Fabric production process with one-way absorbing reflective protection function

A protective function and production process technology, applied in the field of textile fabric production, can solve problems such as poor reflective effect and damage to the surface of reflective silk, and achieve the effects of preventing fabric deformation, maintaining continuous effectiveness, and high visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

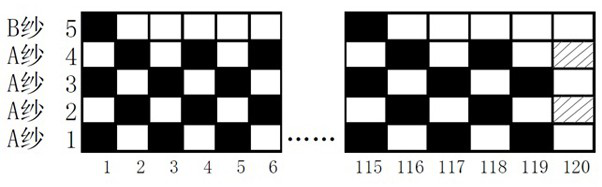

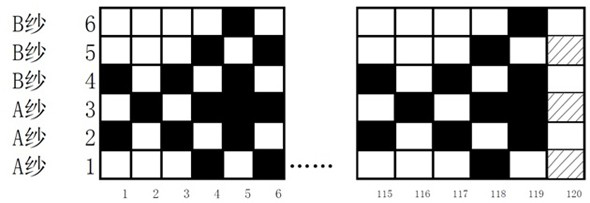

[0033] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] The invention discloses a fabric production process with the function of unidirectional absorption and reflection protection, which comprises the following production steps:

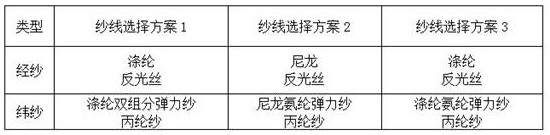

[0035] S1. Yarn selection, choose chemical fiber filament yarn and reflective yarn for warp yarn, elastic yarn and polypropylene yarn for weft yarn. The polypropylene yarn is set on the weft yarn, which is convenient for designing fabric weave with unidirectional suction. Adding stretch yarns to the weft increases the elasticity of the fabric. The setting of the reflective thread makes the front of the final fabric present a reflective effect.

[0036] The reflective yarn is made by coating glass beads on the front and back of the polyester...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com