A layered vibrating shear soil box test device

A technology of test device and vibration device, which is applied in the direction of vibration test, measuring device, machine/structural component test, etc. It can solve the problems of large gap, small size of shear box, high test cost, etc., and achieves convenient installation and application, and reduces The effect of connecting gaps and ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation of the present invention is described in further detail below in conjunction with accompanying drawing:

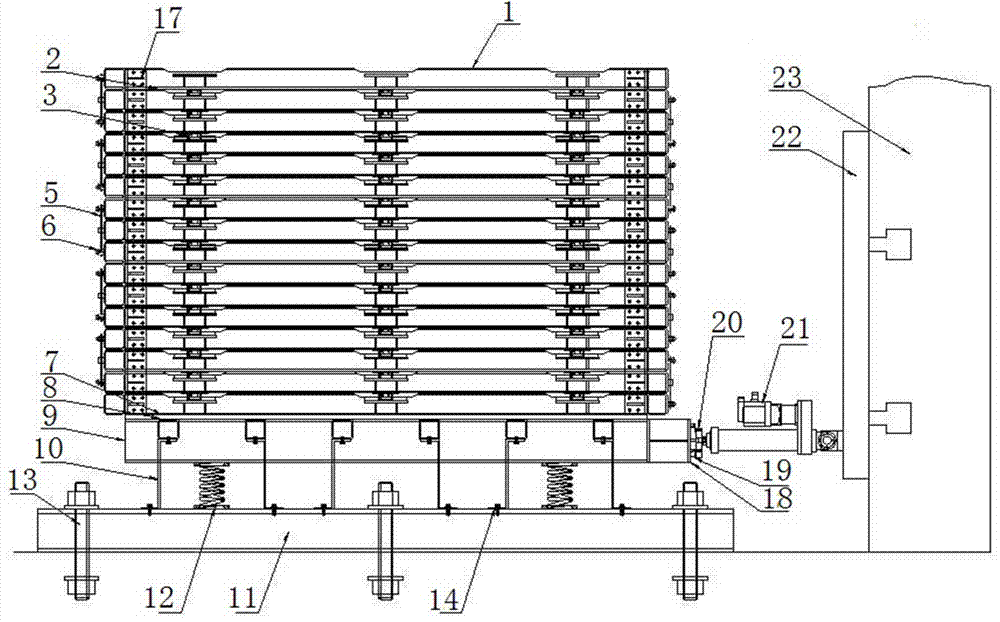

[0020] like figure 1 , figure 2 As shown, the layered vibration shear soil box test device includes a shear soil box, a vibration device supporting the shear soil box, and a driving device for driving the vibration device.

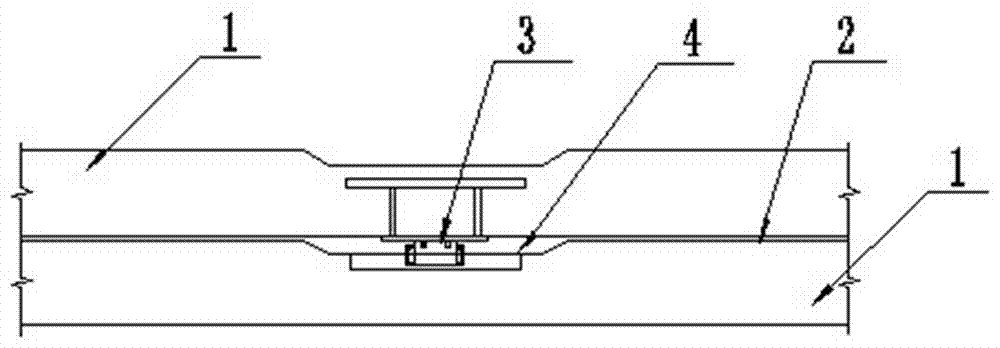

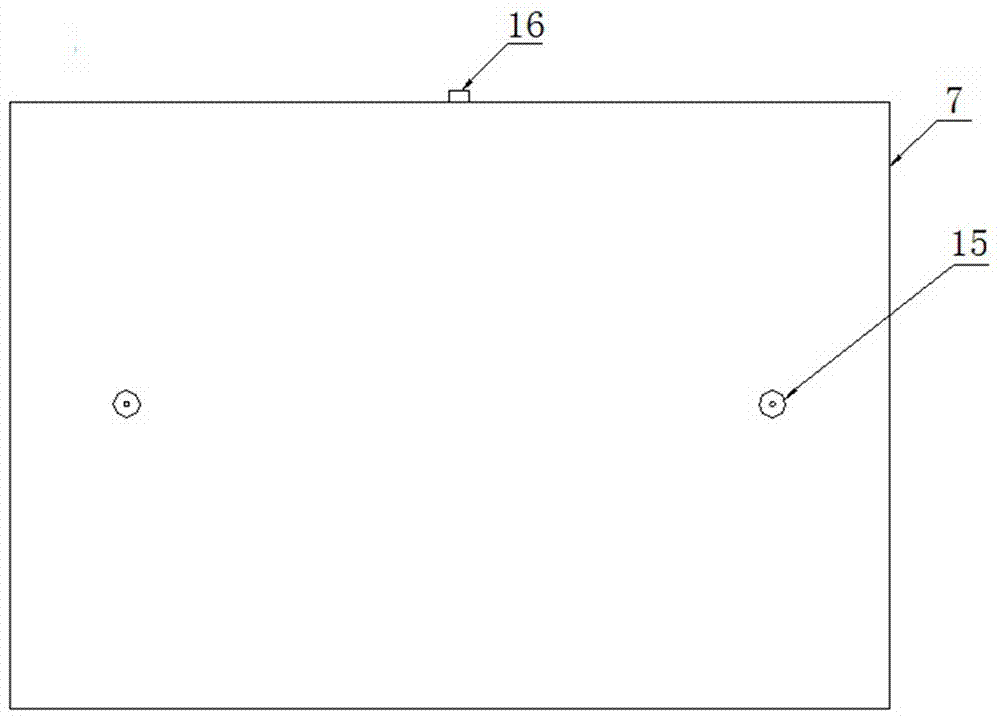

[0021] The main body of the shear soil box is composed of sixteen layers of frame layers 1 of the same size, each frame layer is 3000mm×2000mm, 120mm in height, and the gap between layers is 2mm, and can be locked by six sets arranged along the longitudinal side of frame layer 1 Or loose slide 3 and linear guide 4 kits, stacked together in combination (see Figure 4 ), the four corners of the frame layer 1 are riveted with angle steel 17, the sides between the frame layers are connected by a number of rebound leaf springs 5 and hemispherical column hinges 6, the bottom frame layer is welded on the bottom plate 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com