Method detecting machine start abnormity automatically

An automatic detection and machine technology, applied in the direction of instruments, measuring electronics, measuring devices, etc., can solve the problems of increasing the failure rate of products, not being able to meet the flexibility and convenience of hardware debugging and testing, and automatically restoring factory settings, so as to avoid manpower consumption Material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

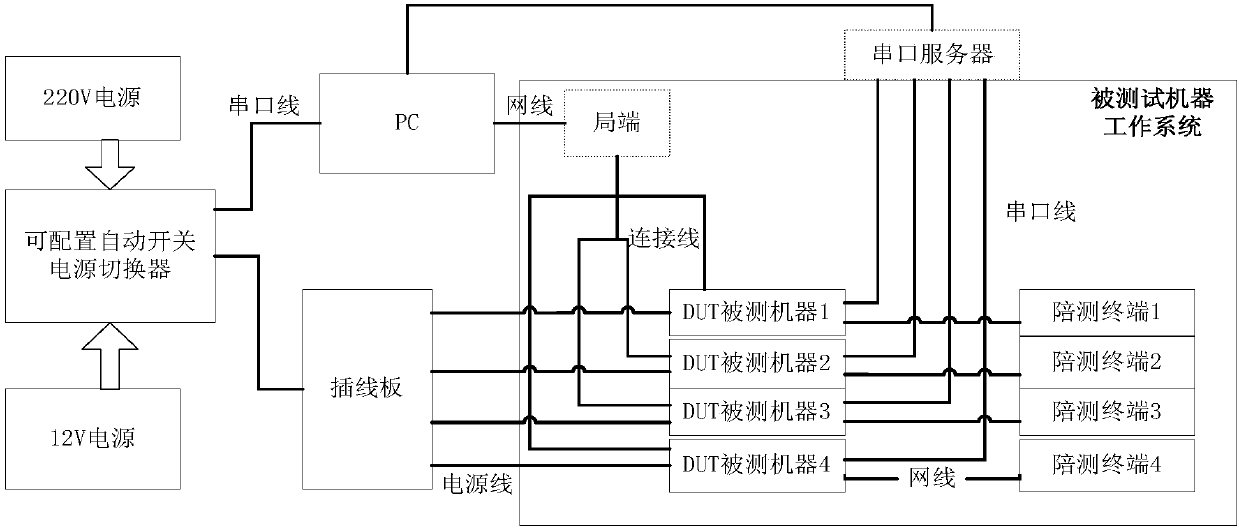

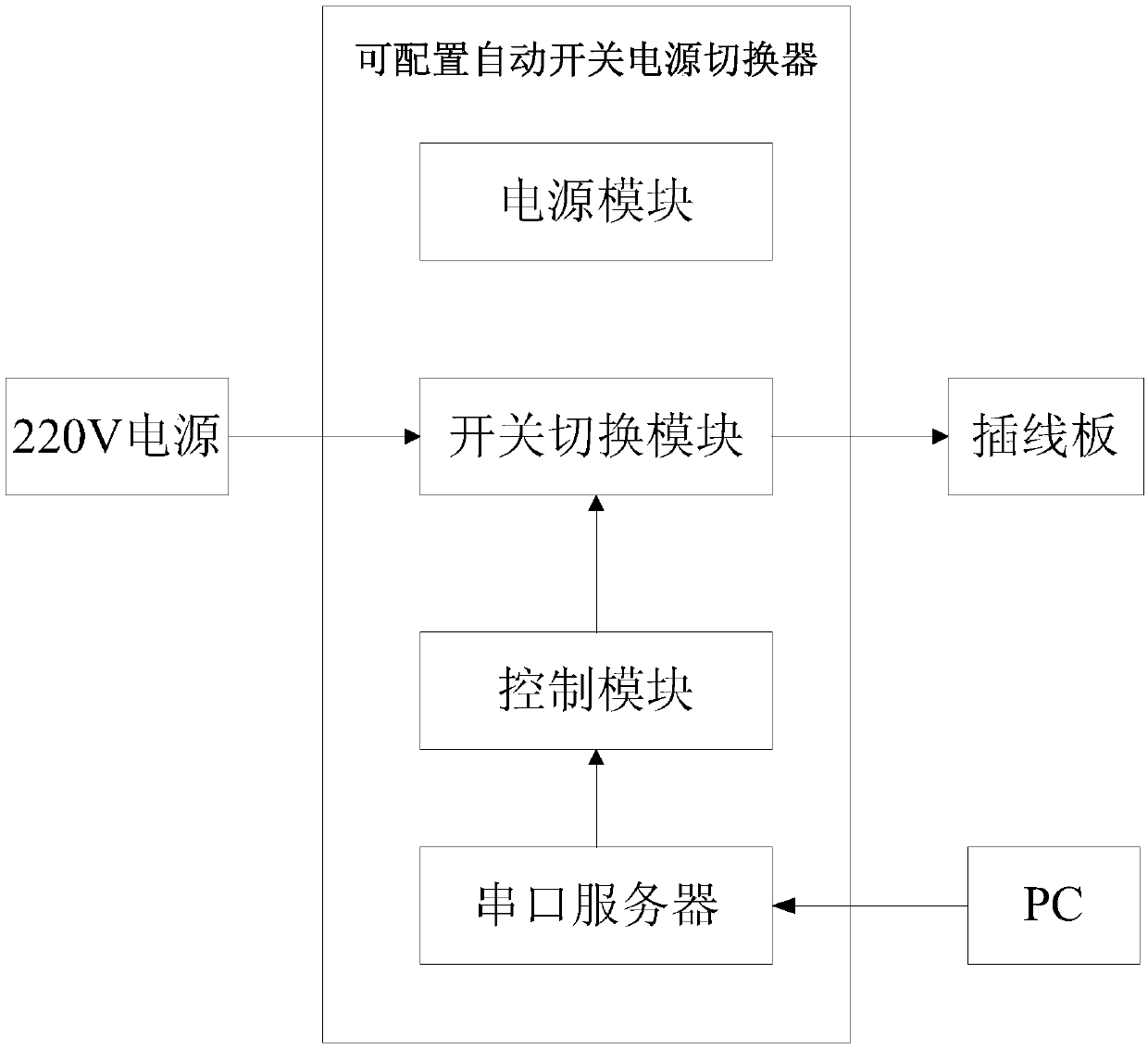

[0024] as attached figure 1 As shown, a method for automatically detecting machine startup abnormalities, including a configurable automatic switching power switch, a PC, a serial port server, and a working system of the machine under test, the working system of the machine under test includes a local end, the machine under test, and an accompanying test terminal;

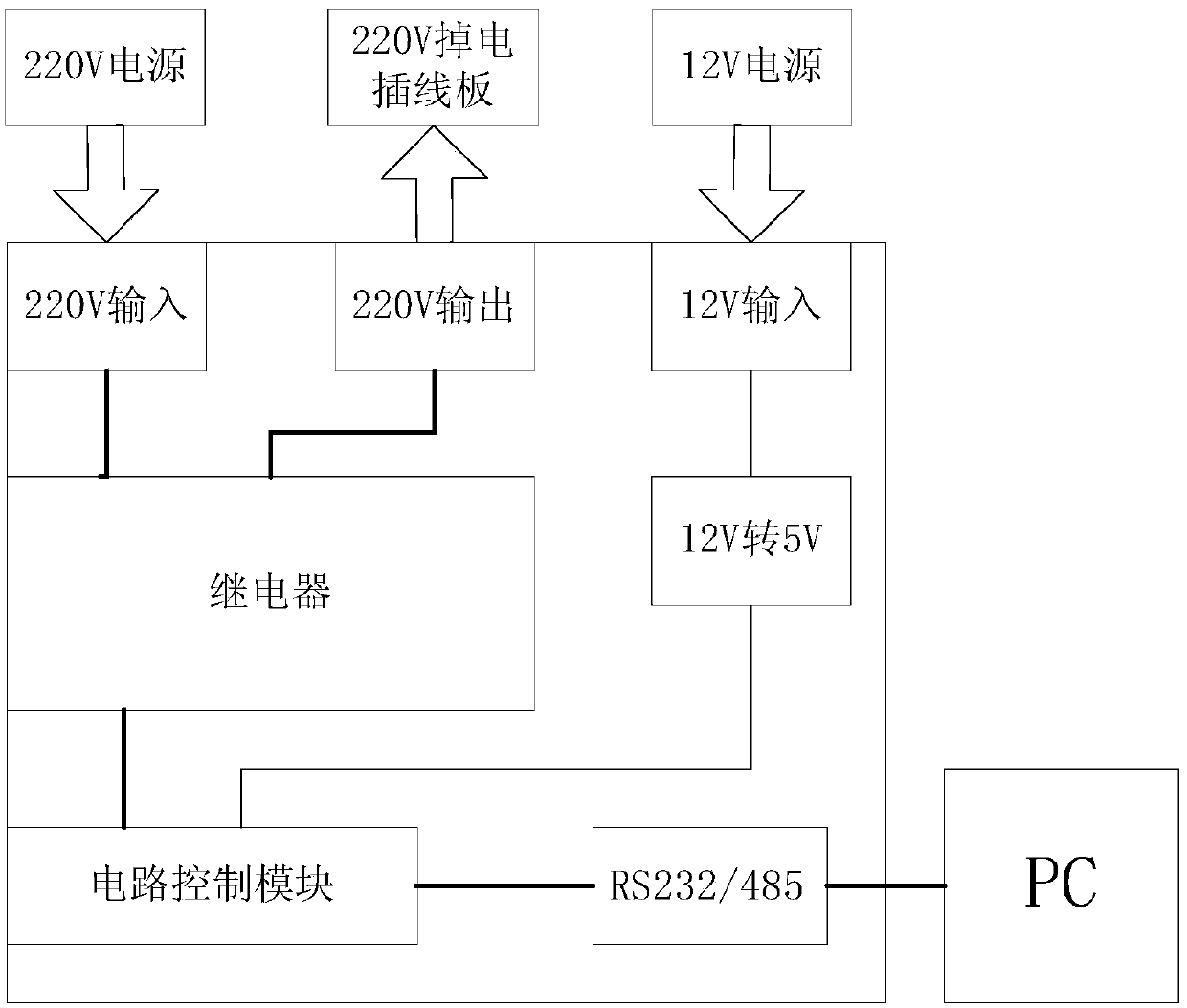

[0025] The configurable automatic switching power supply switch is connected to 220V AC power supply, and outputs 220V power supply for the machine under test through the plug board, and realizes the on-off of 220V voltage through PC software;

[0026] The PC communicates with the configurable automatic switch power switch through the serial port line, controls the power switch of the plug board connected to the tested machine, and analyzes the power-on time by analyzing the data of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com