Energy-saving environment-friendly high-efficiency dust treatment device

A processing device, energy saving and environmental protection technology, applied in transportation and packaging, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of easy damage of filter cartridges, inconvenient operation, etc., to solve inconvenient operation, improve cleaning effect, Creatively conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

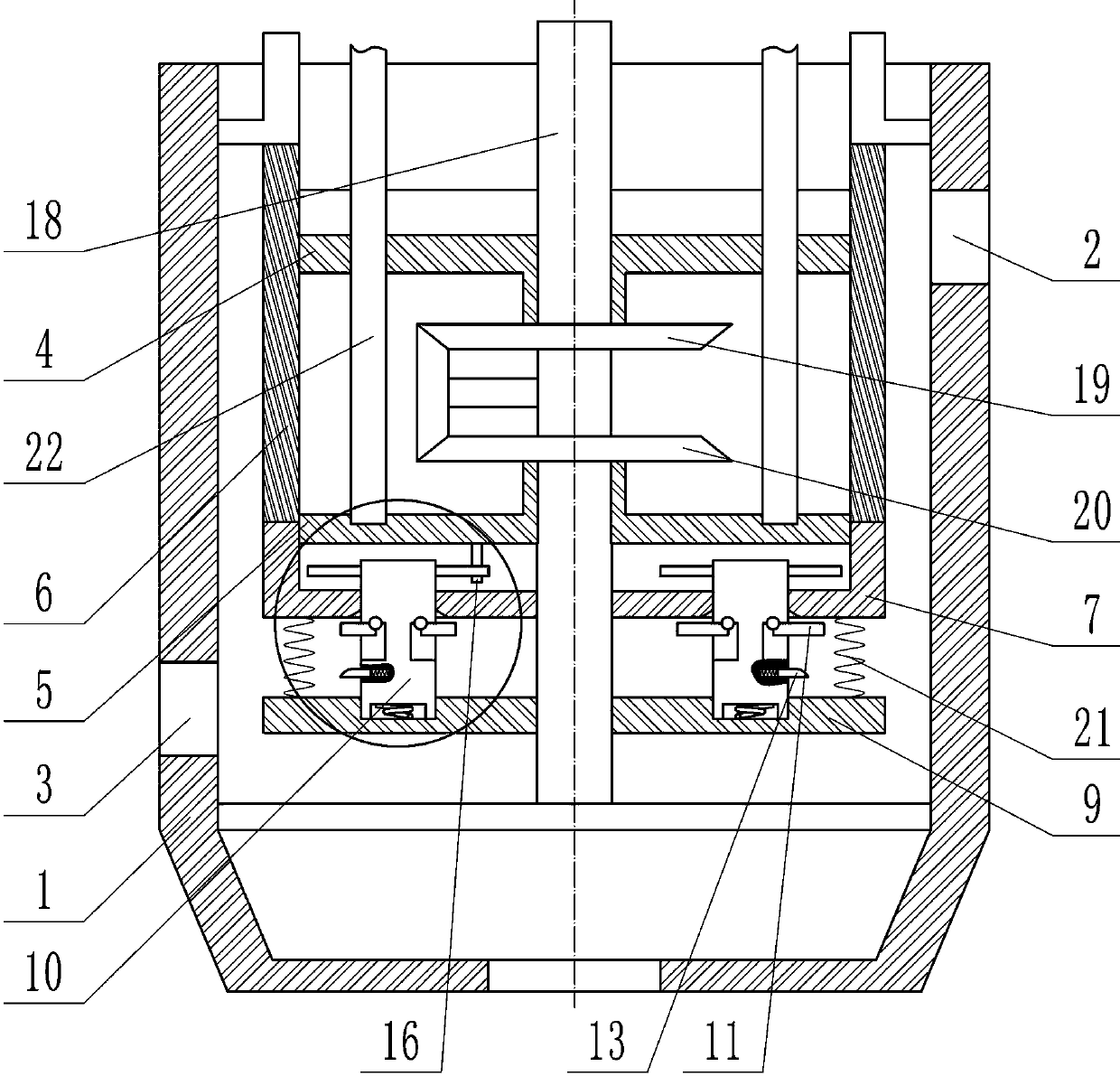

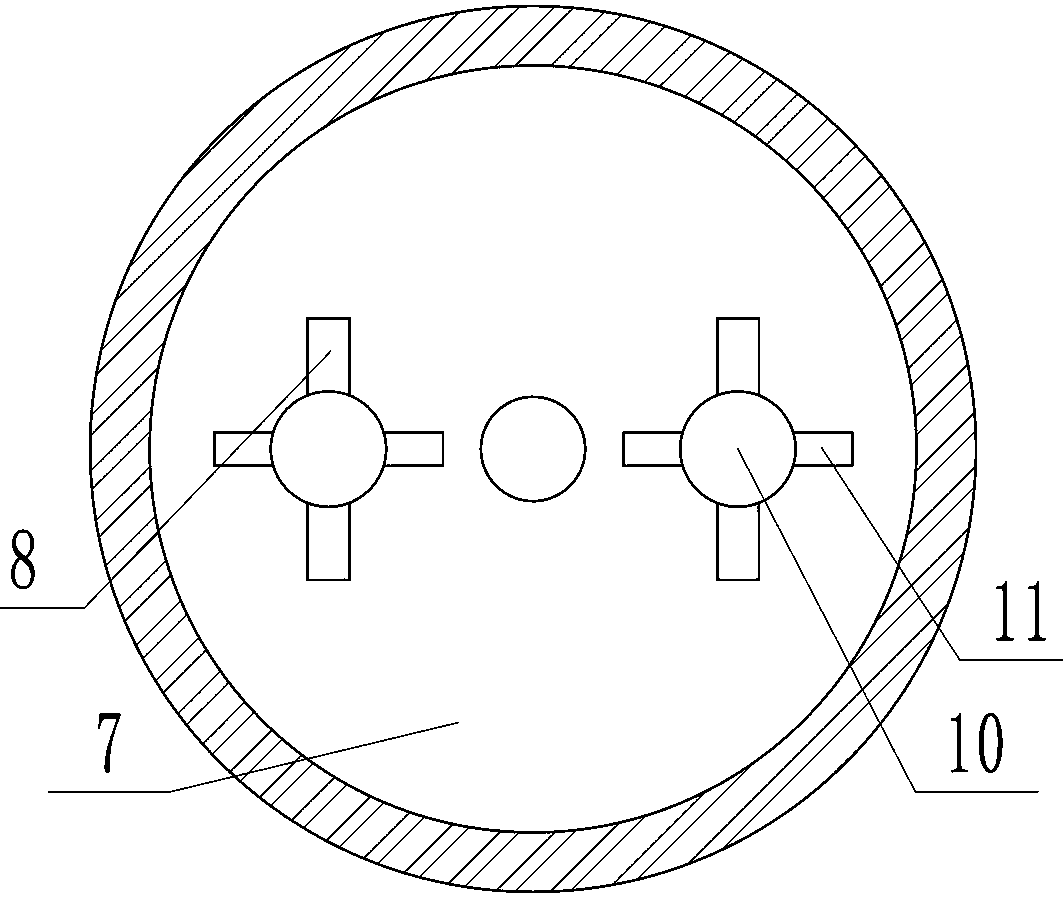

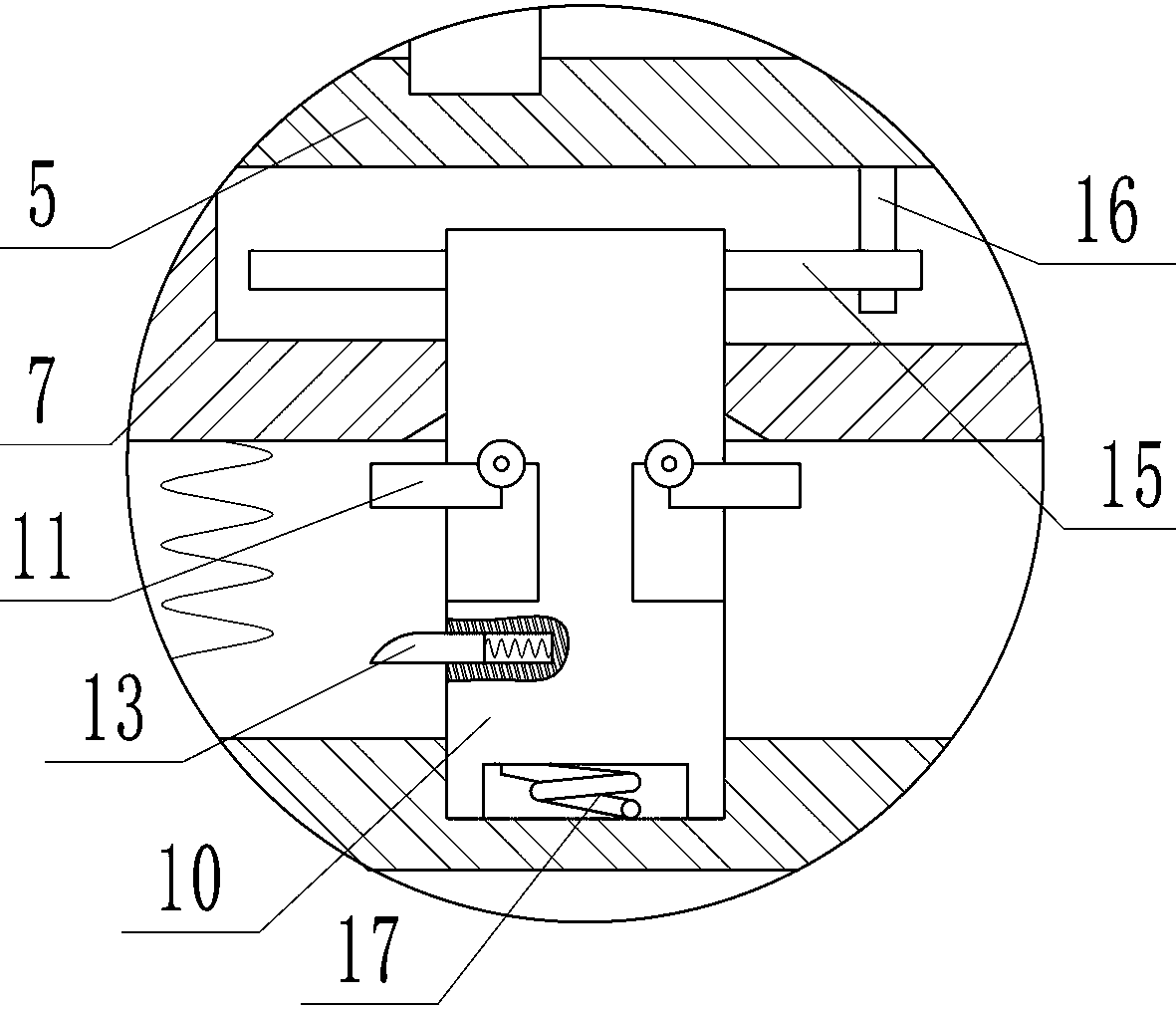

[0020] Depend on Figure 1-10 It can be seen that the present invention includes a vertically placed housing 1, the lower left side of the housing 1 is provided with an air inlet 3, the upper right side of the housing 1 is provided with an exhaust port 2, and the inside of the housing 1 is provided with a horizontally placed and Rotatable upper turntable 4, below the upper turntable 4 is provided with a lower turntable 5 arranged horizontally and opposite to the turn of the lower turntable 4, the connecting line between the centers of the two turntables is on the same vertical straight line, and the outer circles of the two turntables are equipped with A filter cartridge 6 that can move up and down. Both the upper turntable 4 and the lower turntable 5 can drive the filter cartridge 6 to rotate. When the filter cartridge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com