Composite type aluminum ceiling

A ceiling and composite technology, which is applied in the field of building decoration materials, can solve the problems of poor ventilation effect, complicated installation process, and poor fixing effect of aluminum ceilings, and achieve the effects of good connection and fixing effects, improved installation efficiency, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

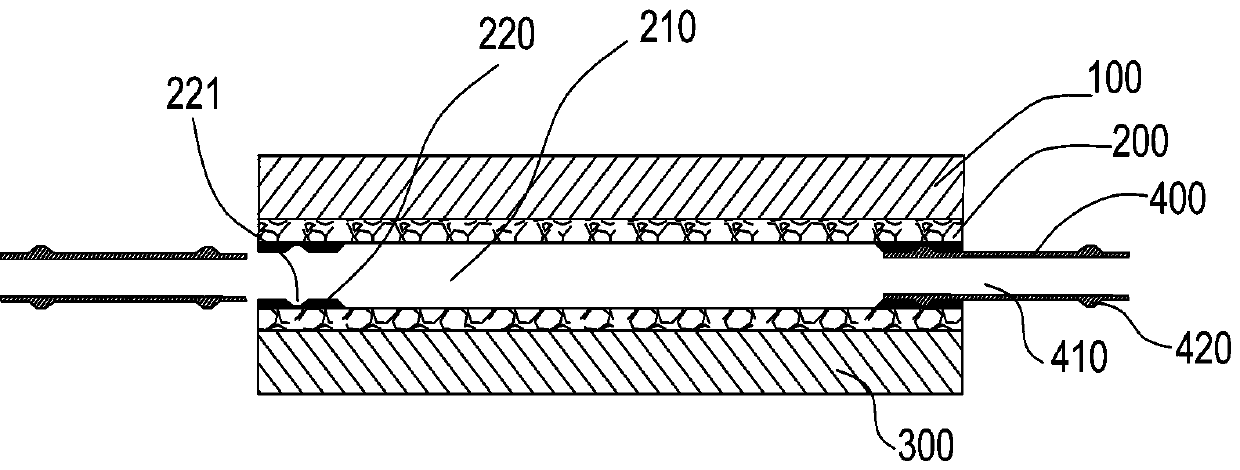

[0024] Such as figure 1 As shown, this embodiment provides a composite aluminum ceiling, including an upper aluminum plate 100, an adhesive layer 200, and a lower aluminum plate 300 arranged in sequence from top to bottom, and the upper aluminum plate 100, the adhesive layer 200, and the lower aluminum plate 300 are rectangular panels , the periphery of the structure composed of them, that is, the four sides are wrapped with a surrounding frame to strengthen the firmness of the structure; the bonding layer 200 can be selected from thermoplastic materials such as resin, rubber, etc., and epoxy-nitrile adhesive is selected in this embodiment, which can be more Good adhesion of the upper and lower aluminum plates, the adhesive layer 200 can help the aluminum ceiling to improve the structural strength through its own toughness, and the adhesive layer 200 can also play a certain role in sound insulation and sound absorption; the adhesive layer 200 is provided with a connecting chann...

Embodiment 2

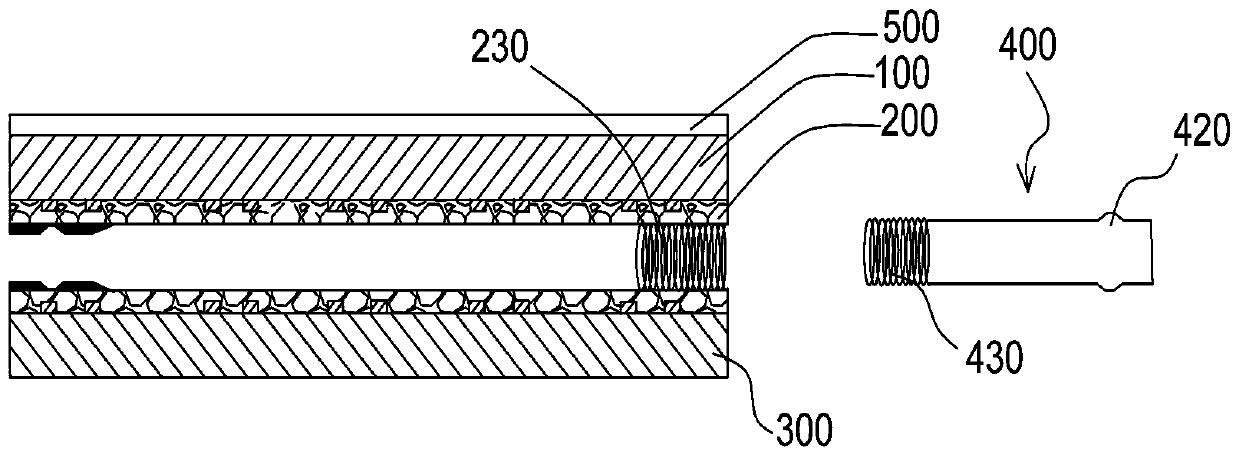

[0031] Such as figure 2 As shown, the composite aluminum ceiling provided in this embodiment has better appearance and firmness.

[0032] A first thread 230 is provided on the inner surface of the connecting channel 210 , and a second thread 430 is provided on the outer surface of the connecting member 400 near the mouth of the connecting channel 210 . The connecting piece 400 is connected to the first thread 230 of the connecting channel 210 in a rotational manner through the second thread 430. In order to make the connection tighter and water-tight, a raw tape can be used to wrap the thread and then rotate to connect; the connecting piece The end of the 400 away from the mouth of the connecting channel 210 is also provided with threads, which can be connected and fixed with other aluminum ceilings provided with the connecting channel 210 .

[0033]More preferably, the way of connecting with another aluminum ceiling is plug-in fixing, which is also more convenient and quick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com