Adsorption type embossing device used for fabric reel embossing mechanisms

An adsorption-type, roll-to-roll technology, applied in the direction of fabric surface trimming, textile and papermaking, thorn pattern, etc., can solve the problems affecting the position of embossing, fabric movement, insecurity, etc., and achieve the effect of guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

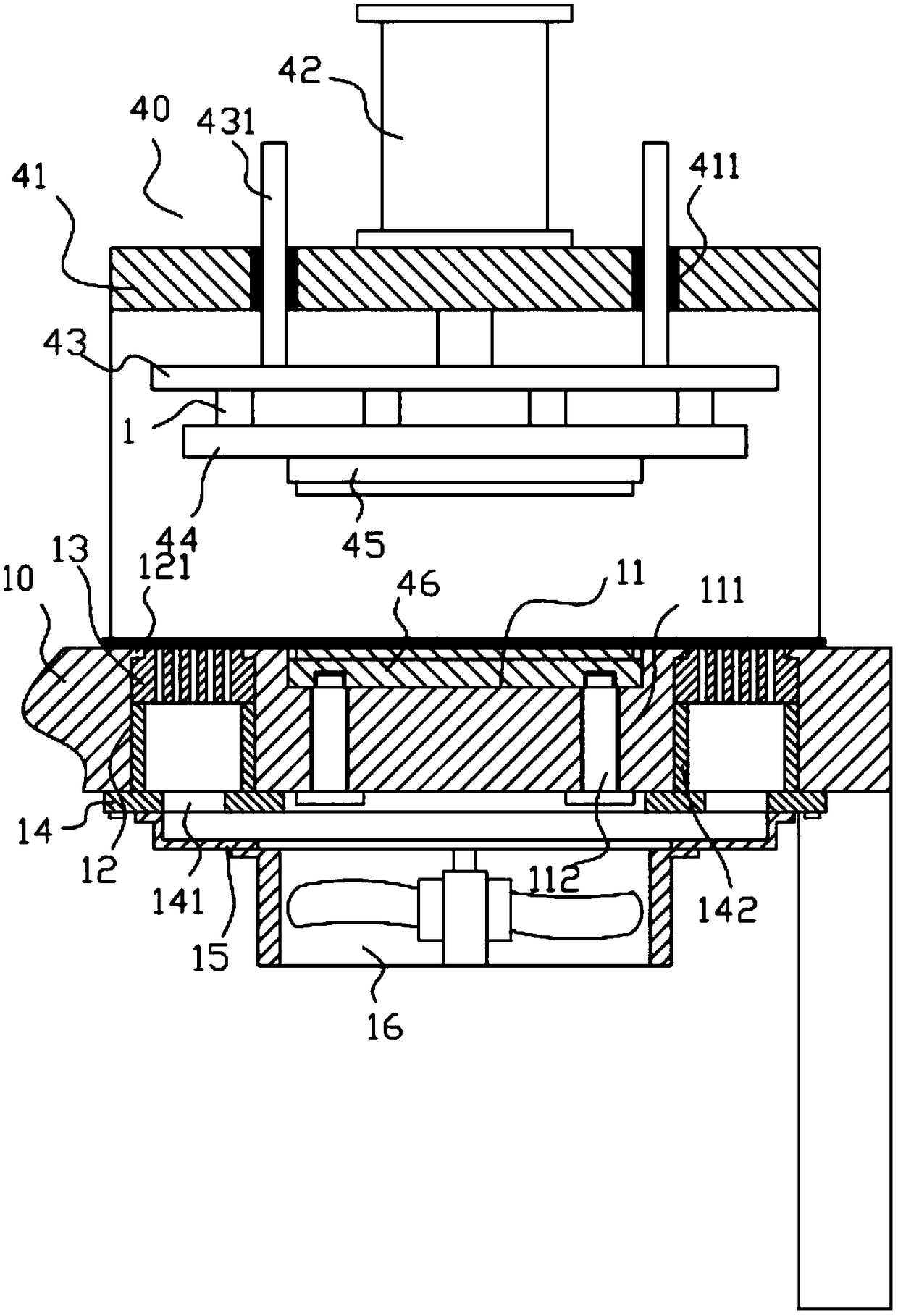

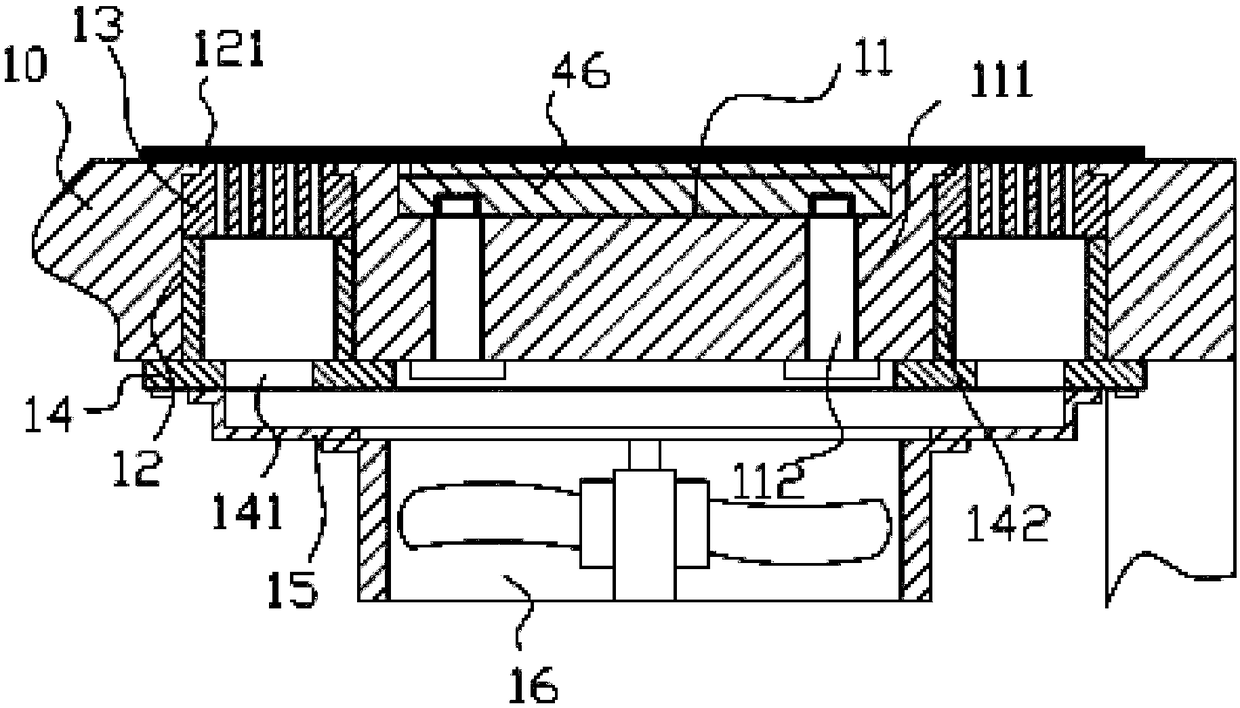

[0017] Example: see Figure 1 to Figure 2 As shown, an adsorption embossing device for a material reel embossing mechanism includes a frame 10, a main support frame 41 is fixed on the top surface of the right end of the top plate of the frame 10, and the main support frame 41 is fixed on the frame 10 On the top surface of the top plate of the main support frame 41, the top surface of the top plate of the main support frame 41 is fixed with a compression oil cylinder 42, and the push rod of the compression oil cylinder 42 passes through the top plate of the main support frame 41 and is fixed with a connecting plate 43, the bottom surface of the connection plate 43 A heating plate 44 is provided, and an upper template 45 is fixed on the bottom surface of the heating plate 44;

[0018] The top surface of the top plate of the frame 10 directly below the upper formwork 45 has an installation groove 11, and the lower formwork 46 is inserted and sleeved in the installation groove 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com