Tool material storage rack

A technology for tool materials and storage racks, applied in the field of tool material storage racks, can solve the problems of inconvenient maintenance, inability to flexibly change the number of storage layers, inconvenient transfer of tool material storage racks, etc., and achieve the effect of convenient transfer and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

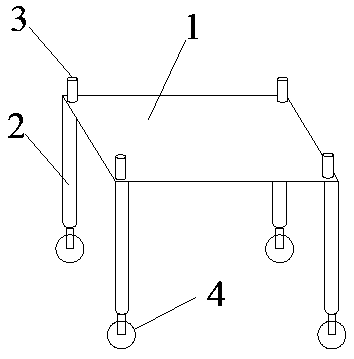

[0012] A tool and material storage rack, characterized in that it includes an object placement plate 1 and four support tubes 2 respectively fixed at the bottom of the four corners of the object placement plate 1, the upper surface of the object placement plate 1 is in contact with the support tubes 2 A connecting piece 3 is provided at a corresponding position, and the connecting piece 3 can be detachably connected with the support tube 2 , and also includes four universal wheels 4 detachably fixed at the bottom of the support tube 2 . The connecting piece 3 is a short tube vertically set on the upper surface of the object placement board 1 .

[0013] This tool material storage rack can be used in combination. When it is necessary to increase the number of storage layers, the four support tubes 2 of the increased tool material storage rack are inserted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com