Cloth cutting and embossing equipment

A technology for embossing and cloth, which is applied in the field of cloth cutting and embossing equipment, which can solve the problems of uneven embossing, uneven force, and uneven linear force of the embossing device, so as to achieve uniform embossing force and improve Embossing effect, the effect of guaranteeing the embossing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

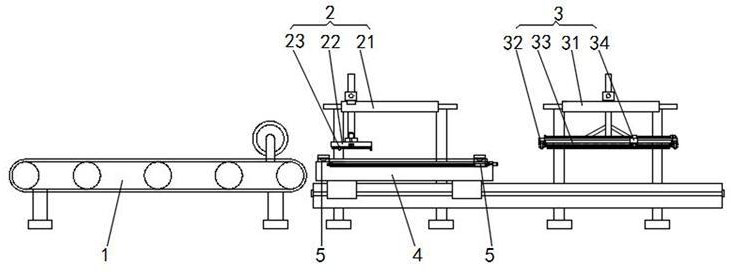

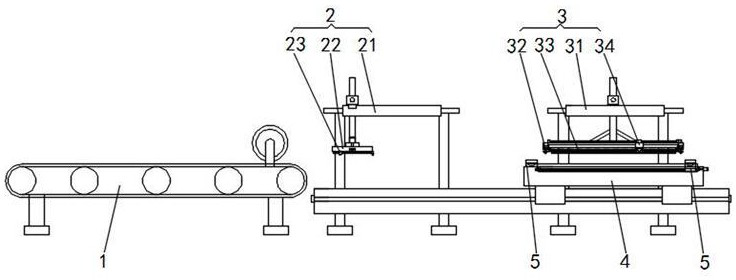

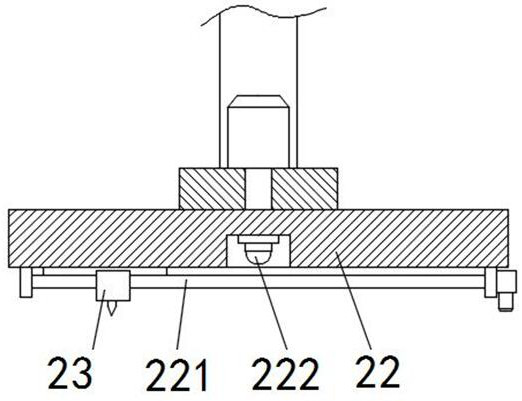

[0026] A kind of cloth cutting and embossing equipment of this embodiment, such as Figure 1-Figure 6 As shown, it includes a feeding device 1, and the discharge end of the feeding device 1 is sequentially provided with a laser cutting device 2 and an embossing device 3 along the cloth conveying direction. A moving stage 4 that moves linearly between the cutting device 2 and the embossing device 3, and cloth tensioning fixtures 5 are arranged on both sides of the moving stage 4 parallel to the direction of cloth transmission; the laser cutting device 2 includes a cutting three-axis moving device 21, a turntable 22 is installed on the moving end of the cutting three-axis moving device 21, and a cutting laser instrument 23 is arranged on the bottom of the turntable 22 for linear movement; the embossing device 3 includes an embossing three-axis moving device 31, an embossing fixture 32 is arranged on the moving end of the embossing three-axis moving device 31, and an embossing te...

Embodiment 2

[0030] This embodiment is further optimized on the basis of embodiment 1, such as Figure 4 As shown, the cloth tensioning fixture 5 includes a tensioning fixture 51, a cloth linear moving device 52, and a measuring grating, and the cloth linear moving device 52 is arranged on the moving stage 4 along the cloth conveying direction and is parallel to the cloth conveying direction. On both sides, one end of the cloth linear moving device 52 close to the feeding device 1 is fixedly provided with a tensioning fixture 51, and the moving end of the cloth linear moving device 52 is also provided with a tensioning fixture 51, and the cloth linear moving device 52 A measuring grating is arranged parallel to one side.

[0031]For ease of description, the fixedly installed tensioning fixture 51 is named as a fixed tensioning fixture 51 , and the tensioning fixture 51 installed on the moving end of the cloth linear moving device 52 is named as a moving tensioning fixture 51 . One end whe...

Embodiment 3

[0034] This embodiment is further optimized on the basis of above-mentioned embodiment 1 or 2, such as Figure 4 As shown, the tensioning fixture 51 includes a first clamping block 511, a second clamping block 512, and a pneumatic telescopic rod 513. The first clamping block 511 is fixedly arranged at one end of the cloth linear moving device 52 close to the feeding device 1 or fixed Set on the moving end of the cloth linear moving device 52, the top of the first clamping block 511 is provided with a pneumatic telescopic rod 513 that rises and falls in the vertical direction, and a second clamping block 512 is arranged on the pneumatic telescopic rod 513, A gap is formed between the first clamping block 511 and the second clamping block 512 for the edge of the cloth to enter.

[0035] When the tensioning clamp 51 is in the loosened state, the pneumatic telescopic rod 513 is in the raised state, and then drives the second clamping block 512 and the first clamping block 511 to l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com