An accurate determination method for pyrolysis products of humic acid organic matter

A technology of pyrolysis and determination method, which is applied in the direction of measuring devices, material separation, and analysis of materials, and can solve problems such as detection errors, separation, and large eluent flow rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

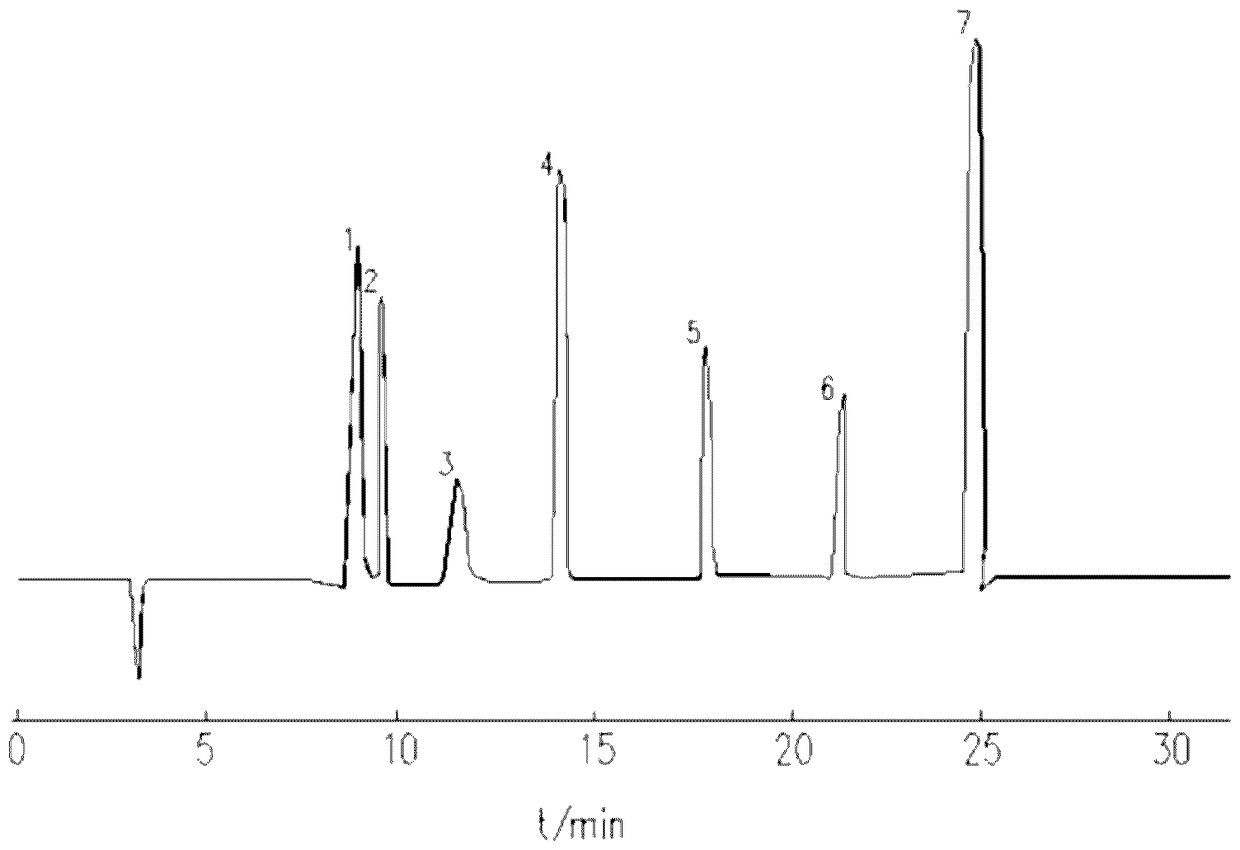

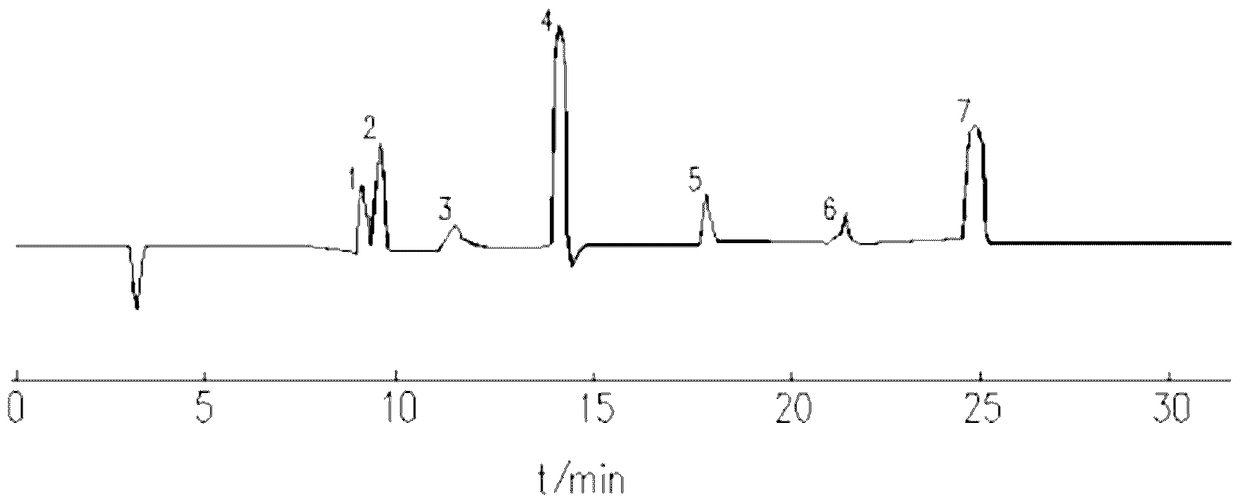

[0016] Example 1: Detection of water vapor samples in an in-service power plant

[0017] 1. Instruments and Reagents

[0018] The instrument used in the experiment is an ion chromatograph, an anion separation column and a protection column are commonly used chromatographic columns, a conductivity detector, and a sampler.

[0019] Sodium Formate, Sodium Acetate, Sodium Fluoride, Sodium Chloride, Sodium Sulfate, Sodium Phosphate, Sodium Nitrate, Potassium Tetraborate, the above drugs are of analytical grade, and the eluent K is prepared 2 B 4 O 7 Solution (gradient concentration eluent), the series of standard stock solutions of each anion are 1000µg / L, the above seven standard stock solutions and eluents are all prepared with ultrapure water with a resistivity of 18.25MΏ·cm, all stored Store in a polyethylene bottle at 0~4°C.

[0020] 2. Configuration of standard liquid and instrument calibration

[0021] According to the concentration range of the sample to be tested and ...

example 2

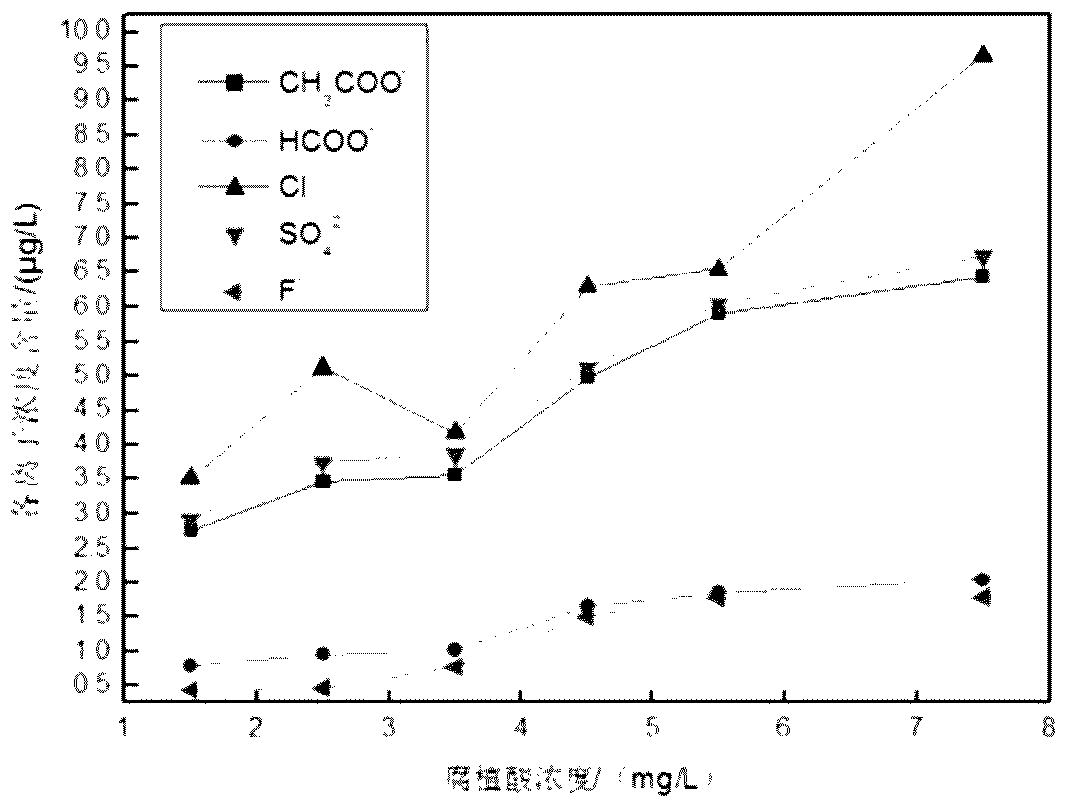

[0029] Example 2: Precise determination of humic acid pyrolysis products at different concentrations

[0030] Repeat the operation steps of above-mentioned example 1, select instruments and reagents, calibrate instruments and configure standard use liquid, carry out chromatography on humic acid pyrolysis solution under different concentrations, adopt gradient elution procedure, obtain the product content results under different concentrations of humic acid decomposition As shown in Table 3 below, the change trend graph is as follows image 3 As shown, among them, the decomposition concentration gradient of humic acid is set to 0µg / L, 1500µg / L, 3500µg / L, 5500µg / L, 7500µg / L, respectively.

[0031] Examples of accurate determination of humic acid pyrolysis products at different concentrations illustrate that the method for accurate measurement of humic acid-based organic matter pyrolysis products involved in the present invention has popularization and applicability, and can be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com