Dust removal vibrating hammer device adjustable in position

A vibrating hammer and adjustable technology, applied in the directions of packaging, transportation and packaging, containers, etc., can solve the problems of inability to have rapping force, deformation and damage of the cylinder, and achieve the effect of avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

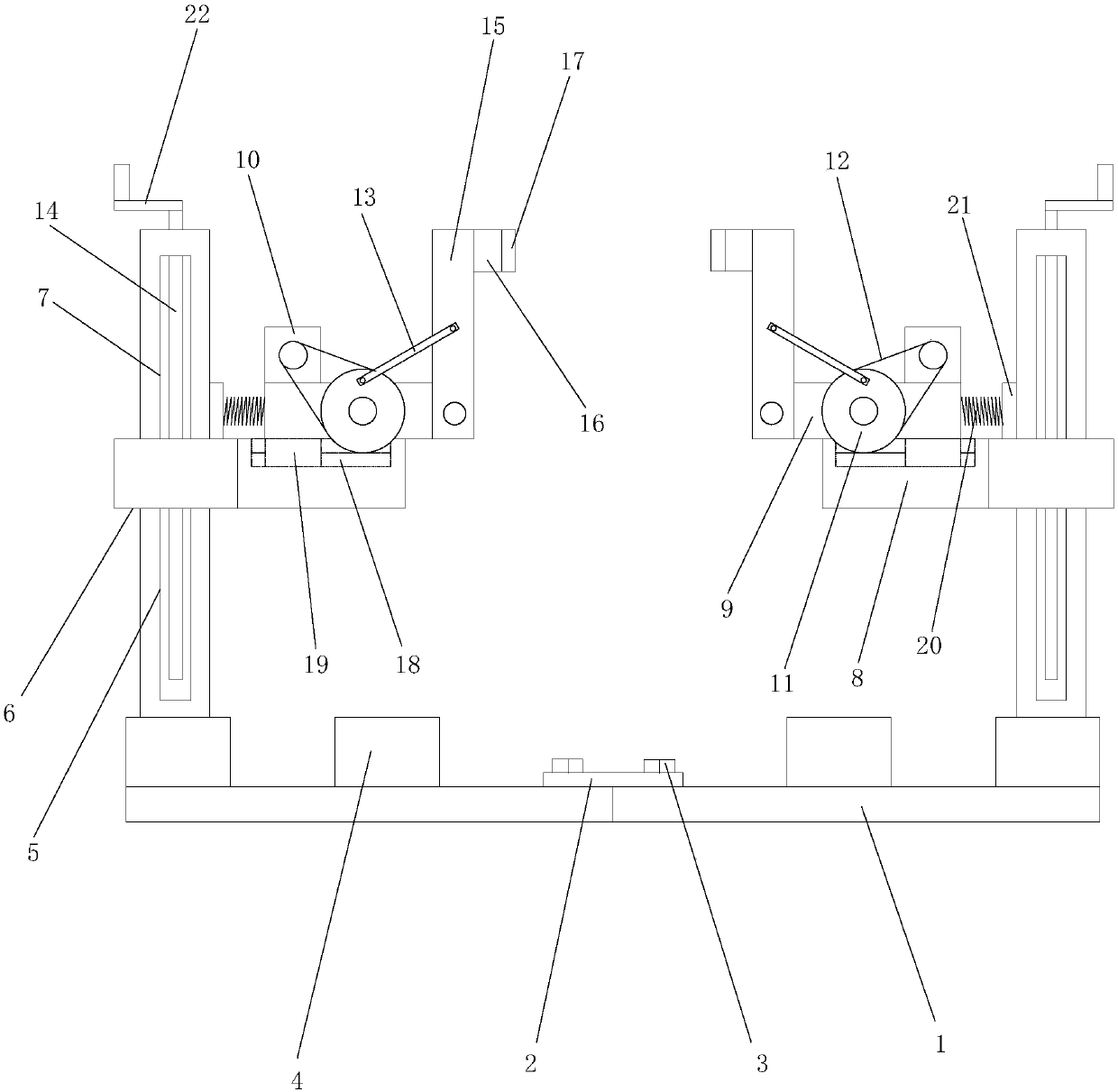

[0010] Such as figure 1 As shown, the position-adjustable dust removal vibratory hammer device disclosed in the present invention includes: two semi-annular bases 1 and two vibratory hammer mechanisms; each vibratory hammer mechanism includes a vertical support column 5, a sliding sleeve 6, and a horizontal support rod 8 , translation rod 9, swing rod 15, drive motor 10, drive disc 11, drive belt 12 and drive rod 13; two semi-annular bases 1 are spliced to form an annular base, and column sockets are arranged at intervals on the annular base 4. The vertical support column 5 of the vibratory hammer mechanism is vertically inserted on the column socket 4; a vertical chute 7 is arranged on the side of the vertical support column 5 along its length; the sliding sleeve 6 is set on the vertical support On the column 5, and on the sliding sleeve 6, a vertical slider that is slidably embedded in the vertical chute 7 is provided; a rotating rod 14 is vertically rotatably installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com