Friction limiting based stable type truck double-row wheel

A stable, truck technology, used in belts/chains/gears, differential transmissions, mechanical equipment, etc., to solve the problems of trucks prone to overturning and unstable turning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

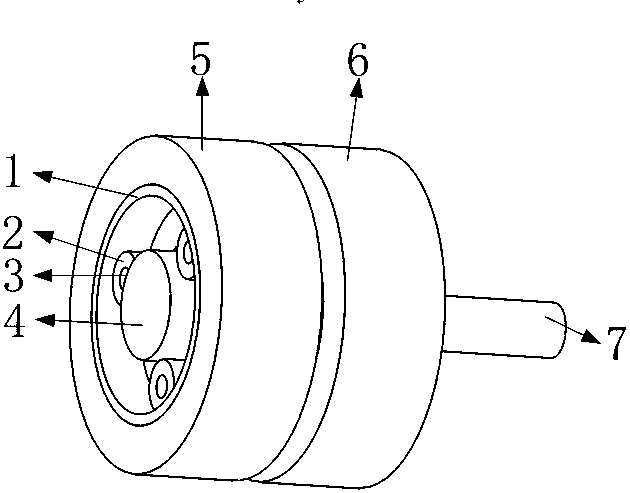

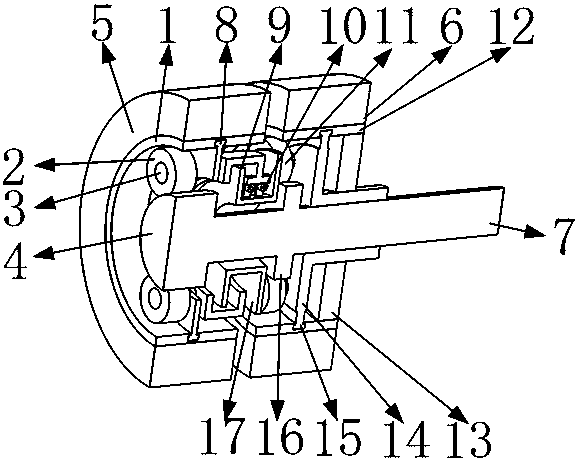

[0036] Such as figure 1 , 2 , 3, it includes the second rim 1, the second planetary wheel 2, the second fixed shaft 3, the third fixed shaft 36, the second sun gear 4, the trigger mechanism 28, the second tire 5, the first tire 6 , input shaft 7, fixed ring 9, second T-shaped ring 8, first planetary gear 11, first rim 12, brake drum 13, first fixed ring 14, first T-shaped ring 15, first sun gear 16 , the third fixed ring 17, the second T-shaped ring groove 18, the first T-shaped ring groove 19, the first fixed shaft 20, the second fixed ring 21, such as image 3 As shown, the inner circle of the second fixed ring 21 is installed on the outer circle of the input shaft 7; as image 3 As shown, the first fixed ring 14 is nested on the outer surface of the input shaft 7; as image 3 , 7 As shown, one end of the first fixing ring 14 is installed on the end face of the second fixing ring 21; as Figure 5 , 7 As shown, the inner surface of the first T-shaped ring 15 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com