Six-row high-speed four-sealed-surface particle packing machine

A kind of particle packaging and high-speed technology, which is applied in packaging machines, packaging, transportation packaging, etc., can solve problems such as inconvenient use and pollution, and achieve the effects of improving production efficiency, improving transmission accuracy, and flexible assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

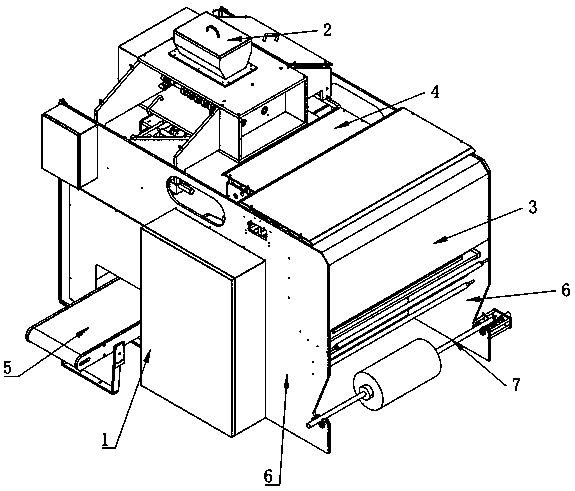

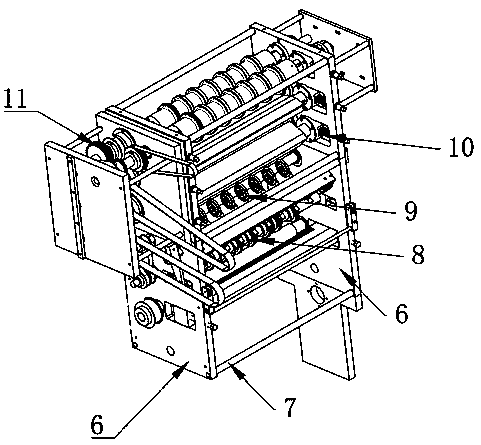

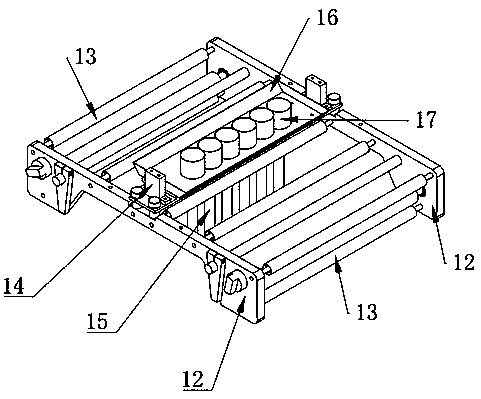

[0019] The six-column high-speed four-side sealing granule packaging machine according to the embodiment of the present invention includes a servo main transmission mechanism 1, a filling mechanism 2, a packaging mechanism 3, a shearing mechanism 4 and a discharge device 5, the main transmission mechanism and the filling mechanism The filling mechanism is arranged between the packaging mechanisms, and the shearing mechanism and the discharge device are sequentially arranged at the discharge port of the packaging mechanism. The servo main transmission mechanism includes left and right side plates 6, paper film fixing shaft 7, traction mechanism 8, cutting mechanism 9 and pressure adjustment mechanism 10 in sequence from bottom to top, and a sealing machine is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com