Efficient filler production die

A high-efficiency, mold-based technology, applied in decorative arts, embossed decorative parts, etc., can solve problems such as unfavorable production efficiency and improvement, and achieve the effect of ensuring the embossing effect, easy to use, and not easy to loosen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

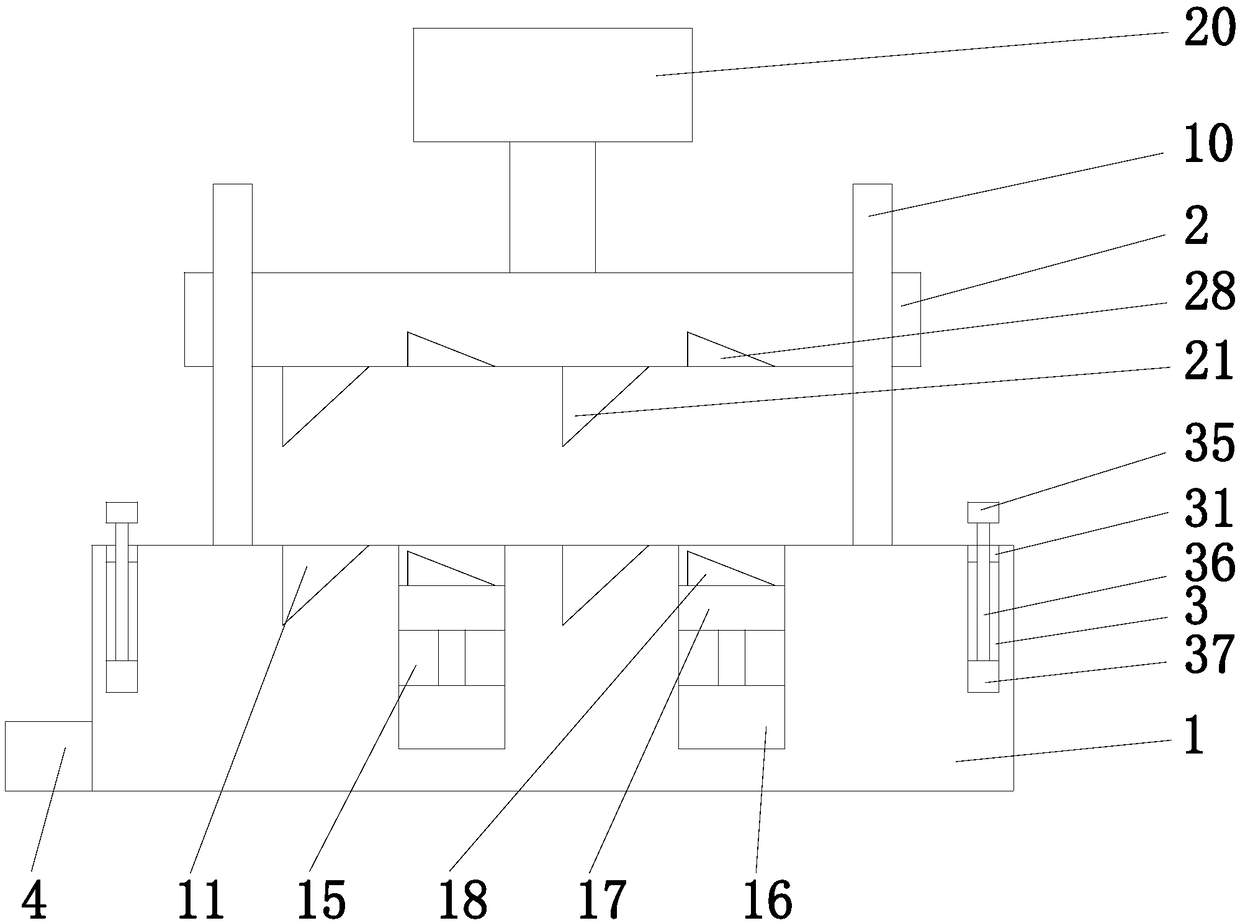

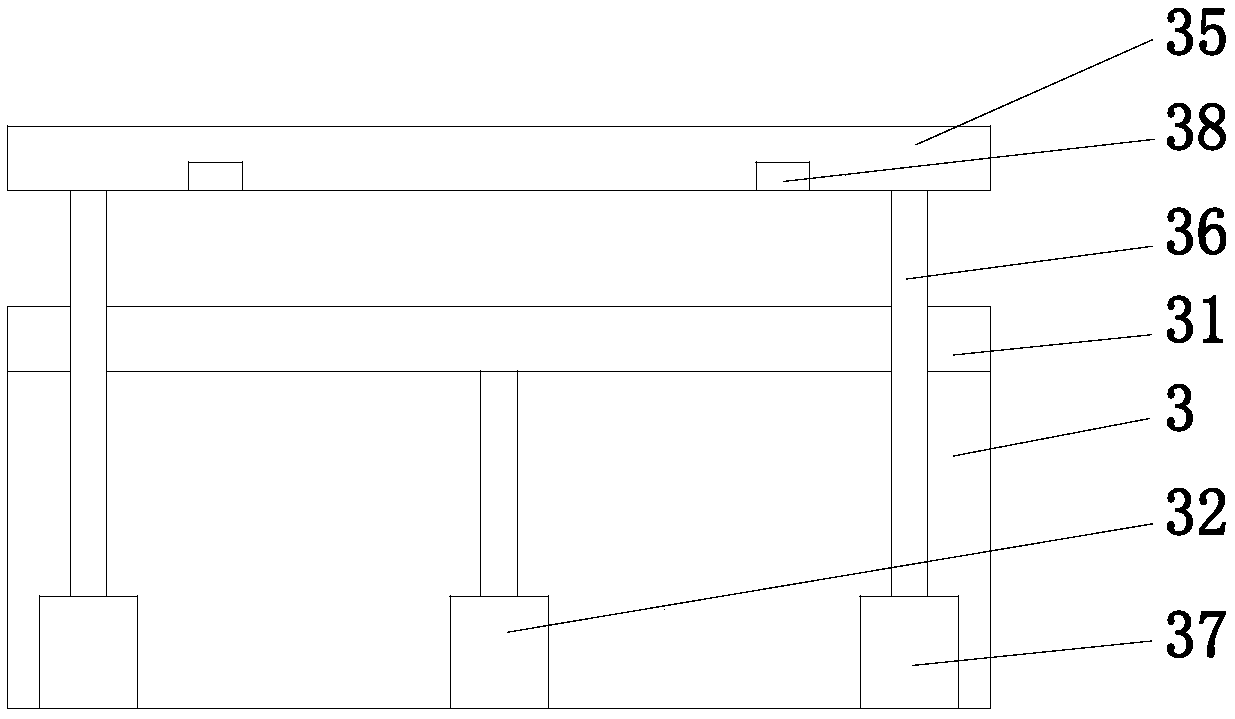

[0016] refer to figure 1 with figure 2 , a kind of high-efficiency filler production mold of the present invention comprises lower die body 1, upper die body 2, lower clamping plate 31, upper clamping plate 35, upper bump 21, lower bump 18, upper groove 28, The lower groove 11, the control device 4, the left and right sides of the lower mold body 1 are respectively provided with a strip-shaped auxiliary groove 3, and a first lifting device 32 is installed in the middle of the bottom of the auxiliary groove 3, and the first lifting device 32 is connected with the A lower clamping plate 31 is connected, and an upper clamping plate 35 is arranged directly above the lower clamping plate 31. A second lifting device 37 is respectively installed on both sides of the bottom of the auxiliary tank 3, and the top of the second lifting device 37 is It is a connecting rod 36, the connecting rod 36 passes through the lower clamping plate 31 and is connected with the upper clamping plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com