Micro switch with forced separation mechanism

A technology of micro switch and separation mechanism, which is applied in the direction of electric switches, electrical components, circuits, etc. It can solve the problems of switch action failure, switch action parameter change, and moving contact piece cannot be reset, so as to prevent material deformation and material thickness increase. thick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

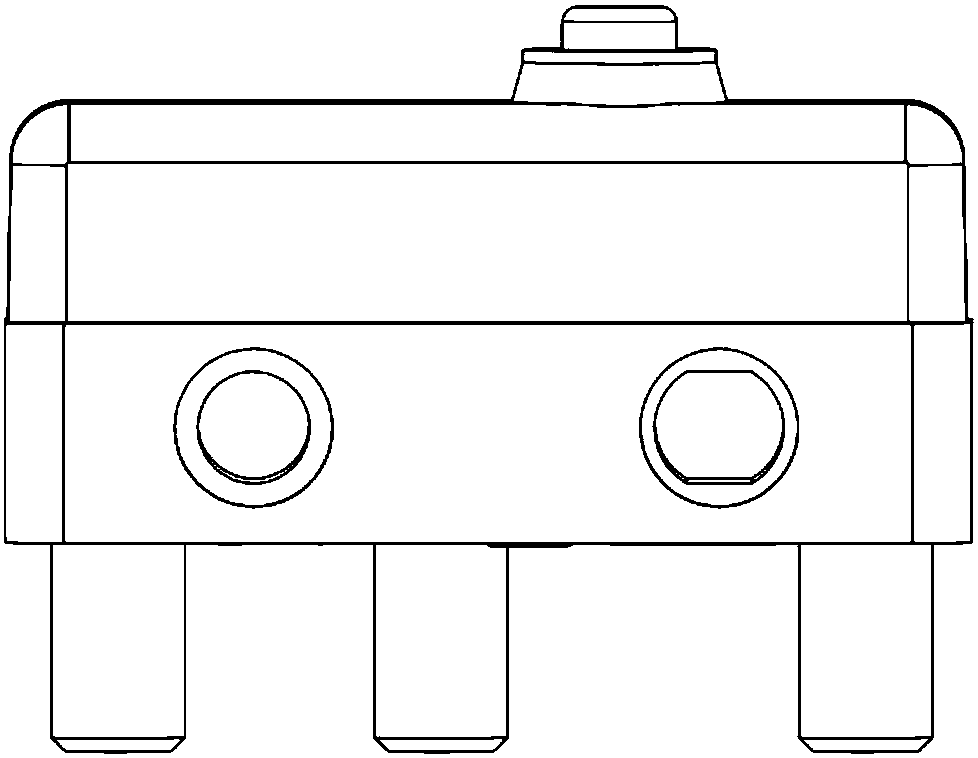

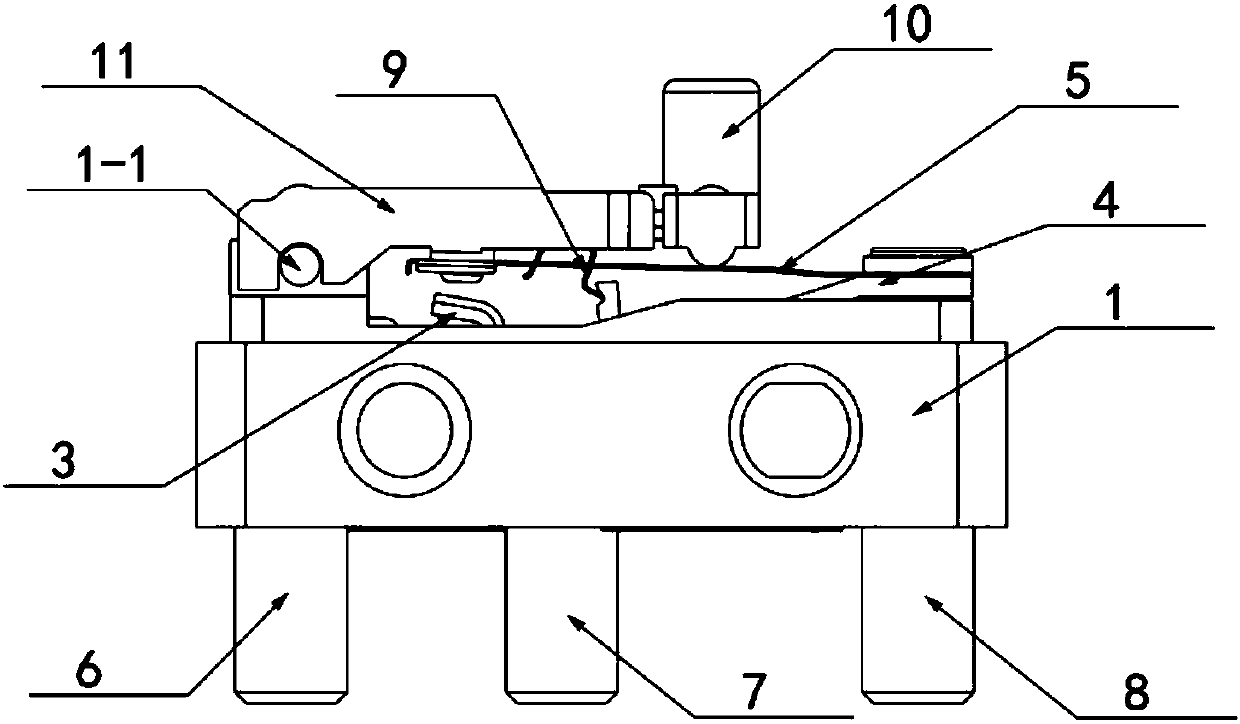

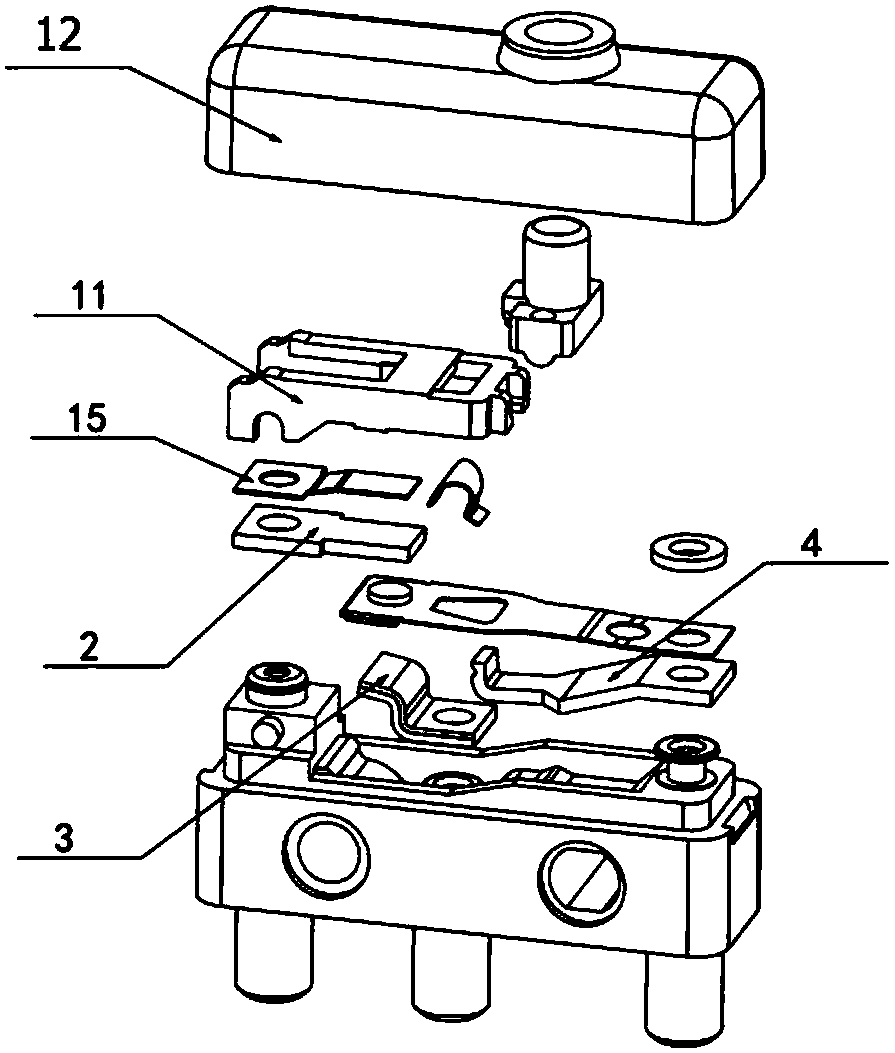

[0044] like figure 1 , figure 2 and image 3 As shown, in the micro switch with a forced separation mechanism of the present invention, the housing 1 is provided with a normally closed static contact assembly and a common terminal static contact assembly, the normally closed static contact assembly is a normally closed static contact 2, and the public The end static contact assembly is a public end static contact 4, and a trigger assembly and an elastic assembly are also provided in the housing. One end of the elastic assembly is electrically connected to the public end static contact assembly, and the other end is electrically connected to the normally closed static contact assembly; The terminal static contact component is provided with a groove, and the above-mentioned elastic component is abutted on the groove. The elastic component can be switched up and down around this groove. A trigger component for driving the movement of the elastic component is connected to the to...

Embodiment 2

[0057] Basically the same as Example 1, the difference is:

[0058] like Figure 8 and Figure 9 As shown, the linkage design of the forced separation part 11 and the button 10 is such that the boss 11-5 of the forced separation part engages with the button groove 10-2, the button 10 moves downward, and the boss 11-5 contacts the groove 10-2 and Drive the forced separation part to rotate.

[0059] The working principle is the same as that of Embodiment 1.

Embodiment 3

[0061] Basically the same as Example 1, the difference is:

[0062] like Figure 10 and Figure 11 As shown, both sides of the forced separation part are provided with bosses 11-5, and both sides of the corresponding button 10 are also provided with grooves 10-2, and the two bosses and grooves are snapped together to realize the button and the forced button during movement. Contact linkage of separating parts.

[0063] The working principle is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com