Regulating type full-frequency horn

An adjustable and loudspeaker technology, applied in the field of full-range speakers, can solve the problems of inconvenient clamping, inconvenient clamping, inconvenient rotation adjustment, etc., and achieve the effect of convenient horizontal rotation adjustment and improved adjustment flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

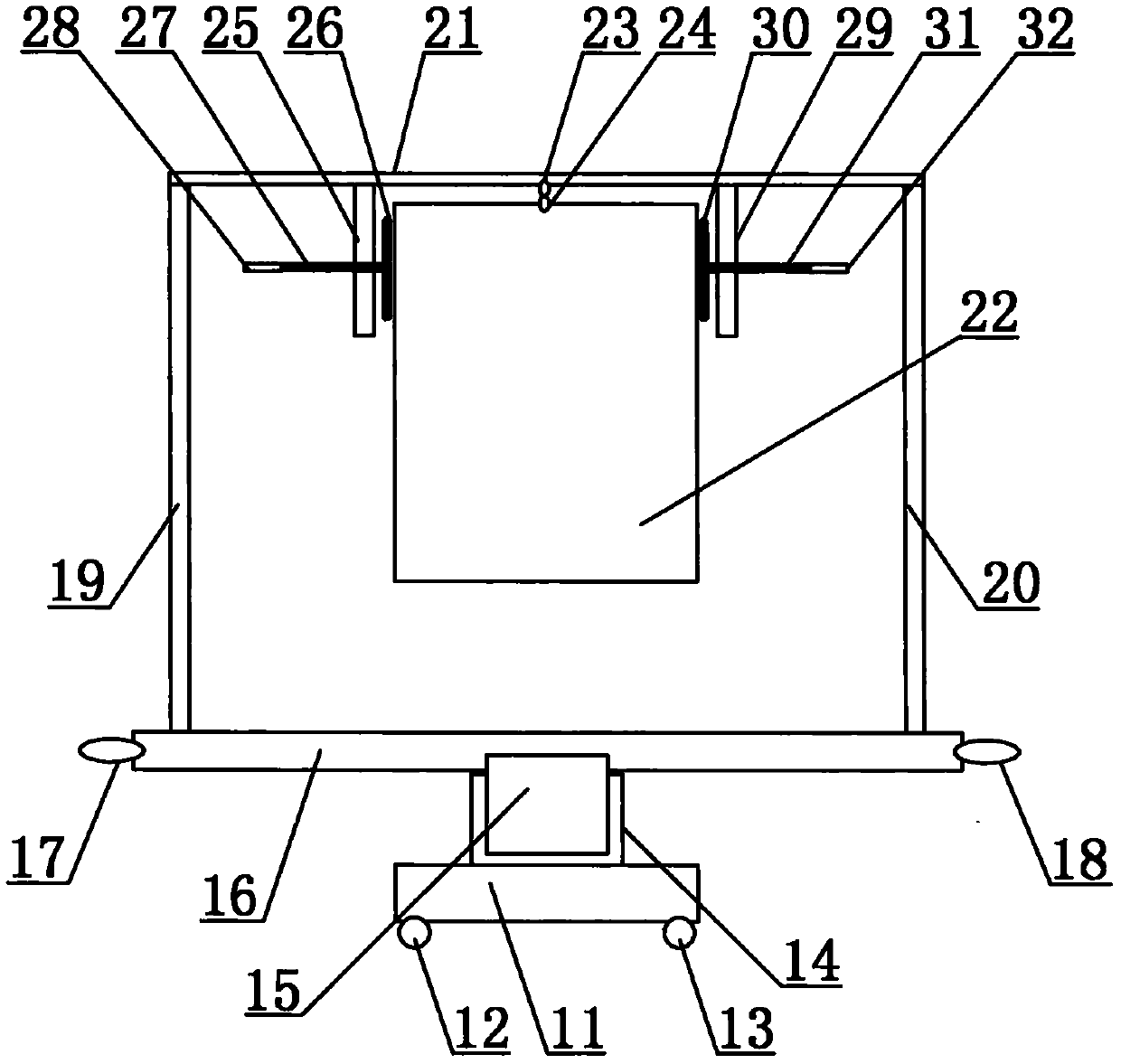

[0014] like figure 1 As shown, an adjustable full-range speaker includes a base 11, the bottom of the base 11 is provided with a first moving wheel 12 and a second moving wheel 13, the first moving wheel 12 and the second moving wheel 13 have the same shape and size, and the first moving wheel 12 and the second moving wheel 13 have the same shape and size. A moving wheel 12 and the second moving wheel 13 are universal wheels; the base 11 is provided with a guide tube 14, the guide tube 14 is vertically arranged, the guide tube 14 is a tubular structure, and the guide tube 14 is sleeved with a coiled tube 15, The coiled tube 15 is vertically arranged, the outer surface of the coiled tube 15 is provided with external threads, the inner surface of the guide tube 14 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com