Test evaluation method for preventing three-way low-stress brittle fracture

An evaluation method and brittle fracture test technology, which is applied in the field of tee test evaluation for oil and gas transmission pipelines, can solve the problems that the sample size cannot be prepared, the test period is long, and the structure is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

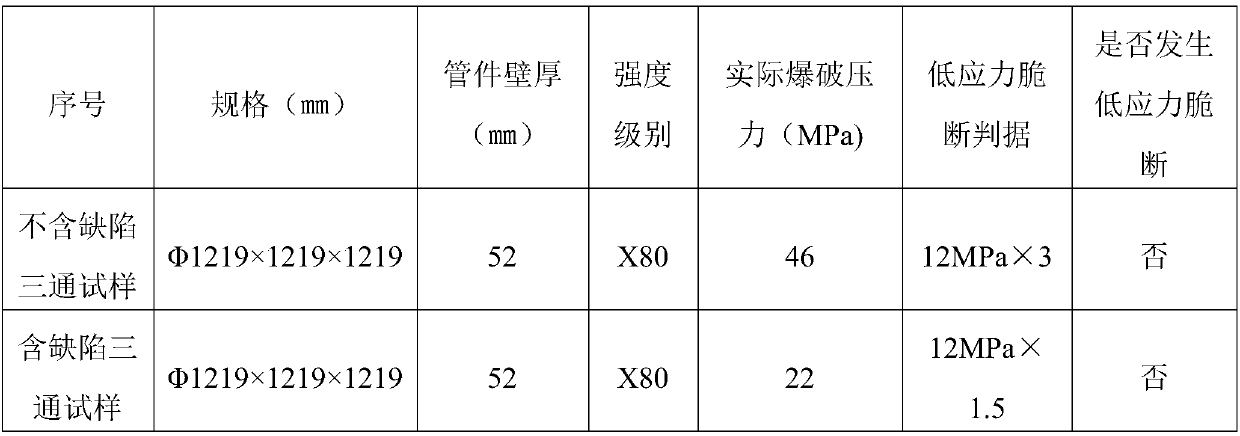

[0020] The present invention provides a kind of test evaluation method for preventing tee low stress brittle fracture, and its preferred embodiment comprises the following steps:

[0021] 1) Carry out preliminary inspection on the tee sample, including appearance inspection, size inspection, non-destructive inspection and physical and chemical performance test.

[0022] 2) Make defects in the weak strength area of the tee sample. The weak strength area is the weak part of the manufacturing process or the concentrated load of the piping system, and the defect is the crack defect made on the surface of the tee. The depth of the crack defect is a quarter of the thickness of the tee pipe wall, and the length of the crack defect is six times the depth of the crack defect. The length direction of the crack defect is perpendicular to the maximum principal stress direction of the tee.

[0023] 3) The hydrostatic pressure test was carried out on the tee sample with defects and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com