Molding sand feeding and loosening device

A feeding and loosening technology, which is applied to the cleaning/processing machinery of casting materials, casting molding equipment, metal processing equipment, etc., can solve the problems of loosening, unreasonable design of molding sand feeding, affecting the processing quality of the production line, etc., and achieves a simple structure. , the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

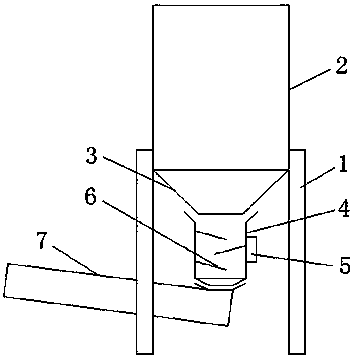

[0012] see figure 1 :

[0013] The molding sand feeding and loosening device includes a box body 2 with an open upper end installed on the bracket 1, a tapered discharge hopper 3 is provided at the bottom of the box body 2, and a receiving box 4 with a bell mouth at the upper end is provided below the discharge hopper 3. A vibrator 5 is installed on the outer wall of the receiving box 4, and a staggered sliding material plate 6 is installed on the opposite inner wall of the receiving box 4. A screw feeder 7 installed obliquely is arranged below the discharge port of the receiving box 4, and the screw feeding The feed port of device 7 is facing the discharge port of receiving box 4.

[0014] The sliding material plate 6 adopts a screen plate, and the cake-shaped molding sand block can be loosened by impacting with the sliding material plate in the falling process of the molding sand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com