Electrothermal drive bistable state MEMS switch

An electrothermal drive, bistable technology, applied in the field of MEMS switches, can solve the problems of output nonlinearity, small driving force, long response time, etc., to reduce the hold signal, reduce system power consumption, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

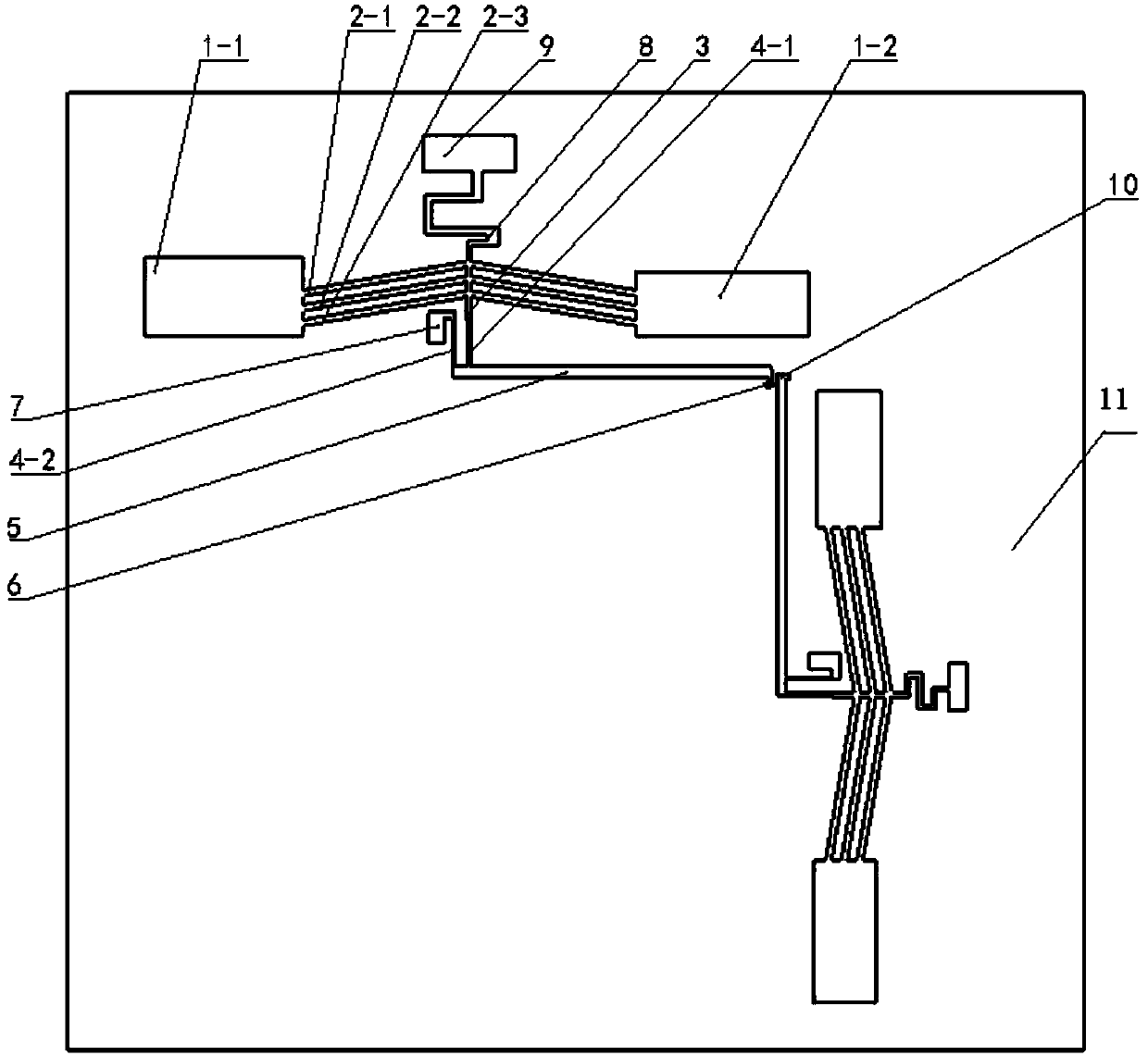

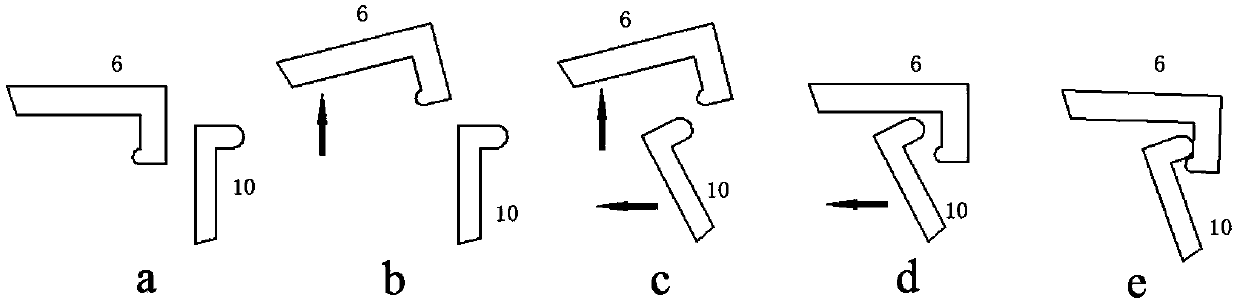

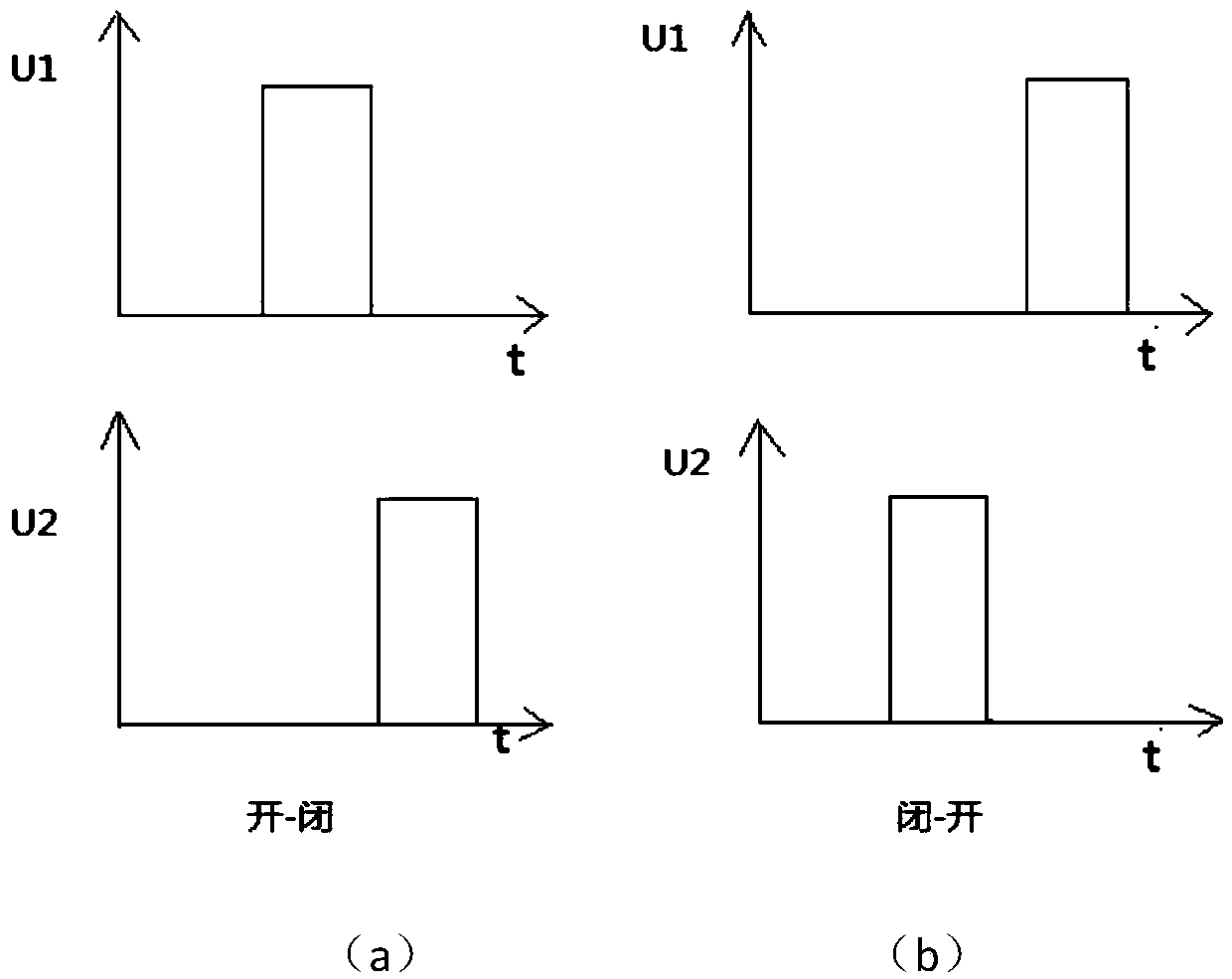

[0023] refer to figure 1 , an electrothermally driven bistable MEMS switch, comprising a square base 11, V-type electrothermal actuators I and V-type electrothermal actuators II are vertically distributed on the square base 11, and the V-type electrothermal actuators I are controlled by a drive circuit U1 Drive the first hook-shaped contact 6, the V-type electrothermal actuator II drives the second hook-shaped contact 10 under the control of another drive circuit U2, the first hook-shaped contact 6 and the second hook-shaped contact 10 contact and conduct When the circuit is connected, the first hook-shaped contact 6 and the second hook-shaped contact 10 do not contact or disconnect the circuit. The driving circuit U1 and the driving circuit U2 are pulse voltages, and there is a phase difference between the driving circuit U1 and the driving circuit U2.

[0024] Descr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com