An electronic inkjet processing platform for roll-to-roll printing with air-floating support function

A technology for printed electronics and processing platforms, applied in printing, printing devices, etc., can solve problems such as the influence of processing errors on film position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail with reference to the accompanying drawings.

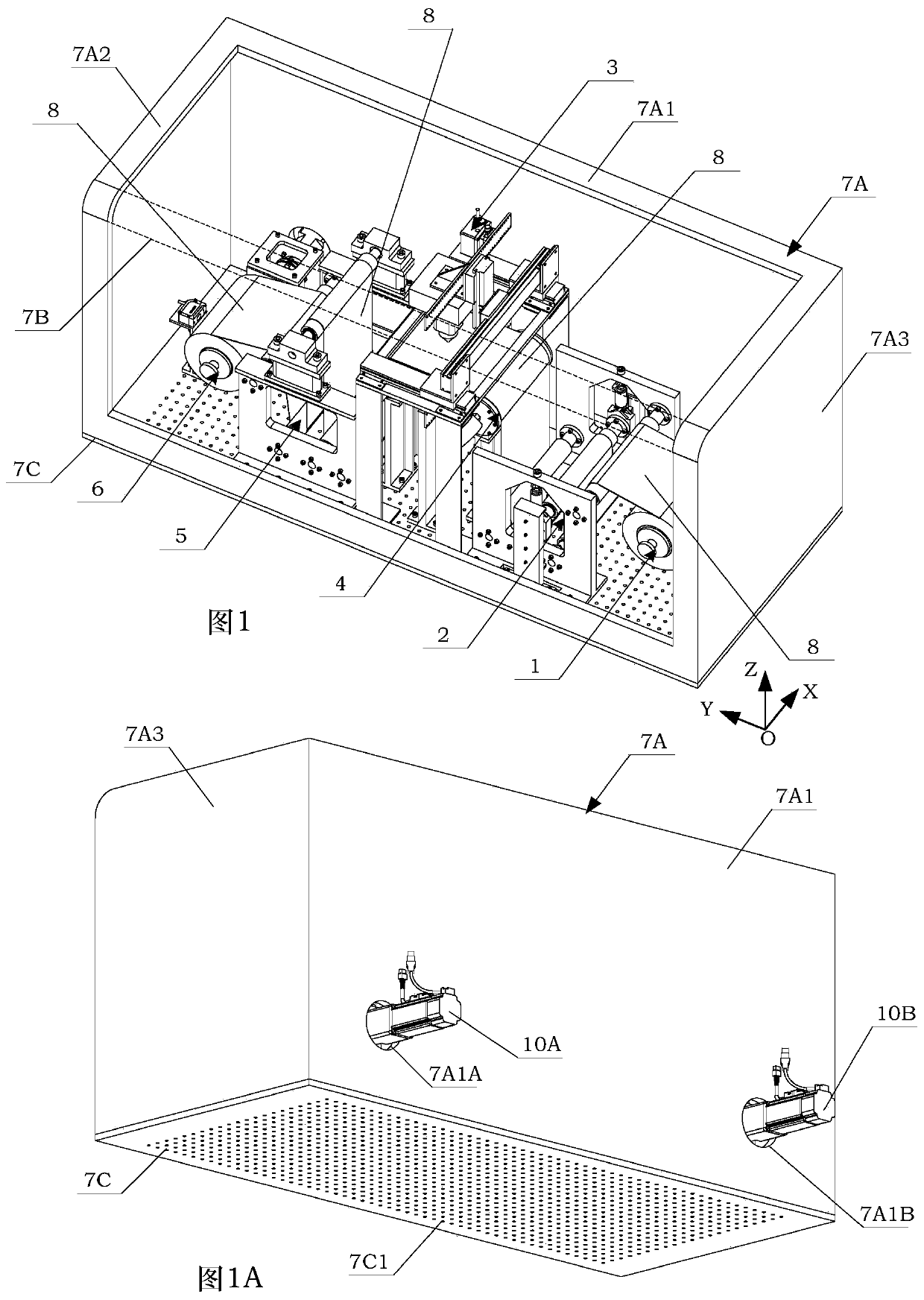

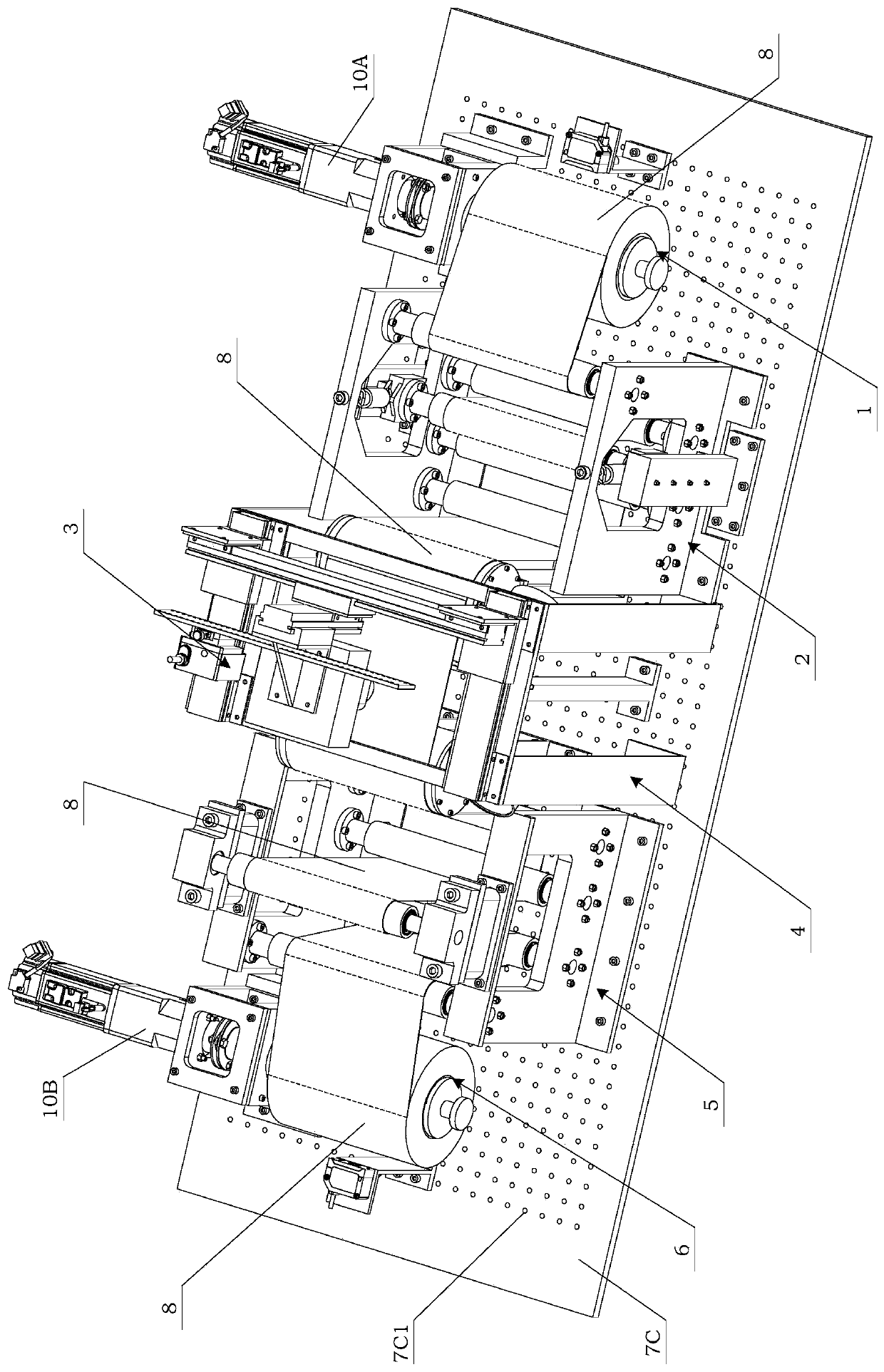

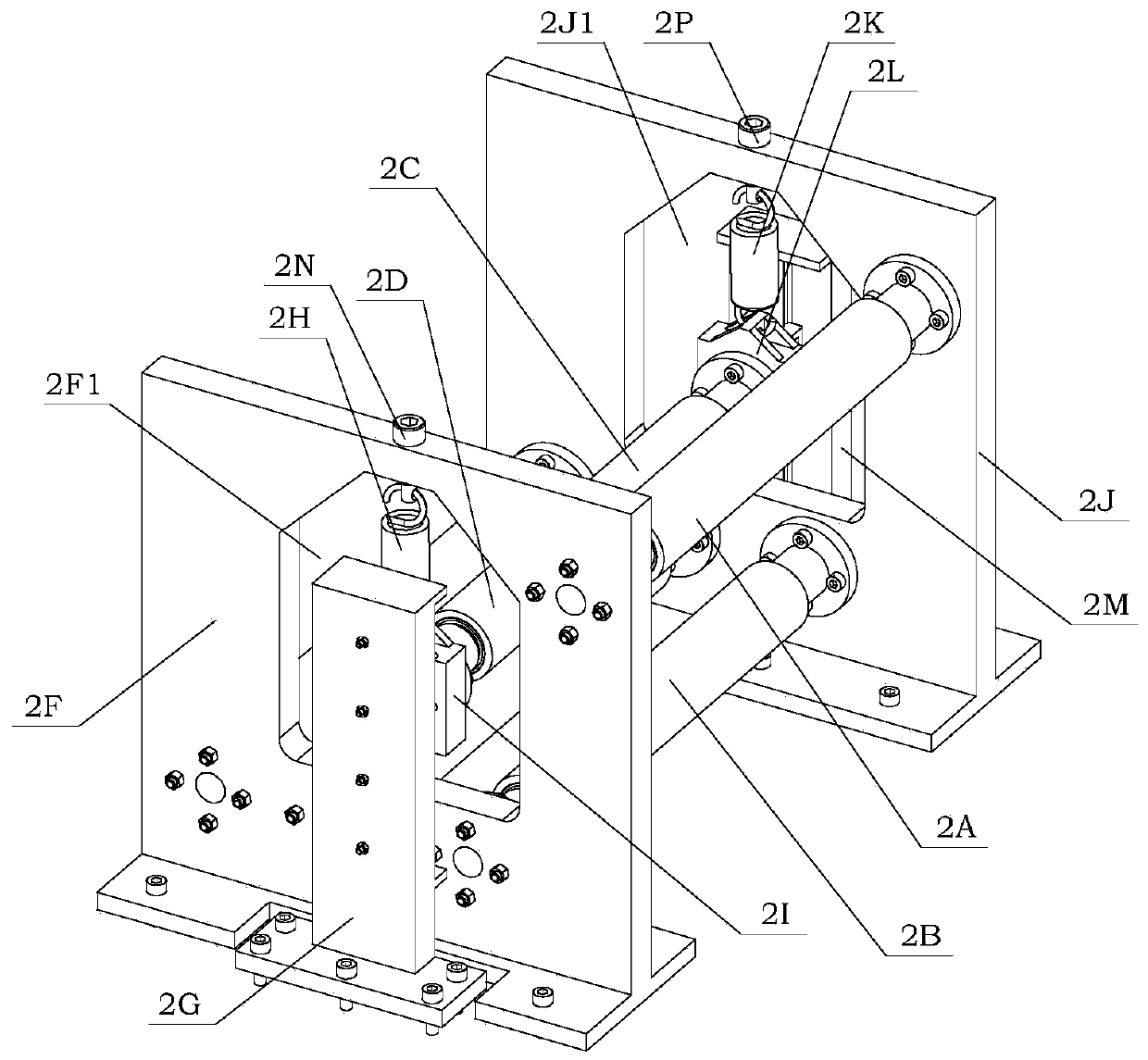

[0054] See figure 1 , Figure 1A , Figure 1B As shown, the present invention designs a roll-to-roll printing electronic inkjet processing platform with air flotation support function. The platform includes an unwinding mechanism 1, a tension adjustment mechanism 2, a nozzle mounting mechanism 3, and a static air flotation roller assembly 4. , Tension detection mechanism 5, winding mechanism 6, outer box 7A, transparent cover 7B and bottom plate 7C.

[0055] Unwinding mechanism 1

[0056] See figure 1 , Figure 1B , Figure 7 , Figure 7A As shown, the unwinding mechanism 1 includes A servo motor 10A, AA bracket 1A, AB bracket 1B, unwinding laser ranging sensor 1C, unwinding reducer 1D, unwinding sleeve 1E, unwinding air expansion shaft 1F, unwinding Reel core barrel 1G, unwind coupling 1H and unwind deep groove ball bearing 1I. A unwinding reducer 1D is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com