Device for automatically detecting skewness degree of packing belt online

An automatic detection device and packing belt technology, which is applied in the field of packing, can solve the problems of loss of both supply and demand, unusable materials, time-consuming and labor-intensive sampling work, etc., and achieve the effect of improving production efficiency and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] At present, the production process of the packing belt generally has the following steps: 1. Ingredients and mixing; 2. Plastic granules are heated and melted; 3. Extruded into water to form a belt embryo; 4. Heated and stretched; Rewinding; 8 packages; 9 storage.

[0030] From the above-mentioned production process of the packing tape, it can be known that it is best to detect the skewness of the packing tape between the shaping processing section and the winding section.

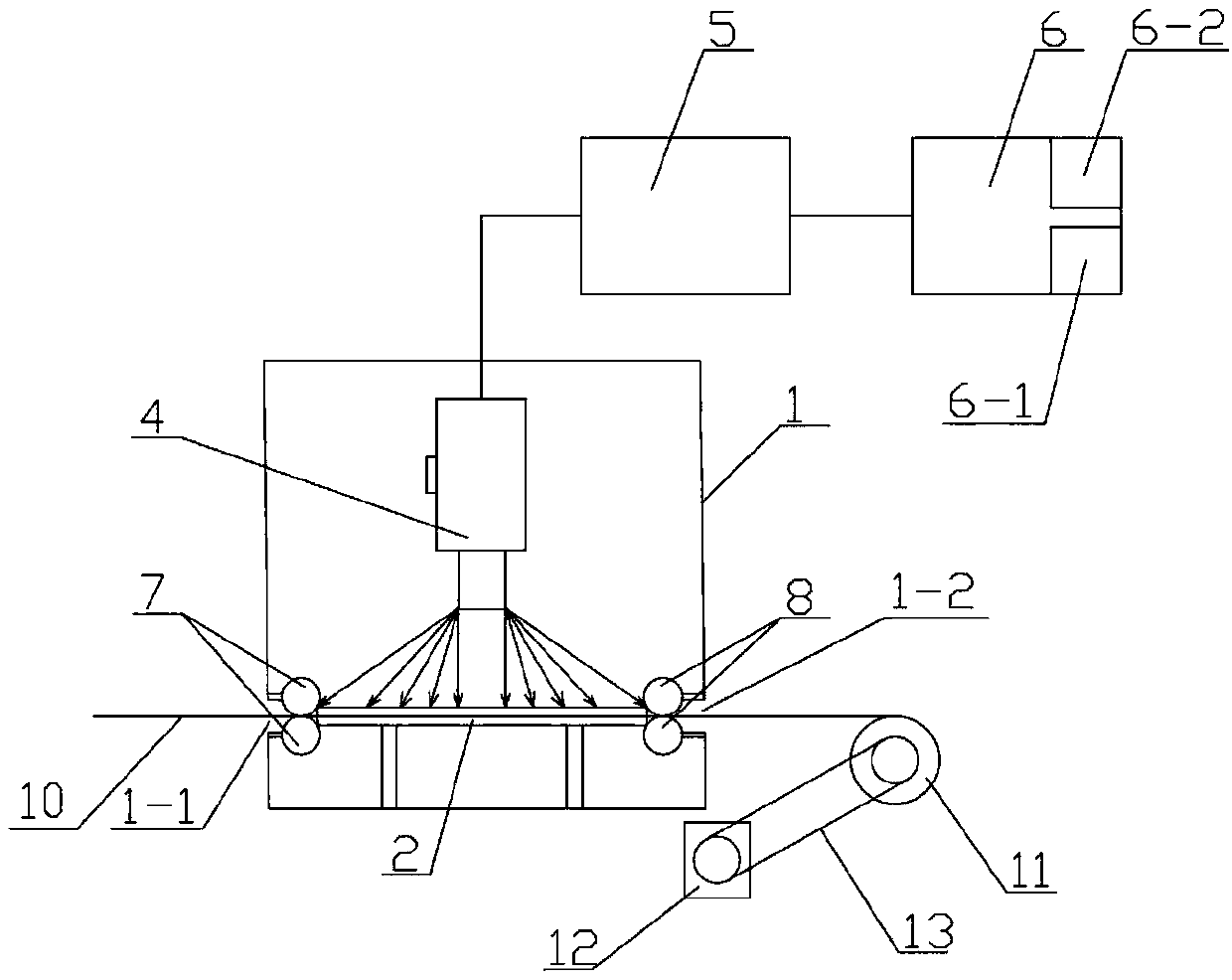

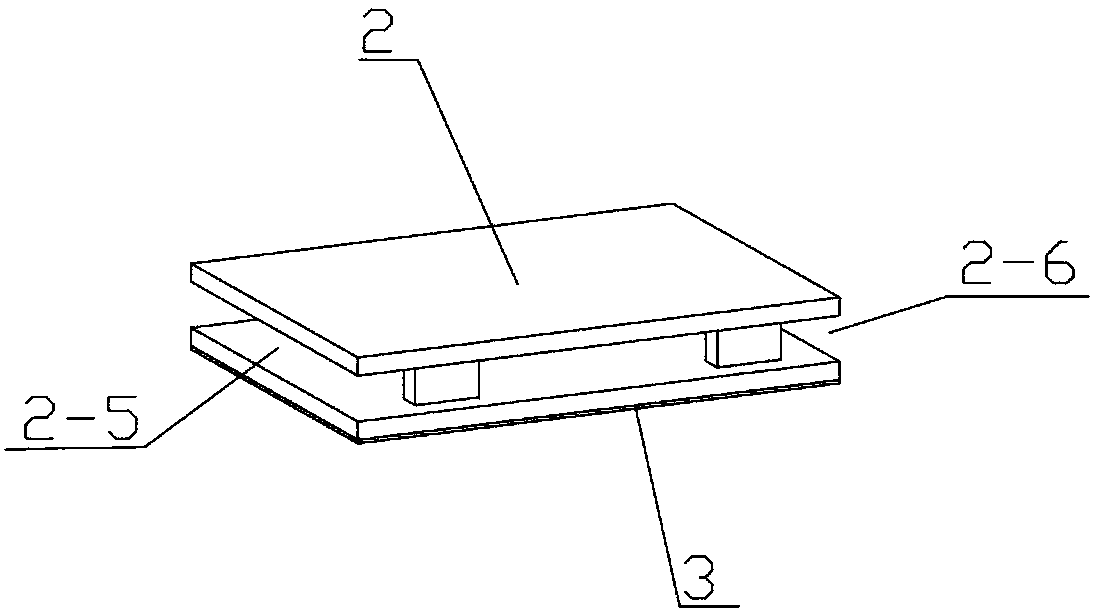

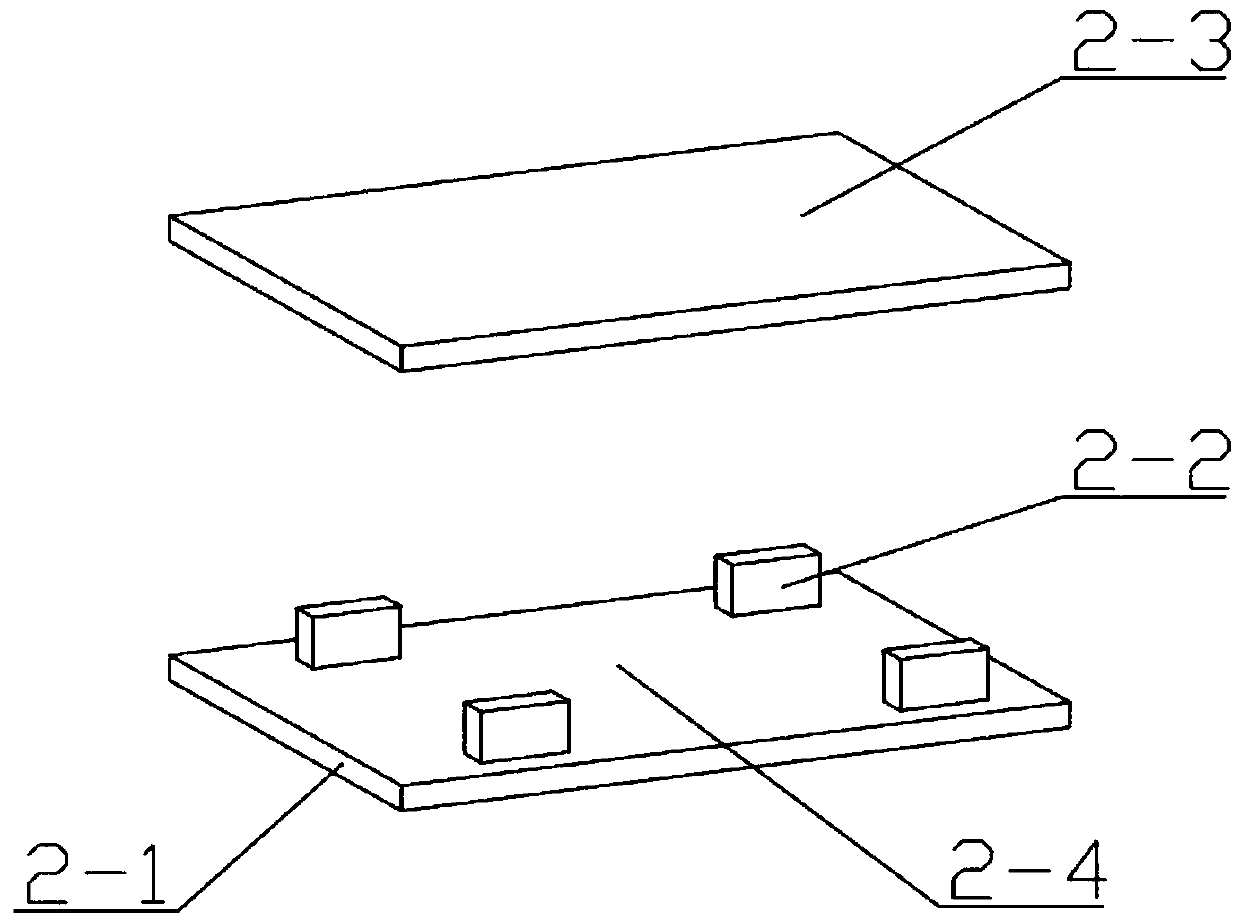

[0031] The present invention provides an online automatic detection device for packing belt skewness, which includes a box body 1 , a positioning component 2 , a graph paper 3 , an image sensor 4 , an image ranging processing module 5 , and a host computer 6 .

[0032] The box body 1 is arranged between the shaping processing section and the winding section, and the box body 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com