Safety warning device for dump truck unloading

A safety warning, dump truck technology, applied in signal devices, tilt-bearing vehicles, etc., can solve the problems of affecting the unloading efficiency, time-consuming and labor-intensive manual command, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

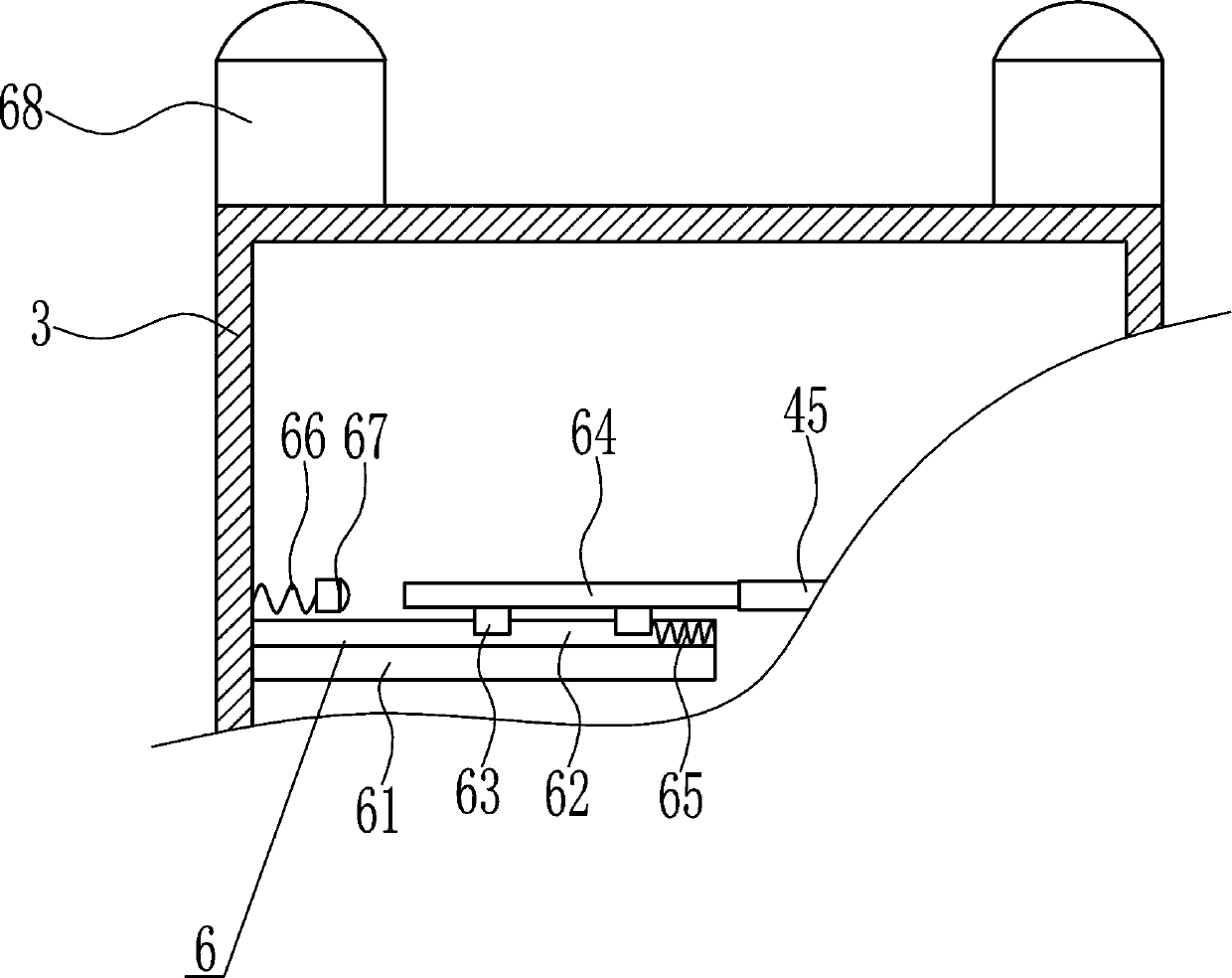

[0036] A dump truck unloading safety warning device, such as Figure 1-8 As shown, it includes a bottom plate 1, a pole 2, a box body 3, a driving device 4 and a ringing device 5. The middle of the top of the bottom plate 1 is connected with a pole 2 by means of bolt connection, and the top of the pole 2 is connected with a box body. 3. A driving device 4 is provided at the inner bottom of the box body 3, and a bell device 5 is provided on the right side of the box body 3.

Embodiment 2

[0038] A dump truck unloading safety warning device, such as Figure 1-8 As shown, it includes a bottom plate 1, a pole 2, a box body 3, a driving device 4 and a ringing device 5. The middle of the top of the bottom plate 1 is connected with a pole 2 by means of bolt connection, and the top of the pole 2 is connected with a box body. 3. A driving device 4 is provided at the inner bottom of the box body 3, and a bell device 5 is provided on the right side of the box body 3.

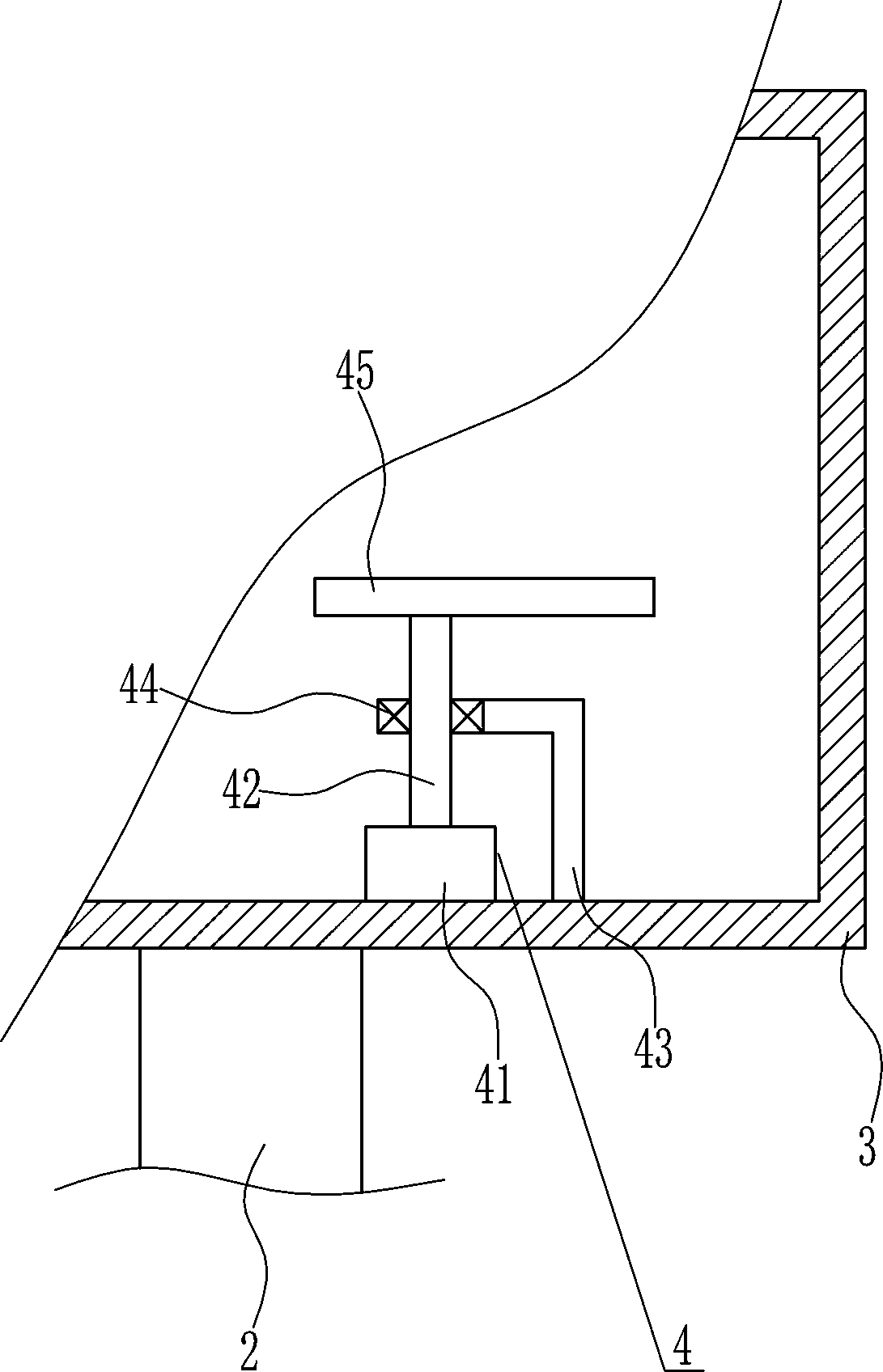

[0039] The driving device 4 includes a first motor 41, a first rotating shaft 42, a first L-shaped rod 43, a bearing seat 44 and a cam 45, and the middle of the inner top of the box body 3 is respectively connected with the first motor 41 and the first motor 41 by bolts. L-shaped bar 43, the first motor 41 is positioned at the left side of the first L-shaped bar 43, the output shaft of the first motor 41 is connected with the first rotating shaft 42 by coupling, the left end of the first L-shaped bar 43 is...

Embodiment 3

[0041] A dump truck unloading safety warning device, such as Figure 1-8 As shown, it includes a bottom plate 1, a pole 2, a box body 3, a driving device 4 and a ringing device 5. The middle of the top of the bottom plate 1 is connected with a pole 2 by means of bolt connection, and the top of the pole 2 is connected with a box body. 3. A driving device 4 is provided at the inner bottom of the box body 3, and a bell device 5 is provided on the right side of the box body 3.

[0042] The driving device 4 includes a first motor 41, a first rotating shaft 42, a first L-shaped rod 43, a bearing seat 44 and a cam 45, and the middle of the inner top of the box body 3 is respectively connected with the first motor 41 and the first motor 41 by bolts. L-shaped bar 43, the first motor 41 is positioned at the left side of the first L-shaped bar 43, the output shaft of the first motor 41 is connected with the first rotating shaft 42 by coupling, the left end of the first L-shaped bar 43 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com