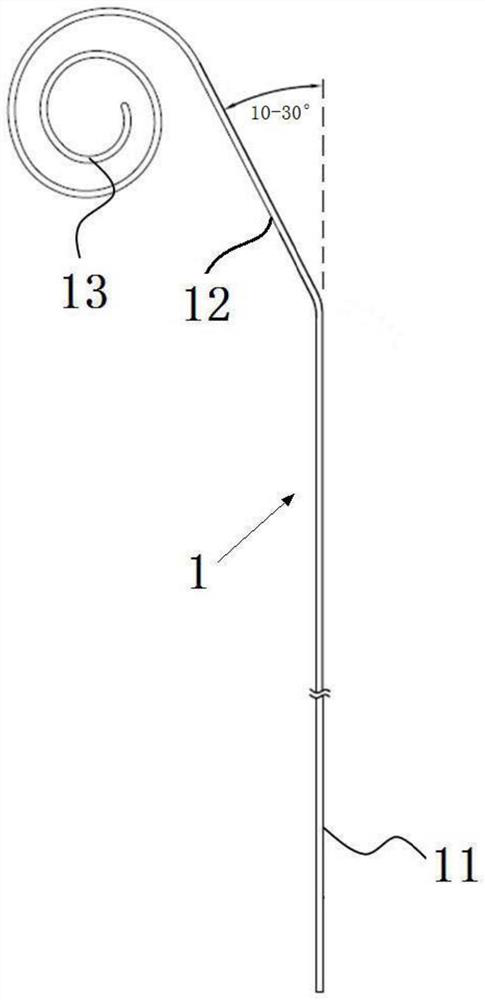

[0080] Such as figure 1 As shown, a percutaneous aortic valve implantation guide wire includes a guide wire body 1,

[0081] The guide wire body 1 includes a connected first section 11, a second section 12 and a helical section 13, the first section 11 is located at the proximal end, the helical section 13 is located at the distal end, and the two ends of the second section 12 are respectively connected to the first section 11 and the helical section 13. Helical segment 13;

[0082] There is a first included angle between the first section 11 and the second section 12; the angle of the first included angle is 30°;

[0083] The helical segment 13 is formed by coiling the guide wire into a helical circle, and the helical coils of the helical segment 13 are located in a plane; the number of helical coils of the helical segment 13 is 4 semicircles;

[0084] The plane formed by the first segment 11 and the second segment 12 coincides with the plane where the helical segment 13 is...

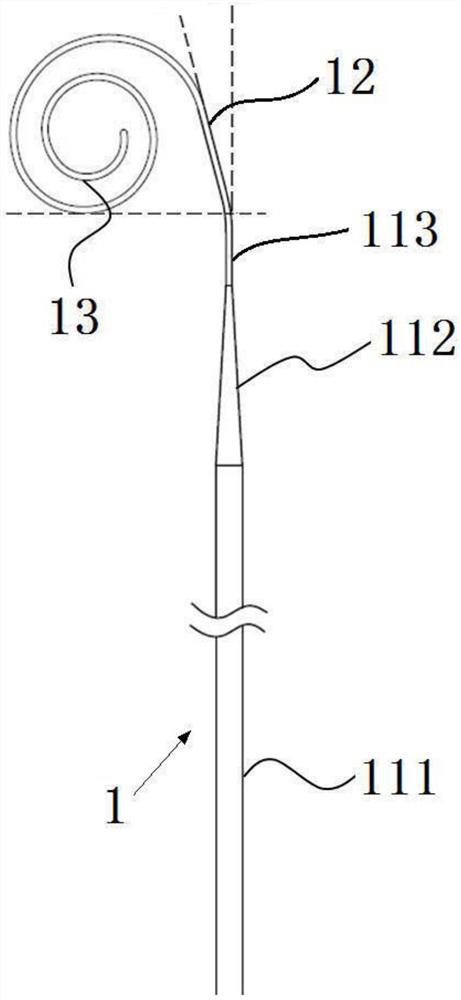

Embodiment 2

[0086] Same as Embodiment 1, except that the angle of the first included angle is 20°.

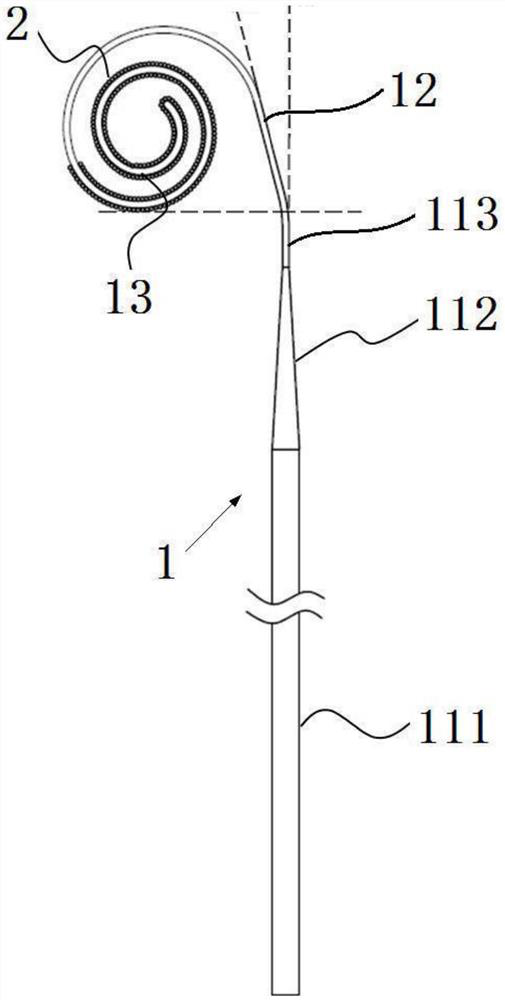

Embodiment 3

[0088] Same as Embodiment 1, the maximum diameter of the helical coil of the helical section 13 is 15 cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com