A pneumatically expandable packer for oil and gas wells

A packer and expansion technology, which is applied in cementing or well logging, oil and gas drilling, and well completion, can solve the problems of packer rubber sleeve corrosion failure, packer downhole difficulty, etc., so that it is not easy to deform and expand, Easy downhole, high deformation and expansion pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the drawings.

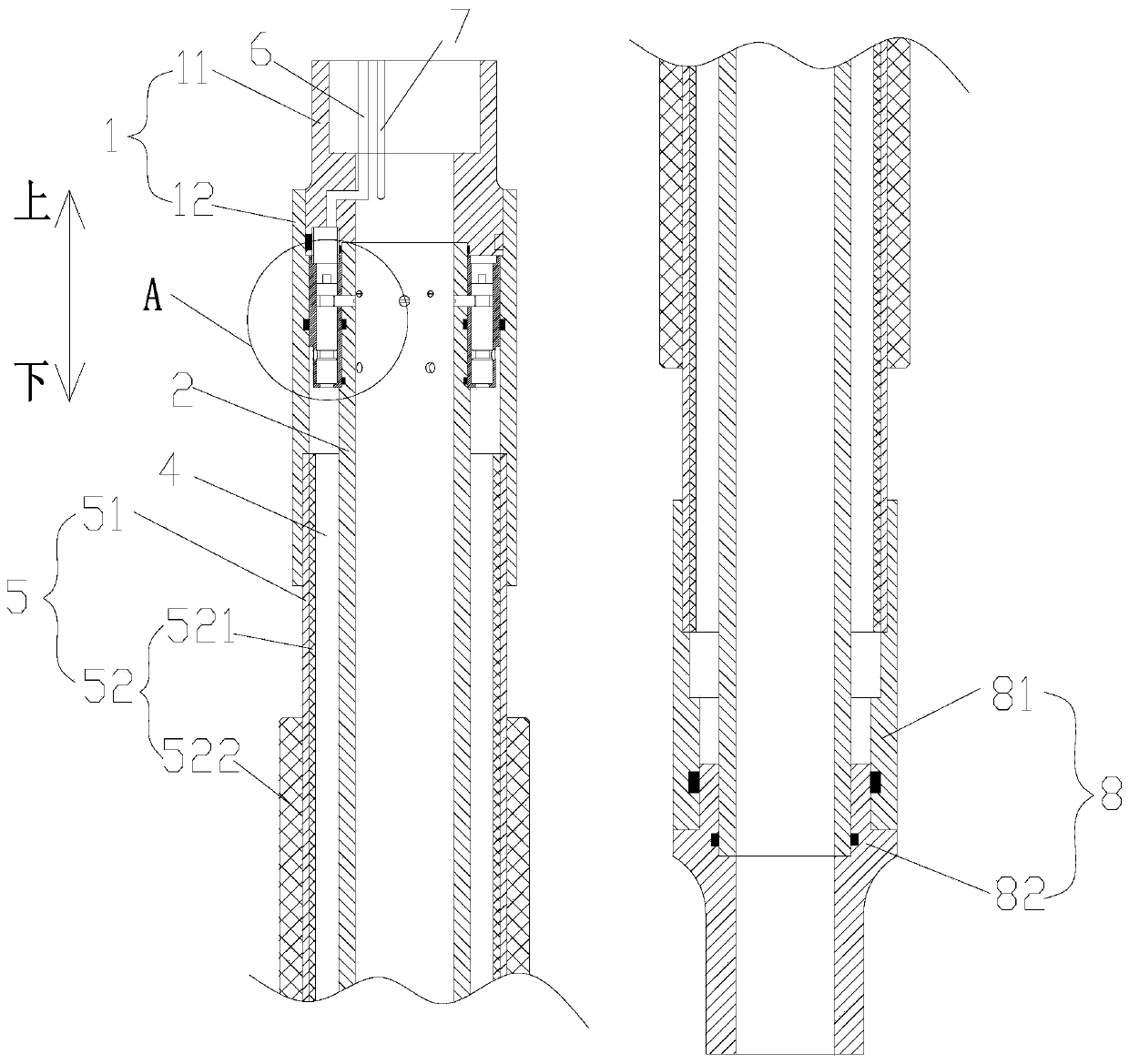

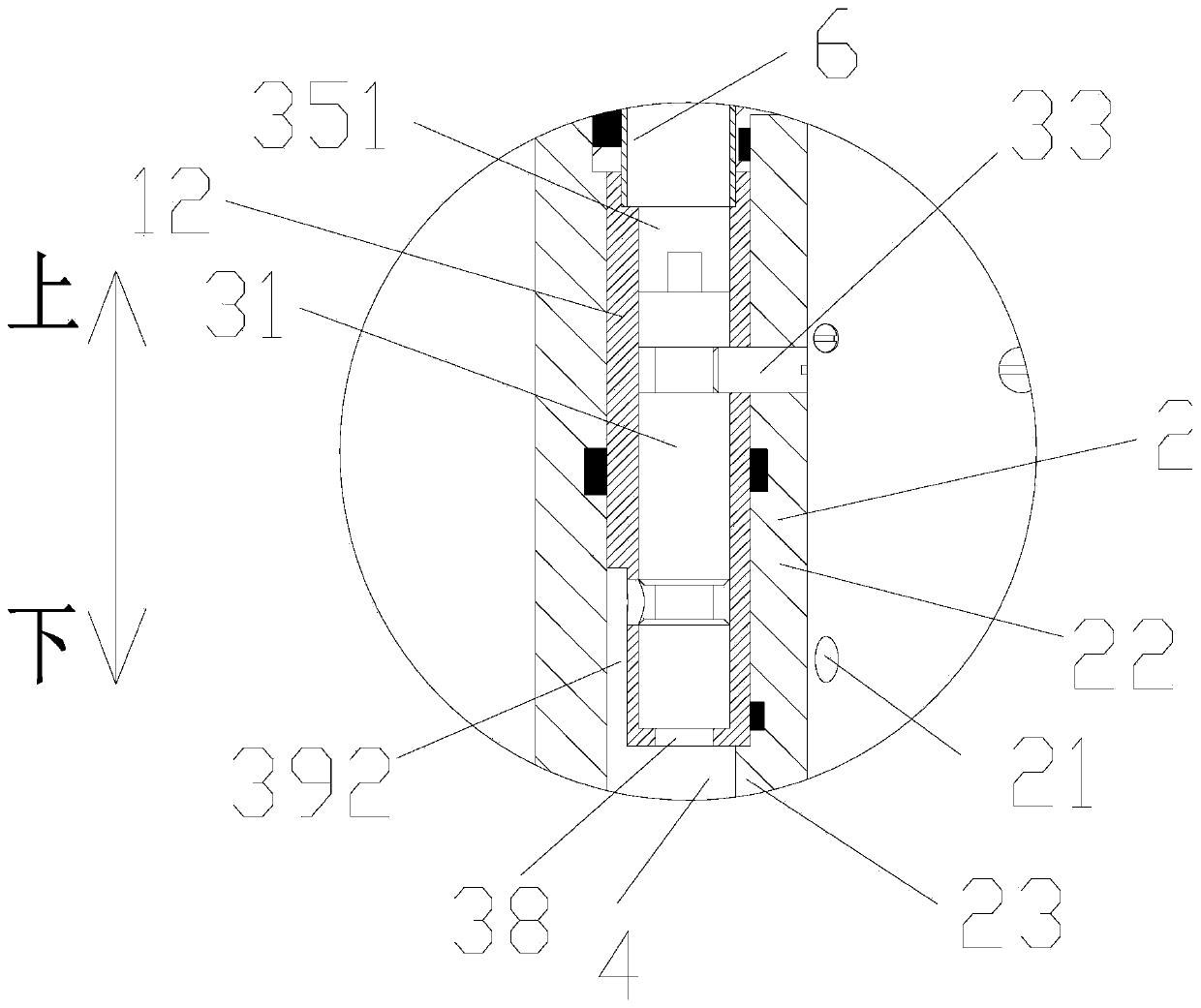

[0027] Such as Figure 1-3 As shown, a plunger-type expansion packer includes a central tube 2, an expansion tube 5, an upper casing 1, a lower casing 8 and a setting valve 3. The expansion tube 5 is sleeved on the central tube 2, and the expansion tube The two ends of 5 are fixedly connected with the upper casing 1 and the lower casing 8 respectively, and the two ends of the central tube 2 are fixedly connected with the upper casing 1 and the lower casing 8 respectively, the central tube 2, the upper casing 1, and the expansion tube 5 cooperates with the lower casing 8 to form an expansion cavity 4,

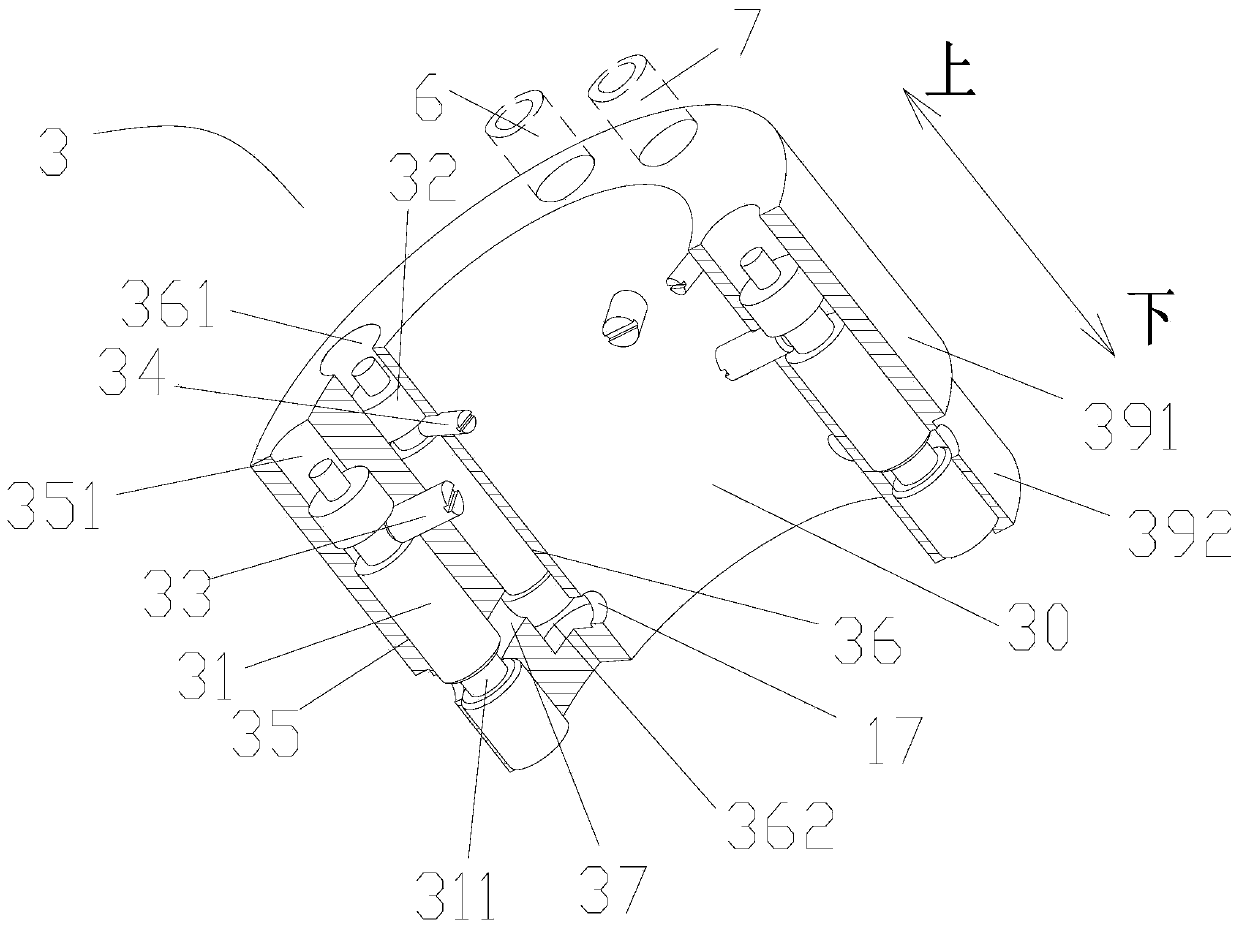

[0028] The setting valve 3 includes a starting valve core 32, a starting nail 34, a blocking valve core 31, a blocking nail 33, a starting cylindrical cavity 36 and a blocking cylindrical cavity 35. The starting valve core 32 is fixed to the starting column by the starting nail 34 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com