Real-time detecting instrument for two-shaft rotating angle differences

A detector and two-axis rotation technology, which is applied in the field of detectors to detect the difference between two-axis rotation angles, can solve the problems that errors affect measurement accuracy and cannot truly and accurately respond to two-axis rotation speeds, and achieve improved measurement accuracy, low cost, and measurement high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

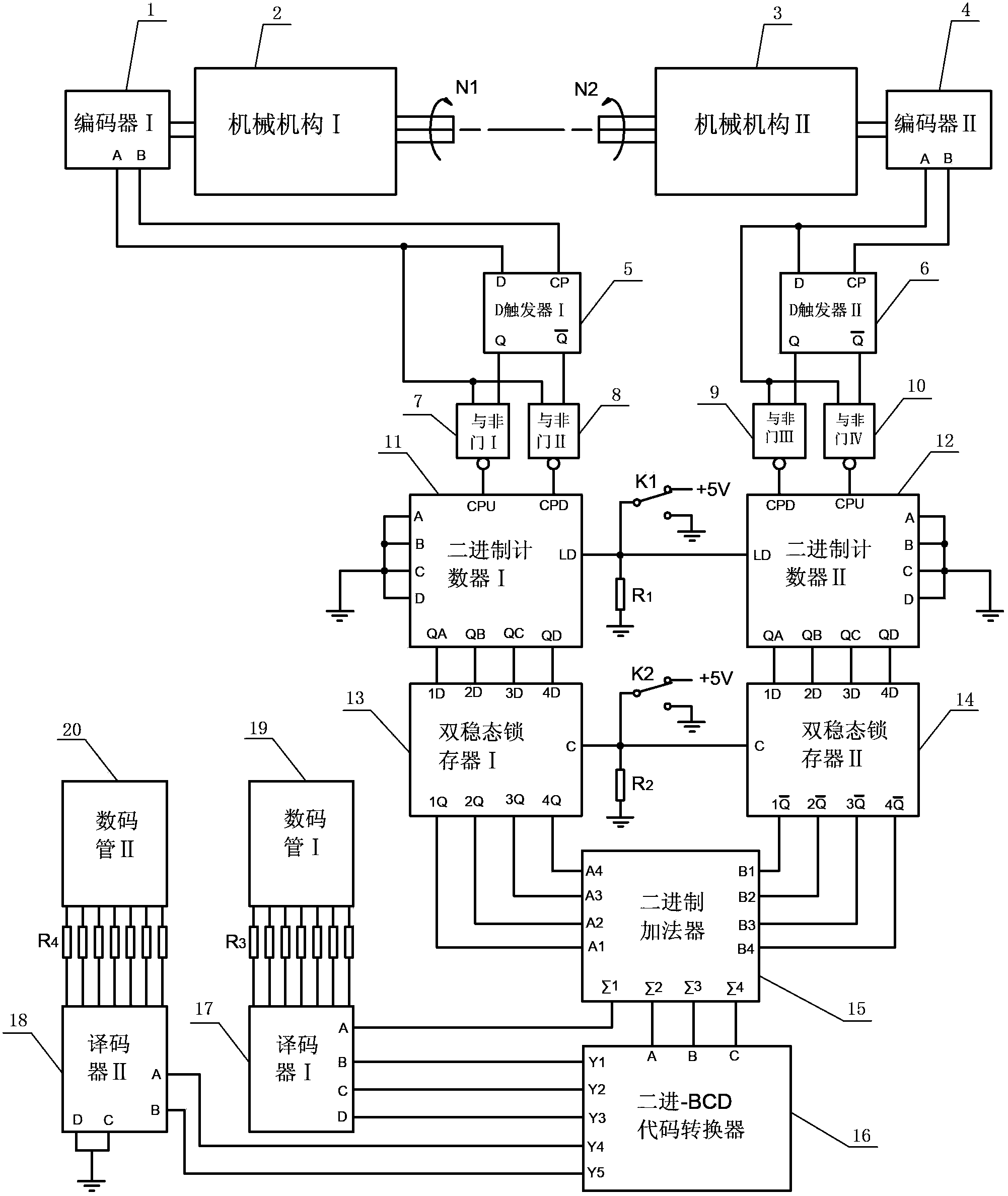

[0015] Such as figure 1 As shown, the real-time two-axis rotation angle difference detector of the present invention (hereinafter referred to as "the detector") includes an encoder, a D flip-flop, a NAND gate, a binary counter, a bistable latch, and a binary adder 15 , Binary-BCD code converter 16, decoder and digital tube.

[0016] The encoder includes an encoder I1 directly connected to the output shaft of the mechanical mechanism I2 and an encoder II4 directly connected to the output shaft of the mechanical mechanism II3. The D flip-flop includes a D flip-flop I5 connected to the output end of the encoder I1 and a D flip-flop II6 connected to the output end of the encoder II4, and the output end of the encoder I1 is connected to the input end and the control end of the D flip-flop I5 respectively. Connection, the output end of the encoder II4 is respectively connected with the input end and the control end of the D flip-flop II6.

[0017] The NAND gate includes a NAND gat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com