Automobile air conditioner air outlet and production equipment and method thereof

A technology for production equipment and automotive air conditioners, which is applied to other household appliances, household components, household appliances, etc., and can solve the problems of not always on the same plane, reducing the pushing speed of the push device, and reducing the integration of the push device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

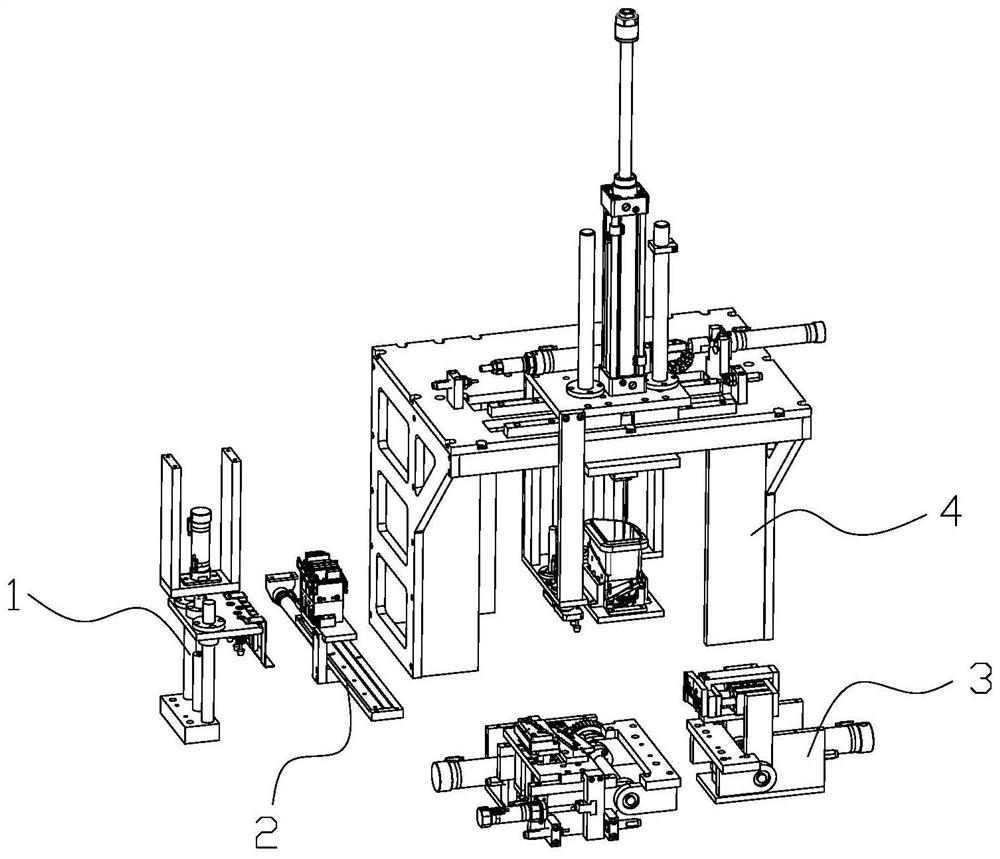

[0043] Such asfigure 1 Shown is a kind of production equipment for the air outlet of automobile air conditioner, which includes a workbench and a blade cutting device 1 fixed on the workbench, a jig conveying device 2, a fixing member installation device 3 and a pressing device 4; The cutting device 1 is connected with the pressing device 4, and the cutting device 1 is connected with one end of the jig conveying device 2; connect.

[0044] The flow direction of the automotive air conditioner blades is: the jig conveying device 2 to the blade cutting device 1 to the fixing part installation device 3 to the pressing device 4 .

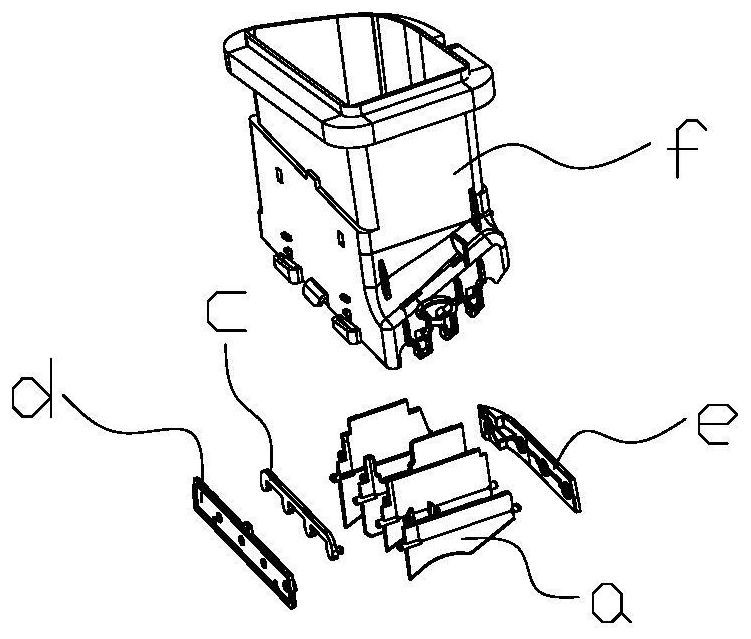

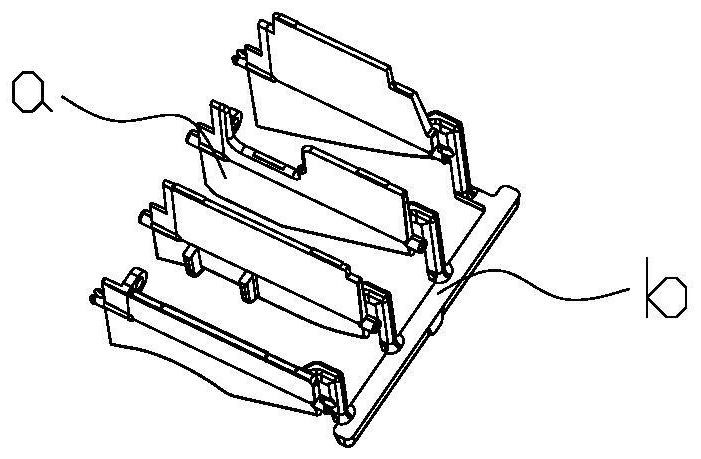

[0045] Such as figure 2 Shown is a schematic diagram of the product structure of the air outlet of the car air conditioner. The air outlet of the automobile air conditioner is composed of a blade a, a connecting rod c, a first clip d, a second clip e and an air outlet shell f: the connecting rod c and the first clip d are respectively fixed at differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com