Sliding rail assembly

A technology of slide rail assembly and locking parts, which is applied in the direction of bearings, linear motion bearings, shafts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

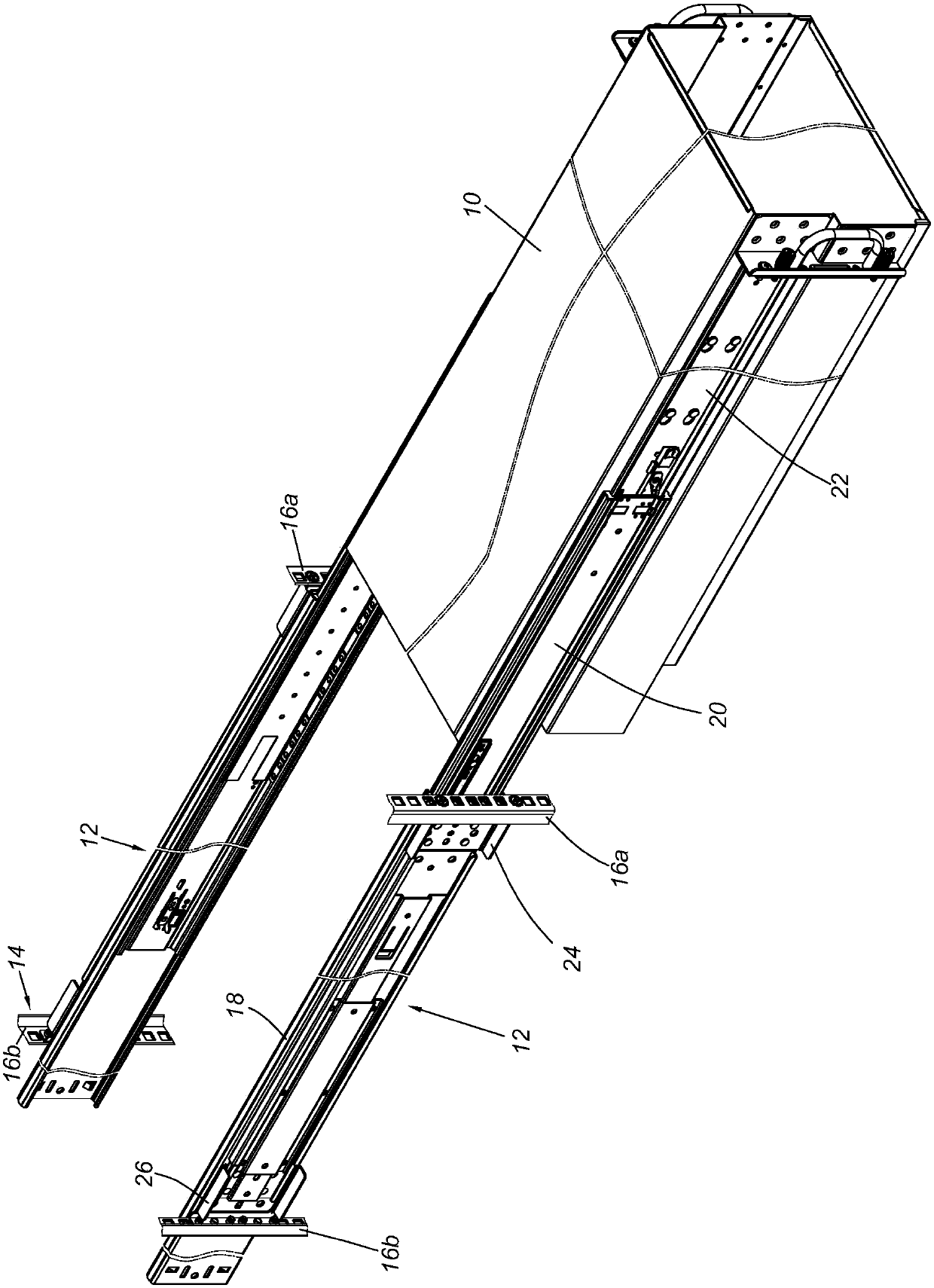

[0037] figure 1 A load 10 is shown mounted to a frame 14 by means of a pair of slide rail assemblies 12 . The carrier 10 may be a chassis of an electronic device or a drawer or the like. The rack 14 includes a pair of first machine columns 16a and a pair of second machine columns 16b. Specifically, each sliding rail assembly 12 includes a first rail 18 , a second rail 20 and a third rail 22 . The two parts of the first rail 18 can be respectively configured with a first bracket 24 and a second bracket 26 for being respectively installed on the first column 16 a and the second column 16 b of the frame 14 . In addition, the third rail 22 is used for mounting the carrier 10 . According to this configuration, with the second rail 20 and the third rail 22 being in an extended state relative to the first rail 18 , the load 10 can be located outside the frame 14 .

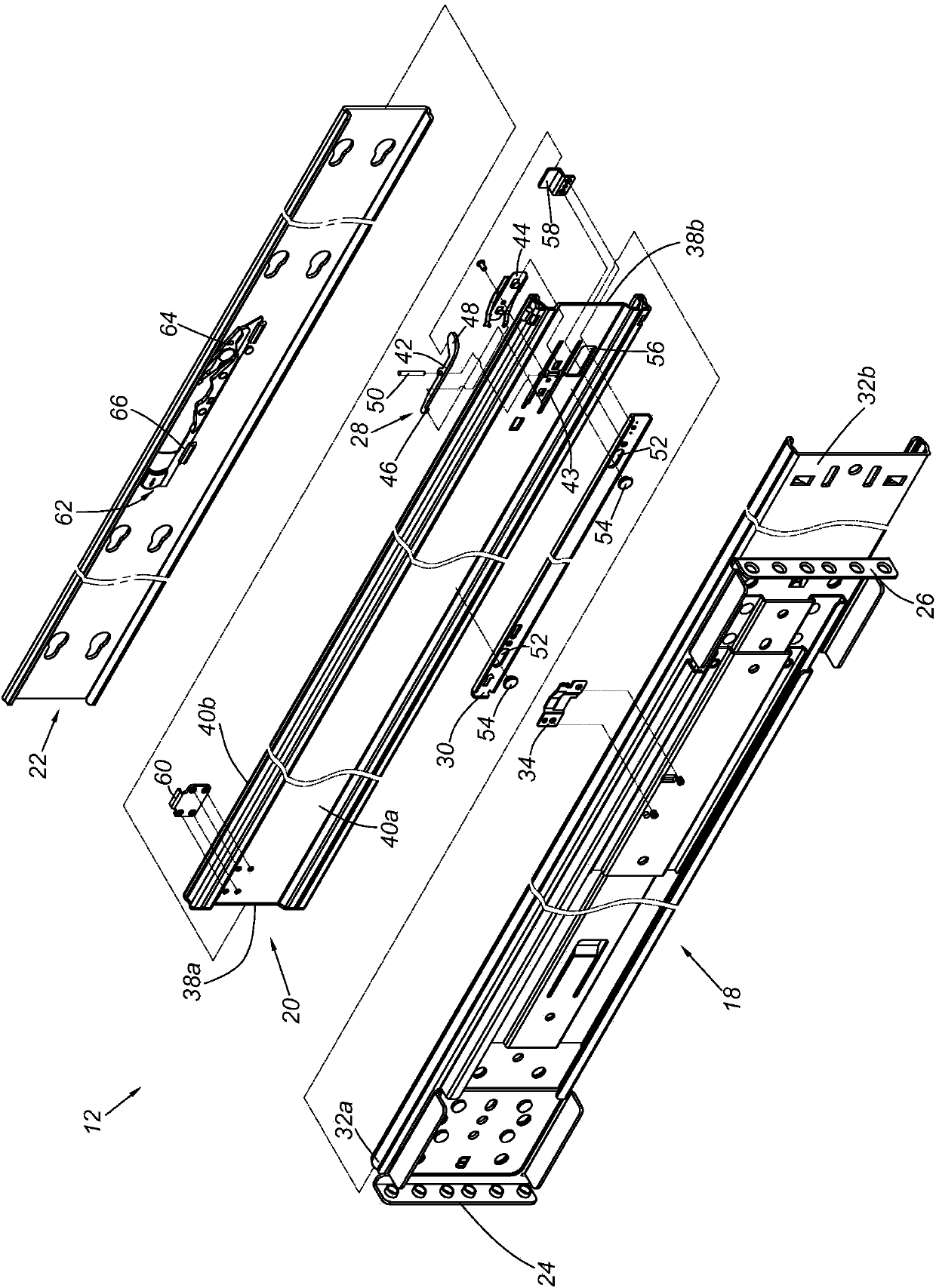

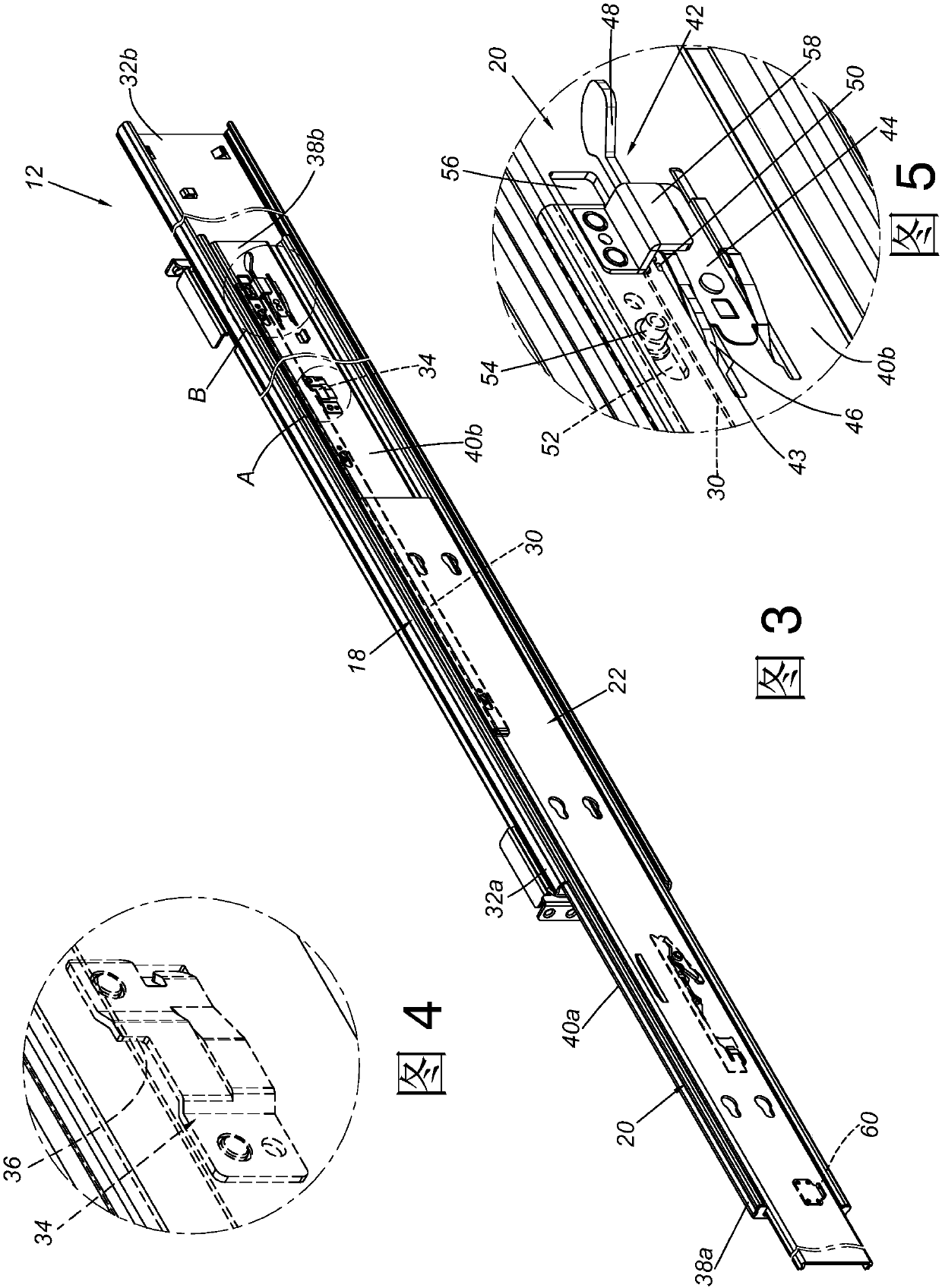

[0038] figure 2 The exploded state of the first rail 18 , the second rail 20 and the third rail 22 of the slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com