Material guard bar piling equipment used for building construction

A technology of building construction and piling equipment, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of time-consuming and labor-intensive, piles are easy to be knocked, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

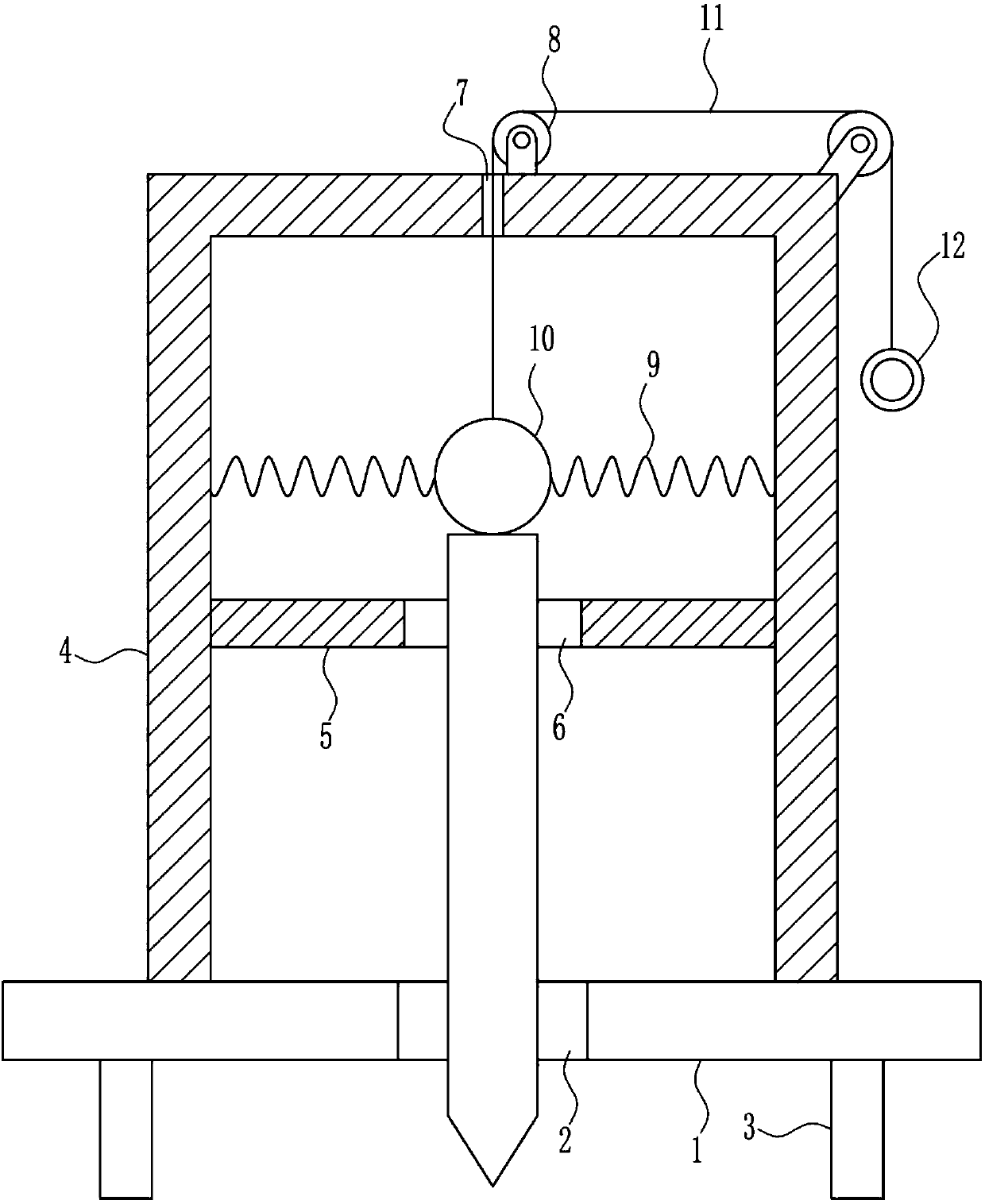

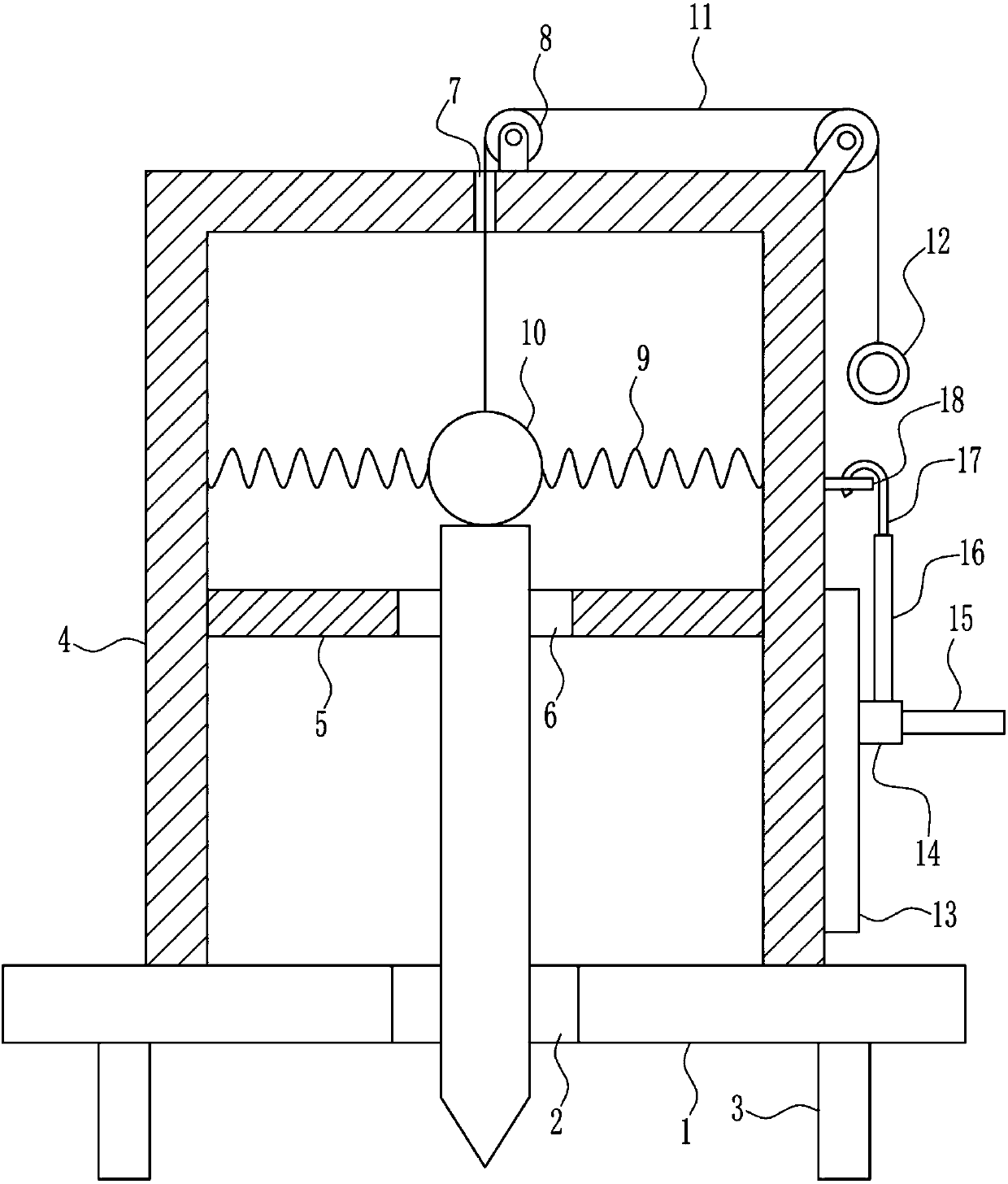

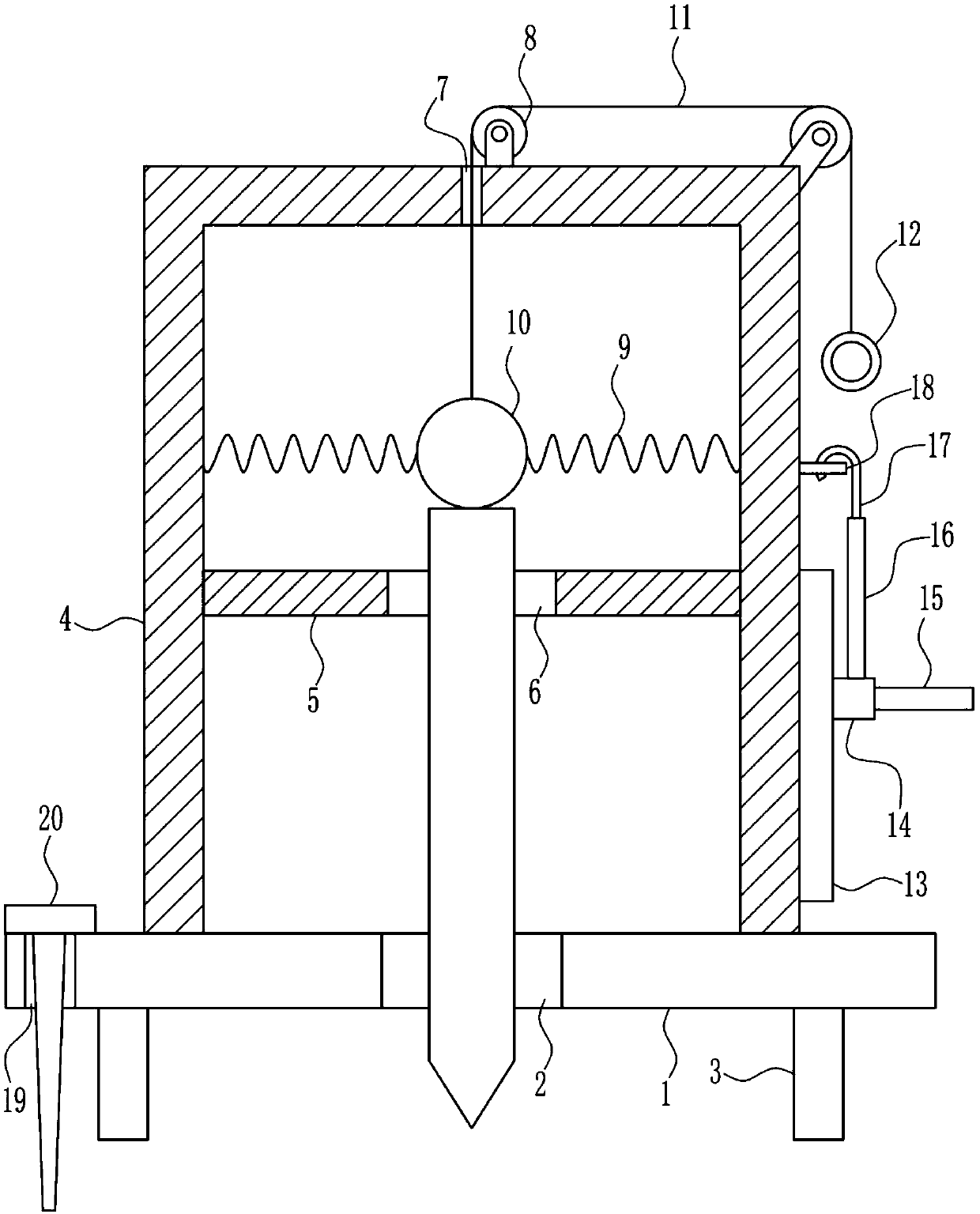

[0023] A material protection fence piling equipment for building construction, such as Figure 1-3 As shown, it includes a support plate 1, a wheel 3, a mounting frame 4, a guide plate 5, a fixed pulley 8, a spring 9, an iron ball 10, a drawstring 11, and a lifting ring 12. The support plate 1 has a placement slot 2 in the middle of the front side, The lower side of the support plate 1 is provided with wheels 3 symmetrically on the left and right sides. The upper middle of the support plate 1 is provided with a mounting frame 4. The mounting frame 4 is provided with a guide plate 5 between the inner middle of the left and right walls. The guide plate 5 has a guide hole in the middle. 6. There is a first through hole 7 in the middle of the upper wall of the mounting frame 4, two fixed pulleys 8 are installed on the right side of the upper wall of the mounting frame 4, and the upper part of the left and right walls of the mounting frame 4 are symmetrically connected with a spring ...

Embodiment 2

[0025] A material protection fence piling equipment for building construction, such as Figure 1-3 As shown, it includes a support plate 1, a wheel 3, a mounting frame 4, a guide plate 5, a fixed pulley 8, a spring 9, an iron ball 10, a drawstring 11, and a lifting ring 12. The support plate 1 has a placement slot 2 in the middle of the front side, The lower side of the support plate 1 is provided with wheels 3 symmetrically on the left and right sides, the upper middle of the support plate 1 is provided with a mounting frame 4, the mounting frame 4 is provided with a guide plate 5 between the inner middle of the left and right walls, and a guide hole is opened in the middle of the guide plate 5 6. There is a first through hole 7 in the middle of the upper wall of the mounting frame 4, two fixed pulleys 8 are installed on the right side of the upper wall of the mounting frame 4, and the upper part of the left and right walls of the mounting frame 4 are symmetrically connected wi...

Embodiment 3

[0028] A material protection fence piling equipment for building construction, such as Figure 1-3 As shown, it includes a support plate 1, a wheel 3, a mounting frame 4, a guide plate 5, a fixed pulley 8, a spring 9, an iron ball 10, a drawstring 11, and a lifting ring 12. The support plate 1 has a placement slot 2 in the middle of the front side, The lower side of the support plate 1 is provided with wheels 3 symmetrically on the left and right sides, the upper middle of the support plate 1 is provided with a mounting frame 4, the mounting frame 4 is provided with a guide plate 5 between the inner middle of the left and right walls, and a guide hole is opened in the middle of the guide plate 5 6. There is a first through hole 7 in the middle of the upper wall of the mounting frame 4, two fixed pulleys 8 are installed on the right side of the upper wall of the mounting frame 4, and the upper part of the left and right walls of the mounting frame 4 are symmetrically connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com