Semi-arc conveying belt used for conveying spherical objects

A semi-arc, conveyor belt technology, applied in the field of conveyor belts, can solve the problems that flat conveyor belts cannot convey round rolling objects, the silicone layer is prone to bubbles, and the endless belt cannot be changed, etc. Light weight and good slotting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

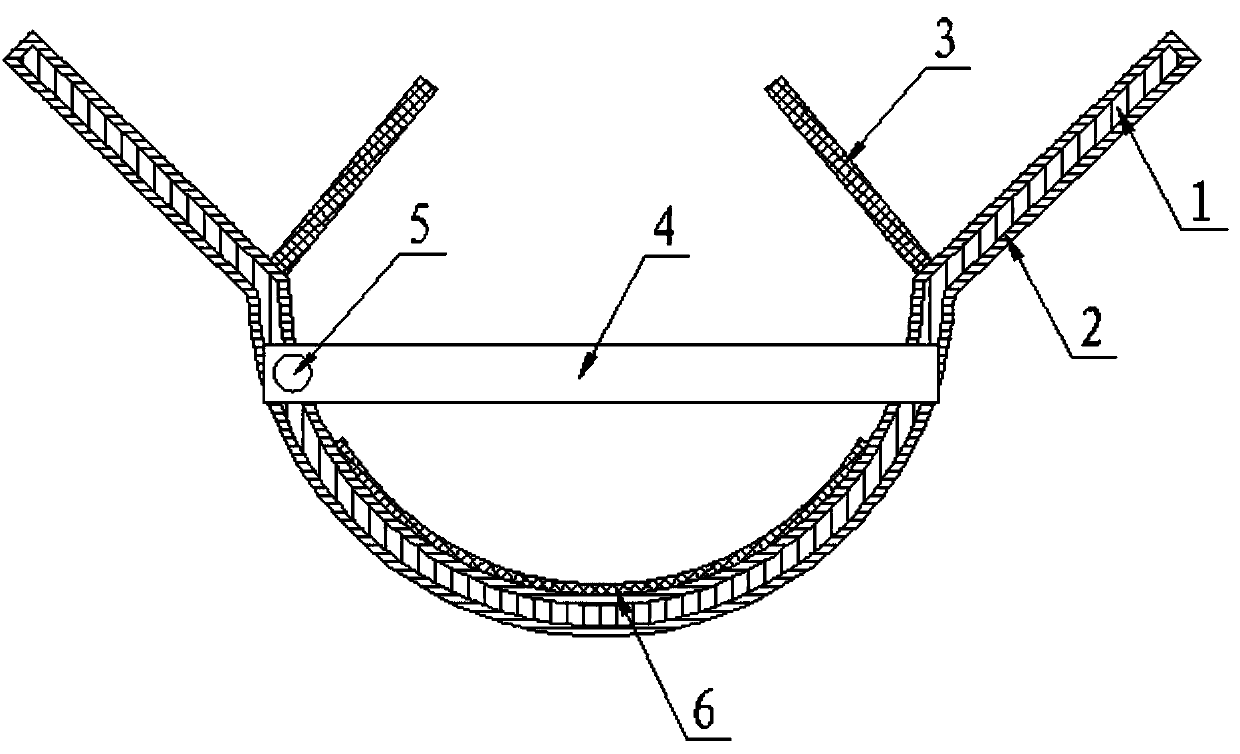

[0020] Embodiment 1: a kind of semi-arc conveyer belt that is used to convey ball, as figure 1 As shown, it includes a skeleton layer 1, an outer covering layer 2, a baffle plate 3, a hinge 4 and a hinge switch 5, the skeleton layer 1 is arranged in the outer covering layer 2, and the skeleton layer 1 is an integral belt core composed of three layers superimposed on each other. The first and fifth layers are dipped canvas made of radial and weft nylon industrial filaments, and the second layer is dipped cord fabric made of radial and weft nylon industrial filaments. The upper end of the overall belt core is V The outer cover layer 2 is a plastic cover layer, and the baffle plate 3 is fixedly arranged at the joint between the upper end and the lower end of the skeleton layer 1, and the internal connection surface between the baffle plate 3 and the lower end surface of the skeleton layer 1 The angle between them is 130°, the baffle 3 is a soft baffle, and the hinge 4 is arranged...

Embodiment 2

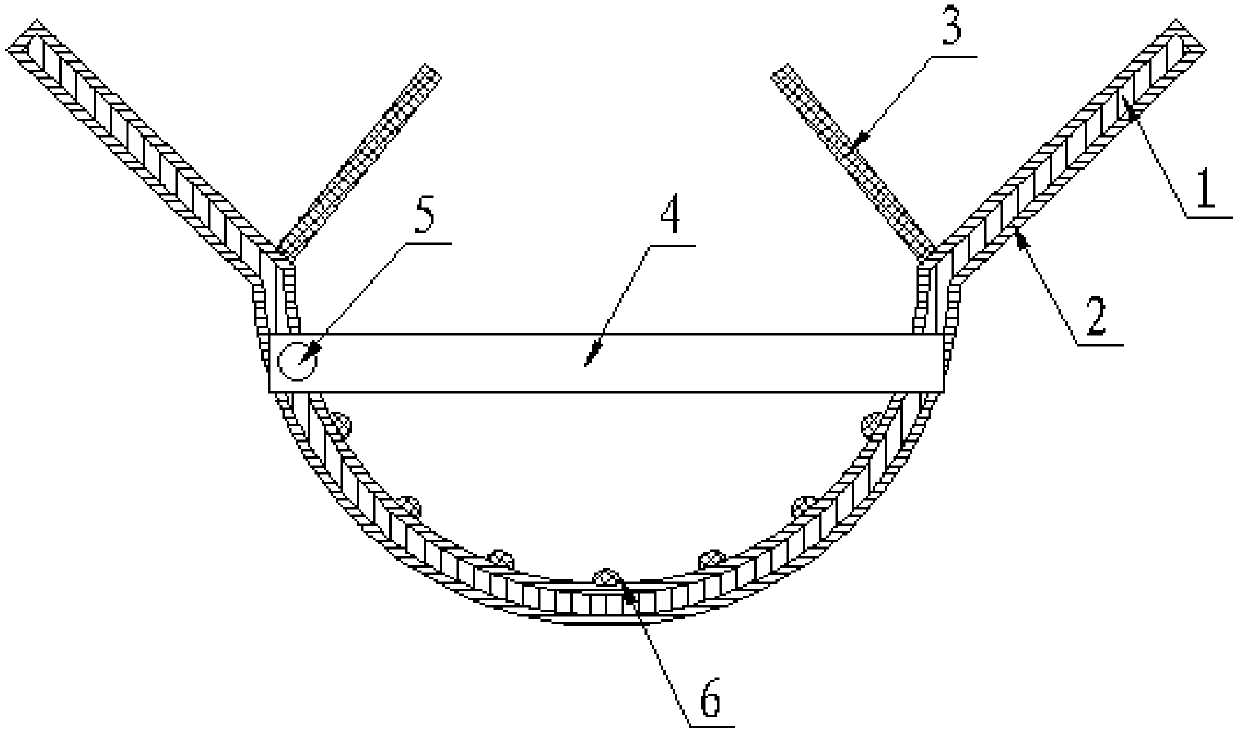

[0021] Embodiment 2: The difference with Embodiment 1 is that, as figure 2 As shown, the anti-slip structure 4 is protruding anti-slip dots arranged at intervals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com