Special overturn detection mechanism for elevator panel

A technology for elevator panels and detection mechanisms, applied in the direction of clockwork mechanisms, lifting devices, rollers, etc., can solve problems such as labor-intensive, low efficiency, and unsafety, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

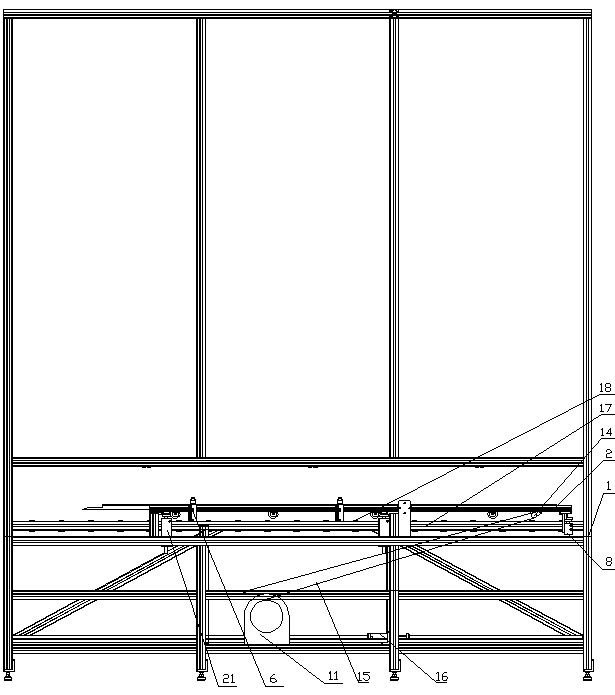

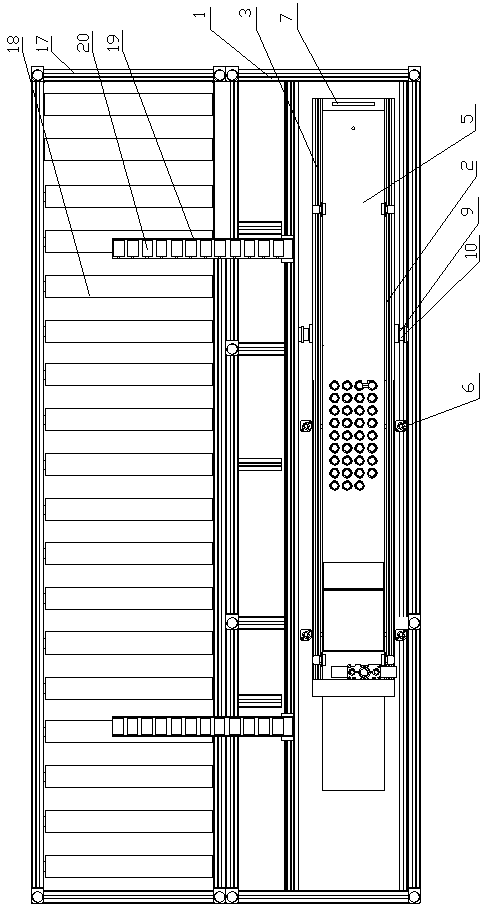

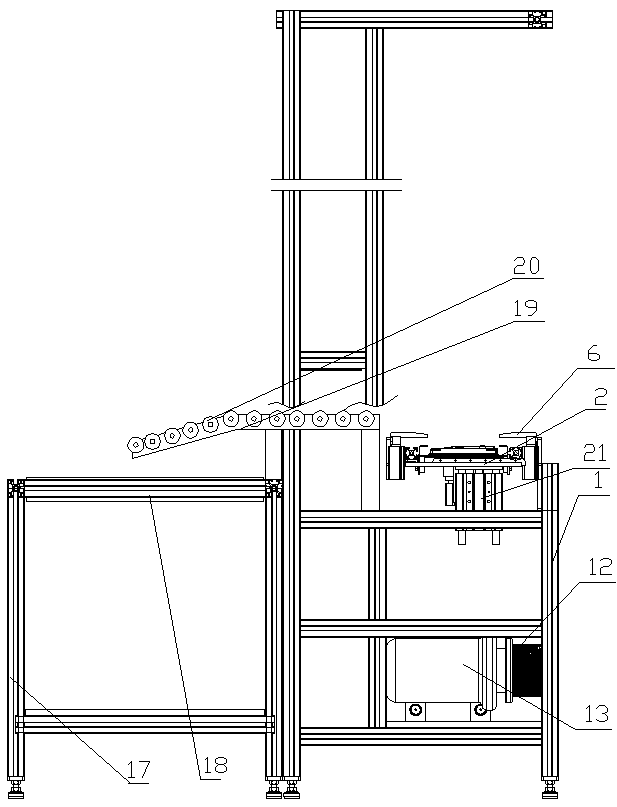

[0018] Such as figure 1 , 2 , 3, shown in 4, the present invention comprises frame 1, the profile support 2 that is rotatably installed on the frame 1, the both sides of profile support 2 width directions are equipped with the fixed shaft 9 that symmetrically arranges, and fixed shaft 9 deflects profile support 2 On the right side in the length direction, two bearing blocks 10 cooperating with the fixed shaft 9 are installed on the frame 1, and the profile support 2 is rotated and installed on the bearing blocks 10 by the fixed shafts 9 on both sides to form the rotation fulcrum of the profile support 2.

[0019] The profile support 2 includes two profiles 3 arranged at intervals, and there are multiple support plates 4 arranged at intervals for supporting the elevator panel 5 connected between the profiles 3, and two profiles 3 are also installed with a support plate for fixing and compressing the elevator panel 5. Rotary compression cylinder 6 on profile support 2, rotary c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com