Hydraulic system for loading machine working device

A technology for working devices and hydraulic systems, applied in the directions of fluid pressure actuation system components, loading/unloading, fluid pressure actuation devices, etc., and can solve problems such as poor lift translation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation will be described below in conjunction with the accompanying drawings.

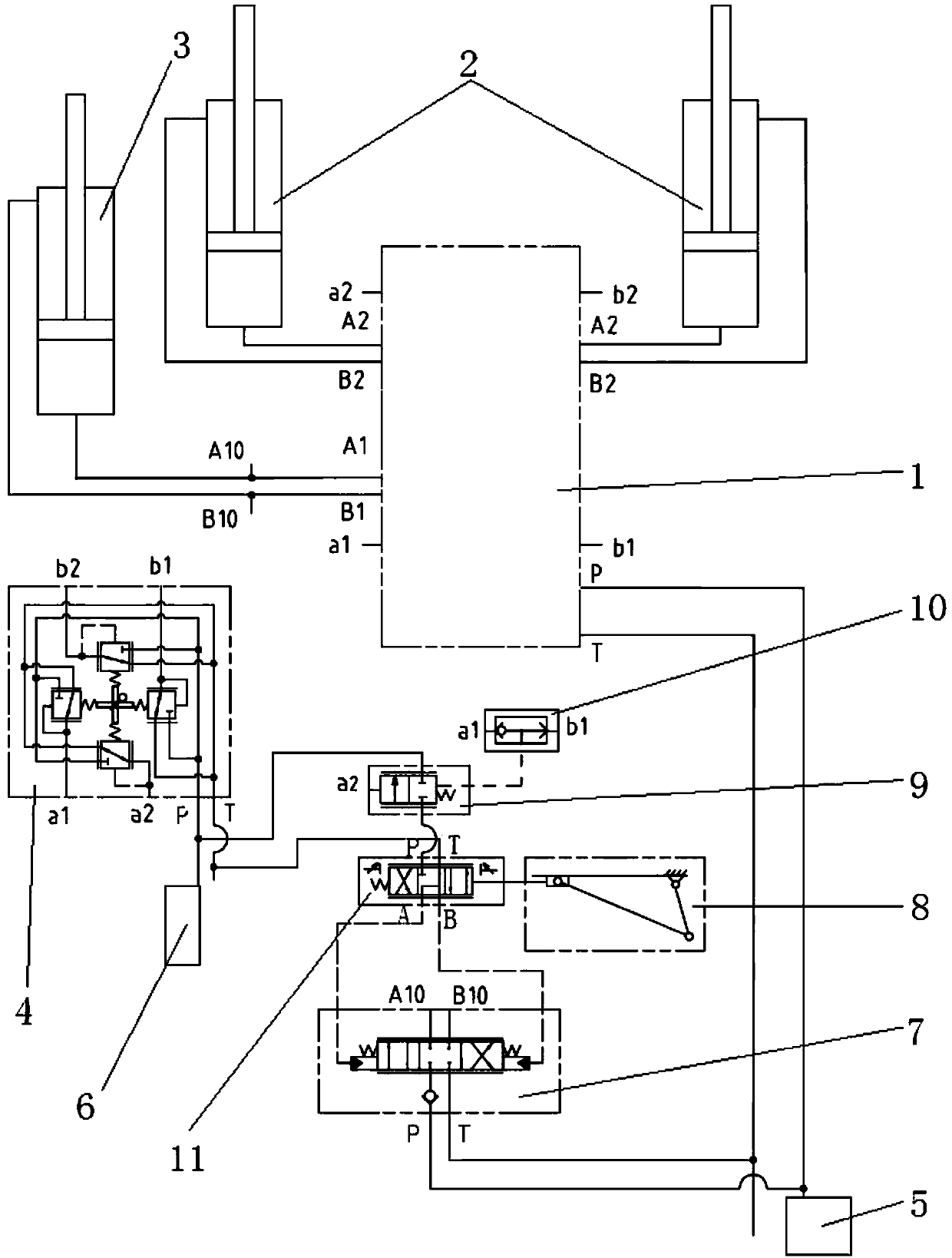

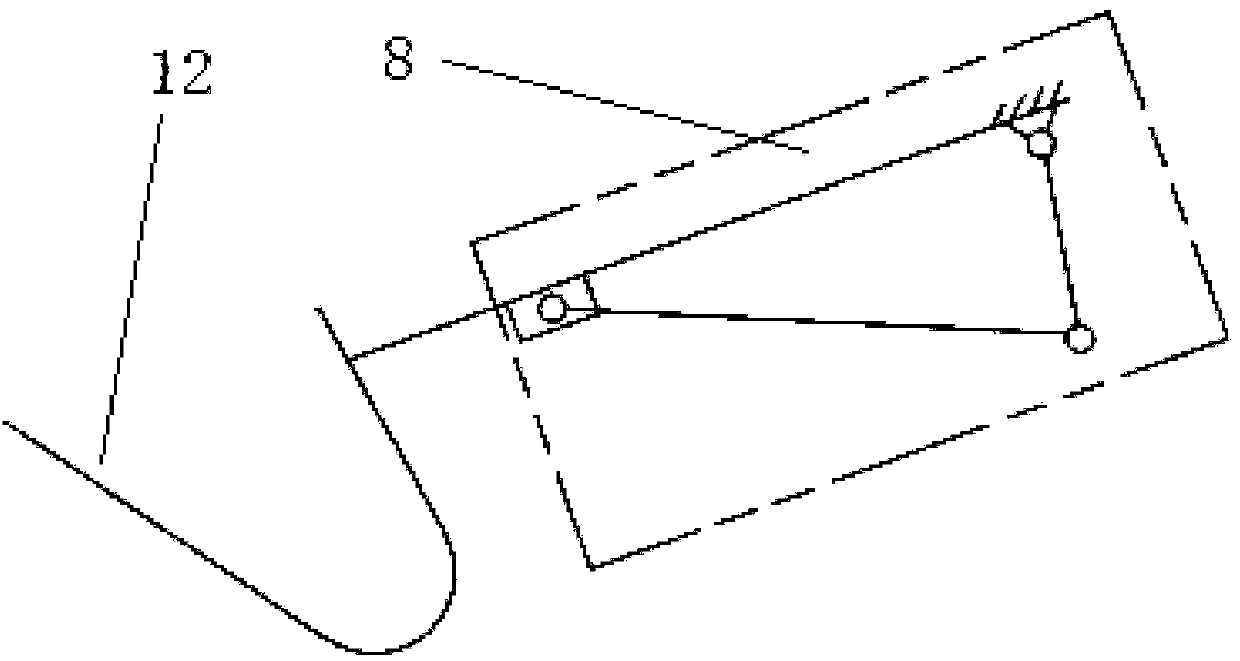

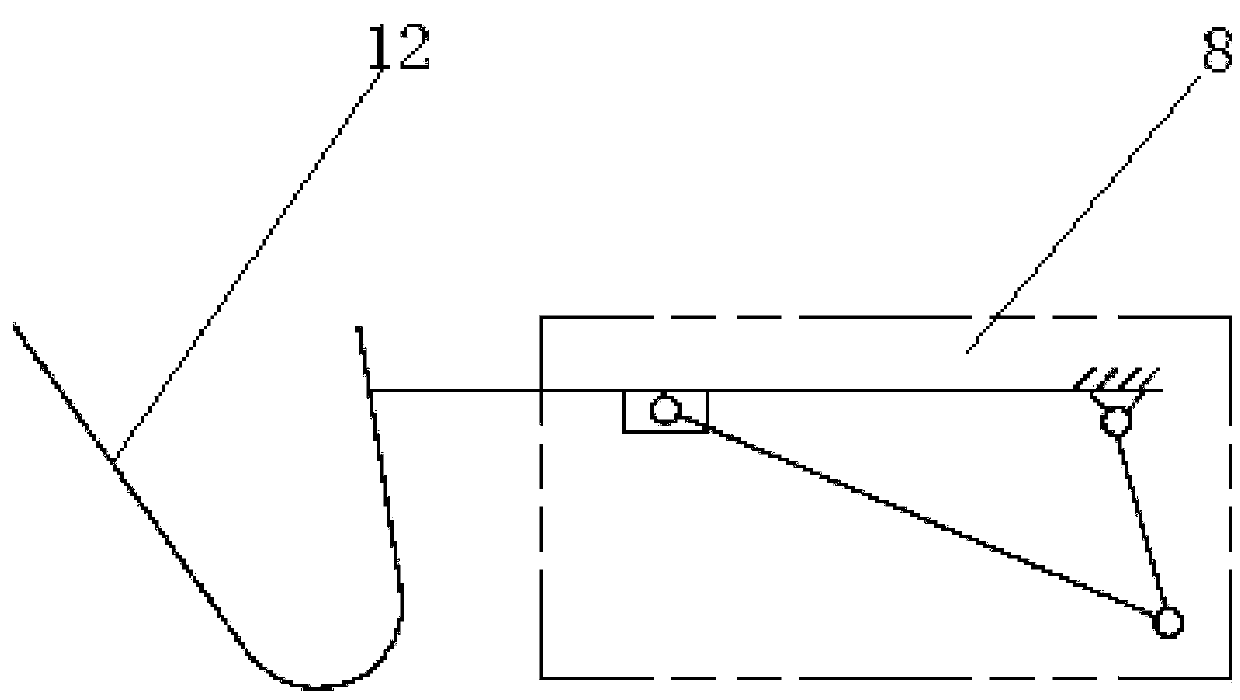

[0021] Such as figure 1 As shown, the present invention is a hydraulic system of a loader working device, and the attachment of the working device is a bucket 12 for shoveling loose materials. The hydraulic system includes a high-pressure oil source 5, a fuel tank circuit, a distribution valve 1, a pilot valve 4, and the like. Distribution valve 1 is a pilot-controlled distribution valve and a closed valve core, which includes the boom joint and the bucket joint. The working oil ports A2 and B2 of the boom joint are respectively connected to the large cavity and Small cavity connection, the pilot oil port of the boom unit is connected to the pilot oil port a2 and b2 of the boom unit of the pilot valve respectively; The ports are respectively connected to the large cavity and small cavity of the bucket oil cylinder, and the pilot oil ports of the bucket joint of the dis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap