Resistance spot-welding control method and system free of parameter setting

A technology of resistance spot welding and control method, which is applied in resistance welding equipment, resistance electrode base, welding power supply, etc., can solve the problems of consuming a lot of manpower and material resources, and achieve the effects of reducing the number of scrapped parts, shortening the development cycle, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

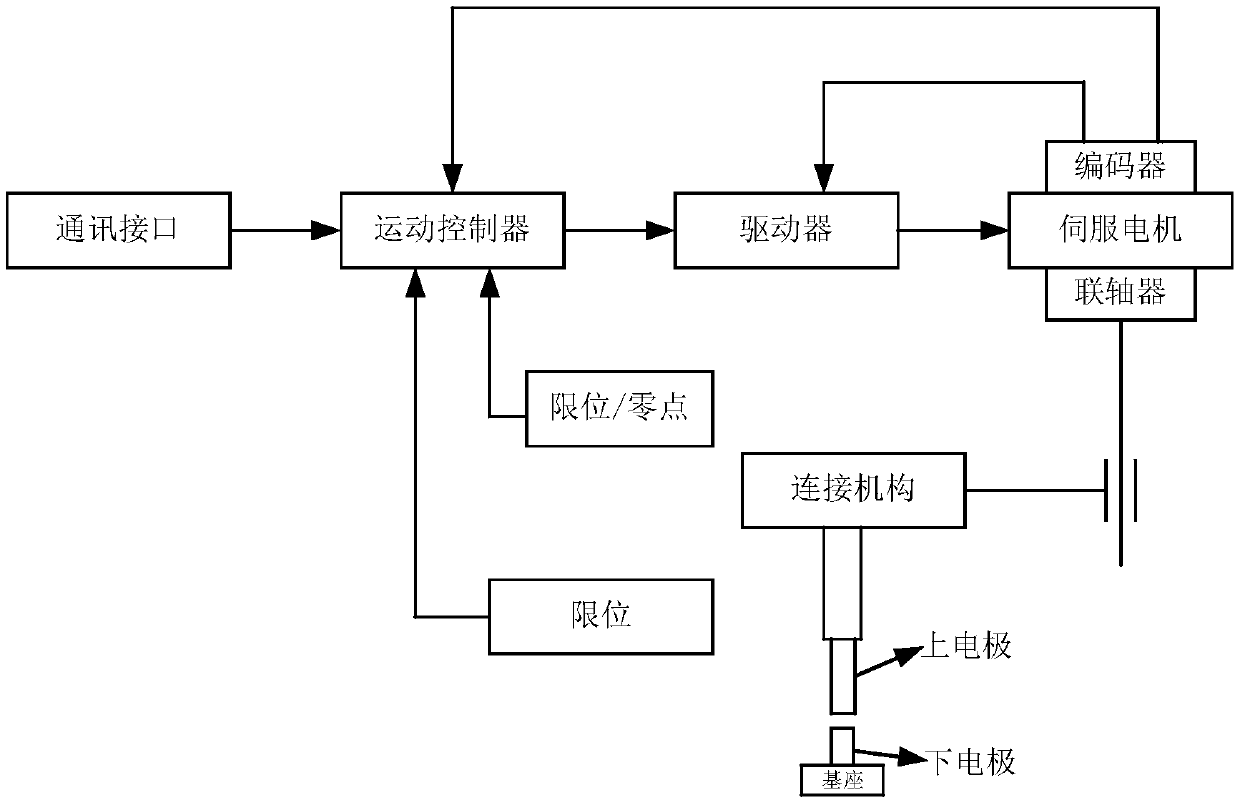

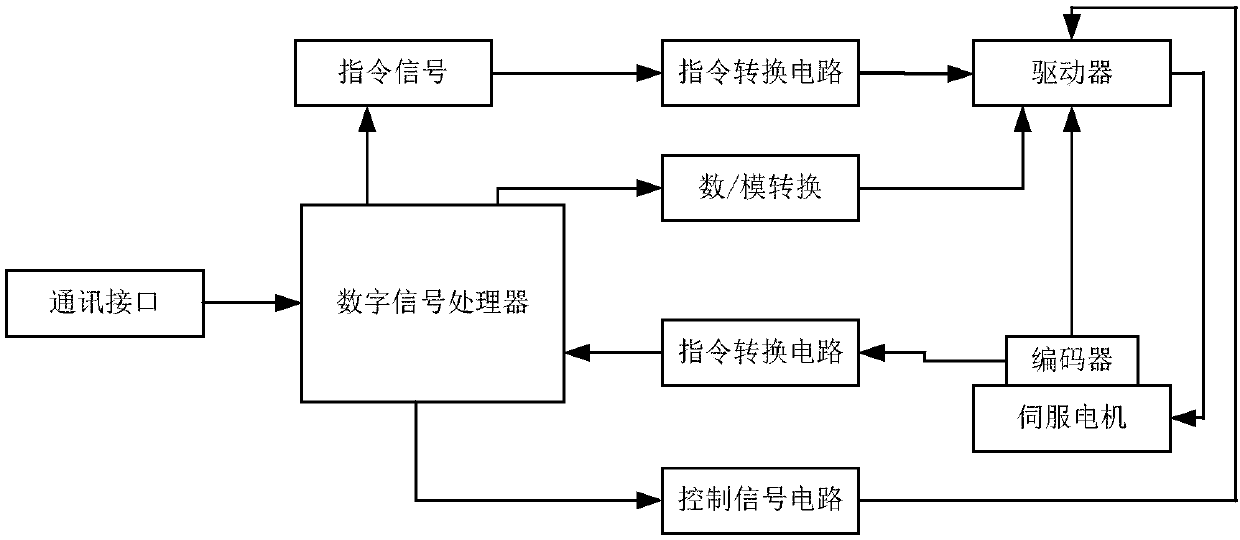

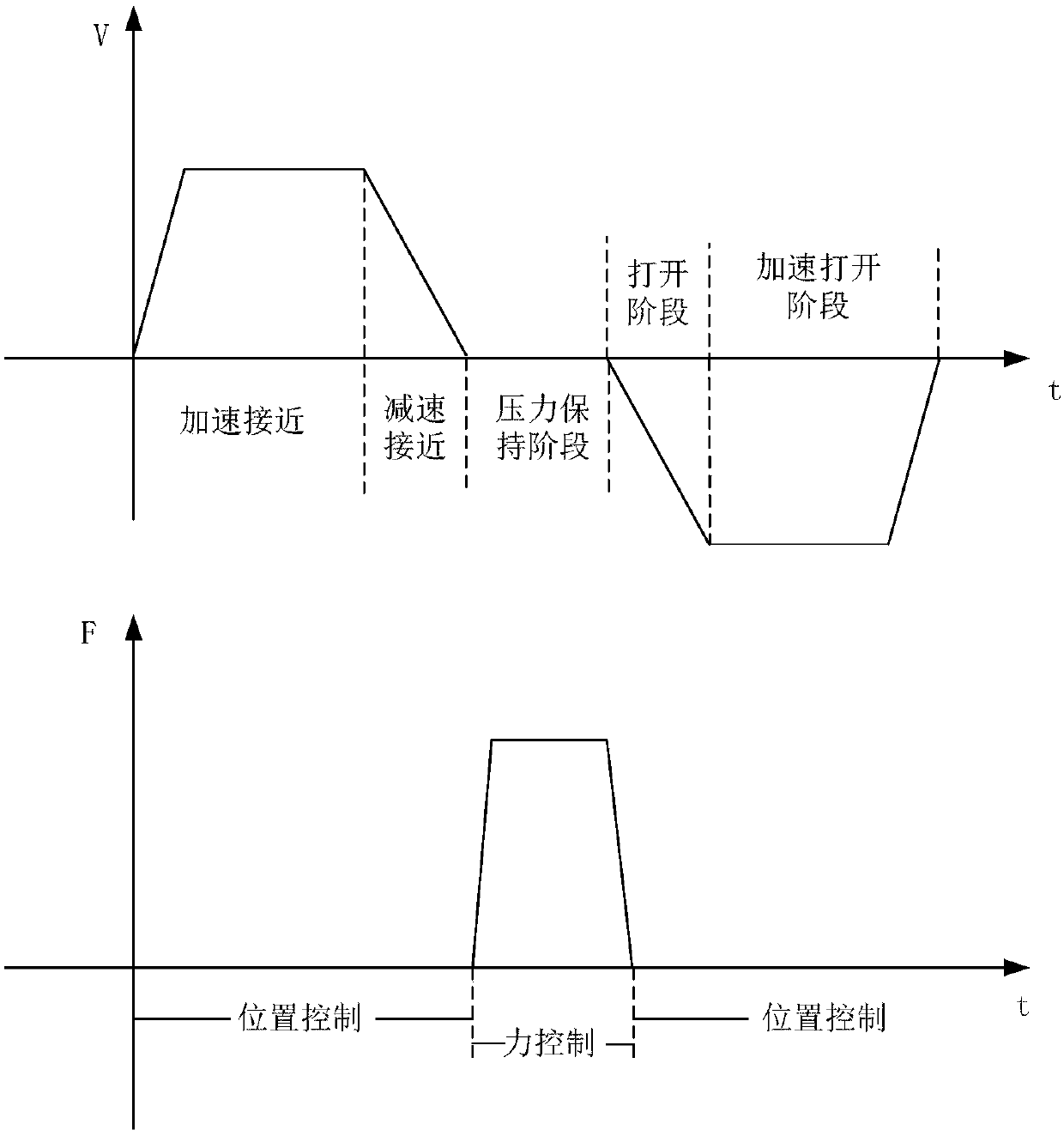

[0032] The present invention is an intermediate frequency inverter resistance spot welding system without parameter setting, including a servo pressurized welding tongs system and a spot welding control system,

[0033] Such as Figure 4 As shown, the servo pressurized welding tongs system includes a welding tongs main body and an intermediate frequency transformer installed thereon, a spot welding servo pressurized system, and an ultrasonic system. The welding tongs main body includes a mounting bracket 1, a welding arm 7, and a main electrode seat 9 and the electrode arm 8, one end of the mounting bracket 1 is equipped with the welding arm 7, and the upper two ends of the welding arm ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap