Hose winding device for fire fighting

A technology of water pipes and equipment, which is applied in the field of coiled water pipe equipment for fire-fighting, and can solve problems such as time-consuming and laborious, affecting the speed of next use, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

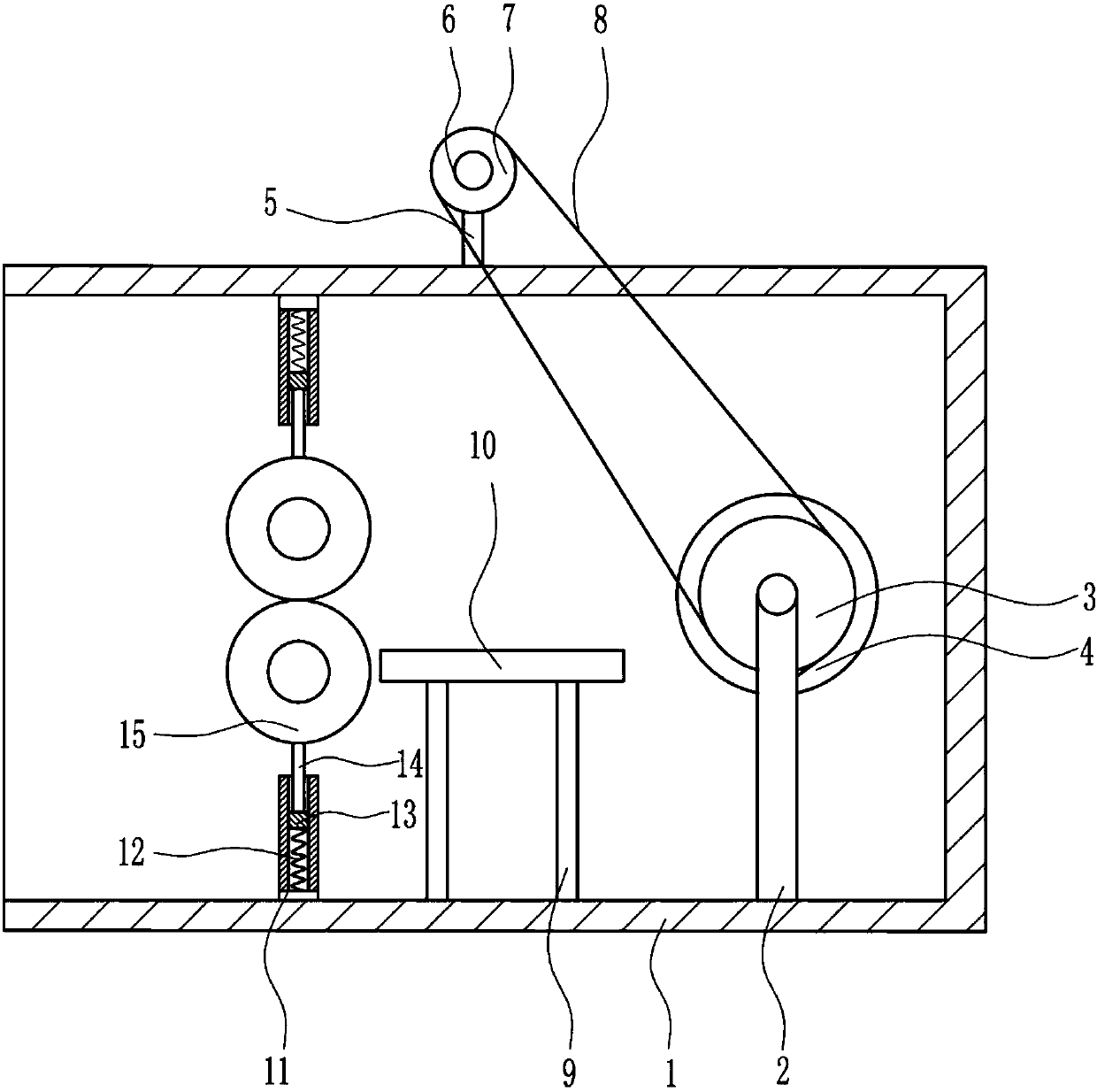

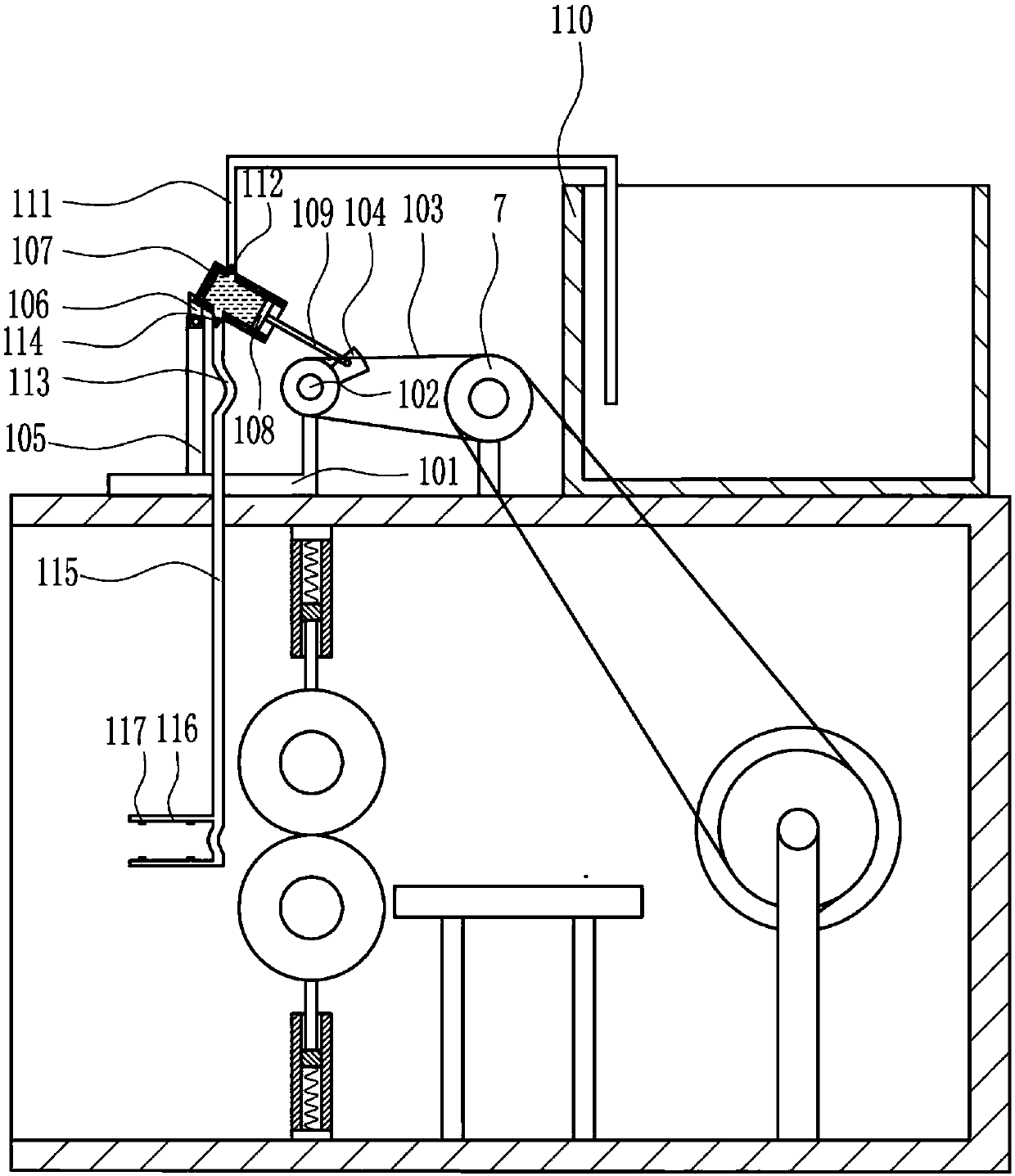

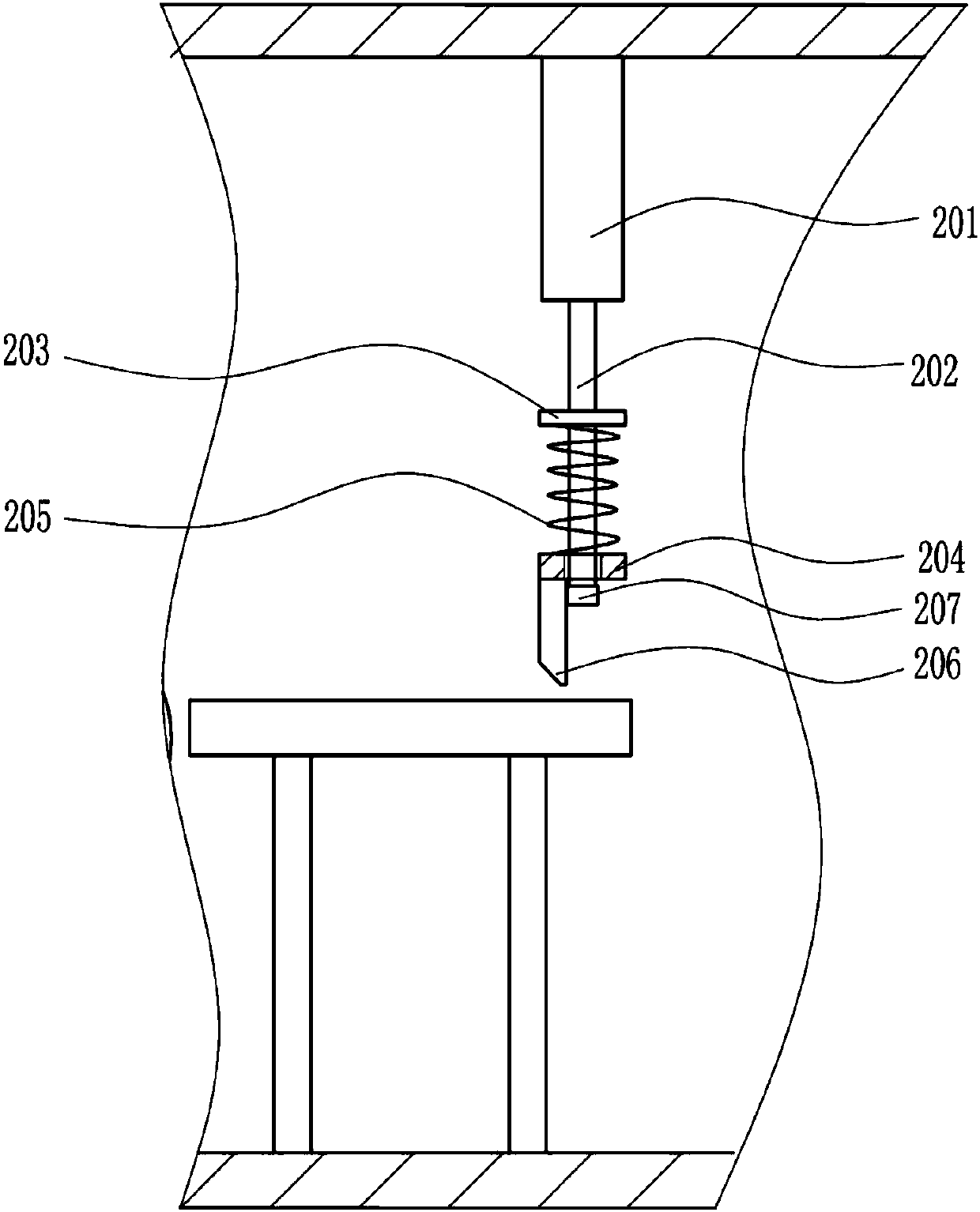

[0027] A kind of rolling water pipe equipment for fire fighting, such as Figure 1-5As shown, it includes a frame 1, a first bracket 2, a first pulley 3, a reel 4, a second bracket 5, a motor 6, a second pulley 7, a first belt 8, a pole 9, a first support Plate 10, slide pipe 11, first spring 12, slide block 13, first connecting rod 14 and first roller 15 are provided with first bracket 2 on the top right side of frame 1, and on the top of first bracket 2 A first belt pulley 3 is movably connected, and a reel 4 is connected behind the first belt pulley 3. A second support 5 is provided outside the upper wall of the frame 1, and a motor 6 is provided on the top of the second support 5. , the output shaft of the motor 6 is connected with a second pulley 7, and is connected between the second pulley 7 and the first pulley 3 through the first belt 8, and is arranged symmetrically up and down on the left side of the frame 1. The slide tube 11 is provided with a first spring 12 at ...

Embodiment 2

[0029] A kind of rolling water pipe equipment for fire fighting, such as Figure 1-5 As shown, it includes a frame 1, a first bracket 2, a first pulley 3, a reel 4, a second bracket 5, a motor 6, a second pulley 7, a first belt 8, a pole 9, a first support Plate 10, slide pipe 11, first spring 12, slide block 13, first connecting rod 14 and first roller 15 are provided with first bracket 2 on the top right side of frame 1, and on the top of first bracket 2 A first belt pulley 3 is movably connected, and a reel 4 is connected behind the first belt pulley 3. A second support 5 is provided outside the upper wall of the frame 1, and a motor 6 is provided on the top of the second support 5. , the output shaft of the motor 6 is connected with a second pulley 7, and is connected between the second pulley 7 and the first pulley 3 through the first belt 8, and is arranged symmetrically up and down on the left side of the frame 1. The slide tube 11 is provided with a first spring 12 at...

Embodiment 3

[0032] A kind of rolling water pipe equipment for fire fighting, such as Figure 1-5 As shown, it includes a frame 1, a first bracket 2, a first pulley 3, a reel 4, a second bracket 5, a motor 6, a second pulley 7, a first belt 8, a pole 9, a first support Plate 10, slide pipe 11, first spring 12, slide block 13, first connecting rod 14 and first roller 15 are provided with first bracket 2 on the top right side of frame 1, and on the top of first bracket 2 A first belt pulley 3 is movably connected, and a reel 4 is connected behind the first belt pulley 3. A second support 5 is provided outside the upper wall of the frame 1, and a motor 6 is provided on the top of the second support 5. , the output shaft of the motor 6 is connected with a second pulley 7, and is connected between the second pulley 7 and the first pulley 3 through the first belt 8, and is arranged symmetrically up and down on the left side of the frame 1. The slide tube 11 is provided with a first spring 12 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com