Through type glass tempering furnace capable of effectively weakening tempering stress patterns

A glass tempering and stress spot technology, which is applied in glass tempering, glass manufacturing equipment, glass transportation equipment, etc., can solve the problems of different heat dissipation of glass, stress difference between front and back of glass, and stress formation, etc., and achieve the goal of reducing stress spot of tempered glass Forming and eliminating uneven heat dissipation and ensuring the flatness of the glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

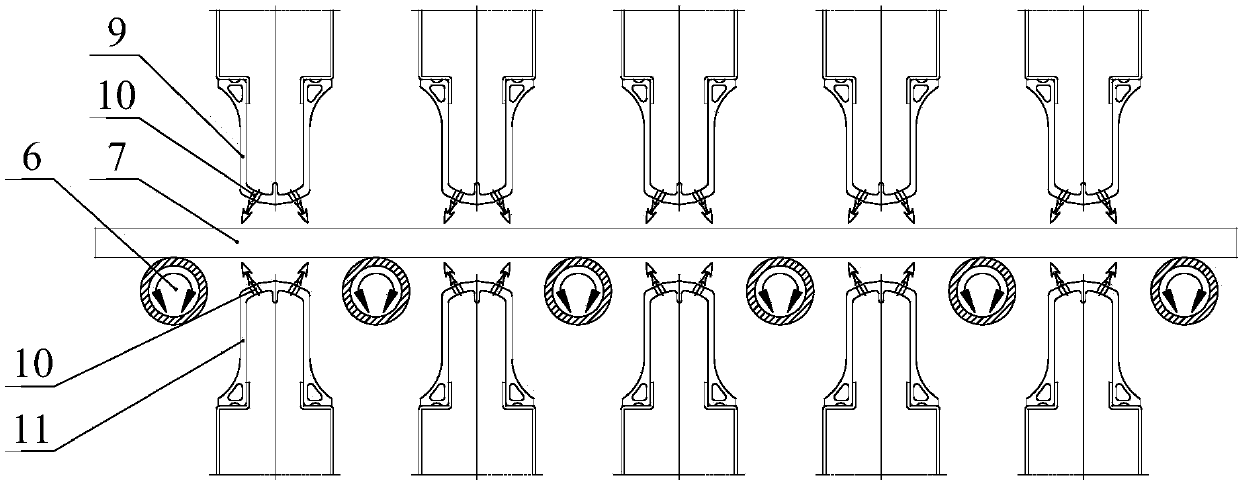

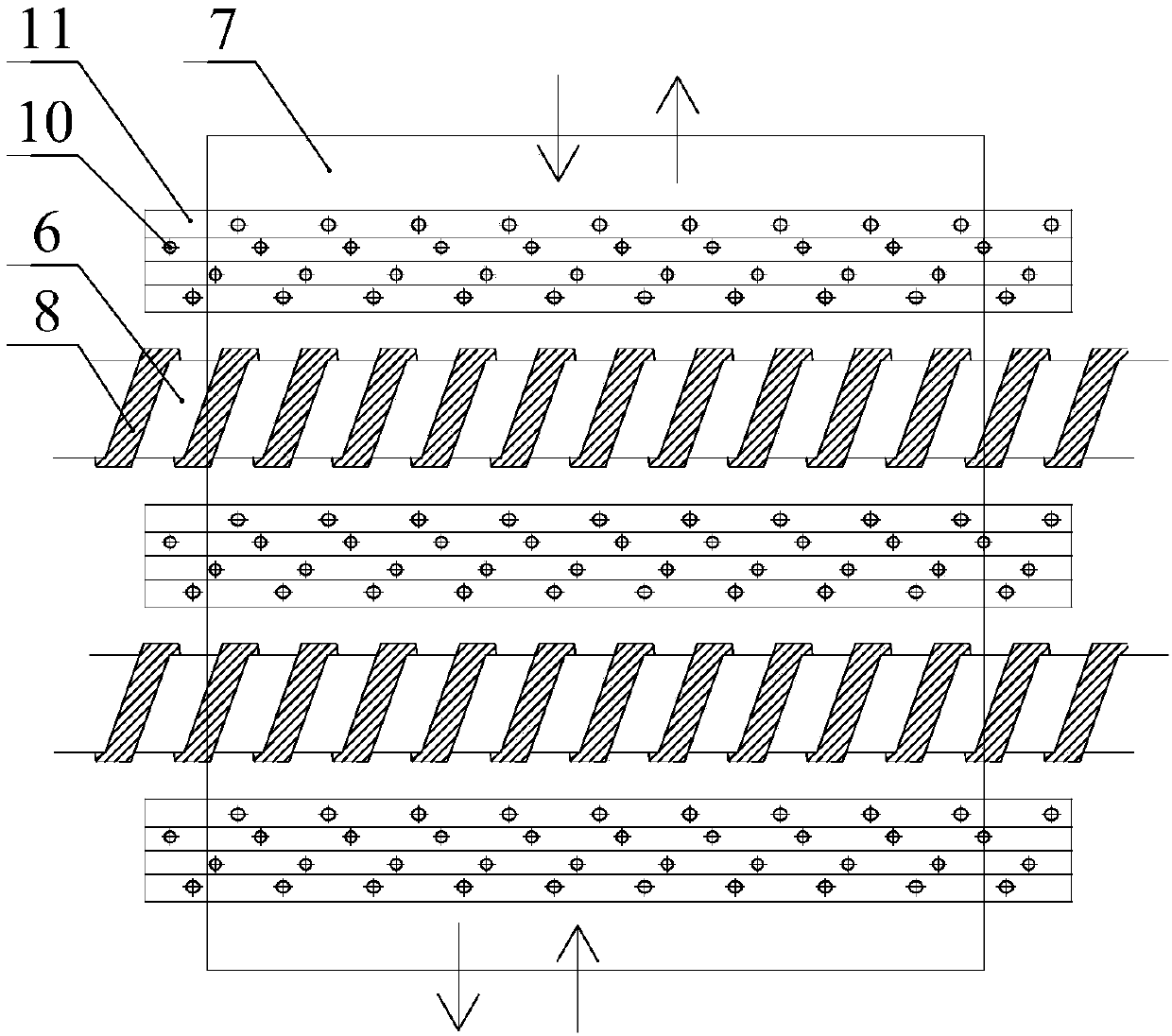

[0043] Below in conjunction with each accompanying drawing, the present invention is described in detail.

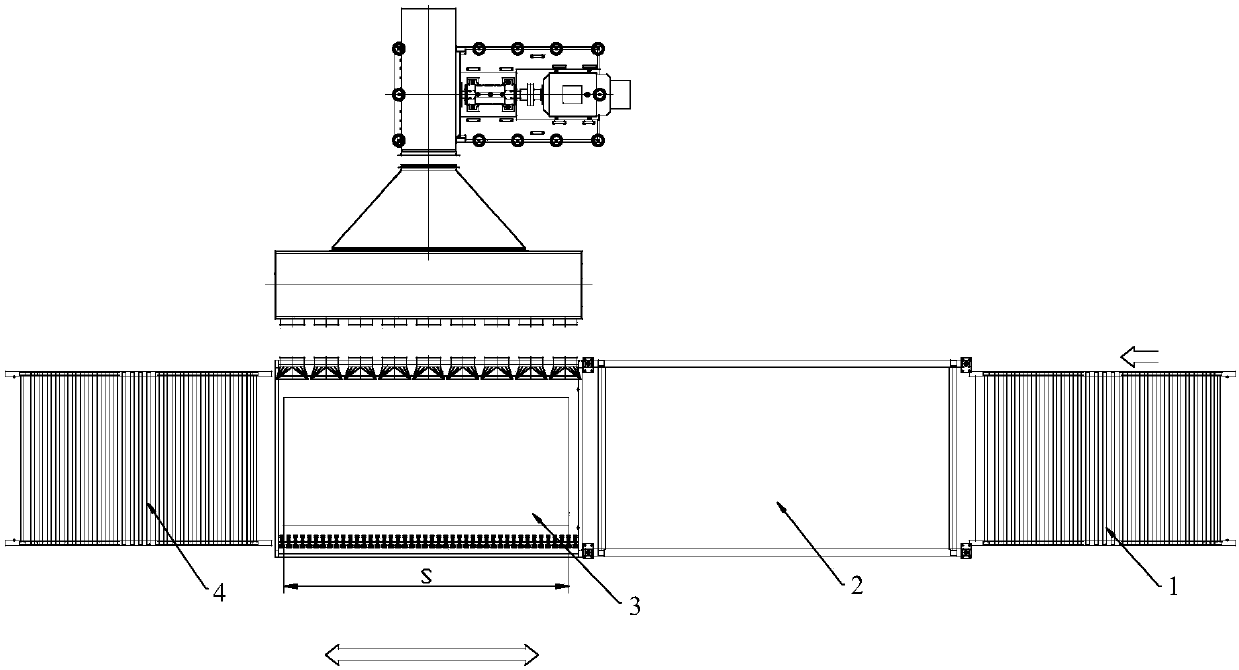

[0044] Such as Figure 5As shown, a pass-through glass tempering furnace that can effectively weaken tempering stress spots includes a heating furnace 2, a scanning tempering device 5, and a cooling device 3 arranged in sequence. The scanning tempering device 5 is used to improve cooling efficiency. The glass in the heating furnace 2 is cooled in one pass, and the cooling device 3 is used for reciprocating cooling of the glass from the scanning tempering device 5 .

[0045] The "one-pass cooling" mentioned in this application refers to a one-time pass without pause and reciprocating movement, similar to a scanning operation; The glass will reciprocate in the cooling device 3; in this application, the cooling device 3 may be the cooling device 3 for reciprocating cooling in the prior art or background technology.

[0046] In the tempering process of tempered glass, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com