High-bearing flexible hinge guiding mechanism

A flexible hinge and guiding mechanism technology, applied in the directions of instruments and instrument parts, etc., can solve the problems such as deflection and displacement of the core motion platform, deformation of the flexible hinge array in the non-working direction, and the core motion platform cannot achieve the expected positioning accuracy, and achieves machining. The effect of low manufacturing cost, flexible processing form and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

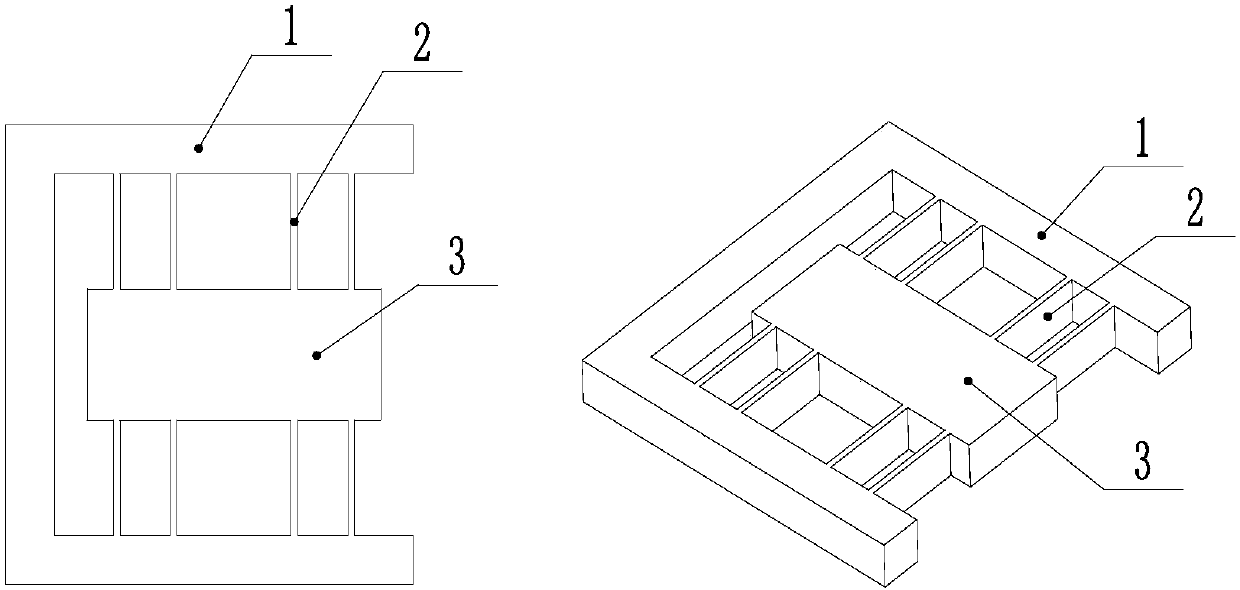

Embodiment 1

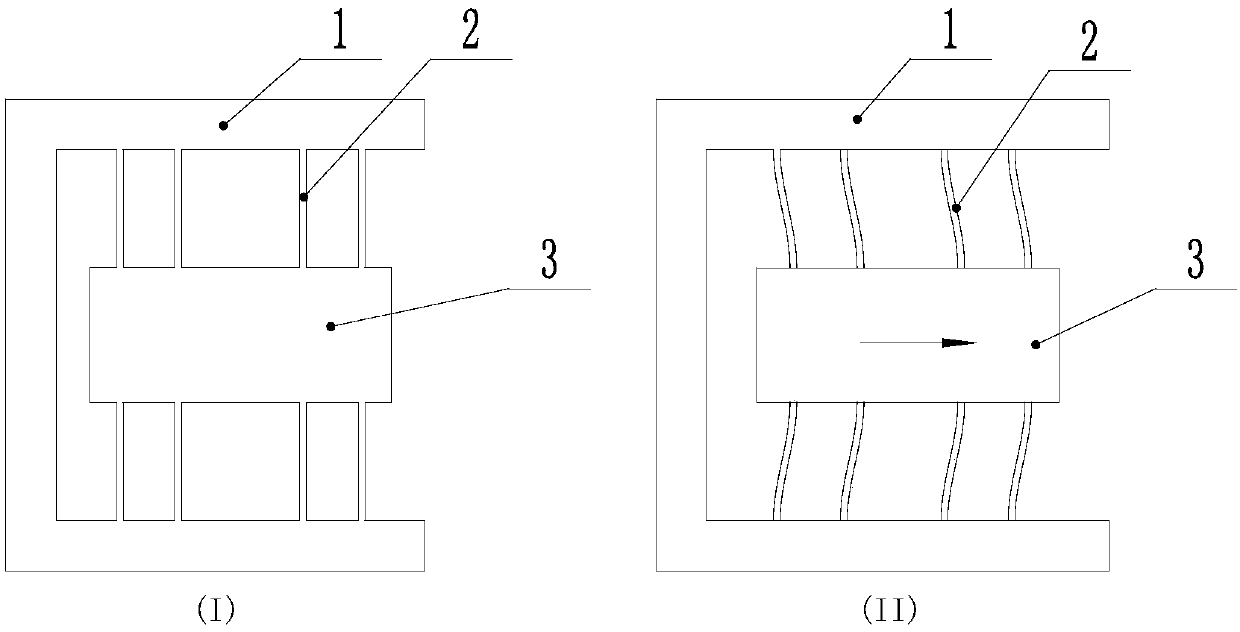

[0041] An embodiment of the large load-bearing flexible hinge guide mechanism proposed by the present invention 1 as Figure 5 shown. The main difference between the guide mechanism shown in Embodiment 1 and the existing flexible hinge guide mechanism is the addition of a sub-flexible hinge (401) for carrying large loads and resisting deformation in the non-working direction. The working principle of embodiment 1 guiding mechanism is: as Figure 6 and Figure 7 As shown, the core motion platform (3) is connected to the rigid support platform (1) through the main flexible hinge group (2) and the secondary flexible hinge group (401) respectively. The flexible hinges in the main flexible hinge group (2) and the secondary flexible hinge group (401) are processed and manufactured in one piece with the rigid support platform (1), and the secondary flexible hinge group (401) is manufactured through a rigid connection part ( 402) Connect with the core motion platform (3). The main...

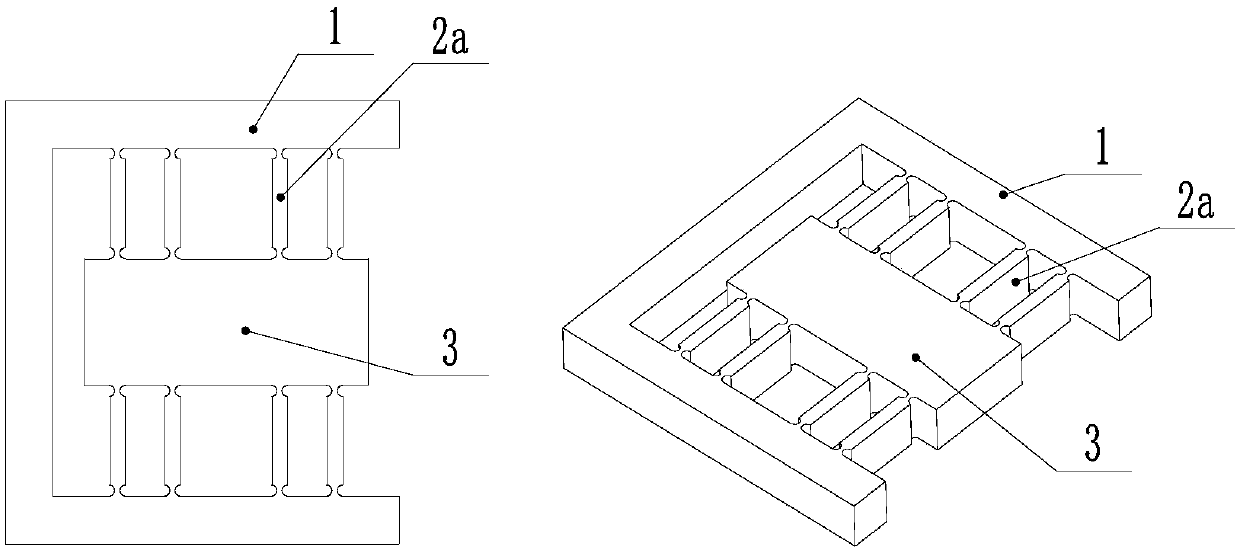

Embodiment 2

[0045] An embodiment of the flexible hinge guiding mechanism proposed by the present invention 2 is as Figure 10 to Figure 12 shown. The main difference between the guiding mechanism of embodiment 2 and the guiding mechanism of embodiment 1 is that the sub-flexible hinge group (401) of embodiment 1 is manufactured by integral processing with the rigid support platform, and the sub-flexible hinge group described in embodiment 2 Groups are manufactured by component assembly.

[0046] Such as Figure 11 and Figure 12 As shown, the sub-flexible hinge group includes spring leaf (401a), bolt group B (405), bolt group C (406), connection block A (407), connection block B (408) and so on. Wherein, the spring piece (401a) is rigidly connected with the rigid support platform (1) through the bolt group B (405), and the core motion platform (3) is connected through the connecting block B (408) and the connecting block A (407) Parts such as bolt group C (406) and the middle part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com