Deep sea full-section observing turbulent mixing section plotter

A profile observation and profiler technology, which is applied in the direction of instruments, measuring devices, components of the damping parts of the measuring device, etc., can solve the problems of probe data acquisition interference, instrument self-vibration, measurement signal interference, etc., to improve its own stability , improve stability and reduce interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

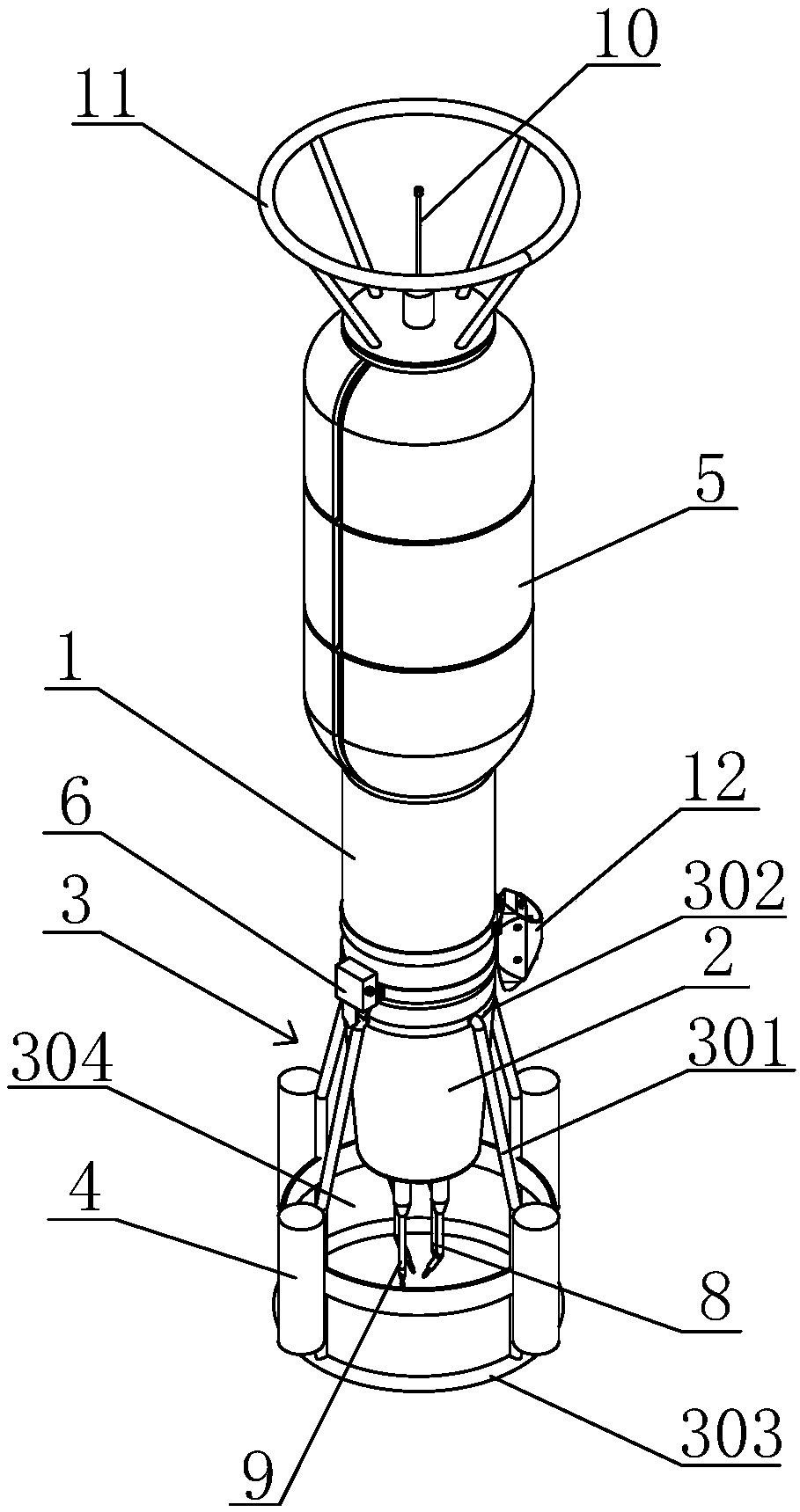

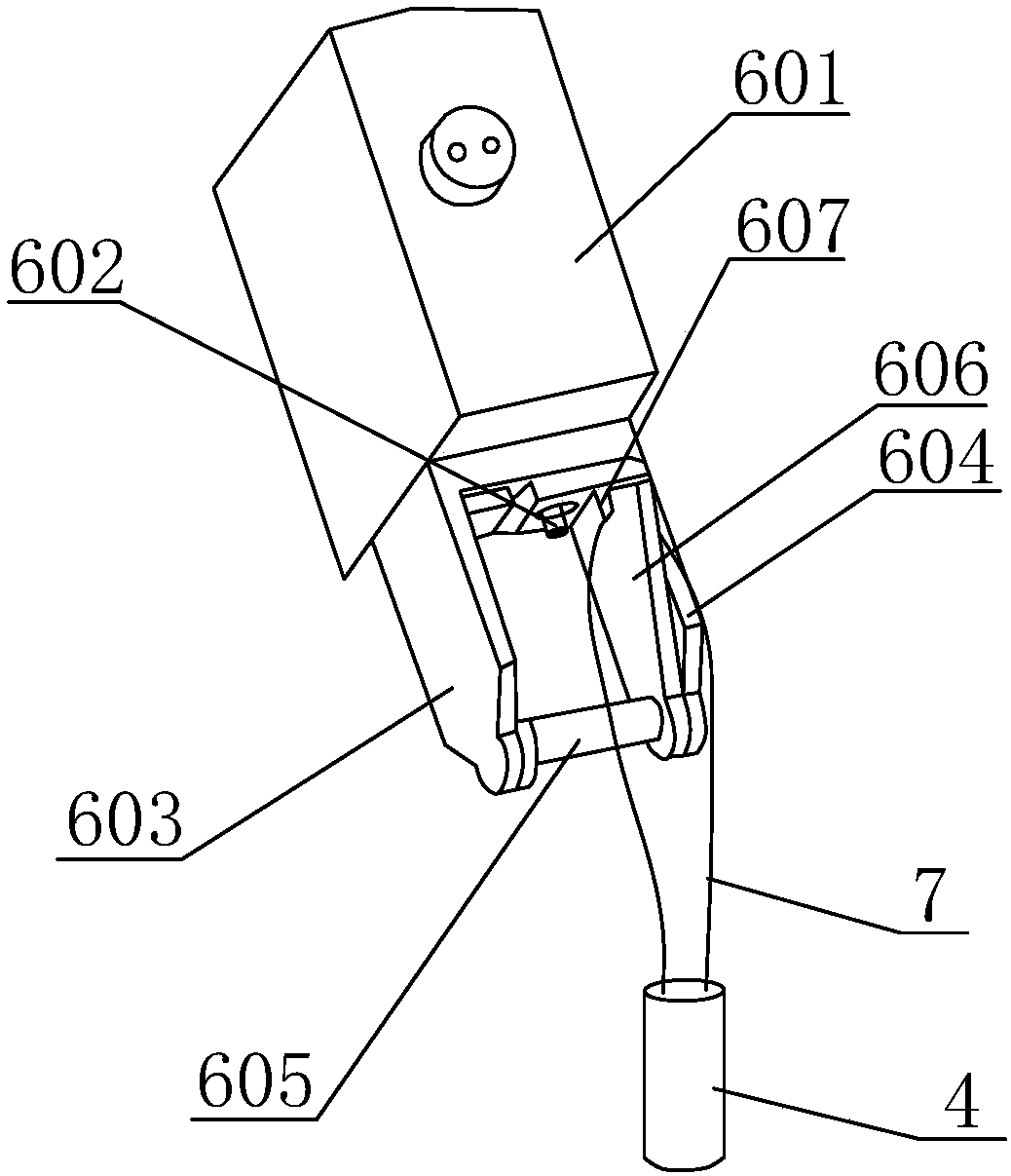

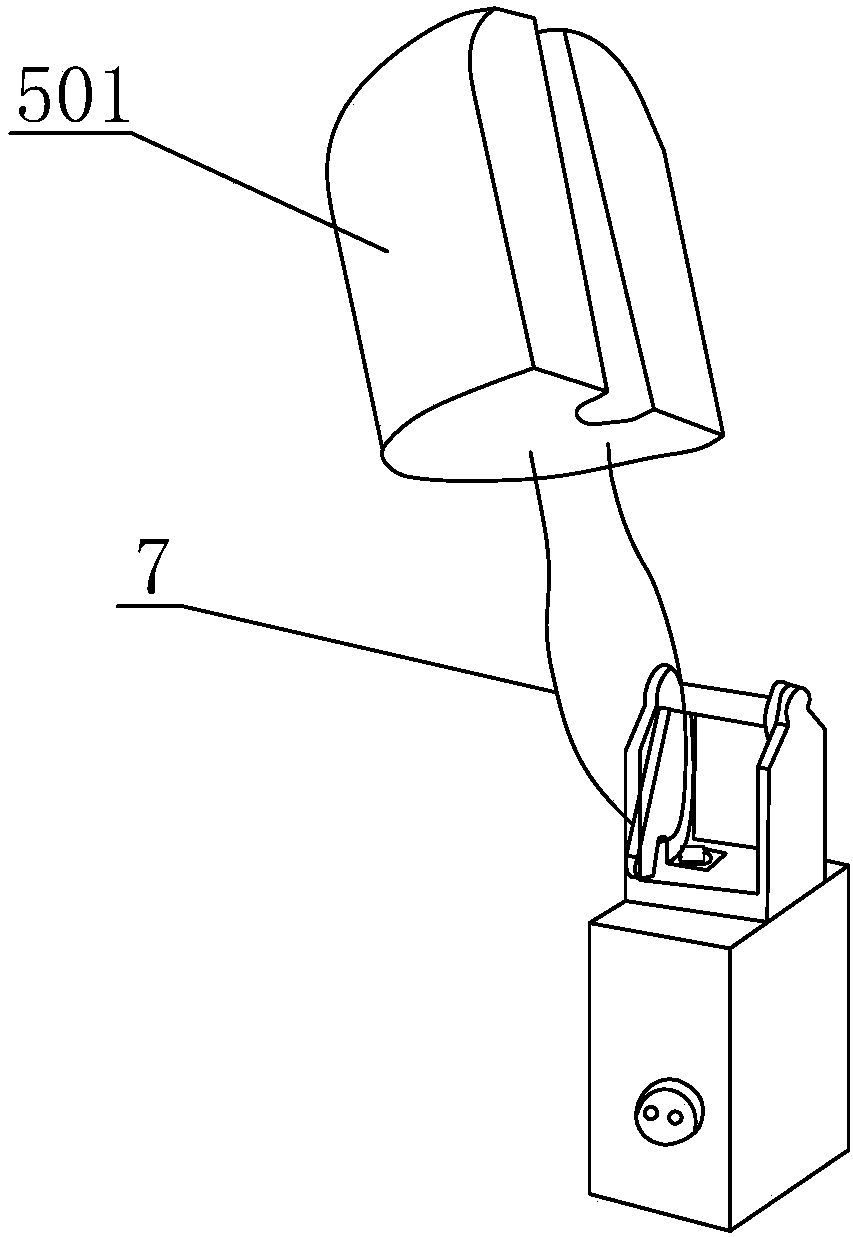

[0022] In conjunction with the accompanying drawings, a deep-sea full-section observation turbulence mixing profiler includes an instrument cabin 1 and a probe cabin 2. The instrument cabin 1 and the probe cabin 2 adopt a split design, and a flexible damper is connected between the instrument cabin 1 and the probe cabin 2. Shock coupling frame 3. The flexible shock-absorbing coupling frame 3 includes a plurality of support rods 301, one end of all the support rods 301 is connected to the fixed ring 302, the fixed ring 302 is connected to the instrument cabin 1, and the other ends of all the support rods 301 are connected to the probe protection On the ring 303, all the support rods 301 surround a protected space 304, the probe cabin 2 is built in the protected space 304, the outer wall of the probe cabin 2 is fixed to part of the support rods 301, and the electrical components between the probe cabin 2 and the instrument cabin 1 Connection via watertight cable.

[0023] A plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com