Pressure oven

An oven and pressure technology, applied in the direction of roaster/barbecue grid, kitchen utensils, household utensils, etc., can solve the problems of inability to release pressure in time, unstable locking, difficult to observe food cooking effect, etc., to increase safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

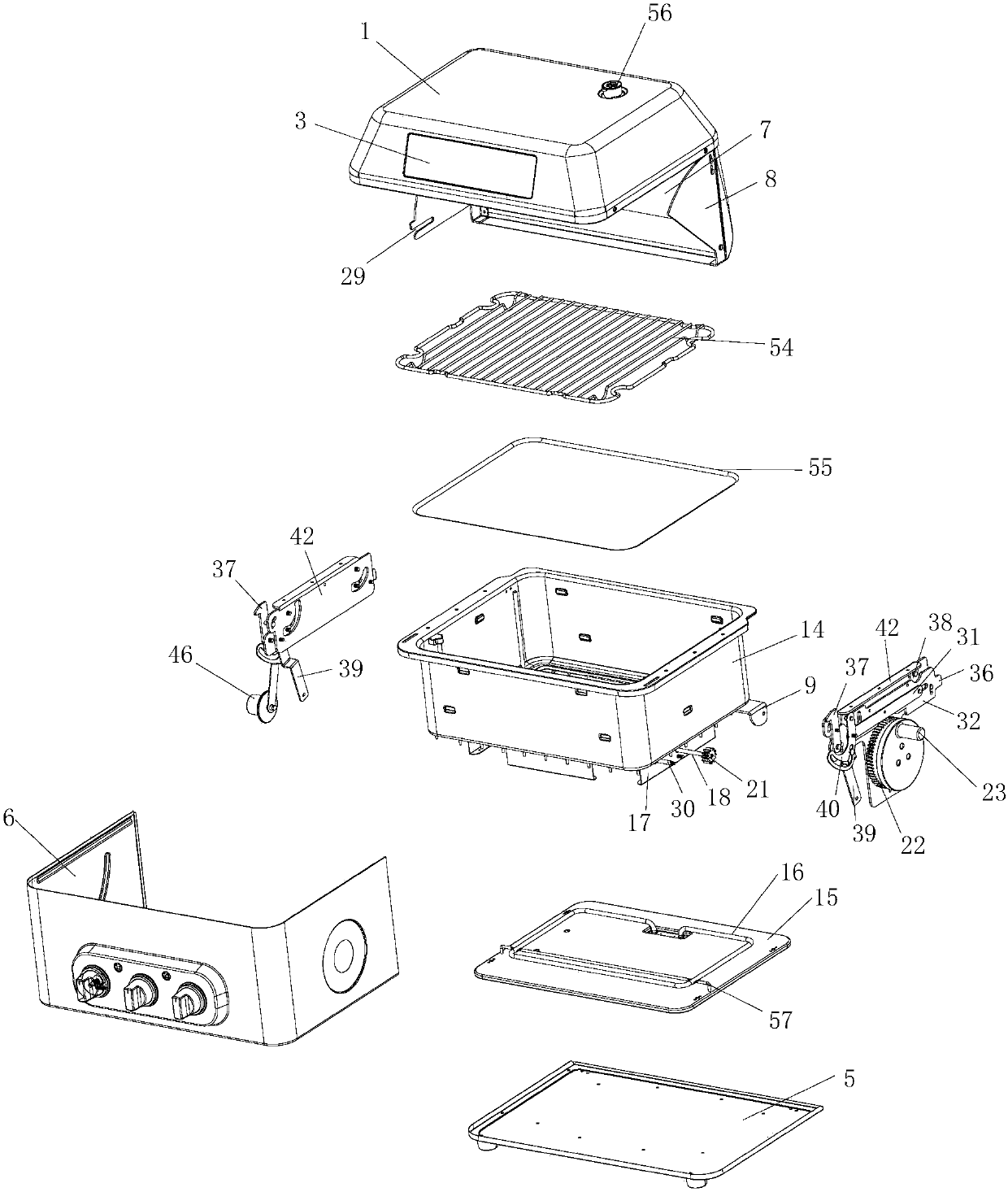

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings.

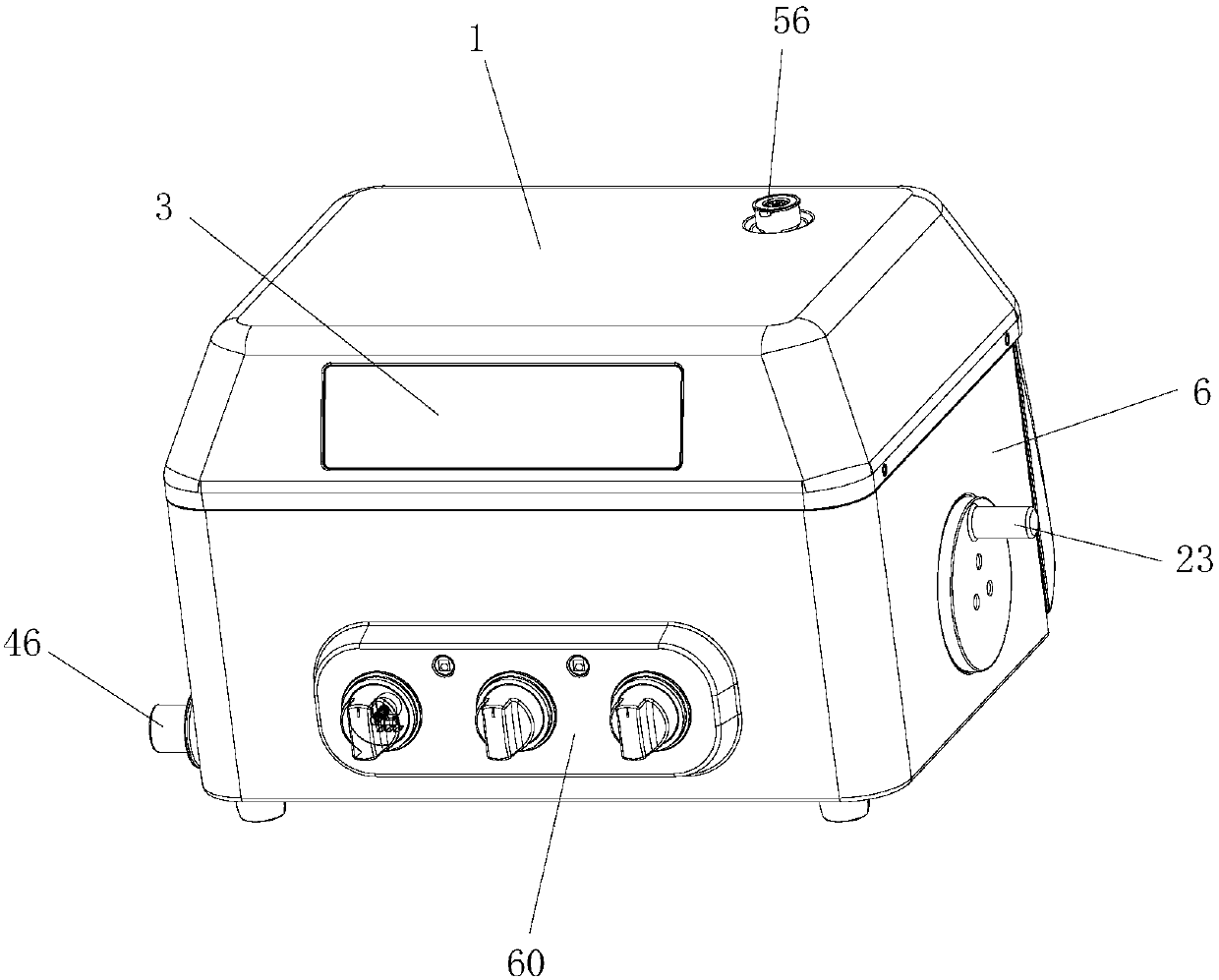

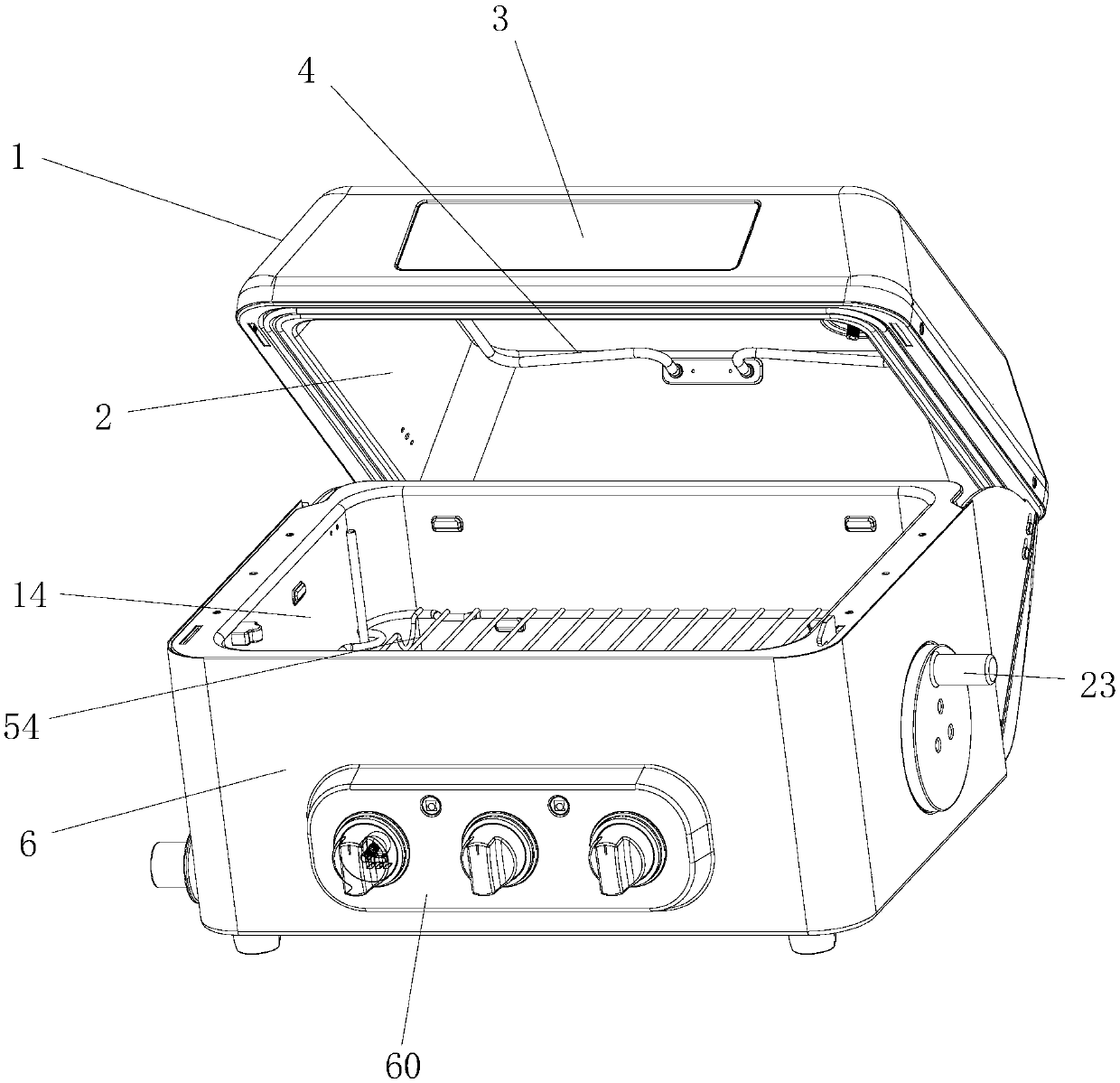

[0055] Such as figure 1 As shown, the present embodiment provides a pressure oven, which includes:

[0056] enclosure; and

[0057] The upper cover assembly is arranged on the top of the box body and can rotate relative to the box body to open or close the pressure oven. The upper cover assembly includes an upper cover 2 and a rotating support part, which is connected to the upper cover 2 and pivotally connected with the lower part of the box to drive the upper cover 2 to rotate relative to the box, and when the upper cover 2 rotates to open the pressure oven Move to the rear of the casing, otherwise move to the front of the casing when the upper cover 2 rotates to close the pressure oven. That is to say, the upper cover 2 realizes the relative rotation with the box body through the rotating supporting part, so that the upper cover 2 can perform the action of open...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap